Concentration device for hydrogen peroxide production and use method thereof

A concentration device, hydrogen peroxide technology, applied in separation methods, chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, etc., can solve the problem of reducing the efficiency of concentrated hydrogen peroxide and improving the efficiency of hydrogen peroxide , Reduce utilization efficiency and other issues, achieve the effect of improving functionality and use effect, ensuring preheating effect, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

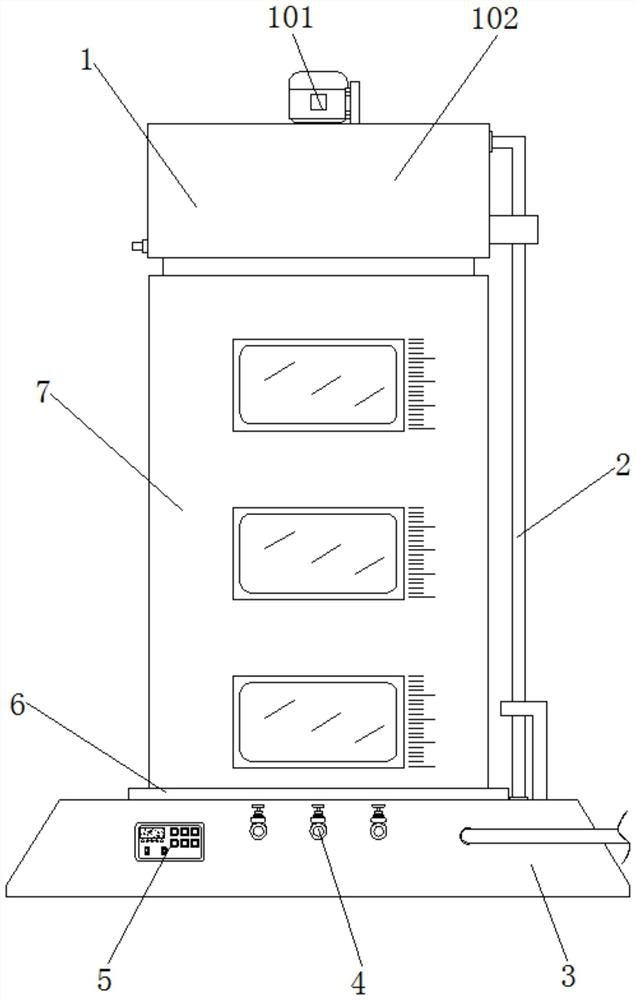

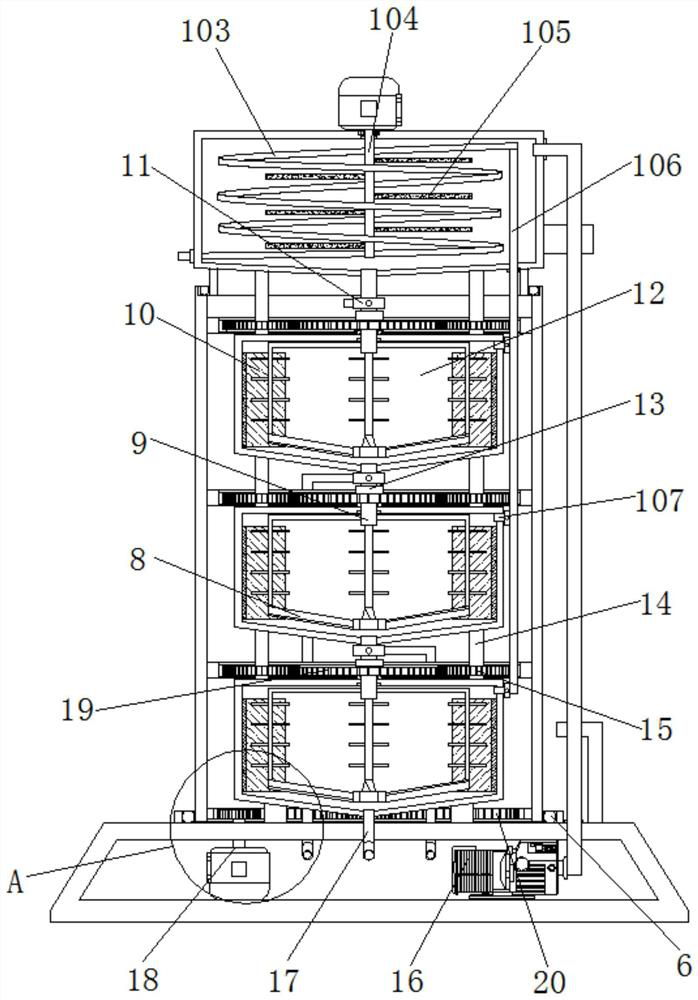

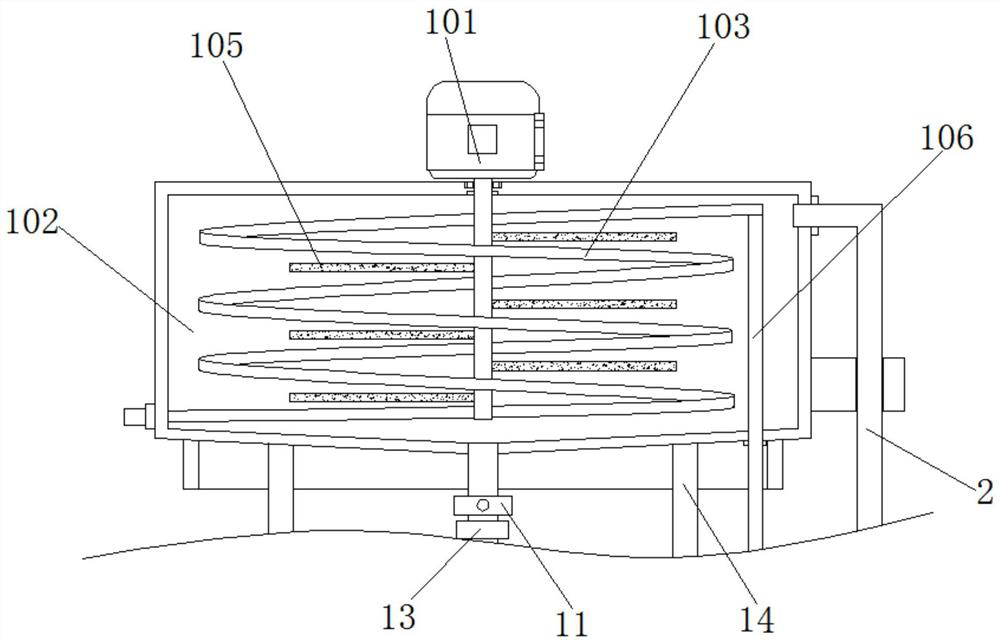

[0032] see Figure 1-7 , the present invention provides a technical solution: a concentration device for the production of hydrogen peroxide, including a base bin 3, a large bearing 6 is installed on the top of the base bin 3, a protection bin 7 is installed on the inside of the big bearing 6, and the protection bin 7 There are three sets of distillation chambers 12 stacked one after the other inside, and the bottommost group of distillation chambers 12 is fixedly connected to the top of the base chamber 3, and four sets of connecting columns 14 are evenly installed on the edge of the top of the distillation chamber 12, and the adjacent two groups of distillation chambers The bin 12 is fixedly connected by four sets of connecting columns 14. A small bearing 21 is installed at the center of the top of the distillation bin 12, and an installation pipe 9 is installed on the inner side of the small bearing 21. A rotary joint 13 is installed on the top of the installation pipe 9, an...

Embodiment 2

[0038] see Figure 1-7 , the present invention provides a technical solution: a concentration device for the production of hydrogen peroxide, including a base bin 3, a large bearing 6 is installed on the top of the base bin 3, a protection bin 7 is installed on the inside of the big bearing 6, and the protection bin 7 There are three sets of distillation chambers 12 stacked one after the other inside, and the bottommost group of distillation chambers 12 is fixedly connected to the top of the base chamber 3, and four sets of connecting columns 14 are evenly installed on the edge of the top of the distillation chamber 12, and the adjacent two groups of distillation chambers The bin 12 is fixedly connected by four sets of connecting columns 14. A small bearing 21 is installed at the center of the top of the distillation bin 12, and an installation pipe 9 is installed on the inner side of the small bearing 21. A rotary joint 13 is installed on the top of the installation pipe 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com