Carbon/carbon composite component chemical vapor infiltration device

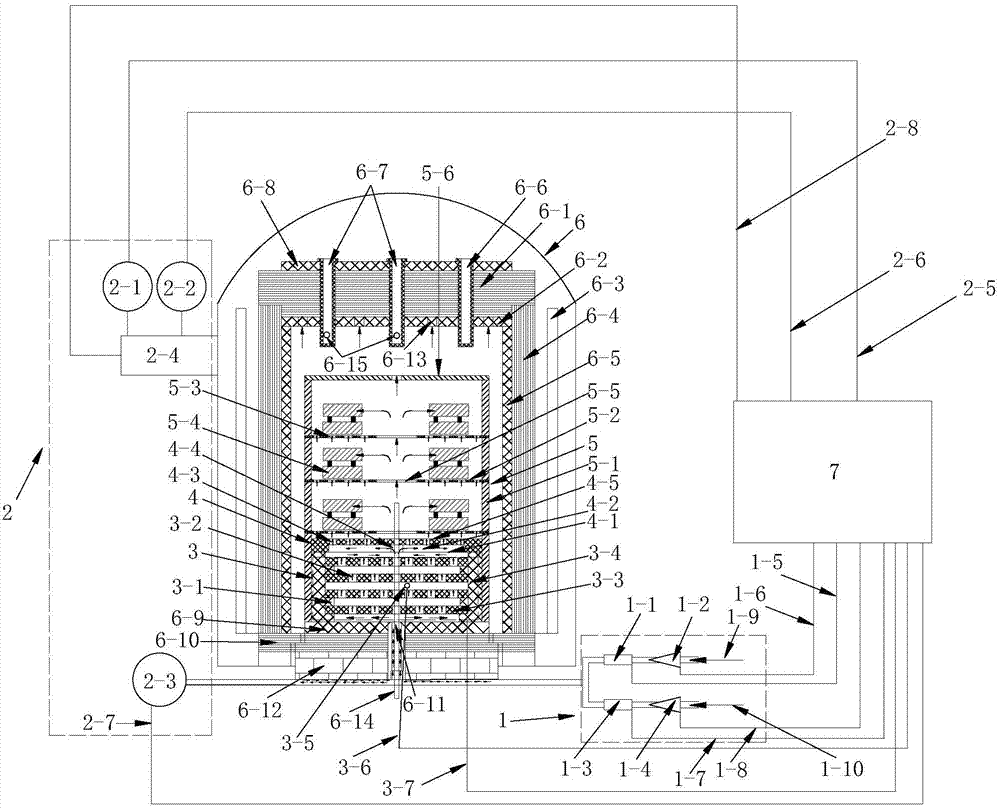

A carbon composite material and chemical vapor infiltration technology, which is applied in the field of chemical vapor deposition furnace preparation devices, can solve the problems of low infiltration efficiency and low utilization rate of reaction gas, and achieves improved infiltration rate, densification efficiency, and reduced Effect of Pore Size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

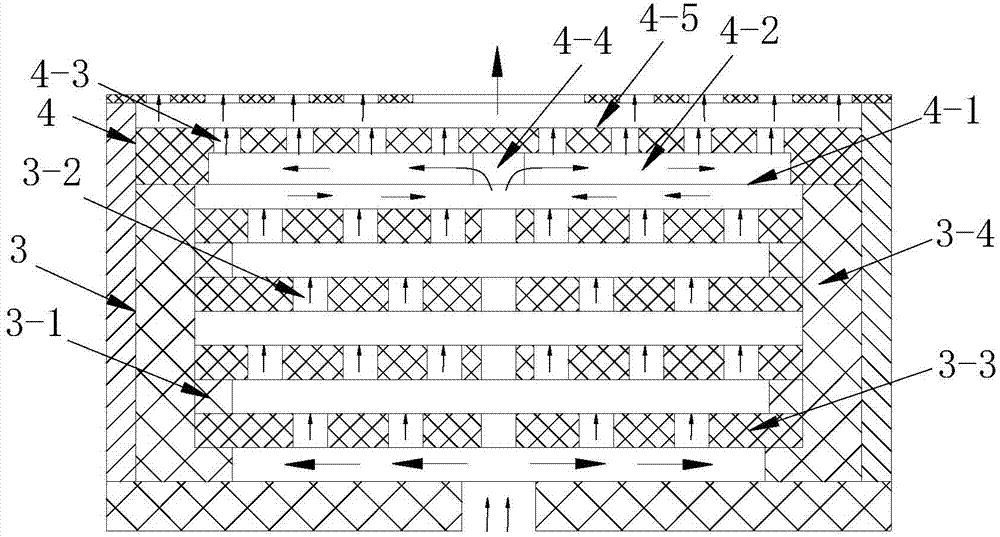

Method used

Image

Examples

Embodiment 1

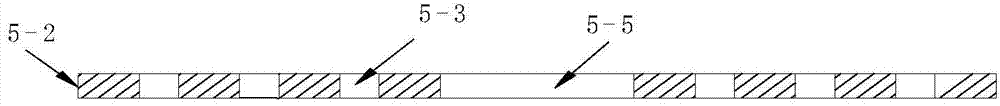

[0038] (1) Furnace loading: put 20 composite material prefabricated bodies (200mm×200mm×16mm) 5-4 horizontally into the porous graphite liner 5-2 in the chemical vapor deposition furnace 6, place the annular graphite tube 5- 1 Place it on the porous graphite liner 5-2, and cover the graphite cover plate 5-6 on the annular graphite tube 5-1 to form a closed percolation chamber 5;

[0039] The thickness of the porous graphite liner is 30mm, the large air guide hole 5-5 is 260mm, and the small air guide hole 5-3 is 13mm.

[0040] The graphite cover plate 5-6 has a thickness of 40mm, and the annular graphite cylinder has a height of 300mm and a thickness of 30mm.

[0041] (2) Vacuumize and check for leaks: evacuate the chemical vapor deposition furnace 6 until the pressure of the second absolute pressure gauge 2-2 is 500Pa, stop vacuuming, and check that the pressure of the chemical vapor deposition furnace 6 is not obvious Variety;

[0042] (3) Power up and heat up: power up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com