Wafer deposition processing method for CVD equipment

A processing method and wafer technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems affecting the utilization rate of CVD equipment, wafer thermal stress fragmentation, etc., to reduce the fragmentation rate and avoid Fragmentation, the effect of ensuring the effect of preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] This embodiment discloses a wafer deposition processing method for CVD equipment.

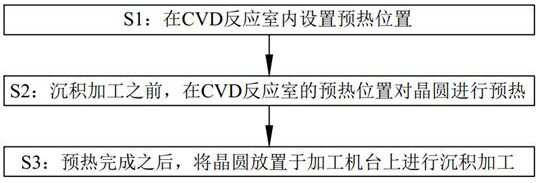

[0031] Such as figure 1 Shown, be used for the wafer deposition processing method of CVD equipment, comprise the following steps:

[0032] S1: Set a preheating position in the CVD reaction chamber; the preheating position is set above the processing machine.

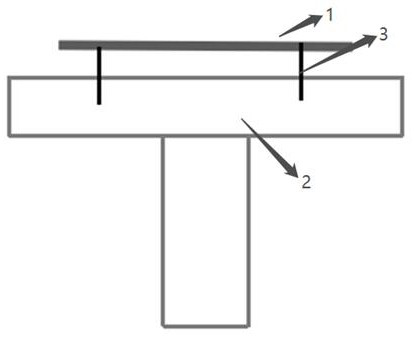

[0033] S2: Before the deposition process, preheat the wafer at the preheating position of the CVD reaction chamber (such as figure 2 shown); the wafer is preheated by the gas flow used to process the wafer for deposition.

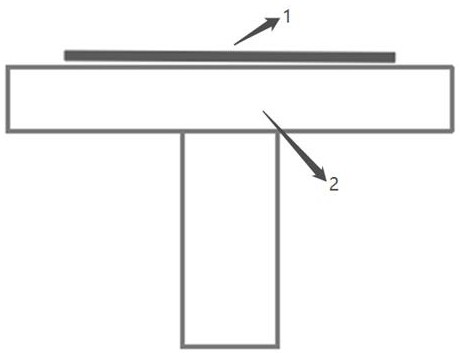

[0034] S3: After the preheating is completed, the wafer is placed on the processing machine for deposition processing (such as image 3 shown).

[0035] The invention preheats the wafer first, so that the wafer can reach a relatively high initial temperature, and then contacts with a high-temperature (400°C) processing machine for deposition processing, thereby solving the problem that the wafer heating cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com