Preparation method of colorful synchronous belt

A timing belt, color technology, applied in the direction of belts, transmission belts, mechanical equipment, etc., to achieve the effect of good wear resistance and elastic modulus, avoid damage, good wear resistance and dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The best mode for carrying out the present invention will be described below with reference to the appropriate drawings.

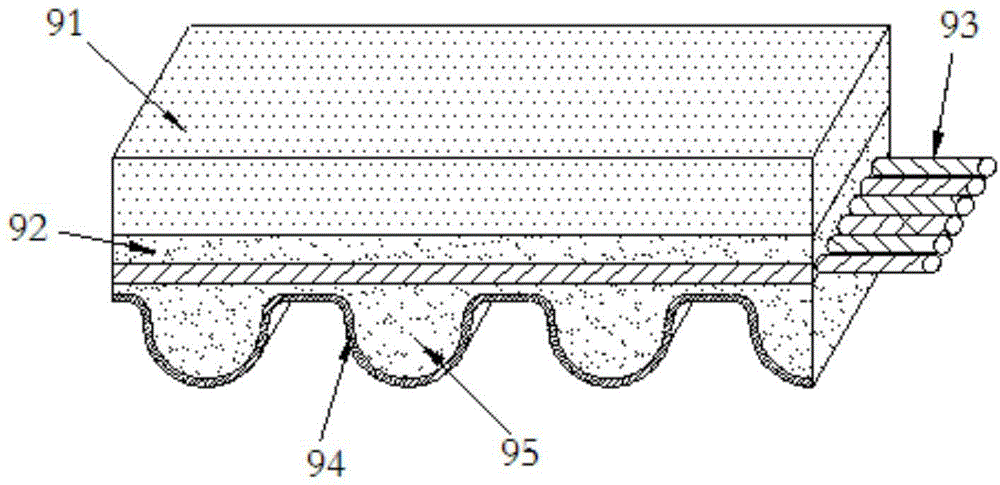

[0025] In the present invention, a method for preparing a color timing belt, the timing belt has an endless belt body, and the endless belt body includes: a plurality of belt teeth 94 equidistantly arranged along the inner peripheral surface of the endless belt body; Elastic nylon cloth 93 coated on the toothed surface; the core rope 92 laid along the circumferential direction of the endless belt inside the endless belt, and the black color with adhesive properties on the surface of the core rope 92 A reinforcement layer 95 and a tape back 91 covered by colored glue on the back of the black reinforcement layer 95;

[0026] The method of the present invention comprises the following steps: put a cloth cover on the forming mold, wind the wire, attach the black film to the forming mold after winding → vulcanize for the first time to obtain a shaped tap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com