Steam injection device

A technology of spraying device and steam, applied in biochemical cleaning device, enzymology/microbiology device, spray evaporation, etc., can solve the problems of increasing production time, wasting resources, increasing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

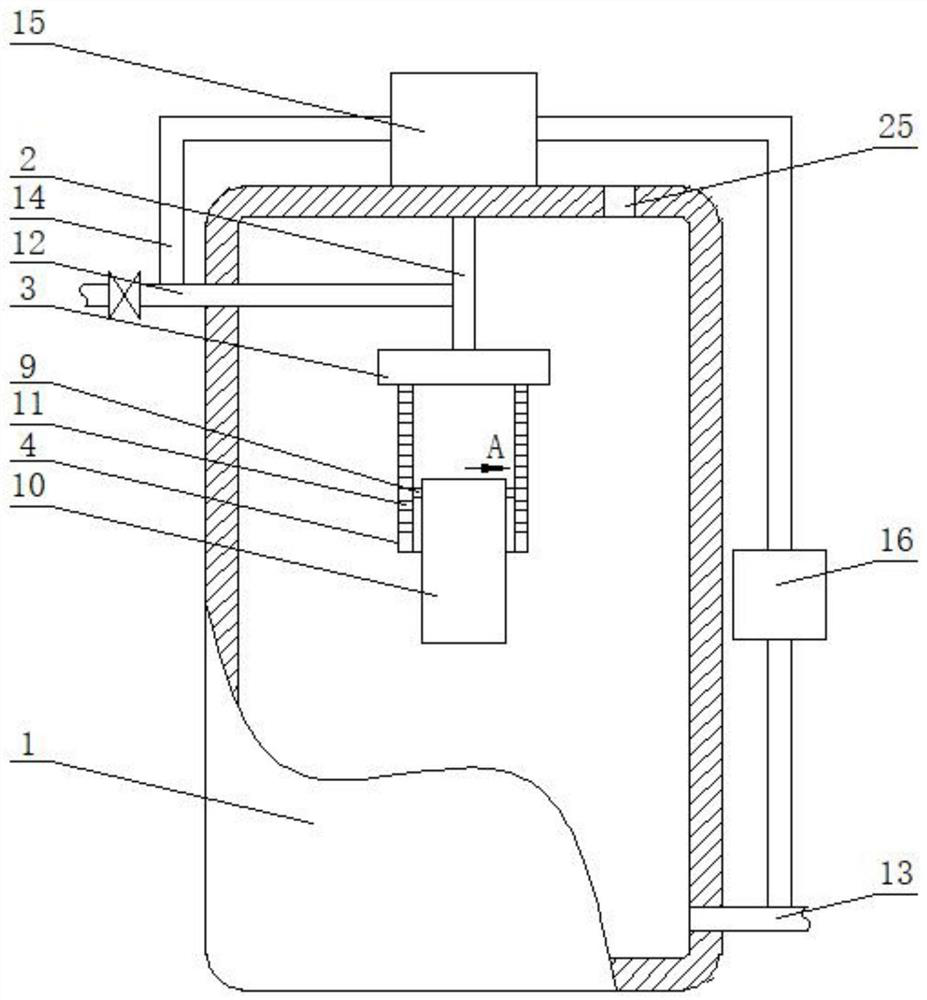

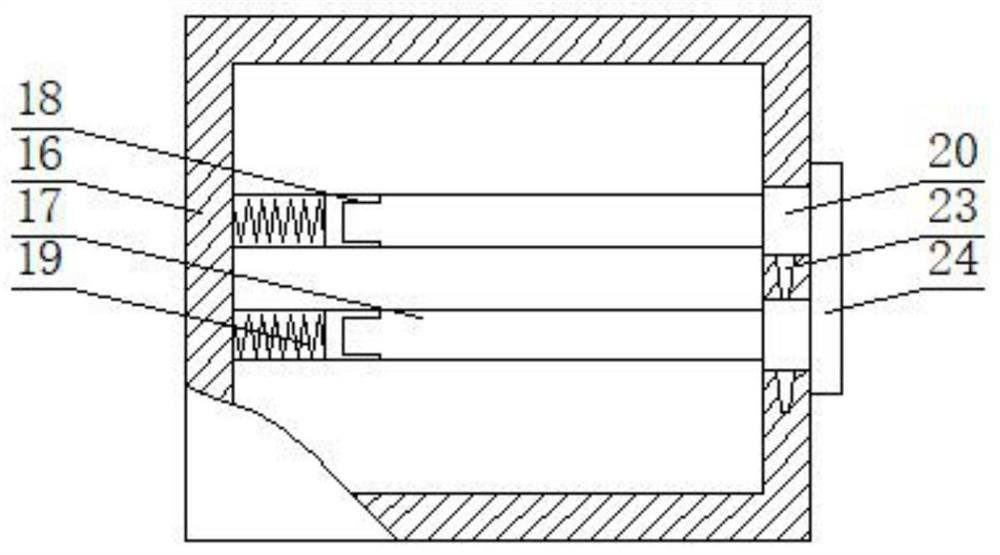

[0027] When using this device, the material is first added to the liquefaction tank 1 through the feed 25 to liquefy the material, and then steam is introduced into the liquefaction tank 1 through the air inlet pipe 12, and the steam enters into the liquefaction tank 1 through the vertical pipe 2 and the connecting plate 3 In the first jet pipe 4, it is ejected through the jet port 11. Since the jet port 11 is opened at 45 degrees, under the reaction force, the first jet pipe 4 rotates around the bearing, and the second jet pipe 10 follows the first jet pipe 4. The rotation of the second air injection pipe 10 will rotate along with the centrifugal force generated by the rotation, and the second air injection pipe 10 will move downward along the first air injection pipe 4, so that the steam can be ejected more evenly, and then the steam will flow out with the air outlet pipe 13, and Filtering through the filter box 16 through the air return pipe 14 enters the air intake pipe 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com