Method and device for sensible heat recovery of quenched dry crushing molten blast furnace slag

A sensible heat recovery and blast furnace slag technology, applied in metal recovery, recycling technology, process efficiency improvement and other directions, can solve the problems of high water consumption for slag flushing, environmental pollution, and ineffective recycling, and save energy. , the effect of easy follow-up treatment and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

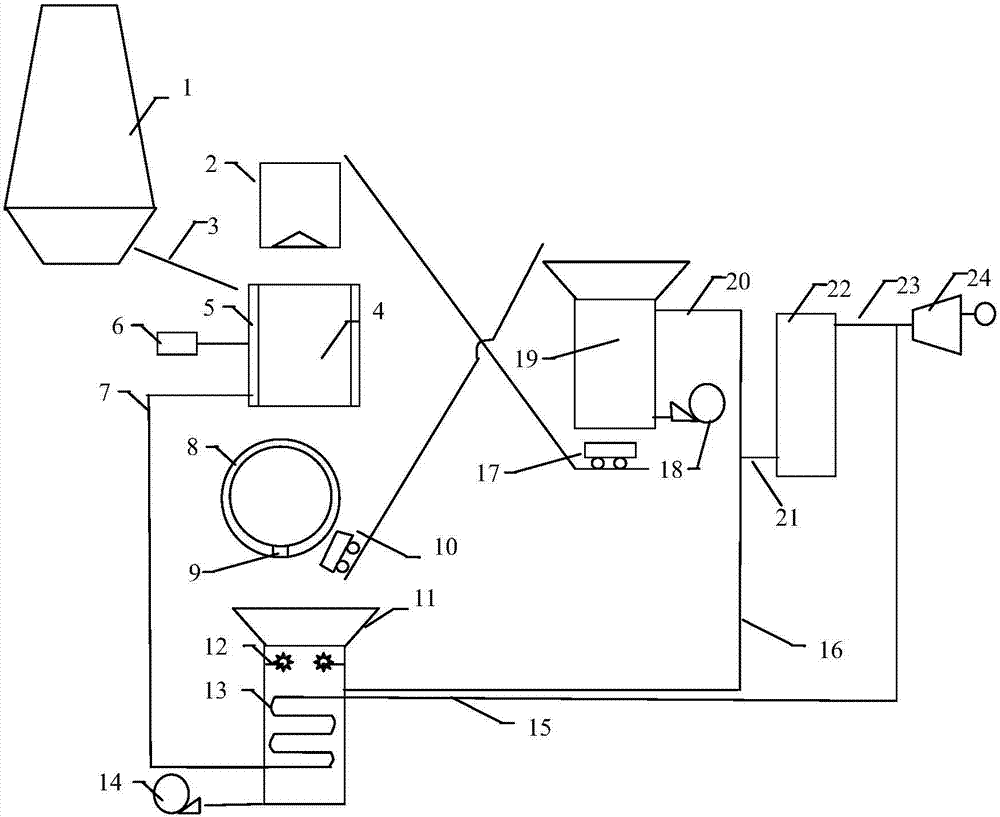

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0023] See figure 1 , which is a structural schematic diagram of an embodiment of a device for recovering sensible heat from quenched and dry crushed molten blast furnace slag of the present invention. The heat exchanger 4 is connected to the blast furnace 1 through the slag ditch 3, and a drum separator 8 is arranged below the heat exchanger 4, and the drum separates The bottom of the machine 8 is provided with a moving bed 11, and the outlet 9 of the drum is connected to the entrance of the moving bed 2 19 through the feeding rail car 10; The outlet of 13 links to each other through steam pipe 15 and steam main pipe 23 at the steam inlet of power generating unit 24; Moving bed one 11 is provided with air blower one 14, and moving bed two 19 is provided with air blower two 18, and moving bed one 11 is through hot air pipeline 16. The moving bed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com