Environment-friendly impregnation liquid, preparation method and application

A kind of dipping liquid, environmental protection technology, applied in the direction of fiber treatment, textile and paper making, fiber type, etc., to achieve the effect of shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 A kind of preparation method of environment-friendly dipping solution A1

[0024] This embodiment provides a kind of preparation method of environment-friendly dipping liquid A1, and it is to take 2kg phenol and 1kg isophorone diisocyanate to carry out cross-linking reaction respectively, obtain 3kg phenol-blocked isophorone diisocyanate, mix it with 2kg Add ethylene glycol and 0.1kg triethylamine into 30kg deionized water, mix and stir at 20°C for 1.5h, at this temperature, add 90kg of butylfenpyridine latex with a solid content of 40% and continue stirring for 2h to obtain a solid content of 25.6%. The environment-friendly dipping solution A1.

Embodiment 2~9

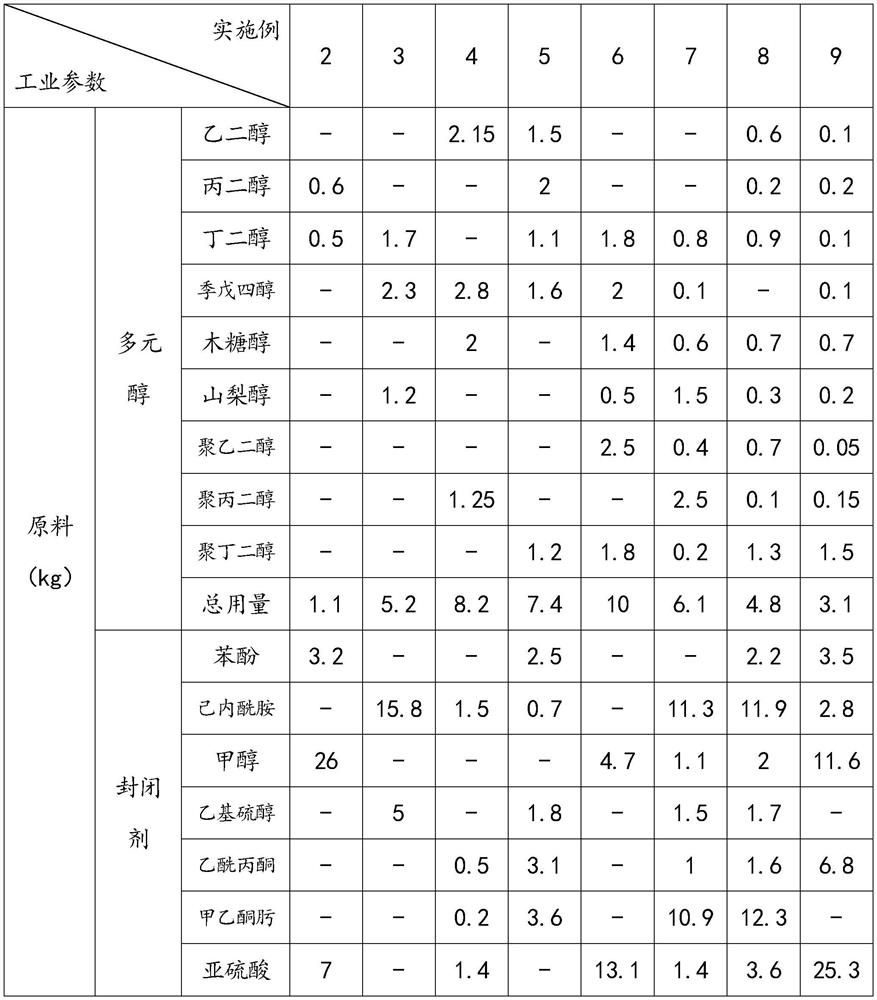

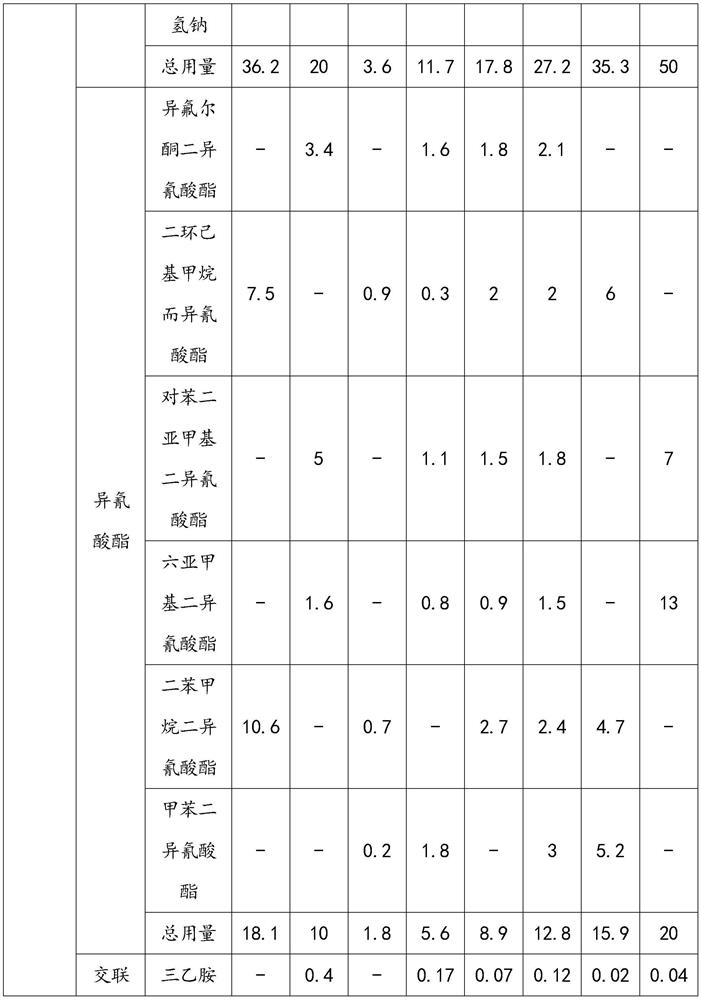

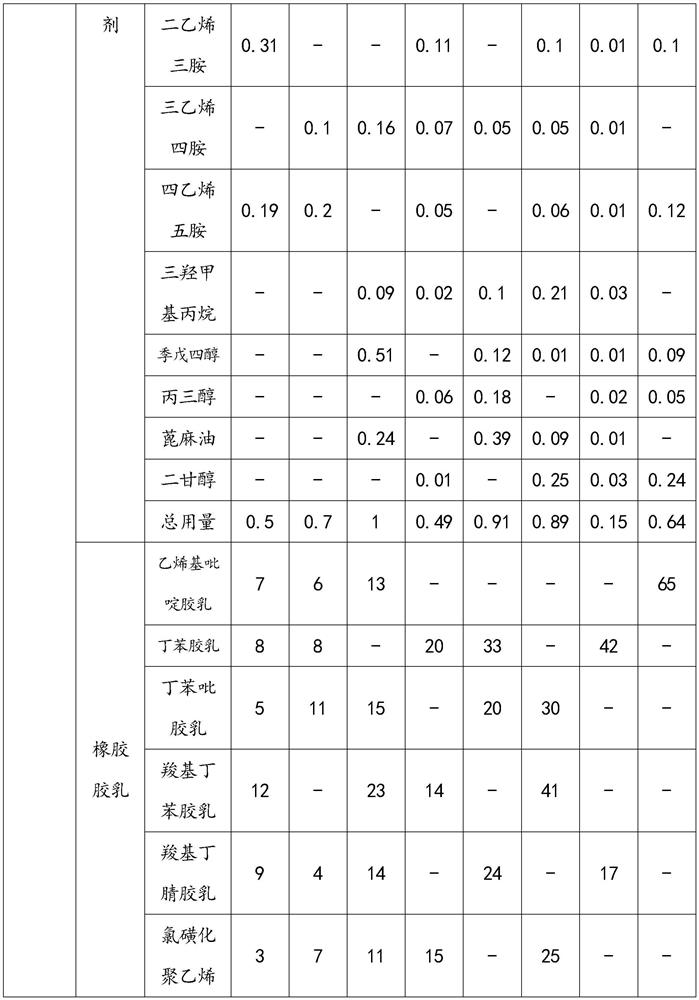

[0025] The preparation method of embodiment 2~9 environment-friendly dipping solution A2~A9

[0026] Embodiments 2 to 9 provide a method for preparing environmentally friendly dipping solutions A2 to A9 in one-to-one correspondence. The preparation method is basically the same as that in Example 1, the only difference being that the raw materials used and their dosage and some process parameters are different. For specific data, see Table 1.

[0027] Table 1: Data sheet of preparation methods of environmental protection dipping solutions A2~A9

[0028]

[0029]

[0030]

[0031]

[0032] Other steps are the same as in Example 1.

Embodiment 10

[0033] Application of embodiment 10 environment-friendly dipping liquid and comparison of dipping effect

[0034] This example is to compare the impregnation effects of the environment-friendly dipping solutions A1-A9 obtained in Examples 1-9 and the traditional RFL dipping solutions by application.

[0035] Respectively intercept 10 sections of aramid fibers with a length of 20m (Shandong Hailong Braite Chemical Fiber Co., Ltd., 1670dtex / 2, the initial twist is 300T / m) and 10 sections of aramid / nylon blended fibers with a length of 20m (Pingdingshan Shenma Cord Fabric Development Co., Ltd., aramid 1670dtex / 2 + Nylon 2100dtex, the initial twist is 280T / m);

[0036] Select 9 sections from the 10 sections of aramid fiber, and adopt the two-bath dipping method (the dipping solution used in the first bath is prepared from 92.4kg deionized water, 3.2kg blocked isocyanate and 1.3kg epoxy resin, and the dipping solution used in the second bath They are respectively the environment-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com