Coal-based solid waste soil stabilizer and preparation method thereof

A soil curing agent and coal-based technology, applied in chemical instruments and methods, soil conditioning materials, agriculture, etc., can solve the problems of increased water reducing agent dosage, shrinkage and cracking of structures, unsatisfactory curing effect, etc., and achieve reactivity Improvement, surface free energy increase, and compensation for shrinkage cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

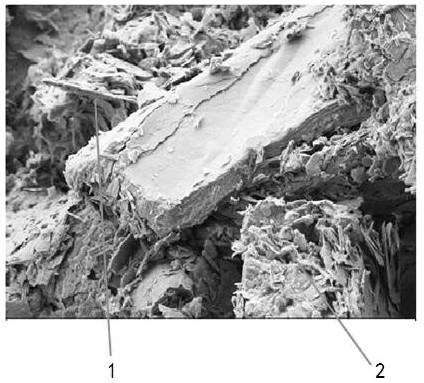

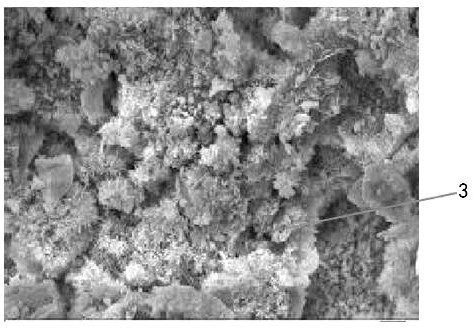

Image

Examples

Embodiment 1

[0031] S1 is ground to make the specific surface area of the sulfur-fixed ash 700m 2 / kg.

[0032] The specific surface area of silica fume determined by S2 is 1200m 2 / kg, the mass of silica fume is calculated and weighed according to the mass of solid sulfur ash.

[0033] S3 calculates the mass of two activators according to the mass of the solid sulfur ash: potassium sulfate and sodium hydroxide, and mixes the above two activators evenly in a ratio of 1:1.

[0034] S4 calculates the quality of the superplasticizer according to the quality of the sulfur-fixing ash.

[0035] S5 is based on 50 parts of sulfur-fixing ash, 3 parts of silica fume, 3 parts of activator, 0.1% superplasticizer (calculated according to the mass of sulfur-fixing ash), 0.3% of polyvinyl alcohol fiber (calculated according to the mass of sulfur-fixing ash), The above materials are stirred for 10 to 15 minutes at a rotational speed of 150 to 300 r / min to obtain a mixed powder.

[0036] S6 On the...

Embodiment 2

[0039] S1 is ground to make the specific surface area of the sulfur-fixed ash 700m 2 / kg.

[0040] The specific surface area of silica fume determined by S2 is 1200m 2 / kg, the mass of silica fume is calculated and weighed according to the mass of solid sulfur ash.

[0041] S3 calculates the mass of two activators according to the mass of the solid sulfur ash: potassium sulfate and sodium hydroxide, and mixes the above two activators evenly in a ratio of 1:1.

[0042] S4 calculates the quality of the superplasticizer according to the quality of the sulfur-fixing ash.

[0043] S5 is based on 75 parts of sulfur-fixing ash, 10 parts of silica fume, 4 parts of activator, 0.3% superplasticizer (calculated according to the mass of sulfur-fixing ash), and 0.5% polyvinyl alcohol fiber (calculated according to the mass of sulfur-fixing ash) , the above materials are stirred for 10 to 15 minutes at a rotational speed of 150 to 300 r / min to obtain a mixed powder.

[0044] S6 On t...

Embodiment 3

[0047]S1 is ground to make the specific surface area of the sulfur-fixed ash 700m 2 / kg.

[0048] The specific surface area of silica fume determined by S2 is 1200m 2 / kg, the mass of silica fume is calculated and weighed according to the mass of solid sulfur ash.

[0049] S3 calculates the mass of two activators according to the mass of the solid sulfur ash: potassium sulfate and sodium hydroxide, and mixes the above two activators evenly in a ratio of 1:1.

[0050] S4 calculates the quality of the superplasticizer according to the quality of the sulfur-fixing ash.

[0051] S5 According to 80 parts of sulfur-fixing ash, 15 parts of silica fume, 5 parts of activator, 0.5% of superplasticizer, and 0.6% of polyvinyl alcohol fiber, the above materials are stirred at a speed of 150-300r / min for 10-15min , have mixed powder.

[0052] S6 On the basis of S5, the subgrade improvement soil test is carried out according to the 10% content mixed with soil (external mixing method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com