Fast response saturation reactor

A fast-response, reactor technology, applied in continuously variable inductors/transformers, electrical components, output power conversion devices, etc., can solve unreliable freewheeling and demagnetization circuits, and insufficient freewheeling and demagnetization circuits Simple, low reliability and other problems, to achieve the effect of simple freewheeling and demagnetization circuit, fast energy consumption and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

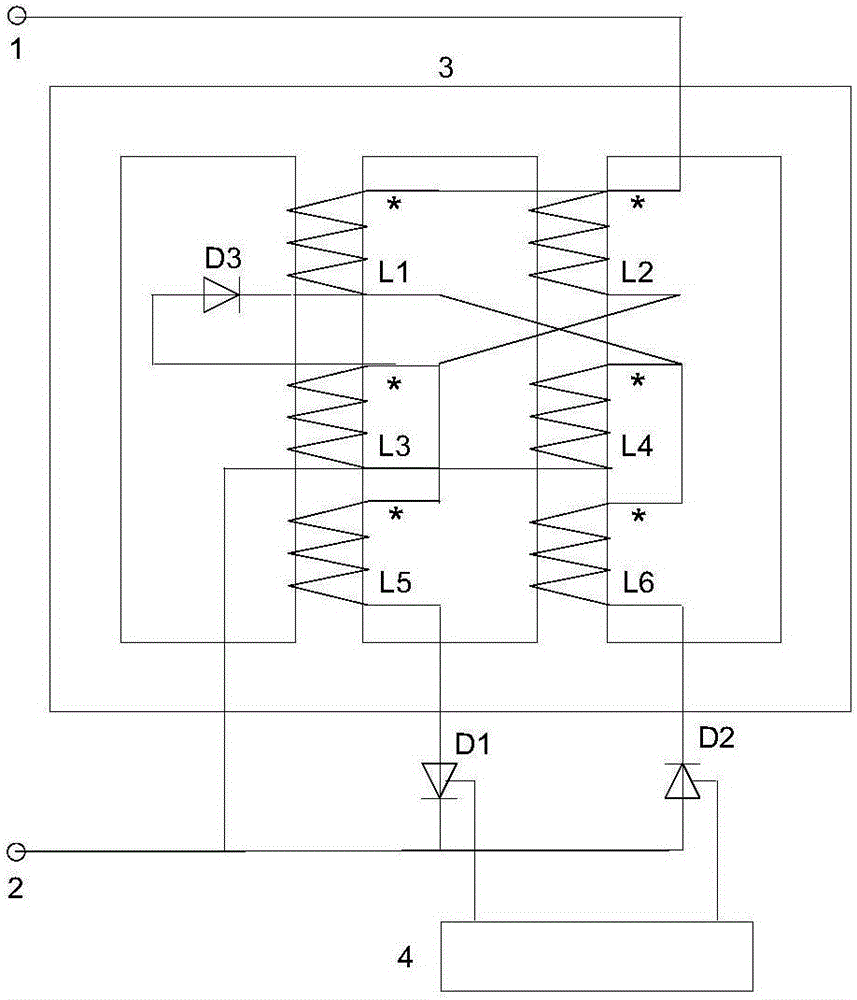

[0035] figure 1 The shown saturable reactor with a freewheeling diode includes a closed-loop iron core of the saturable reactor, each coil installed on two iron core columns of the closed-loop iron core, a thyristor connected to each coil, and a control module for controlling the thyristor; its features are: Yes,

[0036] There are three coils on each of the core legs, the coils at the second position and the coil at the third position have different turns, but the coils at the same position on the two core legs have the same number of turns;

[0037] The synonymous end of the coil at the first position on one of the iron core columns is connected with the same name end of the coil at the second position on the other core column;

[0038] The same-named end of the coil at the third position on each core column is connected with the same-named end of the coil at the second position of the core column;

[0039] The different ends of the coils at the third position on each iron...

Embodiment 2

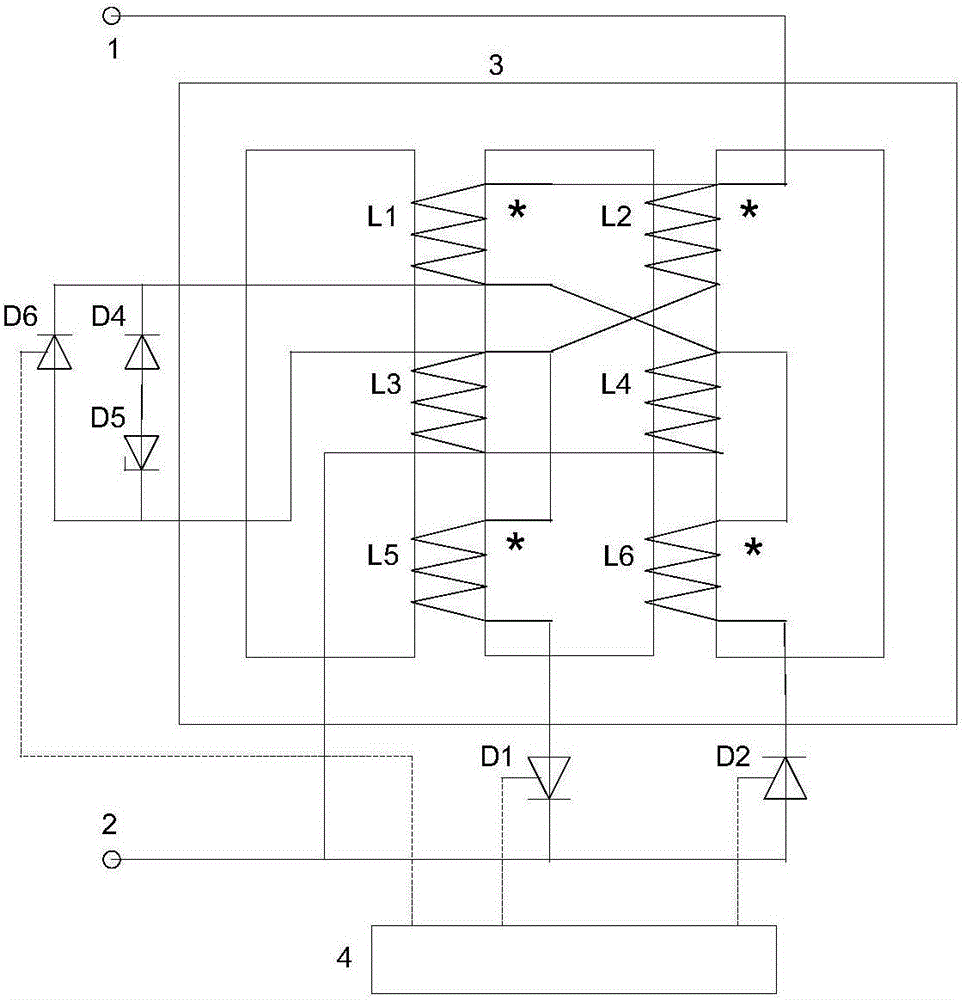

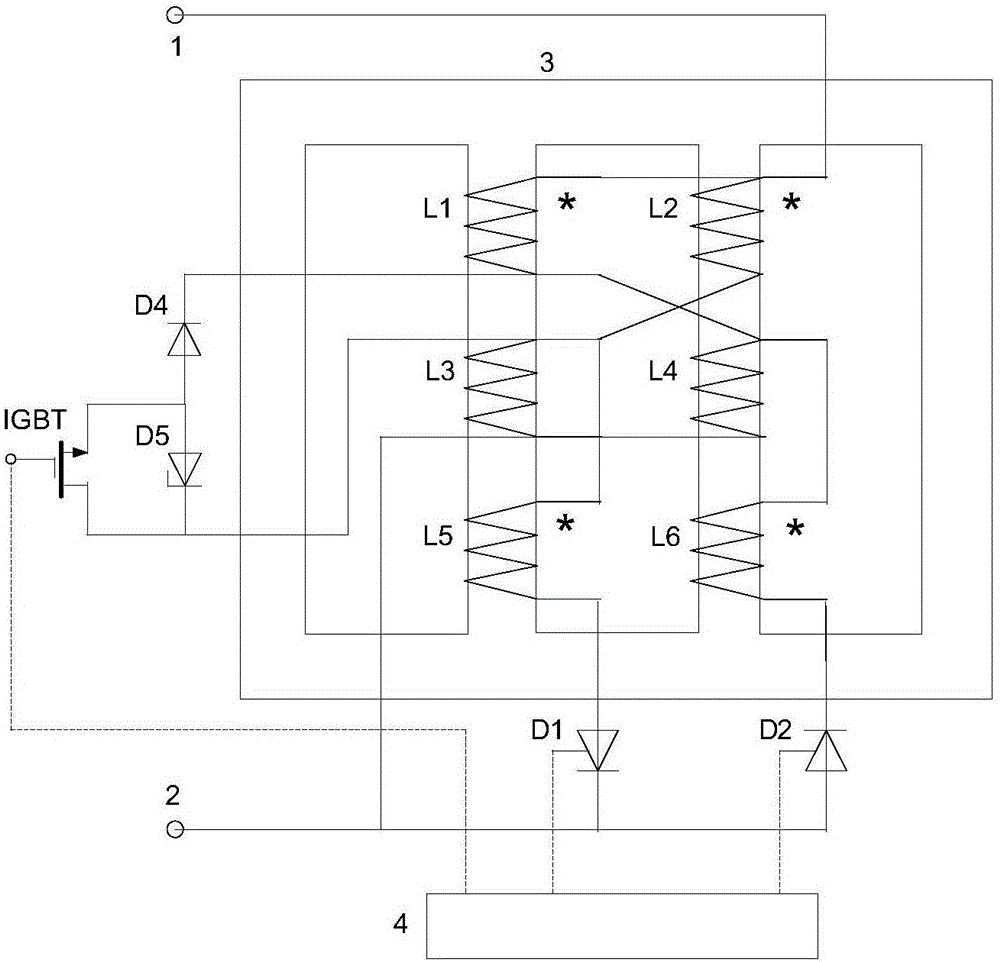

[0057] The structure and connection method of another fast-response saturable reactor are as follows: image 3 As shown (in this embodiment, the saturable reactor can also take other existing forms, not limited to figure 1 given saturable reactor form). from image 3 It can be seen that it is actually replaced by another freewheeling and demagnetizing circuit figure 1 It is composed of the original freewheeling diode of the saturable reactor with freewheeling diode shown.

[0058] The freewheeling and demagnetizing circuit includes diode D4, high-power voltage regulator D5, and IGBT. The diode D4 is connected in reverse series with the high-power Zener tube D5, and the high-power Zener tube D5 is also connected in parallel with the IGBT in the same direction. The control terminal of the IGBT is controlled by the control module 4 .

[0059] image 3 When the shown saturable reactor operates normally and stably, the IGBT is controlled by the control module 4 to be fully tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com