Method for growing nanocrystalline silicon powder

A technology of nanocrystalline silicon and powder, which is applied in the field of preparation of nanocrystalline silicon powder, can solve the problems of poor plasma stability, insufficient decomposition of raw material gas, unsuitable for large-scale industrial production, etc. Low equipment cost and uniform discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

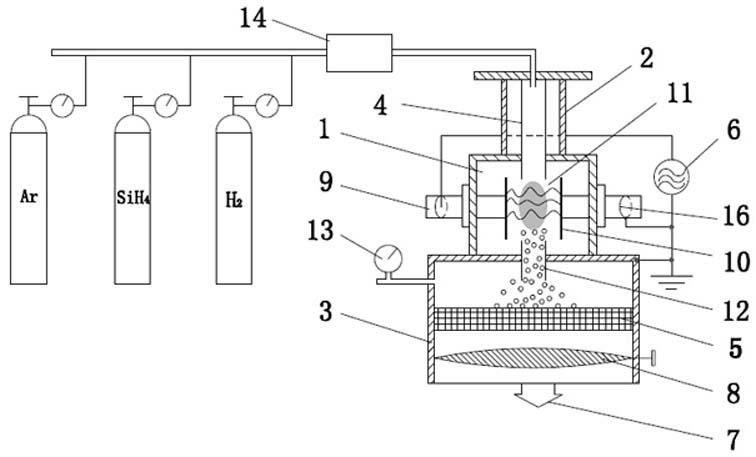

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] A method for growing nanocrystalline silicon powder, the key of which is to comprise the following steps:

[0033] A. Pass the mixed gas from the inlet pipe 2 into the reaction chamber 1, the flow ratio is: argon 30-150sccm, silane 0.8-1.3sccm, hydrogen 1-10sccm, wherein, argon is the working gas, silane hydrogen is the reaction gas;

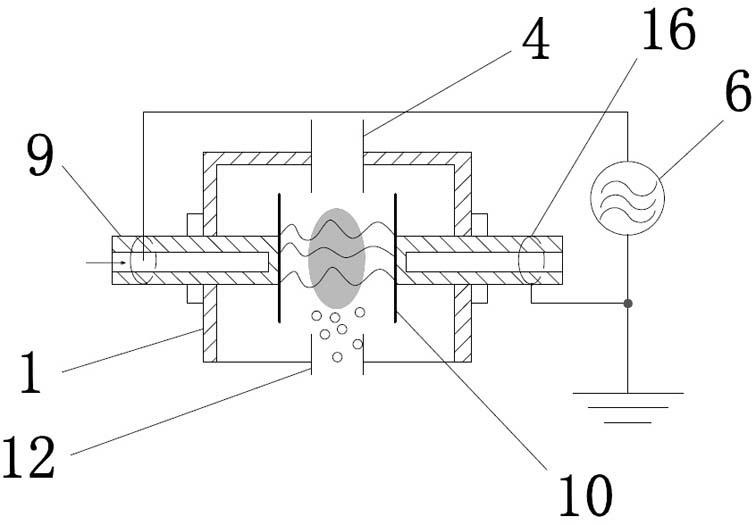

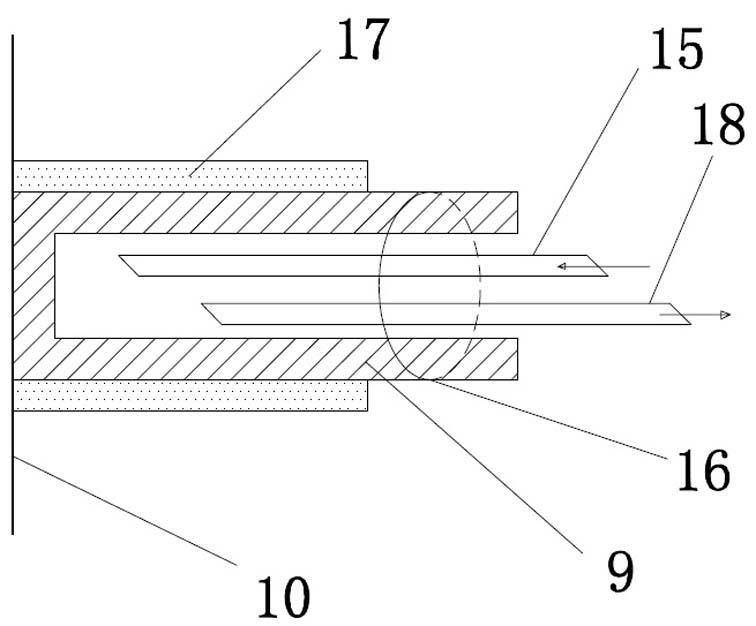

[0034] B. Input radio frequency alternating current into a pair of horizontally arranged electrodes 9 through radio frequency source 6, so that the working gas is discharged, and a plasma region 11 is formed between the quartz plates 10 as electrode barrier layers;

[0035] C. The reaction gas is decomposed by plasma in the plasma region 11, and the decomposed fragments form nanocrystalline silicon nuclei;

[0036] D, adjust the flow rate L of the gas that passes through flowmeter 14 and / or adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com