Microwave heating weight detection device

A technology of weight detection and microwave heating, which is applied in the direction of weighing by removing certain components, can solve the problems of unstable weight detection and microwave inner cavity pressure changes, etc., and achieve simple and easy technical means, low price and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

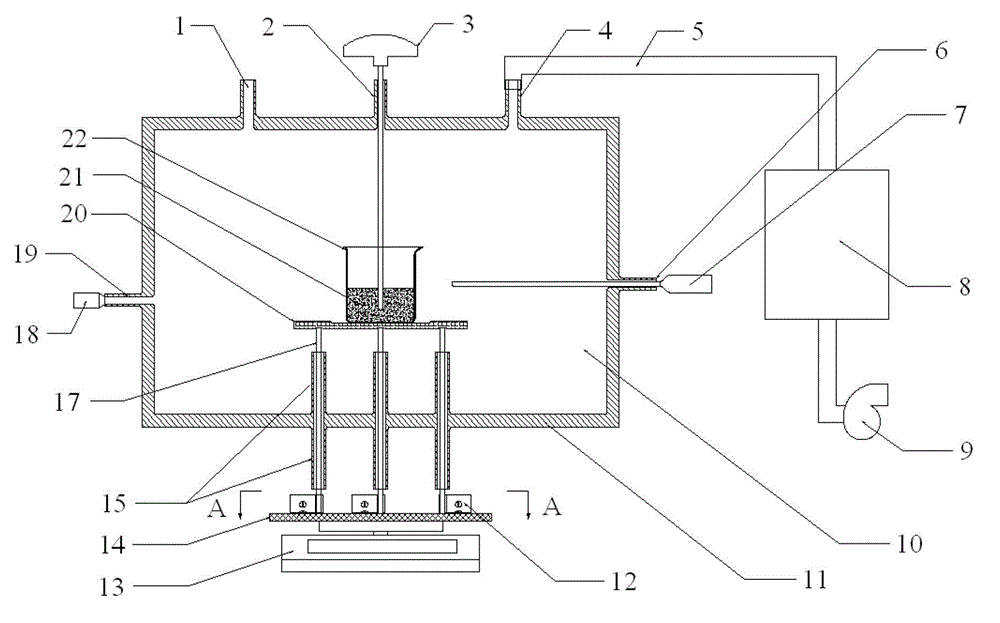

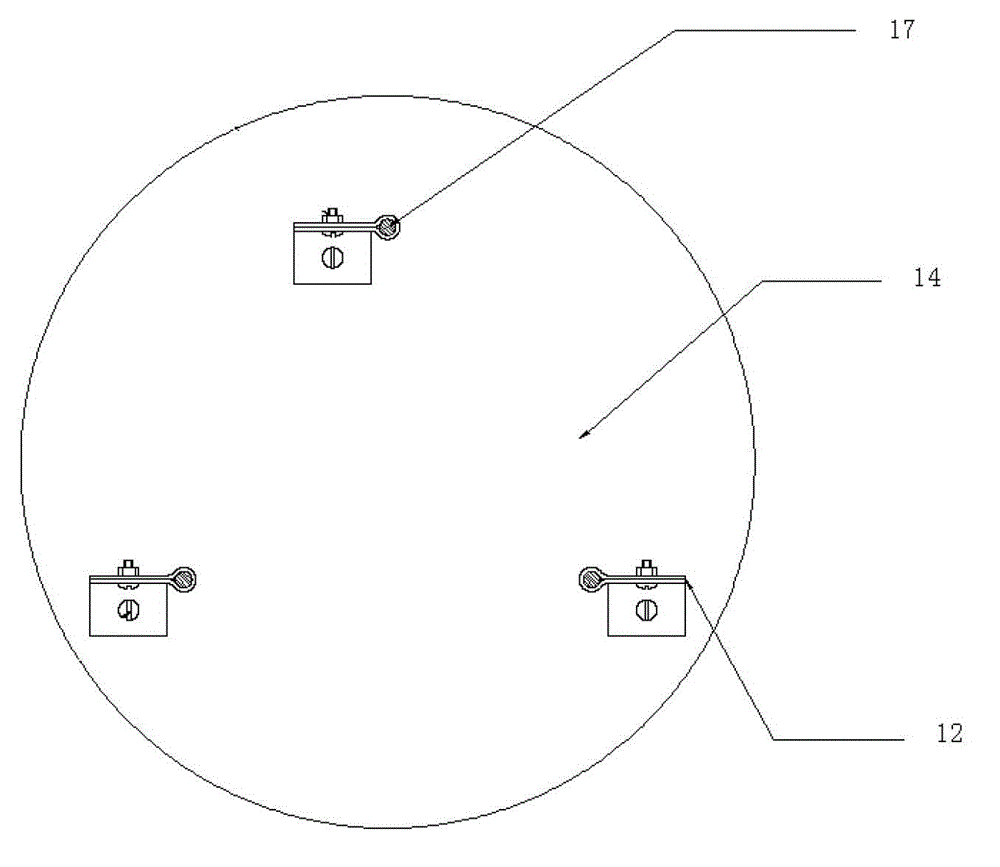

[0020] like figure 1 , figure 2 As shown, the microwave heating weight detection device of the present invention includes a gas processing device, a microwave inner cavity shell 11, a ceramic plate 20 arranged in the microwave inner cavity 10 for placing a quartz bottle 22, and a ceramic plate 20 arranged on the outer bottom of the microwave inner cavity shell 11. Support plate 14; one end of the quartz rod 17 is arranged on the support plate 14 through the fixing clip 12, and the other end passes through the quartz rod jack 15 at the bottom of the microwave inner cavity shell 11 and extends into the microwave inner cavity 10 for supporting the ceramic plate 20; The gas processing device includes a gas processor 8 and a fan 9. One end of the gas processor 8 communicates with the gas outlet 4 of the microwave inner cavity shell 11 through an air duct 5, and the other end of the gas processor 8 communicates with the fan through a pipeline. 9 communicates; the pressure sensor 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com