Gasification device and method for preparing hydrogen-rich synthetic gas from biomass

A gasification device and biomass technology, which is applied in the production of combustible gas, granular/powder fuel gasification, petroleum industry, etc., can solve the problems of sacrificing the calorific value of gasification gas, difficulty in enlarging fixed beds, and high cost. Achieve the effect of promoting steam gasification reaction, improving energy utilization rate, and promoting biomass gasification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

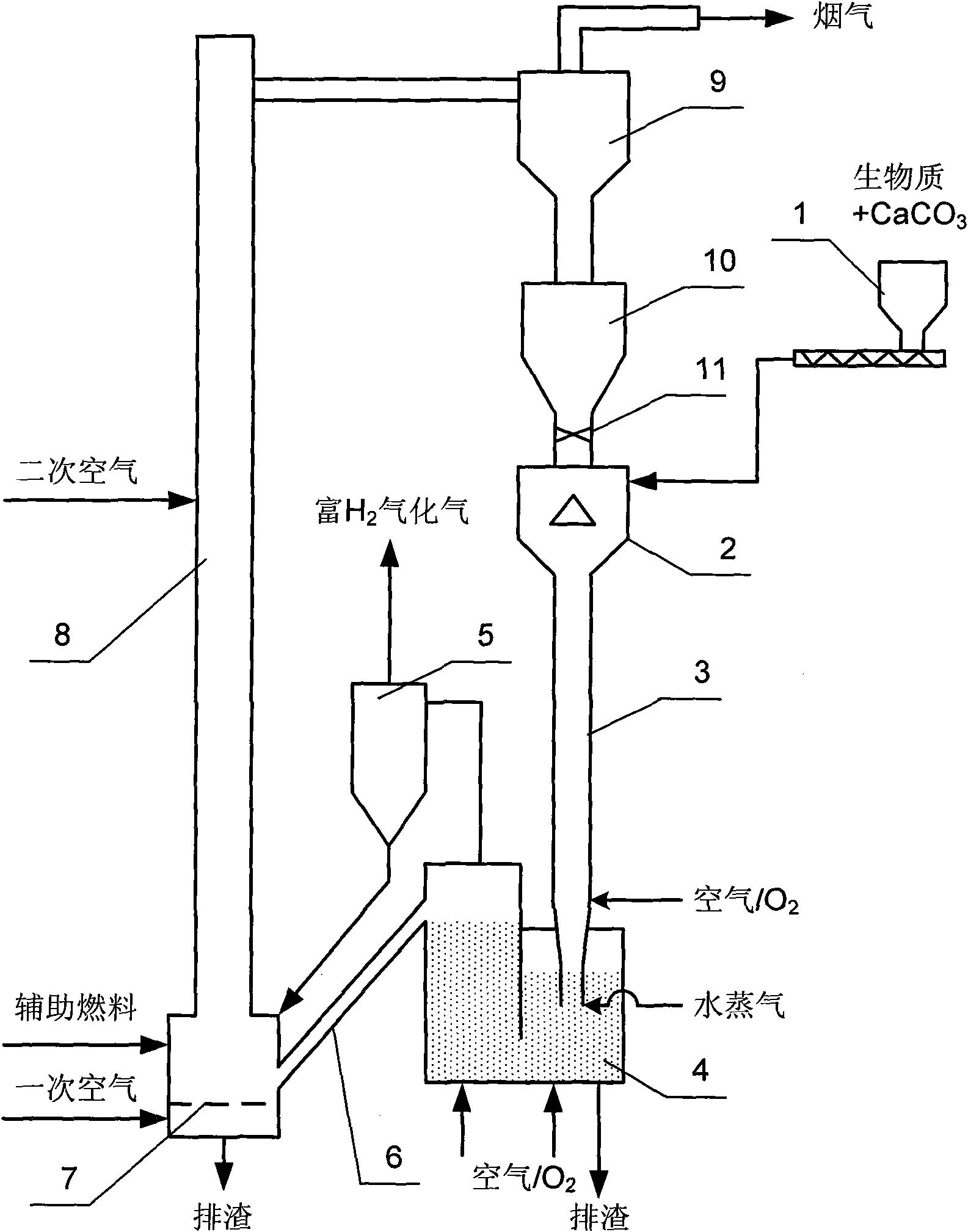

[0050] Example 1 A Process for Producing Low-Tar Hydrogen-rich Syngas by Sawdust Circulating Fluidized Bed Gasification

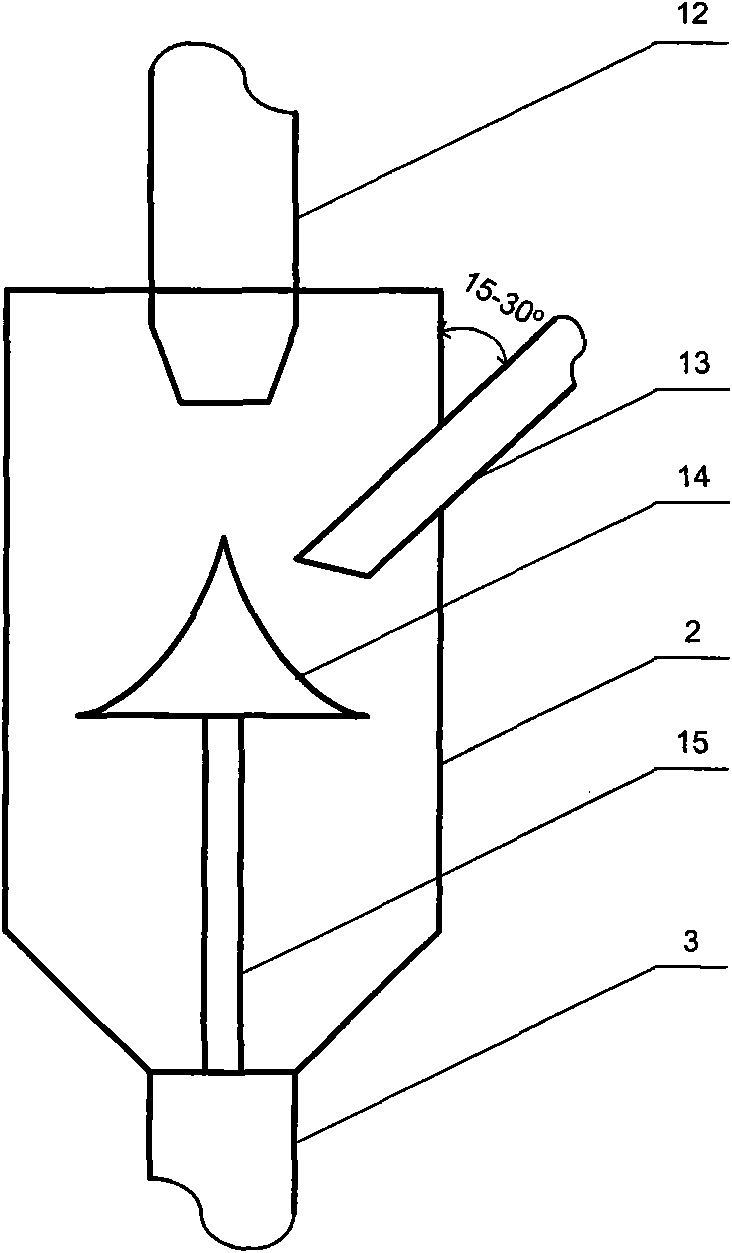

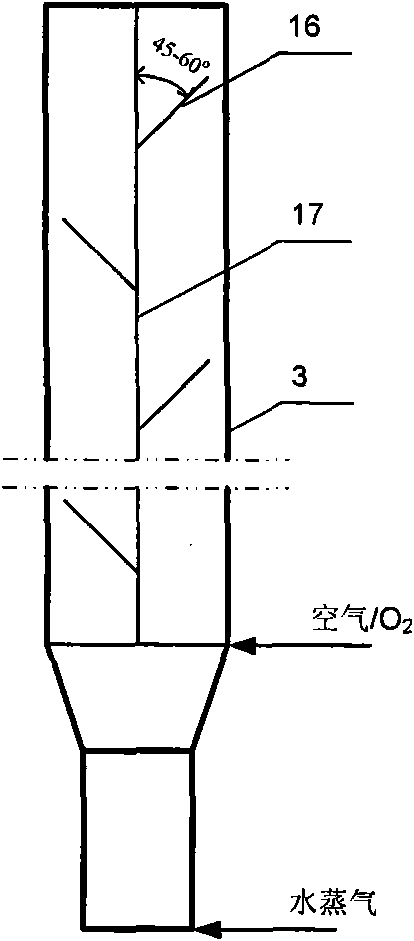

[0051] usefigure 1 The shown device takes the sawdust raw material of the wood processing plant, and the industrial analysis and elemental analysis of the sawdust are as shown in attached table 1. The sawdust and the adsorbent are mixed in a ratio of 95:5 and passed through the biomass feeder 1 through the biomass feed pipe 13 Send it to the mixer 2, and quickly mix and exchange heat with heat carrier and adsorbent at a temperature of 850 °C (the mass ratio of heat carrier and adsorbent is 7:3), and change the circulation rate by adjusting the opening of the disc valve 11, and the sawdust is After heating to about 600°C, the sawdust, heat carrier, and adsorbent are accelerated into the pyrolysis chamber 3 by gravity, and then decelerated to a stationary state by the blockage of the pyrolysis chamber baffle 16, experiencing a cycle of constant acceleration-de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com