Fluid bed electrode direct carbon fuel cell device

A fuel cell and fluidized bed technology, used in solid electrolyte fuel cells, fuel cell additives, battery electrodes, etc., can solve the problems of low heat transfer efficiency of fixed bed reactors, difficult to meet requirements, and continuous supply of carbon fuel. It is convenient to collect current, increase heat transfer effect, and improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

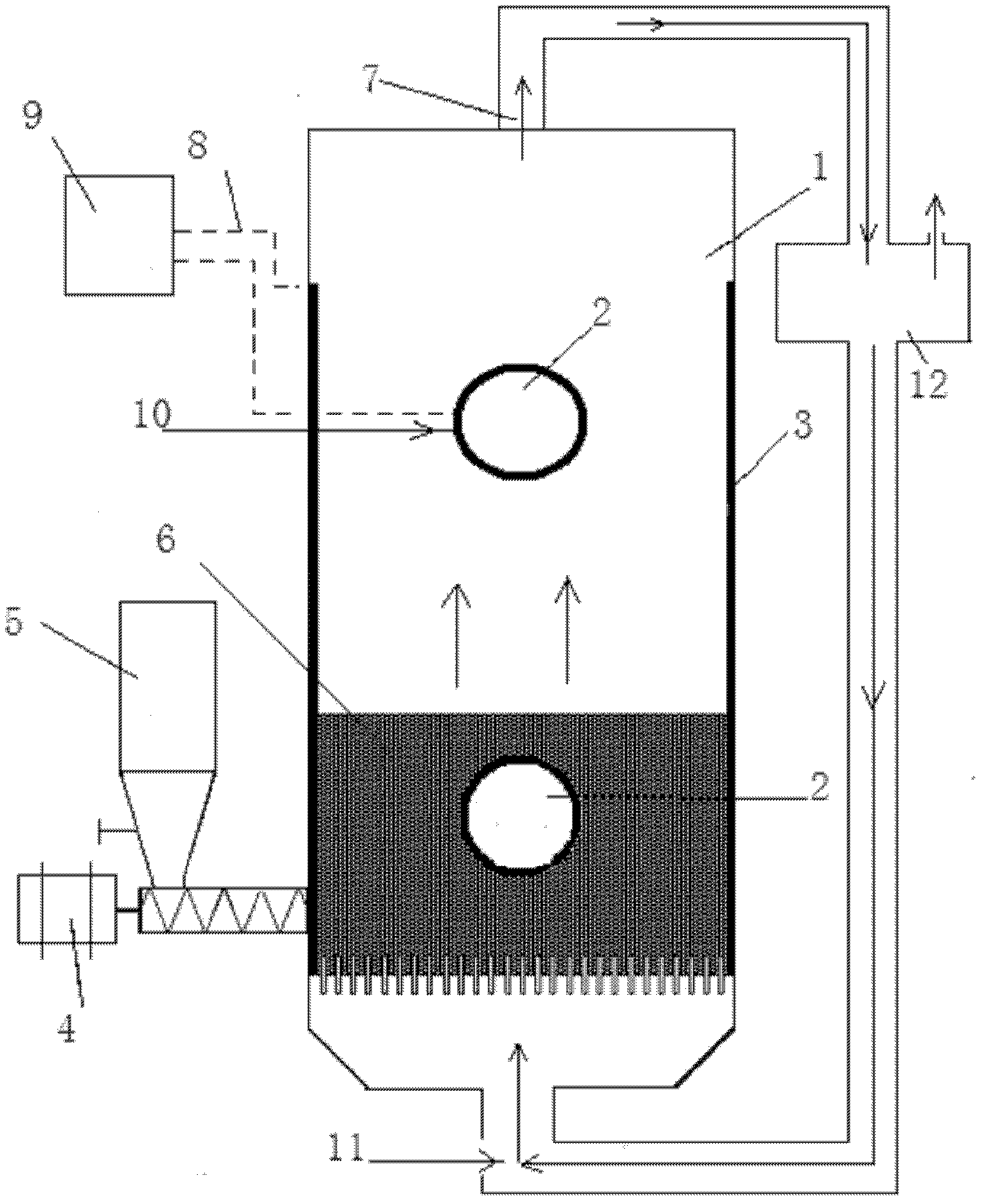

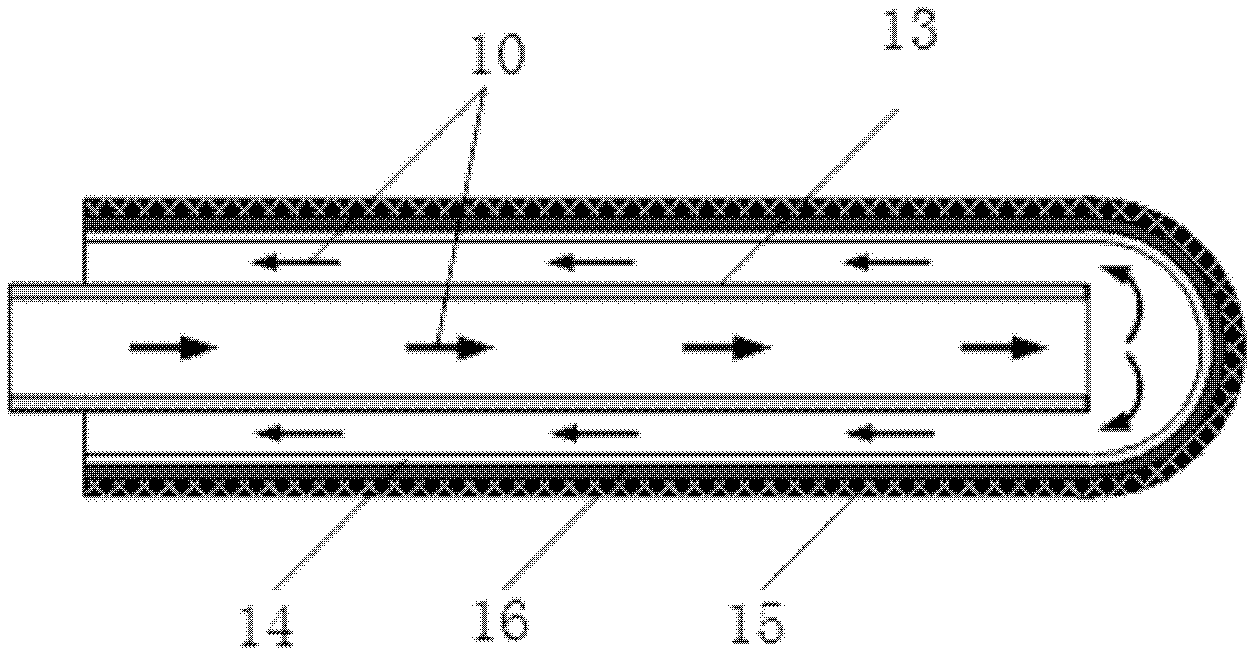

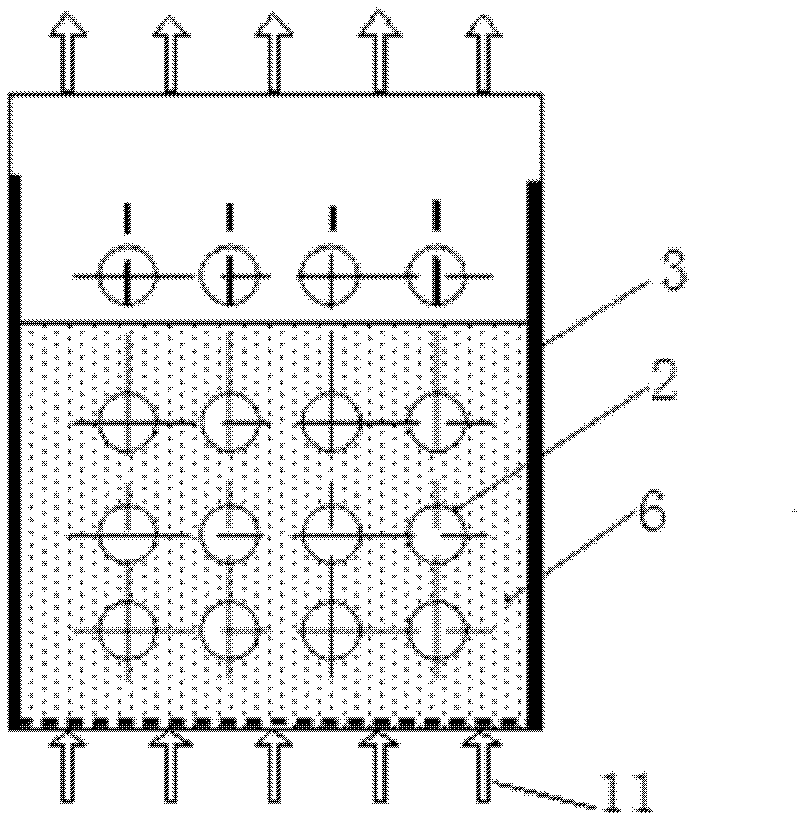

[0022] Fluidized bed electrode direct carbon fuel cell device, which includes a fluidized bed 1, two or more tubular single cells 2, a collector plate 3, a composite carbon fuel 6, a gas circulation device 12, and a screw feeder 4, fuel tank 5 (such as figure 1 shown); the tubular single battery is a blind tube type (such as figure 2 As shown), the open end protrudes from the fluidized bed 1, and the closed end is placed inside the fluidized bed 1. The inner side of the tubular cell is the cathode 14, the outer side is the anode 15, and the middle is the solid oxide electrolyte 16. The tubes 13 are inserted into the battery in parallel, and the layout of the tubular cells is arranged in a row (such as image 3 Shown); collecting plate 3 is placed on the inner wall of fluidized bed 1; composite carbon fuel 6 is filled in the bottom of fluidized bed 1, communicates with screw feeder 4 and fuel tank 5 outside fluidized bed 1; composite carbon fuel 6 is the carbon fuel added to...

Embodiment 2

[0025] Fluidized bed electrode direct carbon fuel cell device, which includes a fluidized bed 1, two or more tubular single cells 2, a collector plate 3, a composite carbon fuel 6, a gas circulation device 12, and a screw feeder 4, fuel tank 5 (such as figure 1 shown); the tubular single battery is a through-tube type (such as Figure 4 As shown), both ends extend out of the fluidized bed 1, the inner side of the tubular single battery is the cathode 14, the outer side is the anode 15, and the middle is the solid oxide electrolyte 16, and the layout of the tubular single battery is in a parallel arrangement (such as image 3 Shown); collecting plate 3 is placed on the inner wall of fluidized bed 1; composite carbon fuel 6 is filled in the bottom of fluidized bed 1, communicates with screw feeder 4 and fuel tank 5 outside fluidized bed 1; composite carbon fuel 6 is the carbon fuel added to the ion conductor, the carbon fuel includes graphite, carbon black, coke, coal and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com