Preparation method of metal catalyst loaded on porous carbon by means of coal or biomass gasification

A technology for supporting metals and catalysts, which is applied in the field of preparing porous carbon-supported metal catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1. Select wood chips as a biomass raw material, dry, grind and sieve them into particles with a size of 60-200 μm to obtain carbon-based raw material particles (referred to as wood chips for short. The industrial analysis is as follows: the moisture content is 9.71%, The ash content is 0.15%, the volatile matter content is 83.04%, and the fixed carbon content is 7.10%).

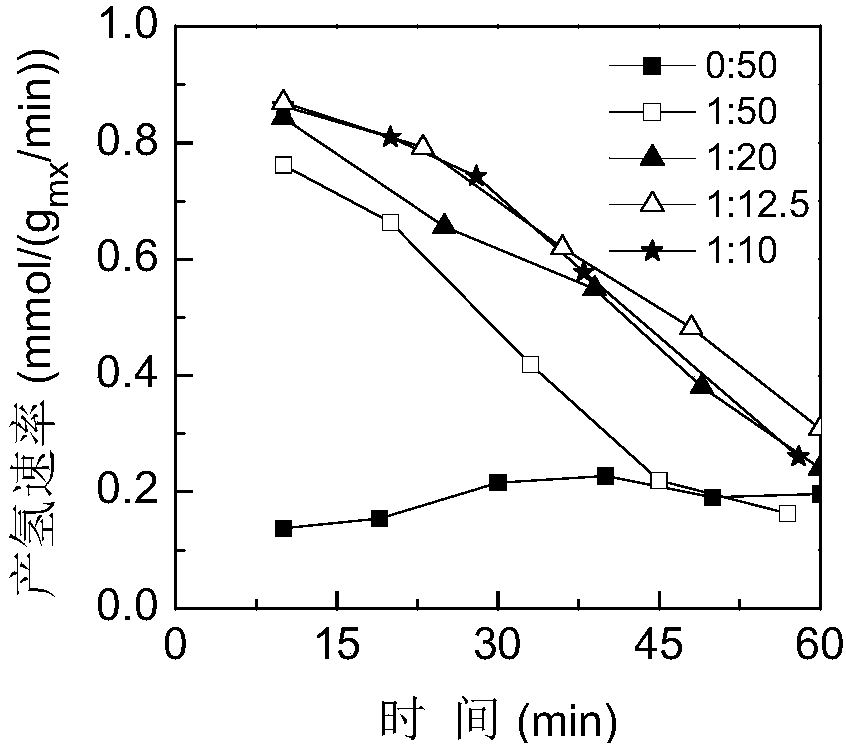

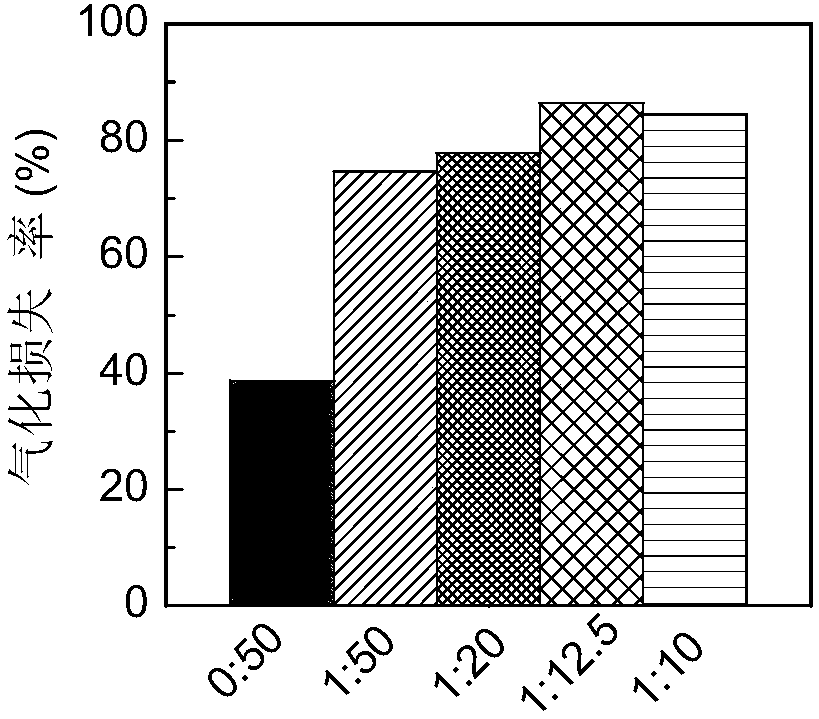

[0037] Step 2, select nickel nitrate (analytical pure) as the precursor of the main component of the catalyst, weigh nickel nitrate and sawdust particles respectively according to the mass ratio of 1:50, and utilize equal volume impregnation method to mix nickel nitrate and sawdust particles Mix evenly; then, under a high-purity nitrogen protective atmosphere, preheat at 390°C for 30 minutes to form a semi-coke-loaded metal oxide (that is, wood chip semi-coke-loaded nickel oxide).

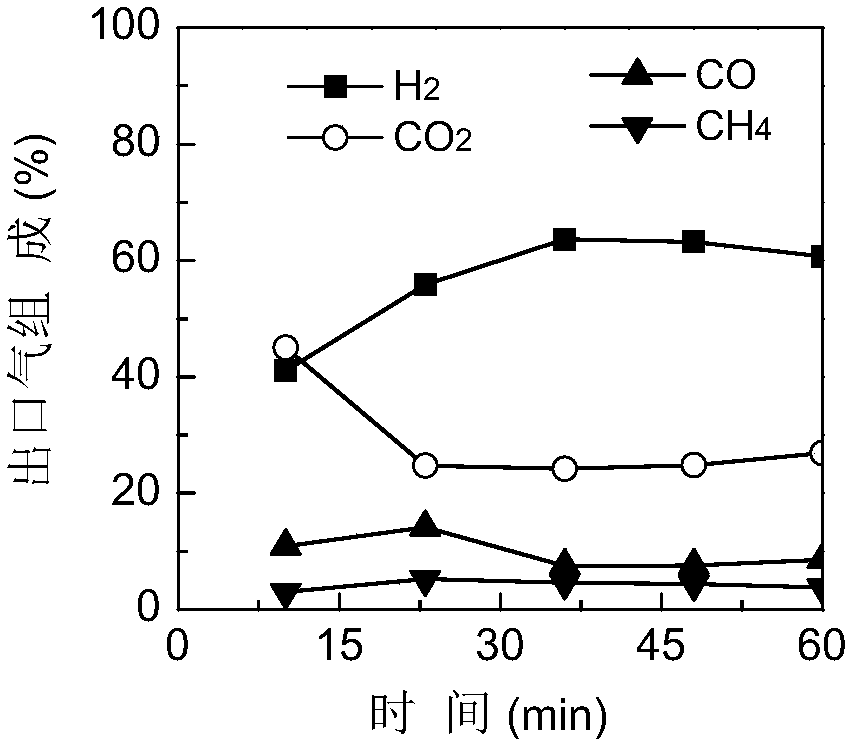

[0038] Step 3. Use semi-coke-loaded metal oxides (i.e., nickel oxide loaded on sawdust semi-coke) as the material fo...

Embodiment 2

[0041] The difference from Example 1 is that nickel nitrate and sawdust particles were weighed respectively according to the mass ratio of 1:20.

Embodiment 3

[0043] The difference from Example 1 is that nickel nitrate and wood chips were weighed according to the mass ratio of 1:12.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com