Two-stage type entrained flow gasification furnace

An entrained-flow and gasifier technology, applied in the field of two-stage entrained-flow gasifier, can solve the problems of high residual carbon content, large mixing kinetic energy, environmental pollution, etc., and achieve the effect of high carbon conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

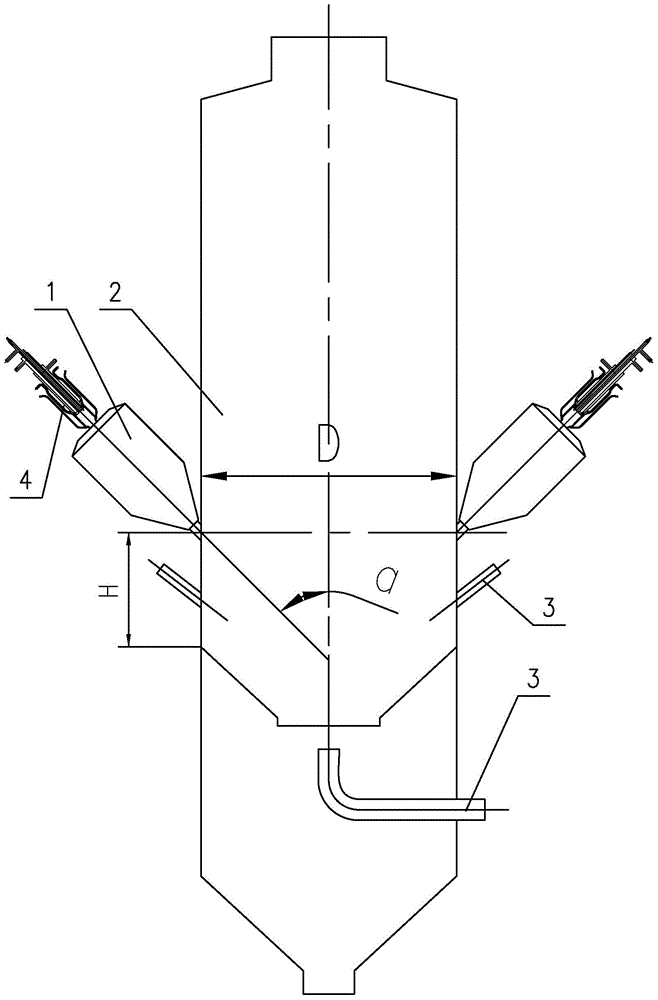

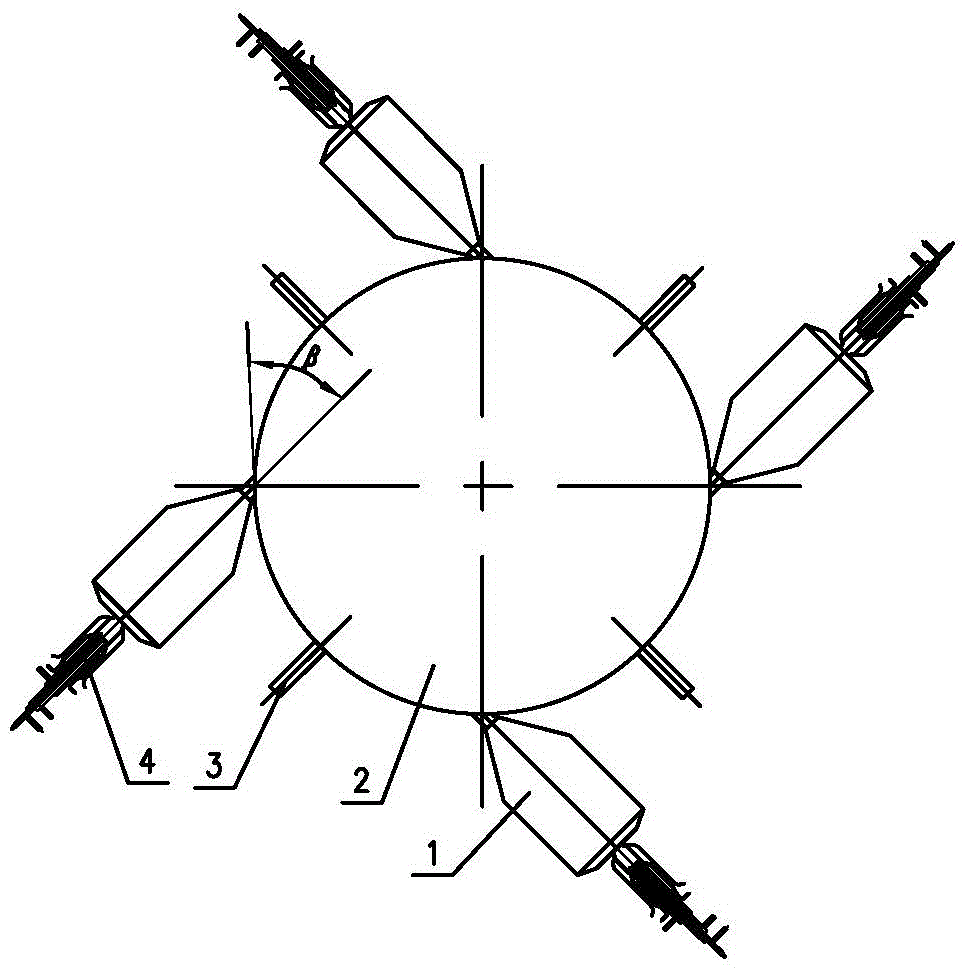

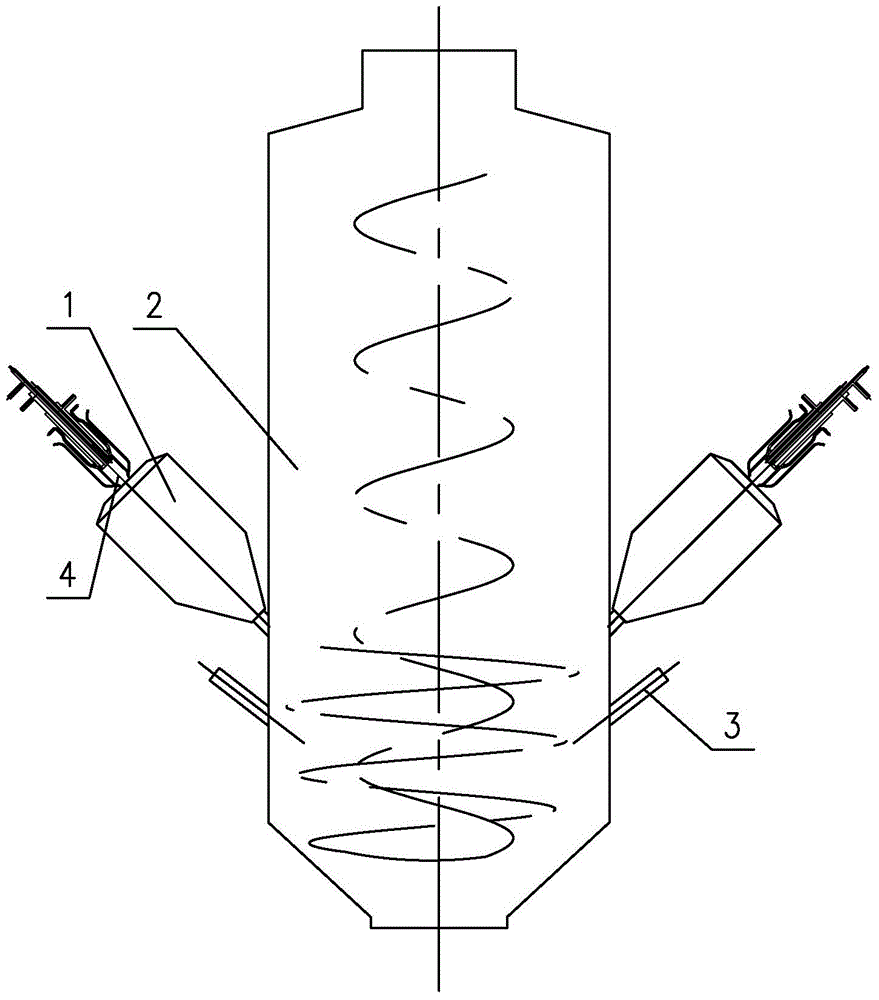

[0042] Such as Figure 1-2 The shown two-stage entrained-flow gasifier is composed of multiple pre-gasification chambers 1 and a main gasification chamber 2. The outlets of the multiple pre-gasification chambers 1 are obliquely inserted into the main gasification chamber. The ratio of the height H from the center to the bottom of the main gasification chamber 2 and the diameter D of the main gasification chamber is 0.3-2:1. On the vertical section, the angle α between the axis of the pre-gasification chamber 1 and the axis of the main gasification chamber 2 is 30-90°. On the horizontal section, the angle β formed by the axis of the pre-gasification chamber 1 and the tangent of the main gasification chamber 2 is 30-90°.

[0043] The top of the pre-gasification chamber 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com