Preparation method for acid resistance soil grounding grid material

A grounding grid, acid-resistant technology, applied in the direction of connecting contact materials, etc., can solve problems such as poor corrosion resistance and poor flexibility, and achieve the effects of improving strength and conductivity, reducing costs, and reducing construction and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

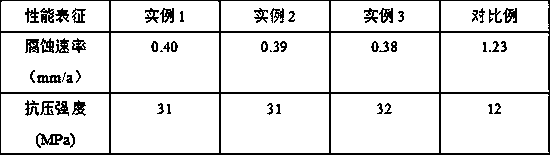

Examples

example 1

[0023] Take 20g of silicon powder, 10g of manganese powder, 20g of copper powder, 850g of aluminum powder, and 10g of zinc powder, put them into an electric arc melting furnace, and conduct a melting reaction at 800°C and 10MPa for 2 hours. , the billet is drawn, and the number of times of drawing is controlled for 3 times to obtain alloy wire. Take 150g chopped carbon fiber, add it to 1000g acrylic emulsion, stir and disperse at 3000r / min for 30min, and obtain a dispersion. Roll expanded graphite into graphite paper, control The pressure is 18MPa, the speed is 3m / min, the thickness of graphite paper is 0.010mm, and the density is 1.0g / cm 3 , and then press 5g / m 2 After the coating is finished, put it in a drying oven and dry it to a constant weight at 105°C to obtain a composite graphite paper. Alloy wires are arranged on the surface of the composite graphite paper, and the distance between the alloy wires is 2cm. Cover a layer of composite graphite paper after the cloth is ...

example 2

[0025] Take 25g of silicon powder, 15g of manganese powder, 35g of copper powder, 875g of aluminum powder, and 15g of zinc powder, put them into an arc melting furnace, and conduct a melting reaction at 850°C and 15MPa for 2 hours. After the melting is completed, carry out hot rolling to obtain a 4mm diameter billet. , the billet is drawn, and the number of times of drawing is controlled 4 times to obtain alloy wire. Take 175g chopped carbon fiber, add it to 1250g acrylic acid emulsion, stir and disperse at 3500r / min for 35min, and obtain a dispersion. Roll expanded graphite into graphite paper, control The pressure is 19MPa, the speed is 3m / min, the thickness of graphite paper is 0.013mm, and the density is 1.1g / cm 3 , and then press 7g / m 2 After the coating is finished, put it in a drying oven and dry it to a constant weight at 107°C to obtain a composite graphite paper. Alloy wires are arranged on the surface of the composite graphite paper, and the distance between the all...

example 3

[0027]Take 30g of silicon powder, 20g of manganese powder, 50g of copper powder, 900g of aluminum powder, and 20g of zinc powder, put them into an arc melting furnace, and conduct a melting reaction at 900°C and 20MPa for 3 hours. After the melting is completed, carry out hot rolling to obtain a 5mm diameter billet. , the billet is drawn, and the number of times of drawing is controlled 5 times to obtain an alloy wire. Take 200g of chopped carbon fiber, add it to 1500g of acrylic emulsion, stir and disperse it at 4000r / min for 40min to obtain a dispersion, and roll the expanded graphite into graphite paper. The pressure is 20MPa, the speed is 4m / min, the thickness of graphite paper is 0.015mm, and the density is 1.2g / cm 3 , and then press 8g / m 2 After the coating is finished, put it in a drying oven and dry it to a constant weight at 110°C to obtain a composite graphite paper. Alloy wires are arranged on the surface of the composite graphite paper. The distance between the all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com