Gasifier burner with water-cooled coiled tube protection for dry feed entrained flow bed

A water-cooled coil and entrained bed technology, which is applied to the gasification of granular/powdered fuels, gasification device feeding tools, and the manufacture of combustible gases, can solve the problems of high manufacturing cost of gasifier burners, gasifier shutdown, Short service life and other problems to achieve the effect of saving time and manpower, low manufacturing cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

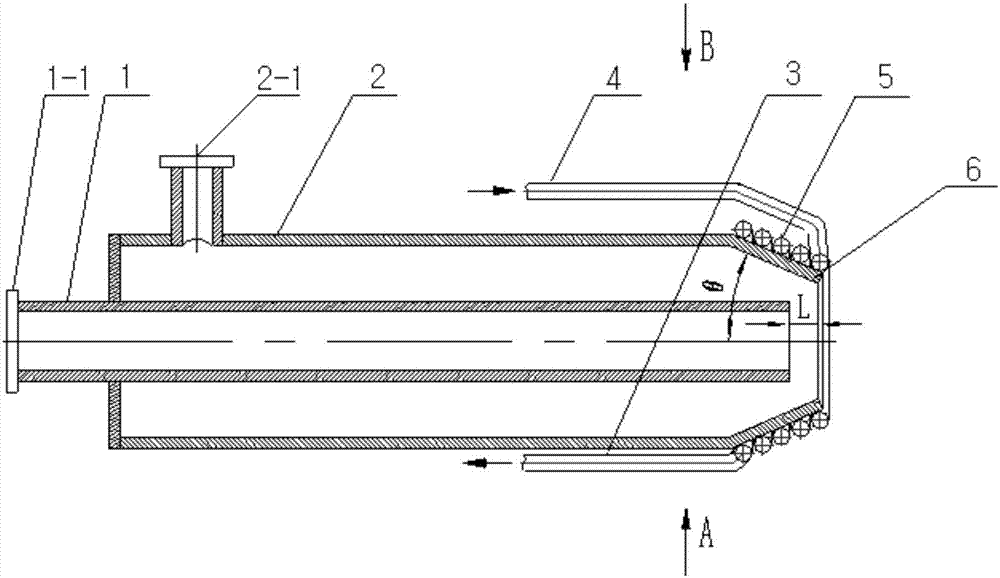

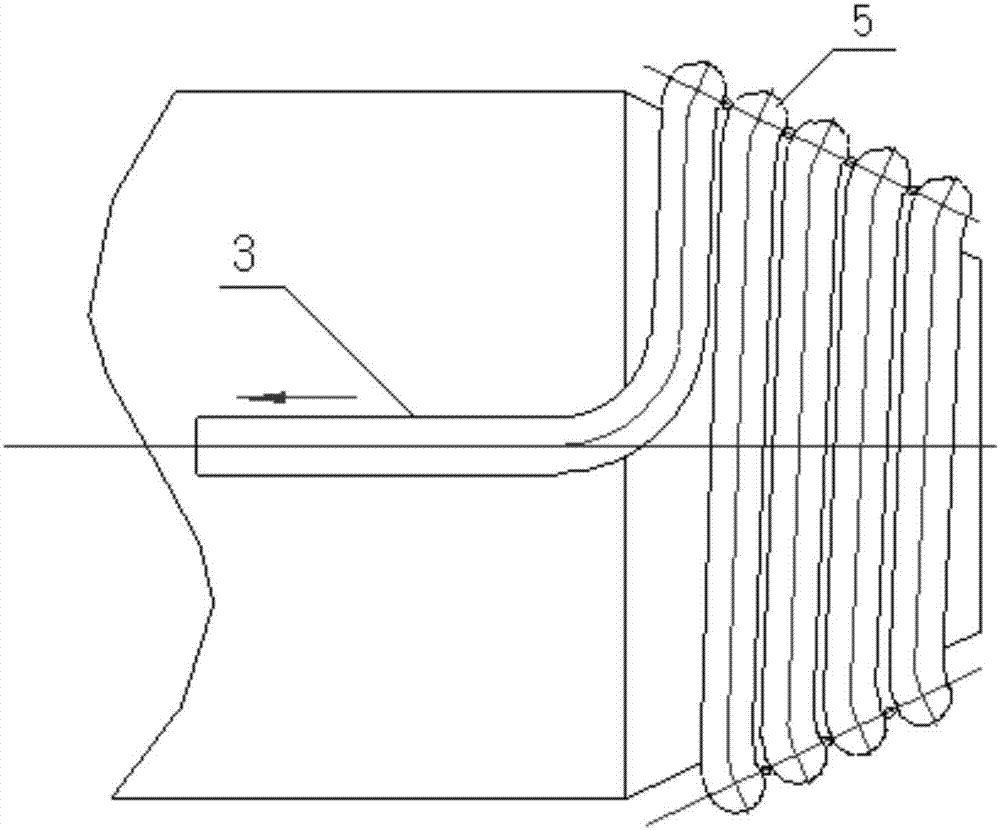

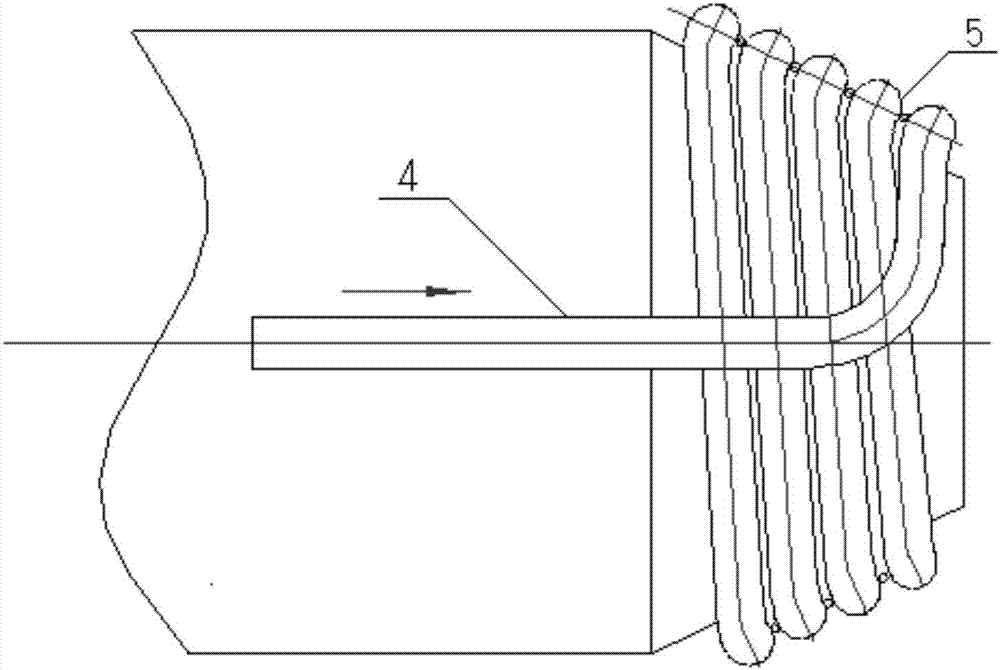

[0043] Specific Embodiment 1: In this embodiment, a dry coal pulverized entrained bed gasifier burner with water-cooling coil protection includes a pulverized coal pipeline 1, a gasification agent pipeline 2, a water-cooling coil 5, and a gasification agent pipeline. Constriction port 6, pulverized coal pipeline 1 and gasification agent pipeline 2 are coaxially arranged from inside to outside, the end of gasification agent pipeline 2 away from the burner head is sealed with the outer wall of pulverized coal pipeline 1, and the top of pulverized coal pipeline 1 A pulverized coal airflow inlet 1-1 is provided, a gasification agent inlet 2-1 is provided near the top of the gasification agent pipeline 2, and a cooling water inlet pipe 4 and a cooling water outlet pipe 3 are respectively arranged at both ends of the water cooling coil 5, The pulverized coal pipeline 1 is a straight pipeline, and the outlet end of the gasification agent pipeline 2 is provided with a constriction port...

specific Embodiment approach 2

[0045] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the contraction angle θ is 0°<θ≤45°, which facilitates the mixing of gasification agent and coal powder and accelerates the coal gasification reaction. . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the L is 0 ≤ L ≤ 50mm, and this setting increases the premixing section of the gasification agent and coal powder to strengthen the gasification agent Mixing with coal powder, while preventing the premixing section from being too long, so that the coal powder burns in advance and ablates the burner. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com