Bamboo-based porous carbon preparation method

A porous carbon, bamboo-based technology, applied in the field of preparation of bamboo-based porous carbon, can solve problems such as environmental pollution and resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

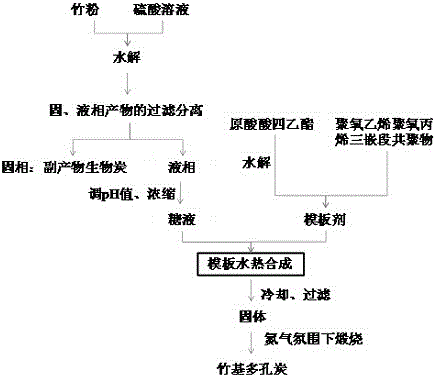

[0019] The embodiment of the present invention provides a preparation method of bamboo-based porous carbon, comprising the following steps: step a) mixing bamboo powder with sulfuric acid solution, then introducing it into a hydrothermal reaction kettle for hydrolysis reaction, cooling, solid-liquid separation, and collecting liquid phase; step b) adjust the pH of the liquid phase to 7 with sodium hydroxide solution, and concentrate to obtain a concentrated sugar solution; step c) mix tetraethyl orthosilicate, hydrochloric acid solution and water, stir and react, and then mix with poly Oxyethylene polyoxypropylene tri-block copolymer is used as a template to mix with the concentrated sugar liquid, and the hydrothermal synthesis reaction is carried out in a hydrothermal reactor, cooled, filtered and separated, and the solid phase product is collected; step d) the described The solid phase product was dried and calcined at high temperature under nitrogen atmosphere to obtain bamb...

Embodiment 1

[0030] Such as figure 1 Shown, bamboo-based porous carbon is prepared according to the following steps:

[0031] Step 1, the hydrolysis of bamboo raw material: import hydrothermal reactor after bamboo powder is mixed with sulfuric acid solution, airtight hydrothermal reactor is heated, the concentration of sulfuric acid solution 10%, hydrolysis reaction temperature 200 o C, reaction time 5 h, bamboo raw material and sulfuric acid solution solid-to-liquid ratio 1kg:10L;

[0032] Step 2. Separation and concentration of the hydrolyzate: after the hydrolysis reaction, take out the hydrothermal reaction kettle and place it in cooling water, and cool it to 80 o Below C, open a kettle to derive the mixture, filter, the solid phase is the by-product biochar, and the liquid phase is adjusted to pH to 7 with 20% sodium hydroxide solution, and then concentrated to the same volume as the reactant sulfuric acid solution by rotary evaporation;

[0033]Step 3. Hydrothermal synthesis of por...

Embodiment 2

[0037] Step 1, the hydrolysis of bamboo raw material: import hydrothermal reactor after bamboo powder is mixed with sulfuric acid solution, airtight hydrothermal reactor is heated, the concentration of sulfuric acid solution 10%, hydrolysis reaction temperature 180 o C, reaction time 7 h, bamboo raw material and sulfuric acid solution solid-to-liquid ratio 1kg:8L;

[0038] Step 2. Separation and concentration of the hydrolyzate: after the hydrolysis reaction, take out the hydrothermal reaction kettle and place it in cooling water, and cool it to 80 o Below C, open a kettle to derive the mixture, filter, the solid phase is the by-product biochar, and the liquid phase is adjusted to pH to 7 with 20% sodium hydroxide solution, and then concentrated to the same volume as the reactant sulfuric acid solution by rotary evaporation;

[0039] Step 3. Hydrothermal synthesis of porous carbon: tetraethyl orthosilicate, 0.2 mol / L hydrochloric acid aqueous solution and water (volume ratio 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com