Blast furnace gas enrichment apparatus and method

A blast furnace gas and gasification device technology, which is applied in the blast furnace gas field, can solve the problems of limited processing capacity, large floor space, large pressure swing adsorption investment, etc., and achieve the effects of reducing direct release, reducing emissions and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

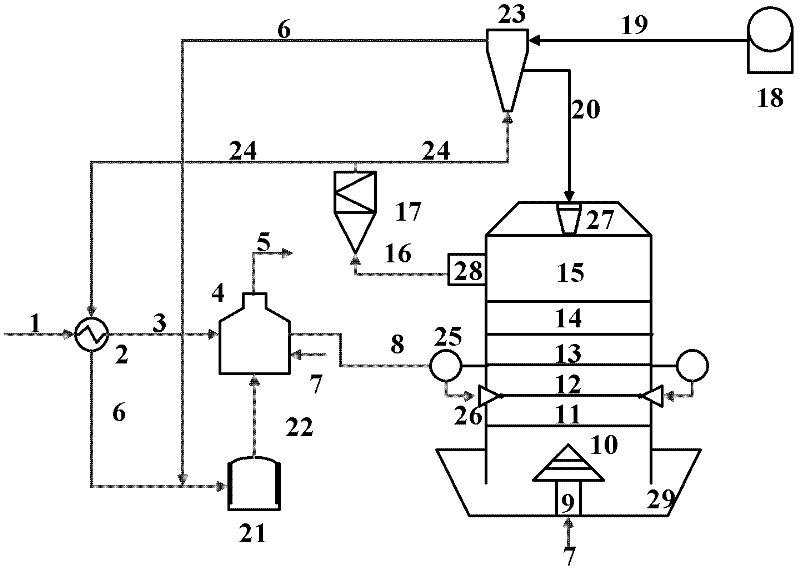

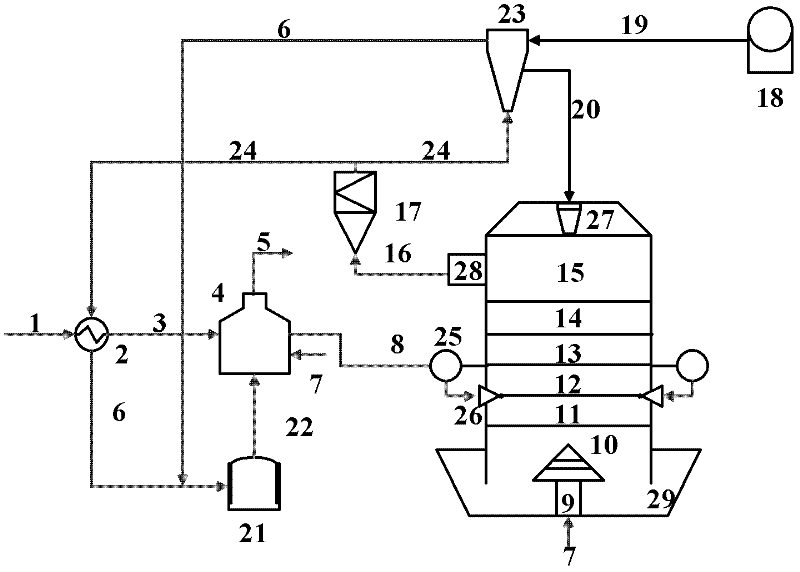

[0019] The blast furnace gas enrichment process described in the present invention is a brand-new design for blast furnace gas enrichment with low calorific value and high carbon dioxide content. Its main process principle is how to effectively reduce CO in the gas. 2 , and increase the CO in the gas, so as to increase the calorific value of the gas and propose a scheme. Its principle is: through the high-temperature gas obtained from the pretreatment of blast furnace gas and the preheated coal, the reduction reaction CO 2 +C=2CO,H 2 O+C→H 2 +CO,2H 2 O+C→CO 2 +2H 2 to reduce CO 2 Content, increase CO, H 2 content, to obtain high calorific value gas.

[0020] The dedusted blast furnace gas 1 is preheated in the heat exchanger 2 by using the high-temperature and high-calorific-value gas 24 after the reaction, and the preheated gas 3 enters the gas heating furnace 4 to use the heat released by the combustion reaction of the high-calorific-value gas 22 and oxygen 7 The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com