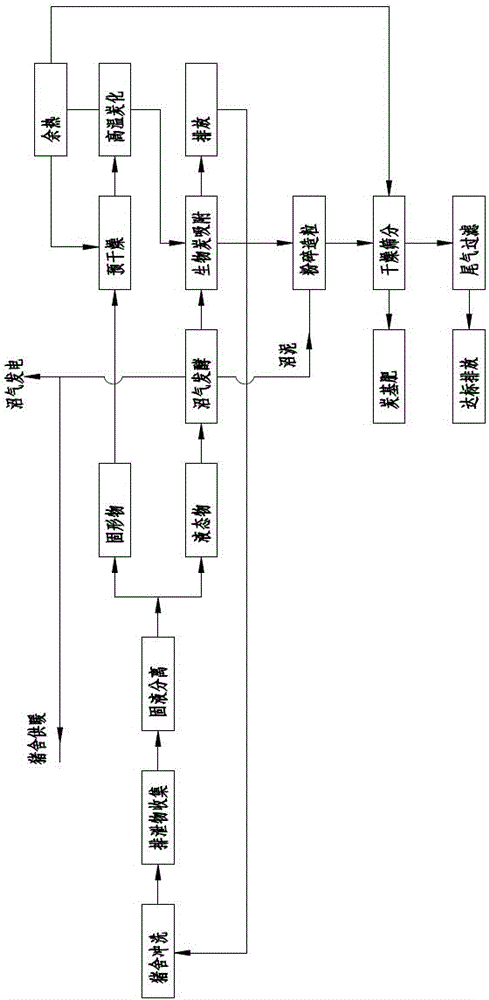

Livestock manure charring fertilizer making system

A technology of poultry manure and carbonization, applied in biochemical instruments, organic fertilizers, fertilization devices, etc., can solve the problems of large amount of poultry manure and difficult treatment, and achieve the goal of reducing water consumption, saving water resources and reducing direct discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

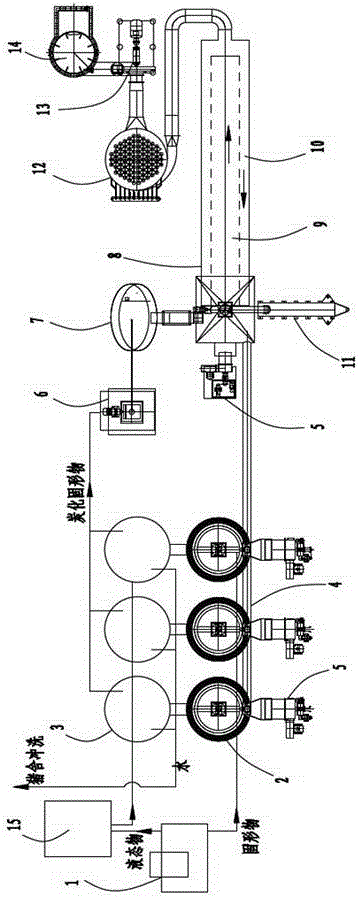

[0018] Embodiment: a kind of excreta carbonization fertilizer making system of pig house breeding, such as figure 1 shown. The head end of the device is a solid-liquid separator 1. After the excrement washed out of the pig house is collected, it is separated into solid and liquid by the solid-liquid separator. The liquid outlet of the solid-liquid separator 1 is connected to the liquid storage cylinder 3; the solid outlet of the solid-liquid separator is connected to the carbonization furnace 2, and one side of the carbonization furnace is provided with a combustion furnace 5 that provides heat, and the discharge port of the carbonization furnace is connected to the liquid storage Barrel 3. There are three carbonization furnaces 2, and the three carbonization furnaces are respectively provided with combustion furnaces 5, and the two carbonization furnaces are connected by waste heat pipes 4. There are three liquid storage cylinders corresponding to the carbonization furnace....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com