Low-carbon zero-emission plant circulation water breeding system based anaerobic denitrification

A technology of recirculating aquaculture and anaerobic denitrification, which is applied in the field of low-carbon zero-emission industrialized recirculating aquaculture system, can solve the problems of many influencing factors, low absorption rate, and difficult operation, so as to reduce environmental pollution and reduce direct Emissions and the effect of reducing the amount of water exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

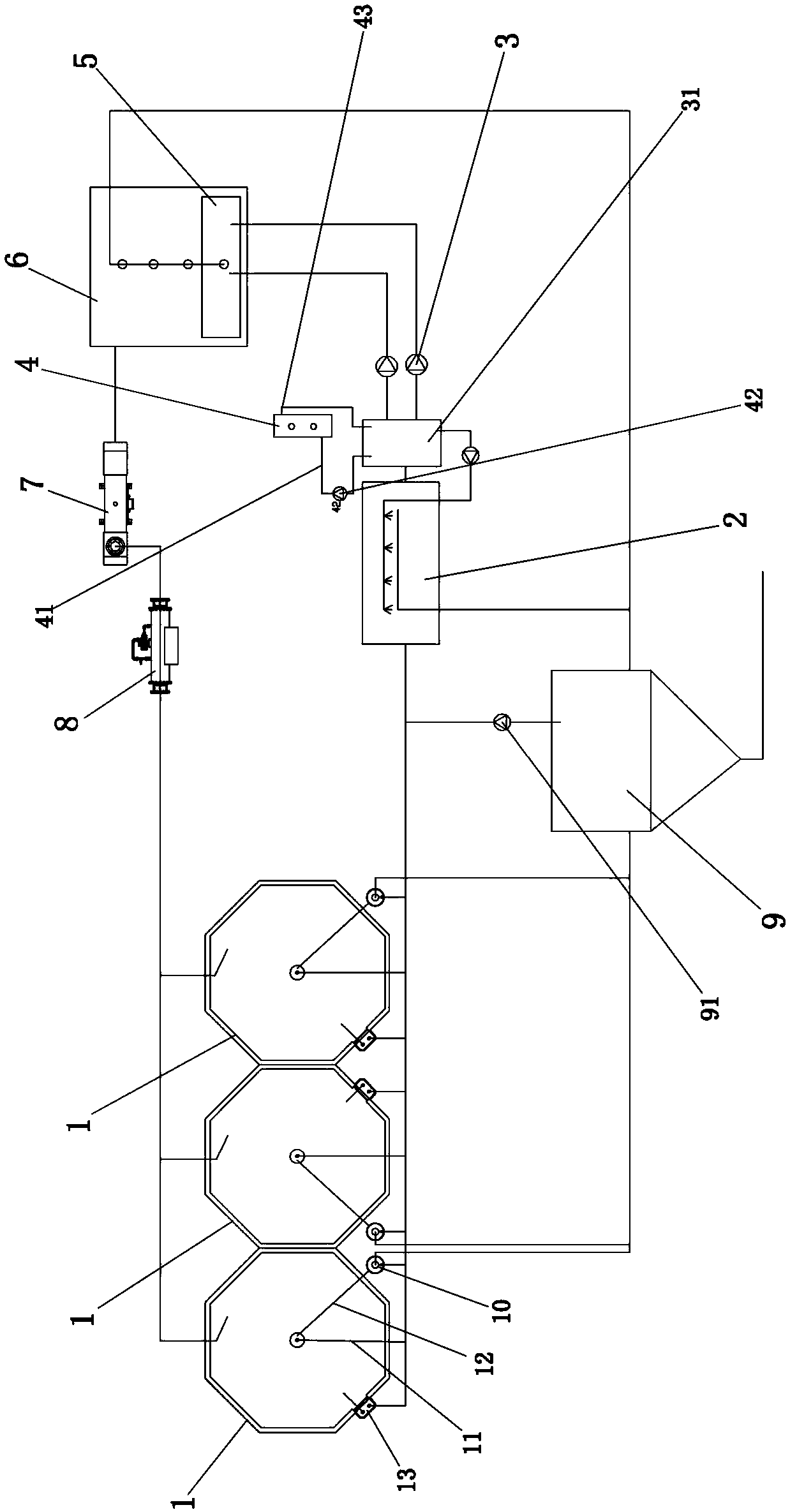

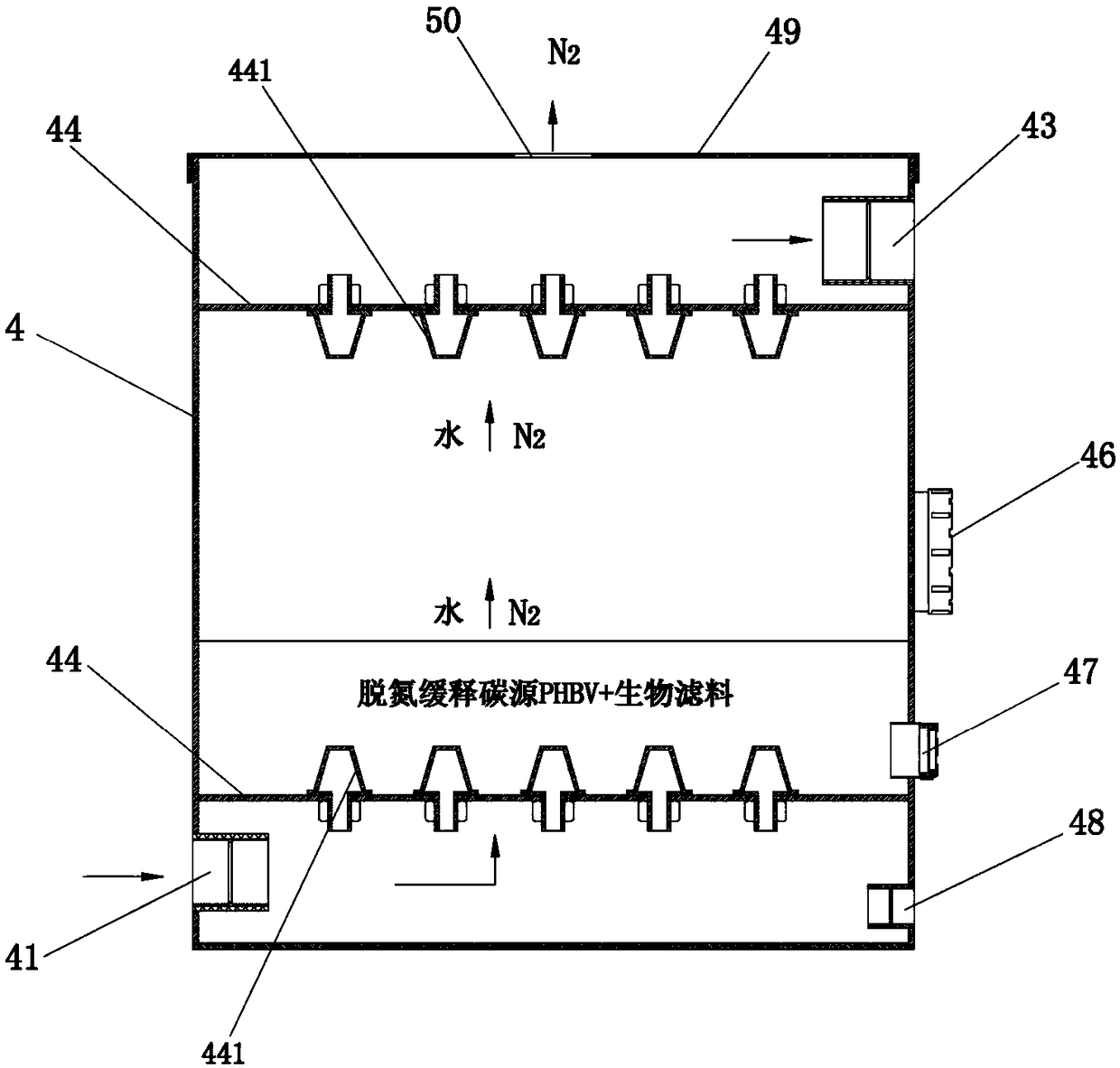

[0025] A low-carbon zero-emission industrialized recirculating aquaculture system based on anaerobic denitrification, such as figure 1 As shown, including circulating water aquaculture tank 1, microfilter 2, large flow and low lift circulating water pump 3, CO 2 Remove trickle biological filter 5, mobile biological filter bed 6, ultraviolet sterilization and disinfection machine 7, high-efficiency pure oxygen mixer 8, the CO 2 Excavate trickle biological filter 5 and be positioned at the front end of moving biological filter bed 6; The CO 2 A cotton-free biological filter ball is arranged in the trickling biological filter 5; the mobile biological filter bed 6 is filled with suspended particle biological filler; the circulating aquaculture pond 1 is a three-way sewage structure, and the bottom is provided with a double pipeline Sewage discharge, the main drainage pipeline 11 is connected with the microfiltration machine 2; the bottom sewage collection pipeline 12 first flows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com