Method for observing morphology of ultrafine powder sample by using scanning electron microscope

An electron microscope, ultra-fine powder technology, applied in the direction of analyzing materials, instruments, etc., to achieve good dispersion, good effect, and good detection selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

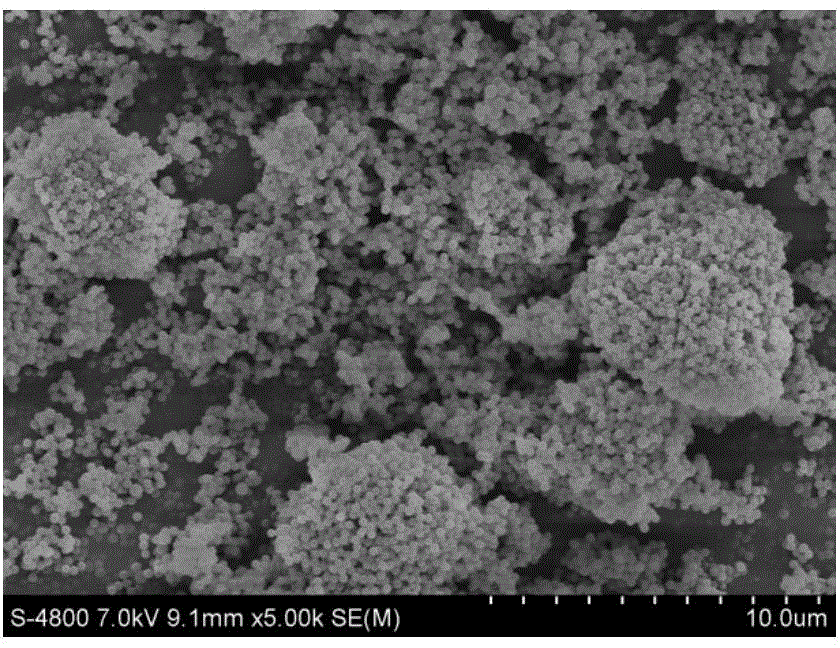

[0029] The specific steps of the analysis method of the superfine powder sample PVDF morphology observation that the present embodiment provides are as follows:

[0030] 1) Evenly spread the superfine powder sample PVDF20mg~40mg on the weighing paper;

[0031] 2) After rubbing two pieces of plastic film (area 10cm×10cm, thickness 50-80μm) to generate static electricity, place the charged side of one of the plastic films horizontally above the powder, about 2cm away from the PVDF powder, and use electrostatic force to absorb a part powder on plastic film; on film;

[0032] 3) Cut a piece of double-sided conductive tape, and use one side of the tape to glue the electrostatically adsorbed powder on the film;

[0033] 4) Use compressed air to fully purge the PVDF powder bonded to the double-sided conductive tape, so that only a small amount of powder with strong adhesion to the conductive tape remains;

[0034] 5) Peel off the protective layer on the other side of the double-sid...

Embodiment 2

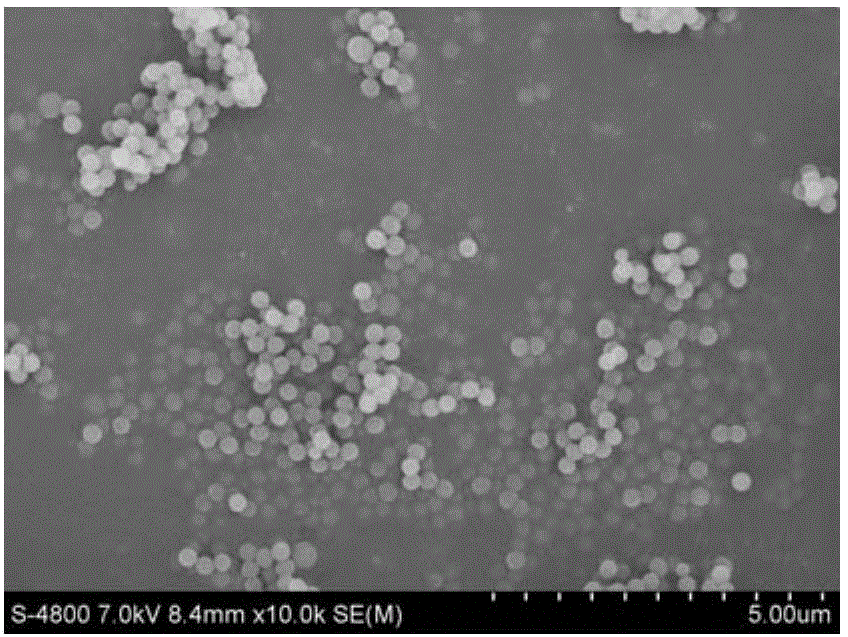

[0038] The specific steps of the analysis method for the observation of the nanoscale synthetic silica morphology of the ultrafine powder sample provided in this example are as follows:

[0039] 1) Evenly spread 20mg-40mg of superfine powder sample silicon dioxide on the weighing paper;

[0040] 2) After rubbing two pieces of plastic film (10cmX10cm) to generate static electricity, place the charged side of one of the plastic films horizontally above the powder, about 2cm away from the silica powder, and use electrostatic force to absorb a part of the powder on the film;

[0041] 3) Cut a piece of double-sided conductive tape, and use one side of the tape to glue the electrostatically adsorbed powder on the film;

[0042] 4) Use compressed air to fully purge the silica powder bonded to the double-sided conductive tape, so that only a small amount of powder with strong adhesion to the conductive tape remains;

[0043] 5) Peel off the protective layer on the other side of the d...

Embodiment 3

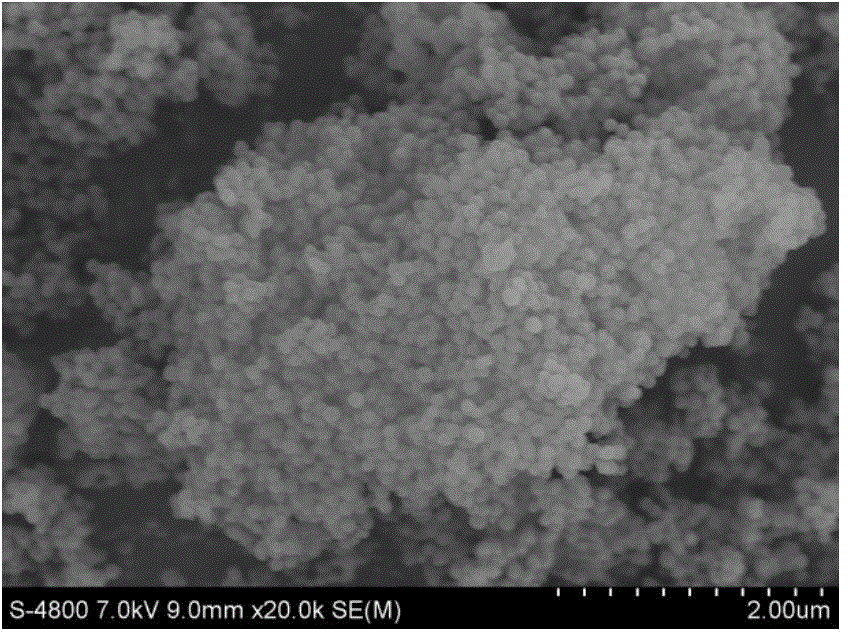

[0047] The specific steps of the analysis method for the observation of the carbon nanotube powder morphology provided by the present embodiment are as follows:

[0048] 1) Evenly spread 20mg to 40mg of carbon nanotube powder on the weighing paper;

[0049] 2) After rubbing two pieces of plastic film (10cmX10cm) to generate static electricity, place the charged side of one of the plastic films horizontally above the powder, about 2cm away from the silica powder, and use electrostatic force to absorb a part of the powder on the film;

[0050] 3) Cut a piece of double-sided conductive tape, and use one side of the tape to glue the electrostatically adsorbed powder on the film;

[0051] 4) Use compressed air to fully purge the silica powder bonded to the double-sided conductive tape, so that only a small amount of powder with strong adhesion to the conductive tape remains;

[0052] 5) Peel off the protective layer on the other side of the double-sided conductive tape, and stick ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com