Energy-saving stove preheating premixed combustible gas by using after heat

A gas preheating, energy-saving stove technology, applied in heating fuel, household heating, household stove/stove, etc., can solve the problem of no stove integrated, delay waste heat discharge, increase waste heat utilization efficiency, and increase heat exchange. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

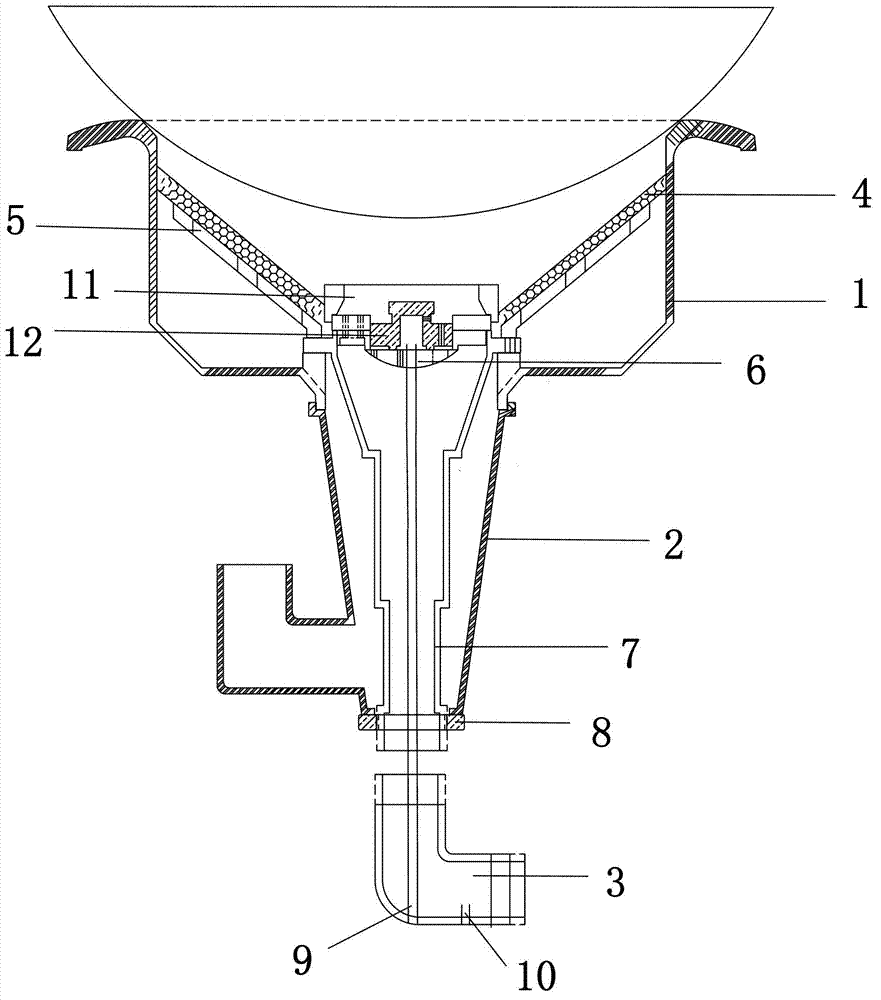

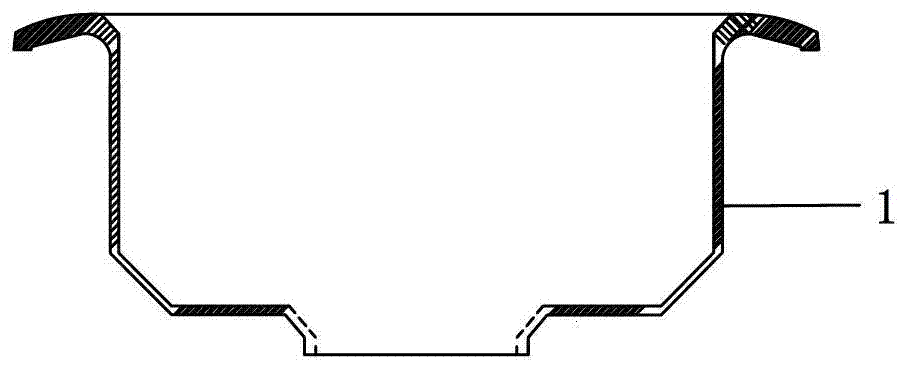

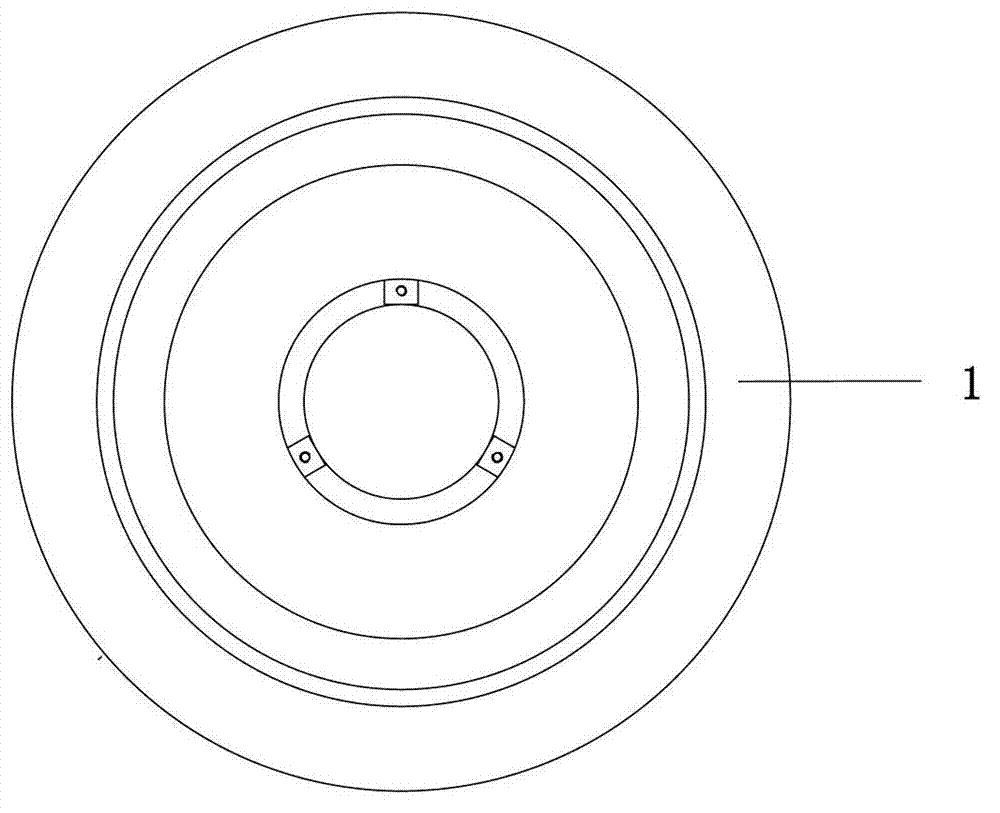

[0041] refer to figure 1 , 2 , 3, 4, 5, 6, 11, 12, 13, and 14, the present invention uses waste heat to preheat the energy-saving stove for premixed gas, including a stove pan 1, a flue gas guide hood 2, and an air duct bend Head 3, honeycomb porous ceramics 4, energy-gathering plate frame 5, burner 6 and mixing chamber 7, hob 1 is a hollow cylindrical pan with a hole in the middle, and the edge of hob 1 has a flange in contact with the pot. There are three bends in 1. The bottom of the furnace plate 1 communicates with the flue gas duct 2. The structure of the flue gas duct 2 is a circular table structure with a large upper part and a smaller bottom. The outer side of the lower part of the flue gas duct 2 There is an exhaust pipe, and the outlet of the exhaust pipe is connected to the tail of the cooker. The smoke guide cover 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com