Precise temperature control reaction kettle based on phase change material

A technology of phase change materials and precise temperature control, which is applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

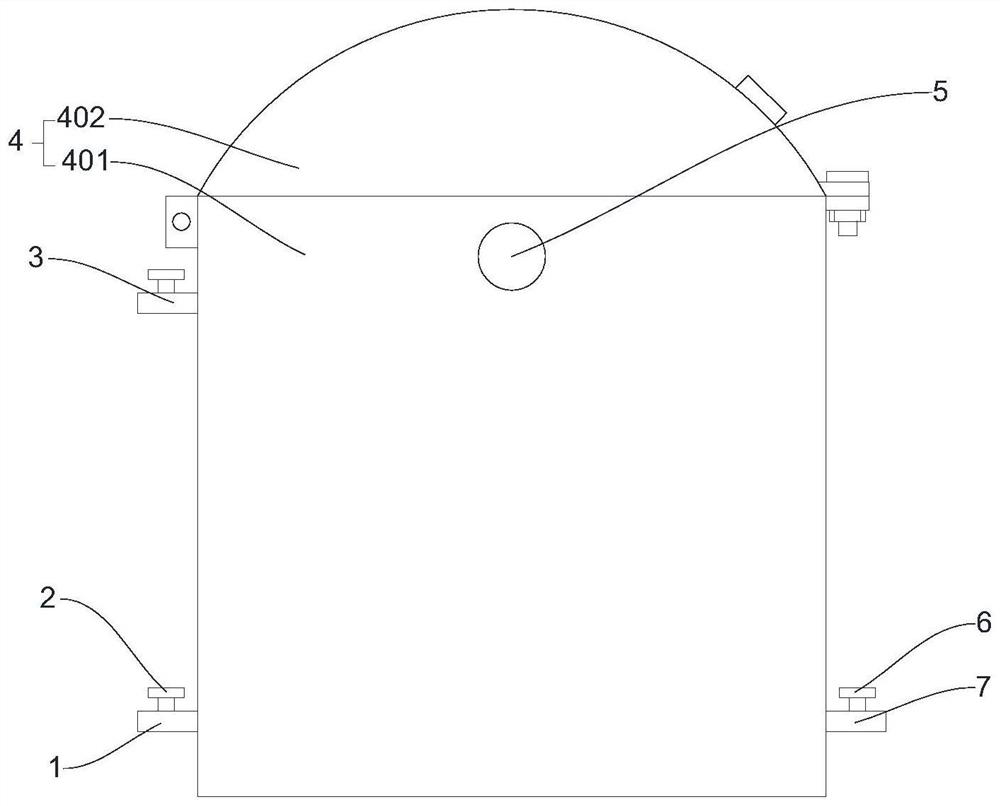

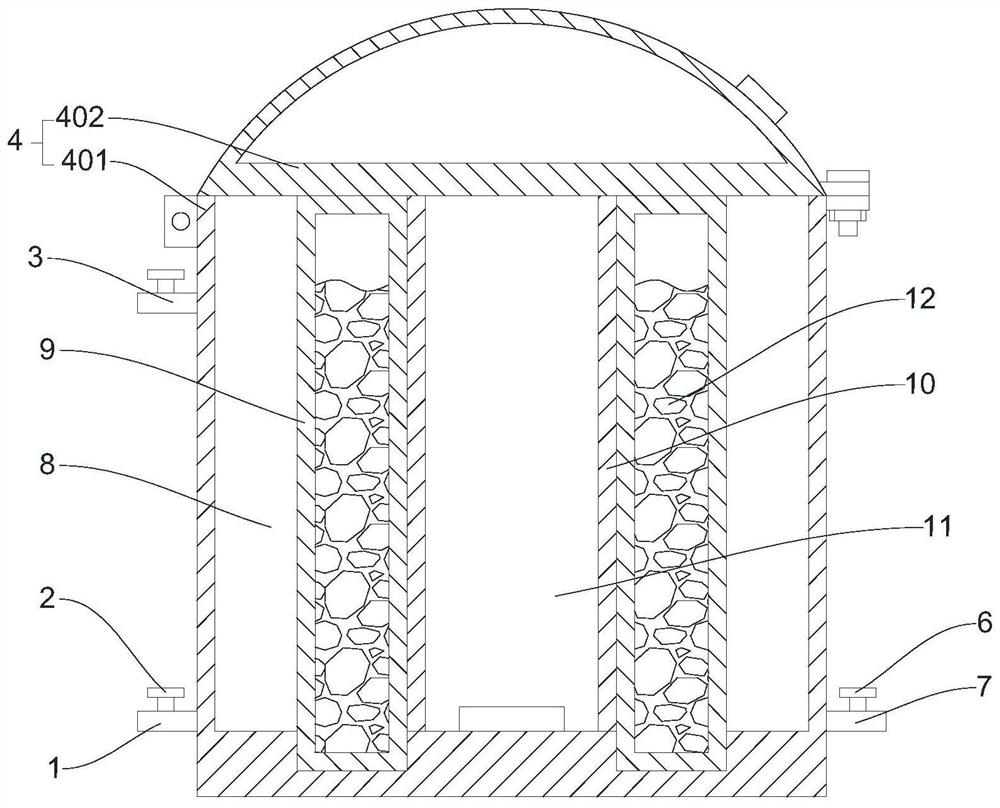

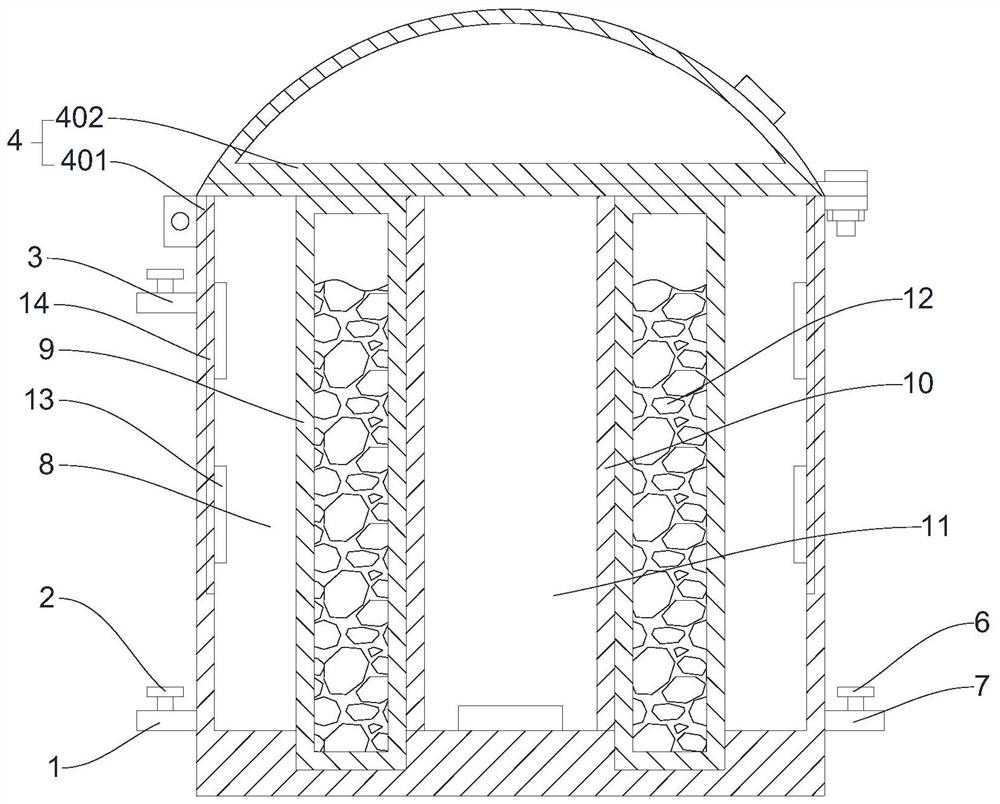

[0035] Please refer to figure 1 , figure 2 The present embodiment provides a reaction kettle based on phase change material 12 for precise temperature control, including a reaction kettle body 4, a reaction chamber 11 is arranged in the reaction kettle body 4, and a heat transfer adjustment device for heat transfer with the reaction chamber 11 is provided. Greenhouse 8, the above-mentioned reaction kettle body 4 is provided with an internal hollow temperature control member 9, the hollow cavity of the above-mentioned temperature control member 9 is filled with a phase change material 12, and the above-mentioned temperature control member 9 is arranged in the above-mentioned reaction chamber 11 and the above-mentioned temperature-regulating chamber 8 Between, the above-mentioned temperature control member 9 is used for the temperature transmission between the above-mentioned reaction chamber 11 and the above-mentioned regulating chamber 8 .

[0036] It is worth noting that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com