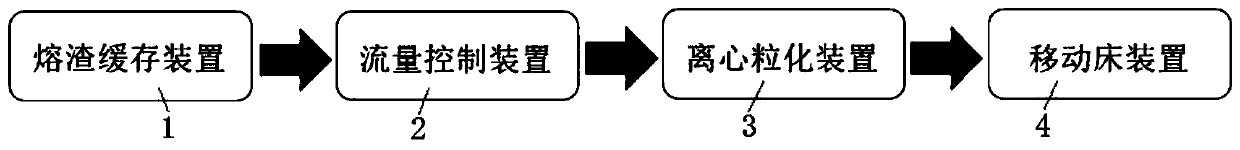

Liquid-state molten slag waste heat recycling system

A technology of waste heat recovery system and liquid slag, which is applied in the direction of recycling technology, can solve the problems of lack of recovery technology, etc., and achieve the effect of improving sufficient heat exchange, ensuring stable operation, and improving the smooth discharge of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

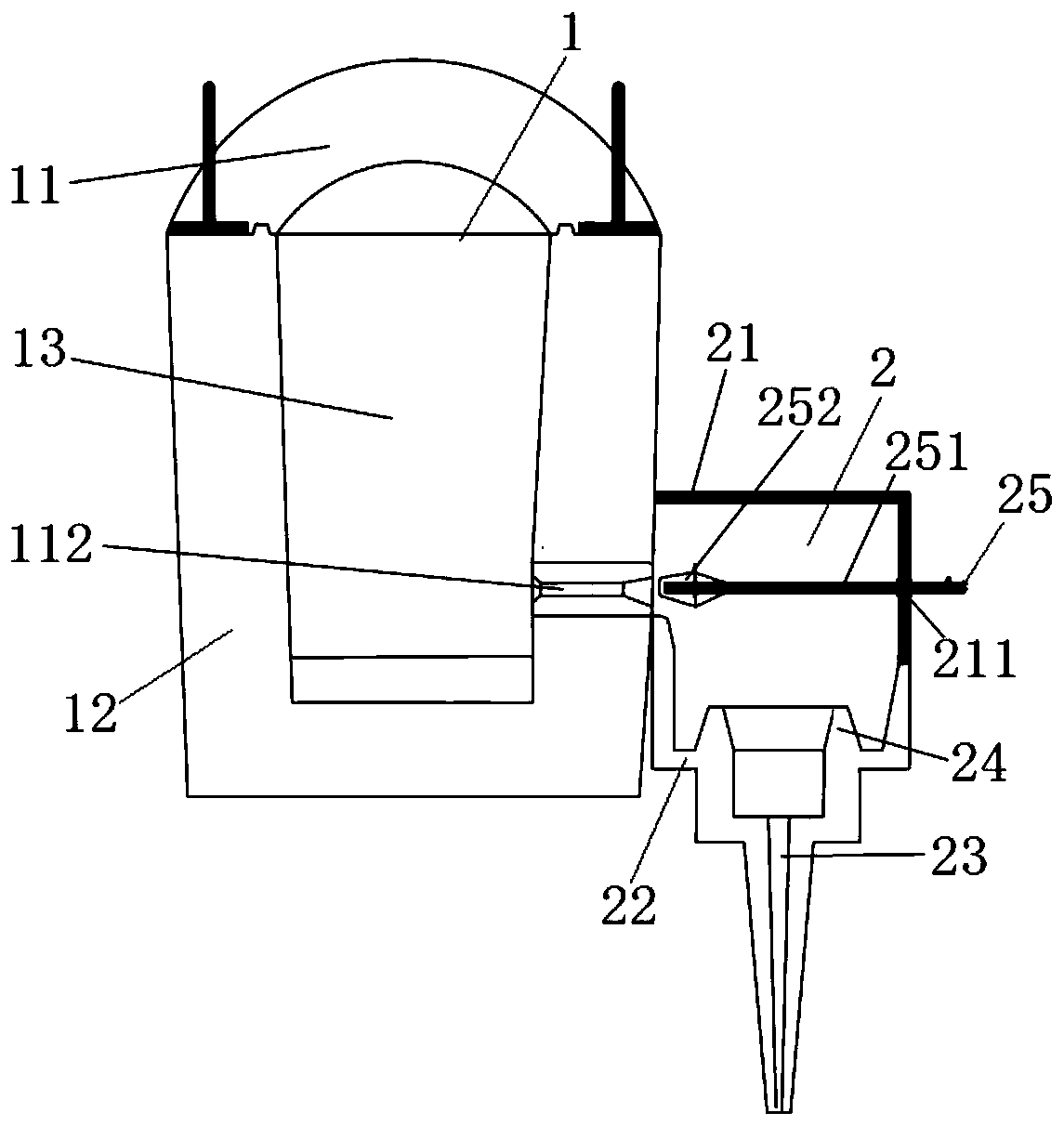

Method used

Image

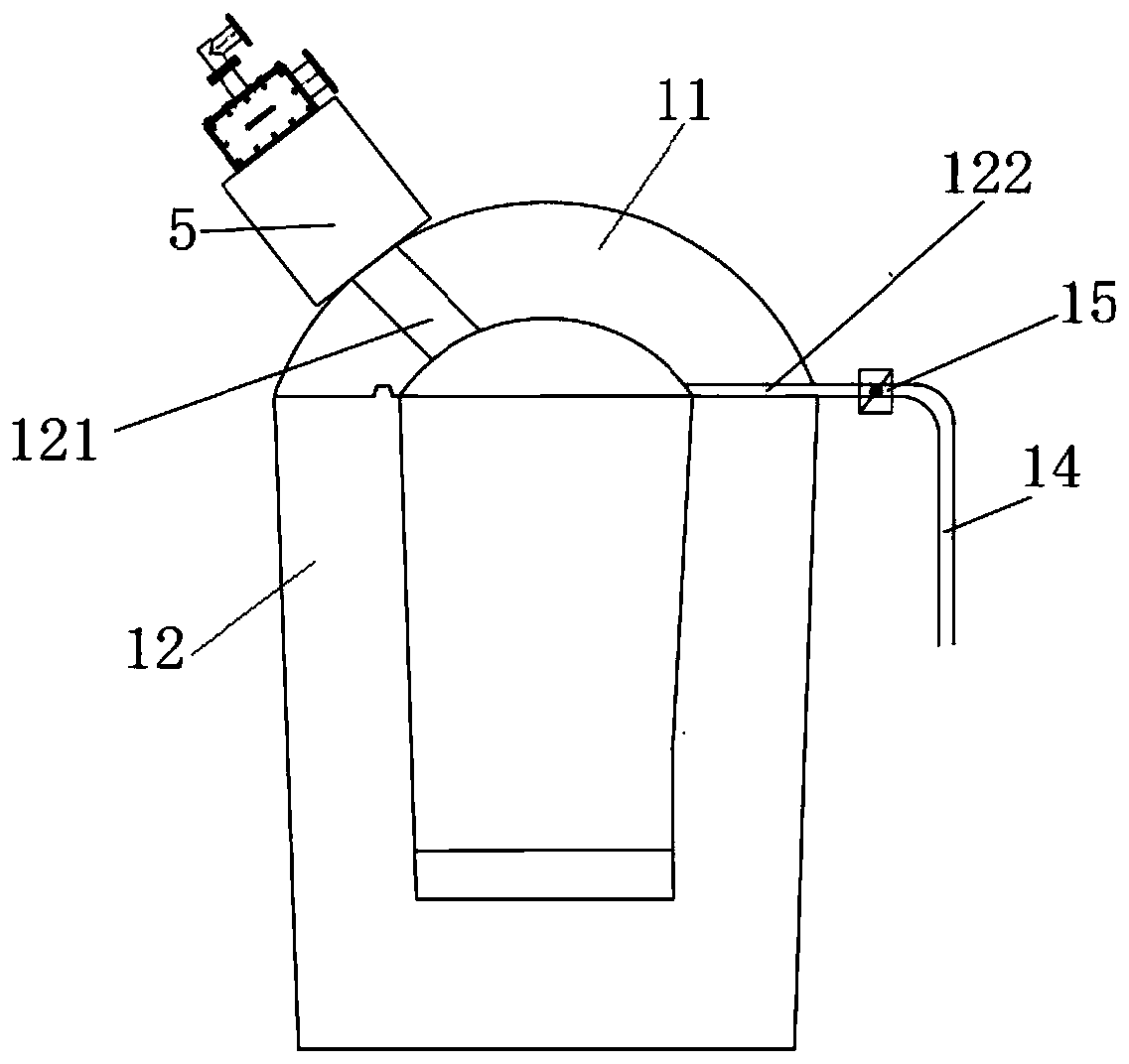

Examples

Embodiment approach

[0066] a) Open the flue gas outlet gap around the top of the granulation bin, the flue gas flows into the flue gas annular header through the flue gas outlet gap around the granulation bin, and finally set up a collection flue on the flue gas annular header to draw out the flue gas .

[0067] b) Open the flue gas outlet gap around the slag discharge pipe in the center of the granulation bin, the flue gas flows into the flue gas annular header through the flue gas outlet gap in the center of the granulation bin, and finally set up a collection flue on the flue gas annular header to lead out smoke.

[0068] In the connecting section between the moving bed waste heat recovery device and the granulation rotor, a slag cotton scraper is installed. The slag cotton scraper is arranged on both sides of the granulation rotor, arranged at 180°, designed according to the sawtooth structure, and adopts 310S stainless steel for high temperature resistance material. In the early stage of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com