Patents

Literature

41results about How to "No risk of cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

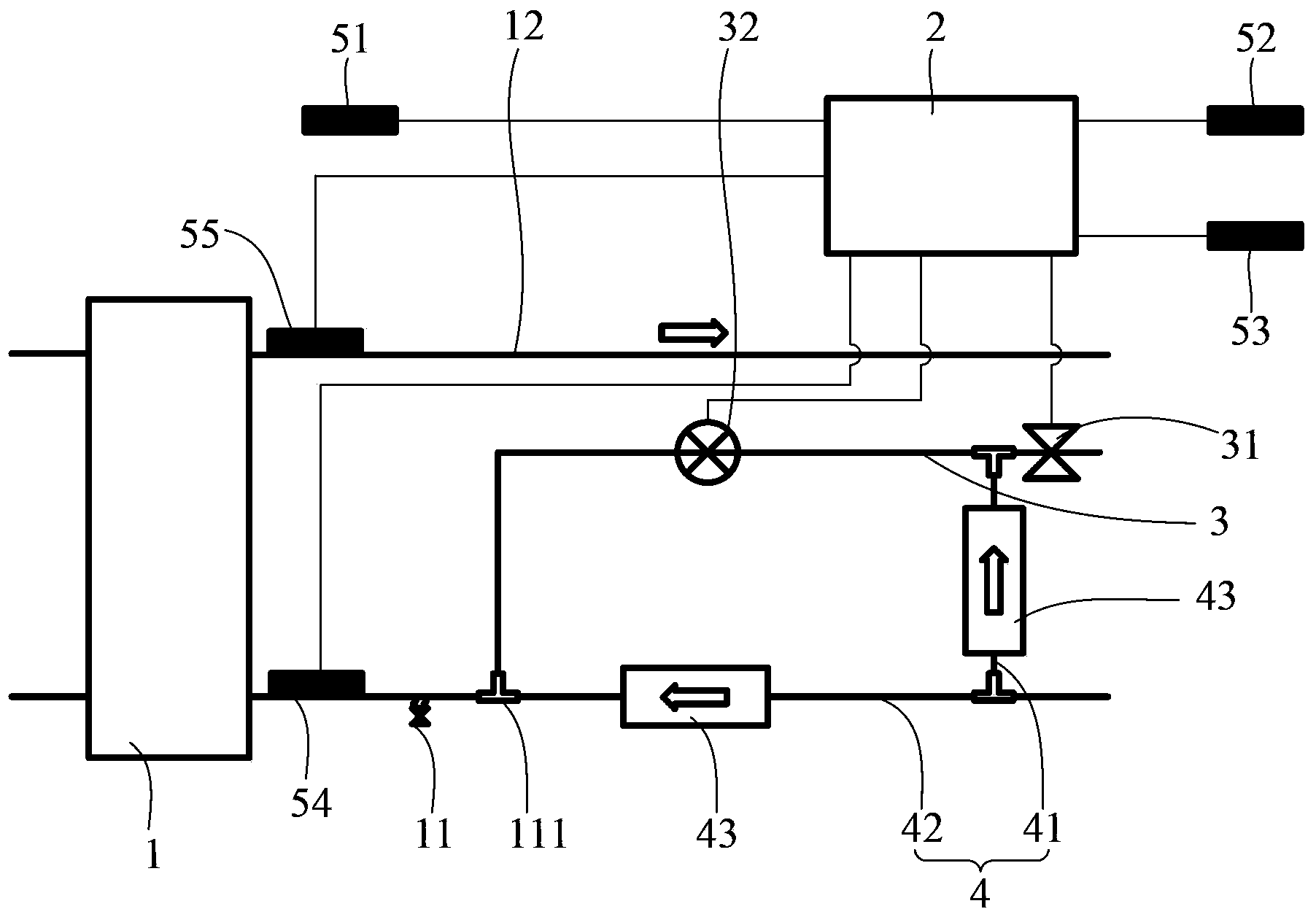

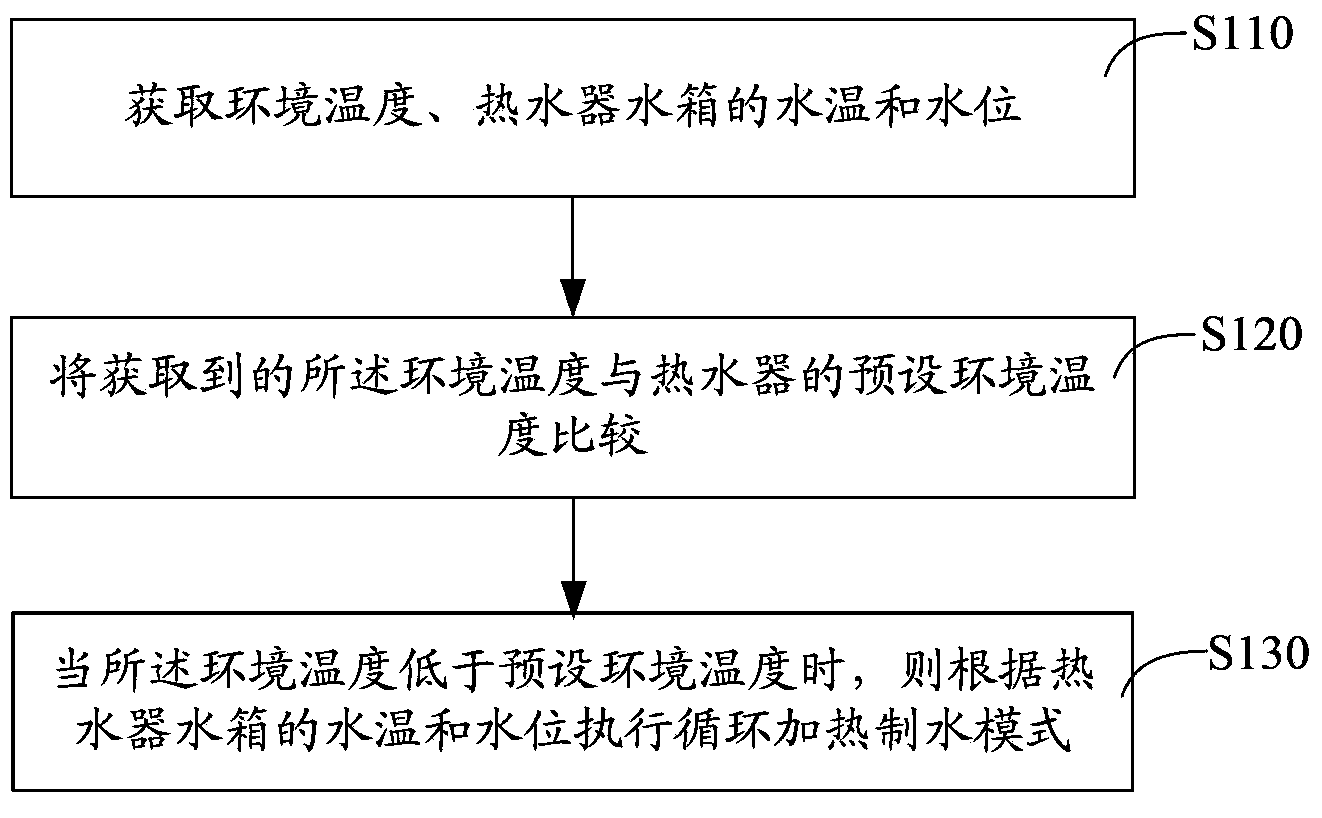

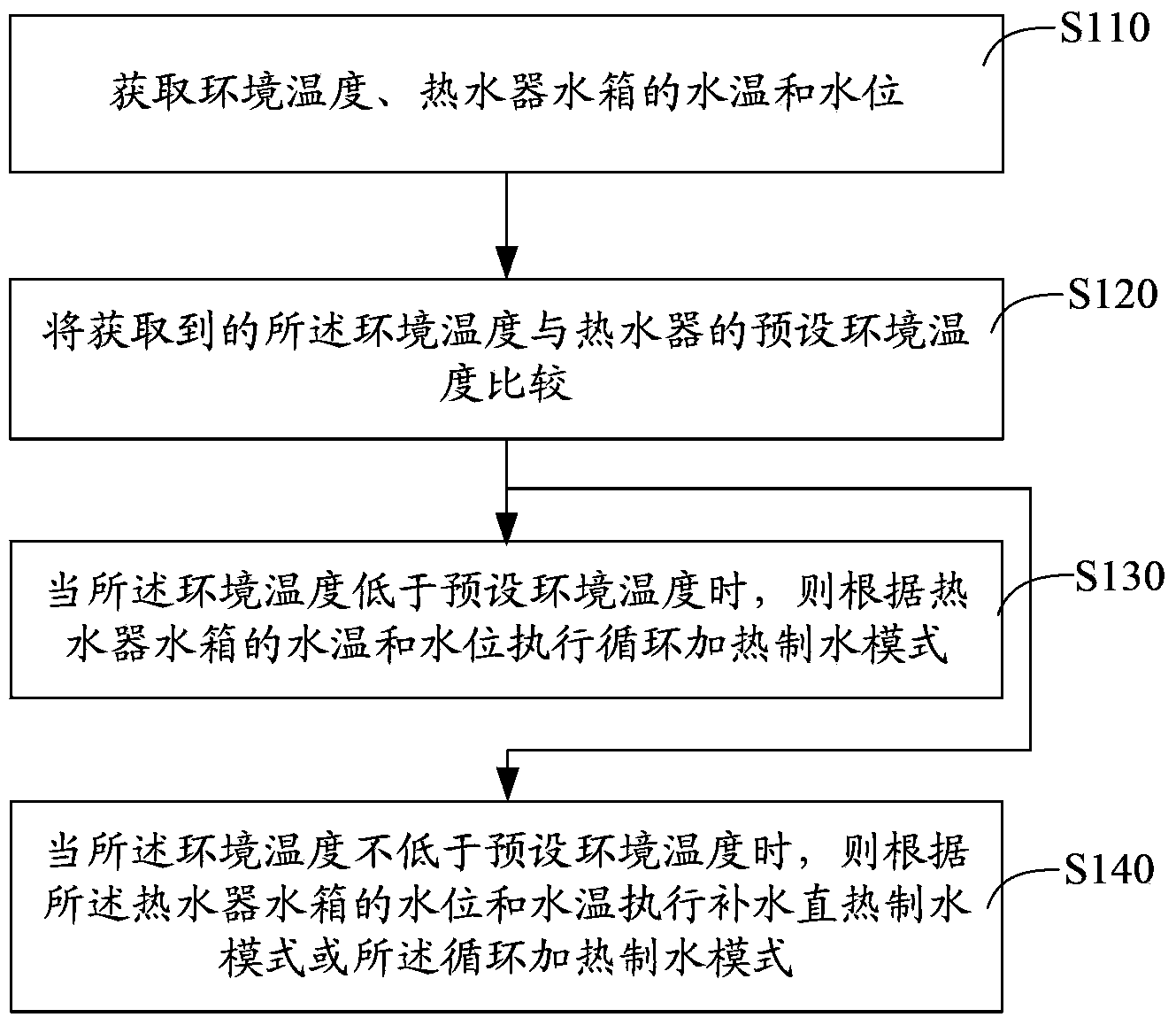

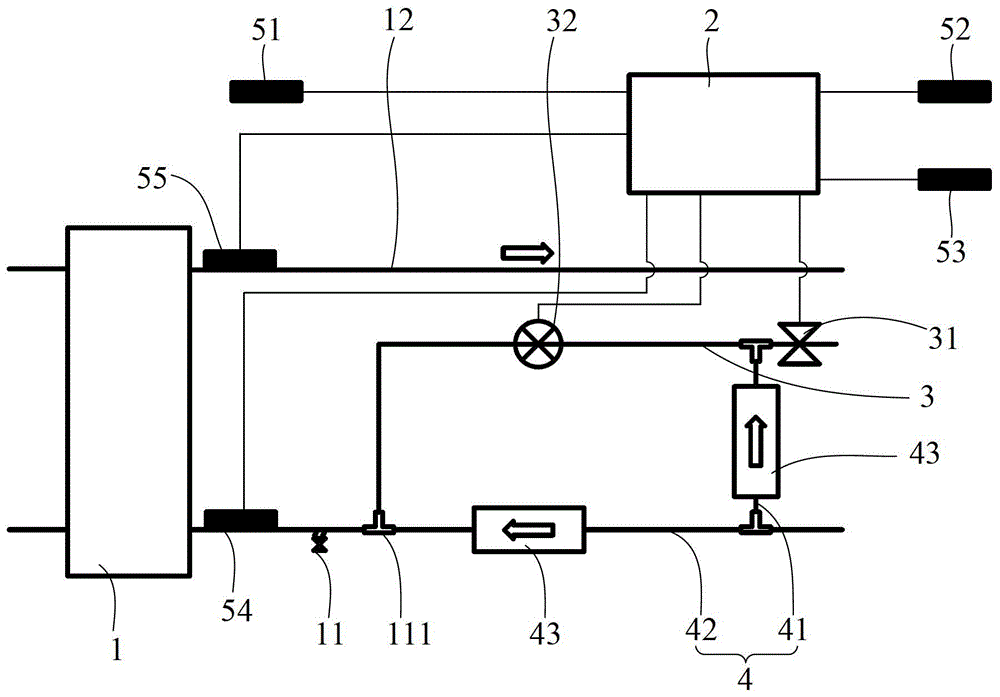

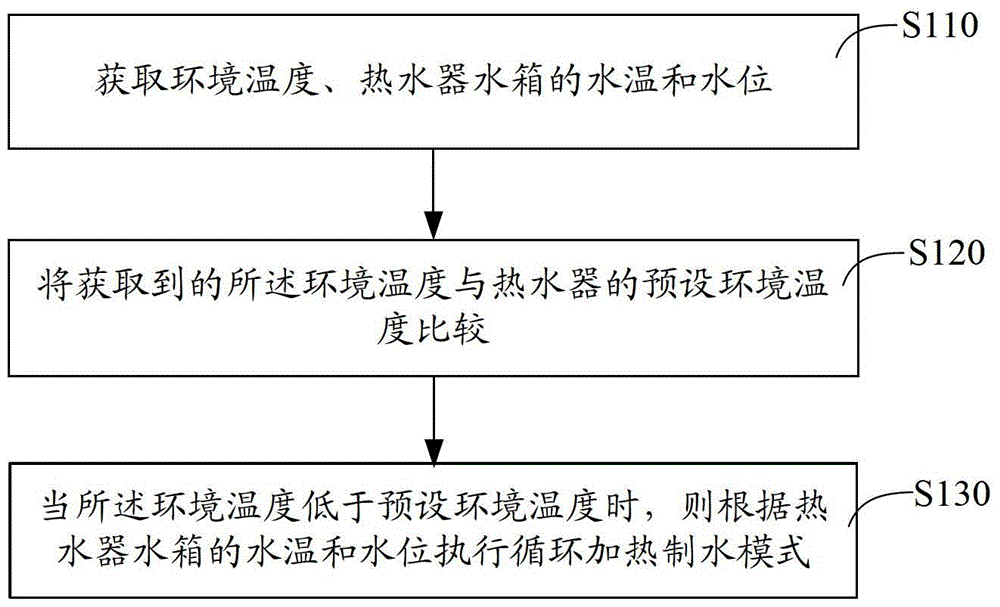

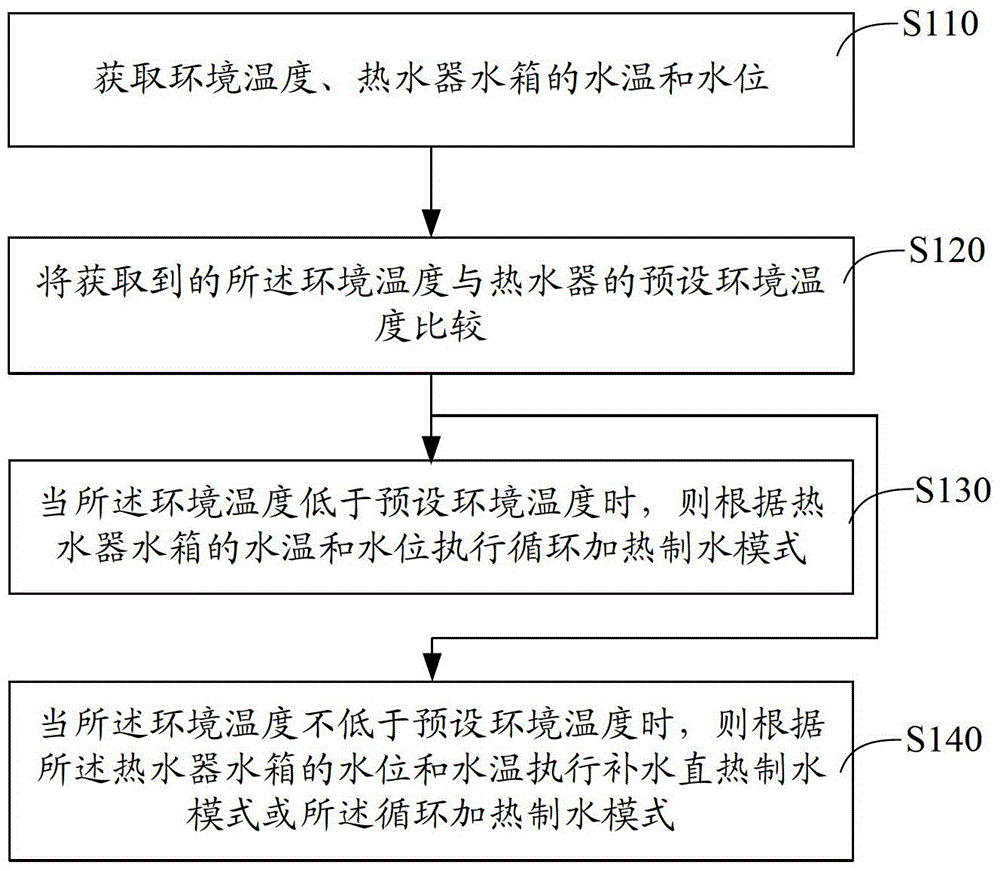

Water heater pipeline anti-freezing control method and system and water heater

Provided are a water heater pipeline anti-freezing control method and system and a water heater. The method includes acquiring environment temperature and water temperature and water level of a water tank of the water heater; comparing the environment temperature and the preset environment temperature; when the environment temperature is lower than the preset environment temperature, executing the circulation heating water producing mode where water in a water inlet pipe and a water outlet pipe of the water heater flows in a circulation mode according to the water temperature and the water level of the water tank of the water heater; when the water heater is applied under the condition that the environment temperature is lower than the preset environment temperature, entering the circulation heating water producing mode enabling the water in the water inlet pipe and the water outlet pipe of the water heater to flow in the circulation mode. Flowing water passes through both the cold water inlet pipe and the circulation water inlet pipe of the water heater, the requirement for hot water usage can be met, and the pipeline has no freezing risks.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD

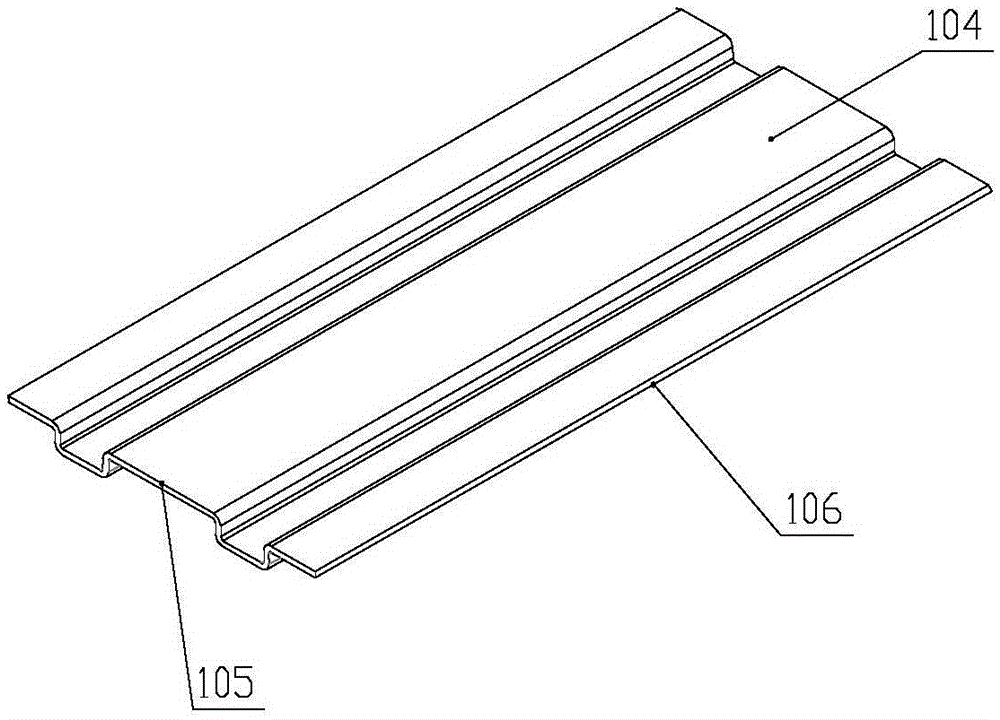

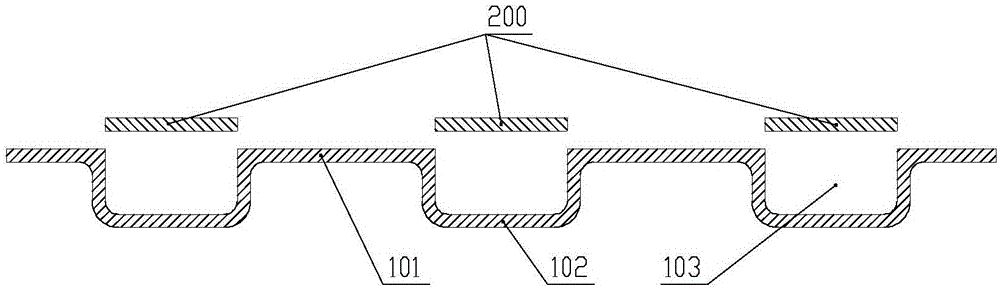

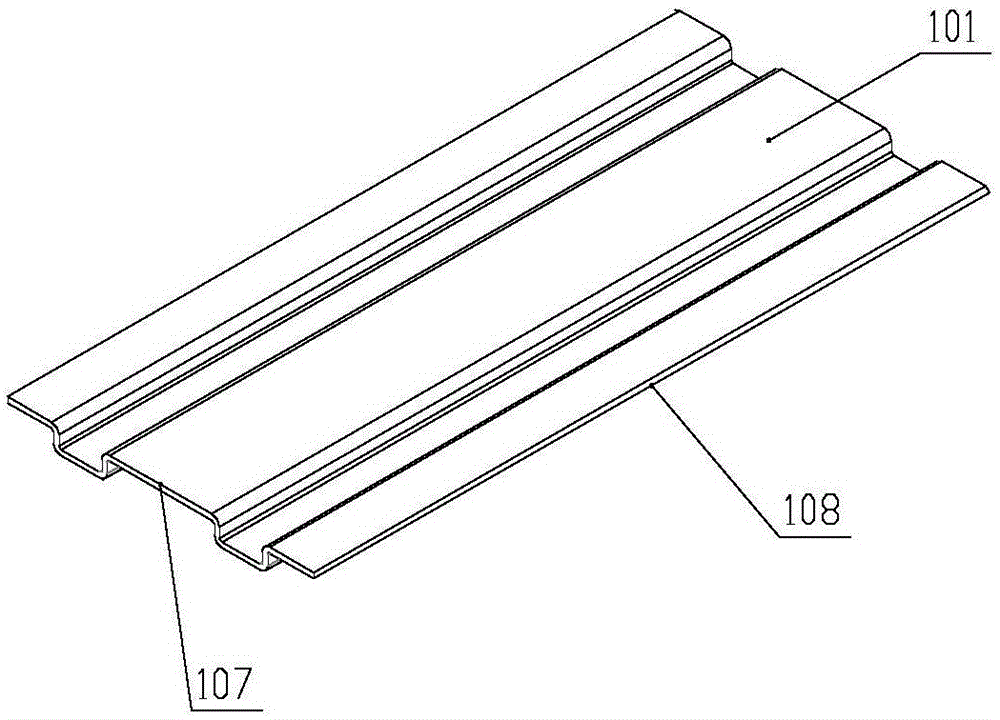

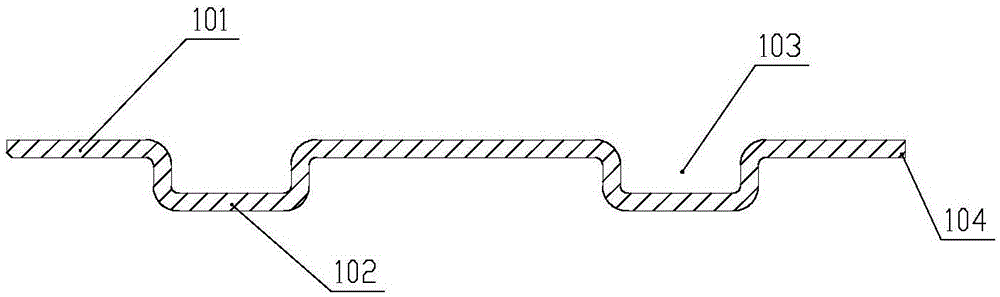

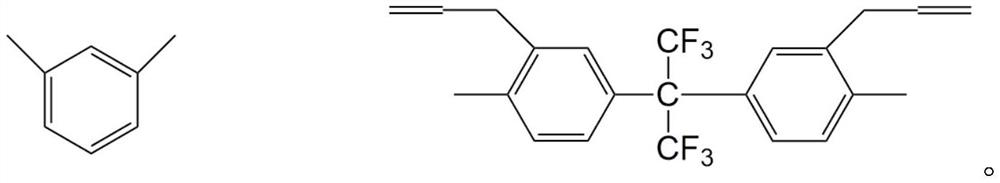

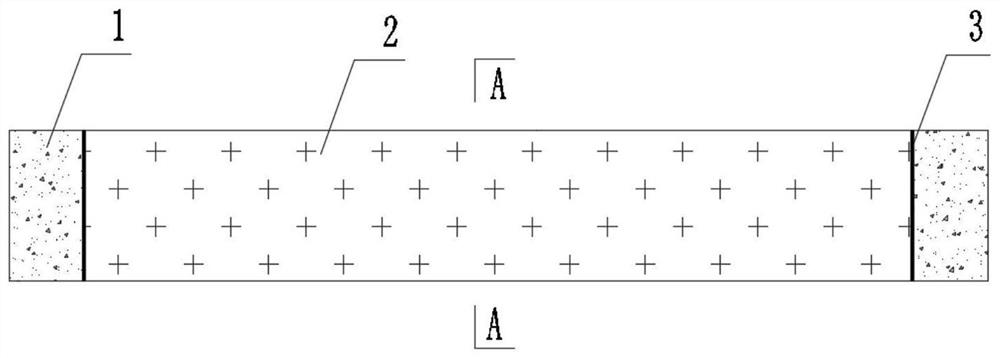

Steel-concrete combined structure pipeline with spiral reinforcing ring and manufacturing method of steel-concrete combined structure pipeline

InactiveCN105114715AHigh compressive strengthAvoid crackingRigid pipesEngineeringCompressive strength

The invention discloses a steel-concrete combined structure pipeline with a spiral reinforcing ring and a manufacturing method of the steel-concrete combined structure pipeline. The steel-concrete combined structure pipeline comprises a pipe body. The surface of the pipe body extends outwards to form a protruding rib spirally arranged on the outer wall of the pipe body. A groove is formed by the protruding rib and the pipe body and provided with a blocking steel belt for blocking a groove opening of the groove. The hollow reinforcing ring is formed between the protruding rib and the blocking steel belt and filled with concrete. The steel-concrete combined structure pipeline has the advantages that by additionally arranging the spiral reinforcing ring integrally formed together with the pipe body, the annular strength of the pipeline is enhanced; by filling the reinforcing ring with concrete, the pressure resistant strength of the pipe body is further improved; by means of the pipeline, the purpose of using large-size steel structure products in underground common pipeline projects, underground comprehensive pipe galleries and underground traffic roads and metros is achieved; meanwhile, the method is easy to operate, easy and convenient to construct and capable of shortening construction period and reducing cost.

Owner:NANJING LIANZHONG CONSTR ENG TECH

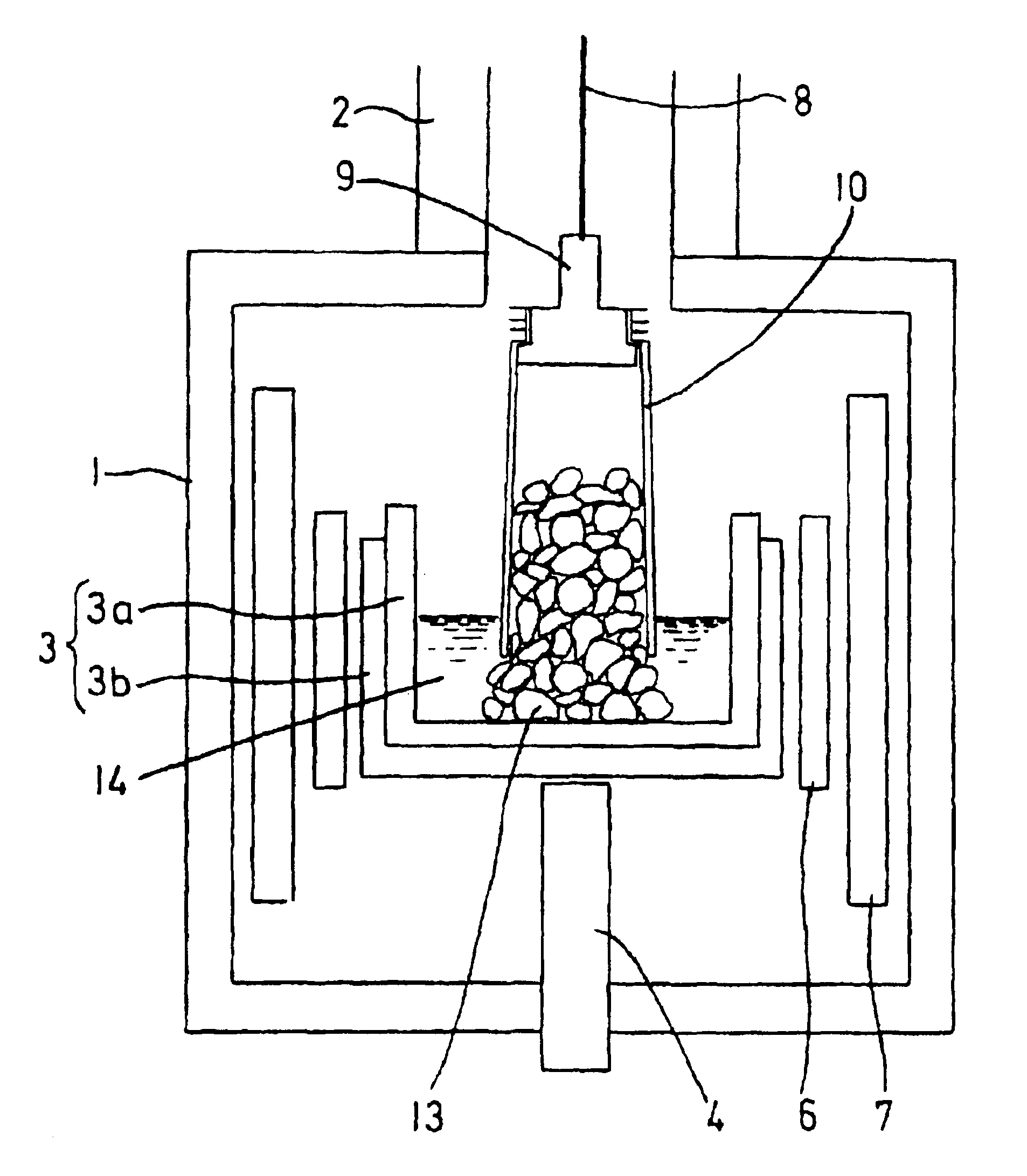

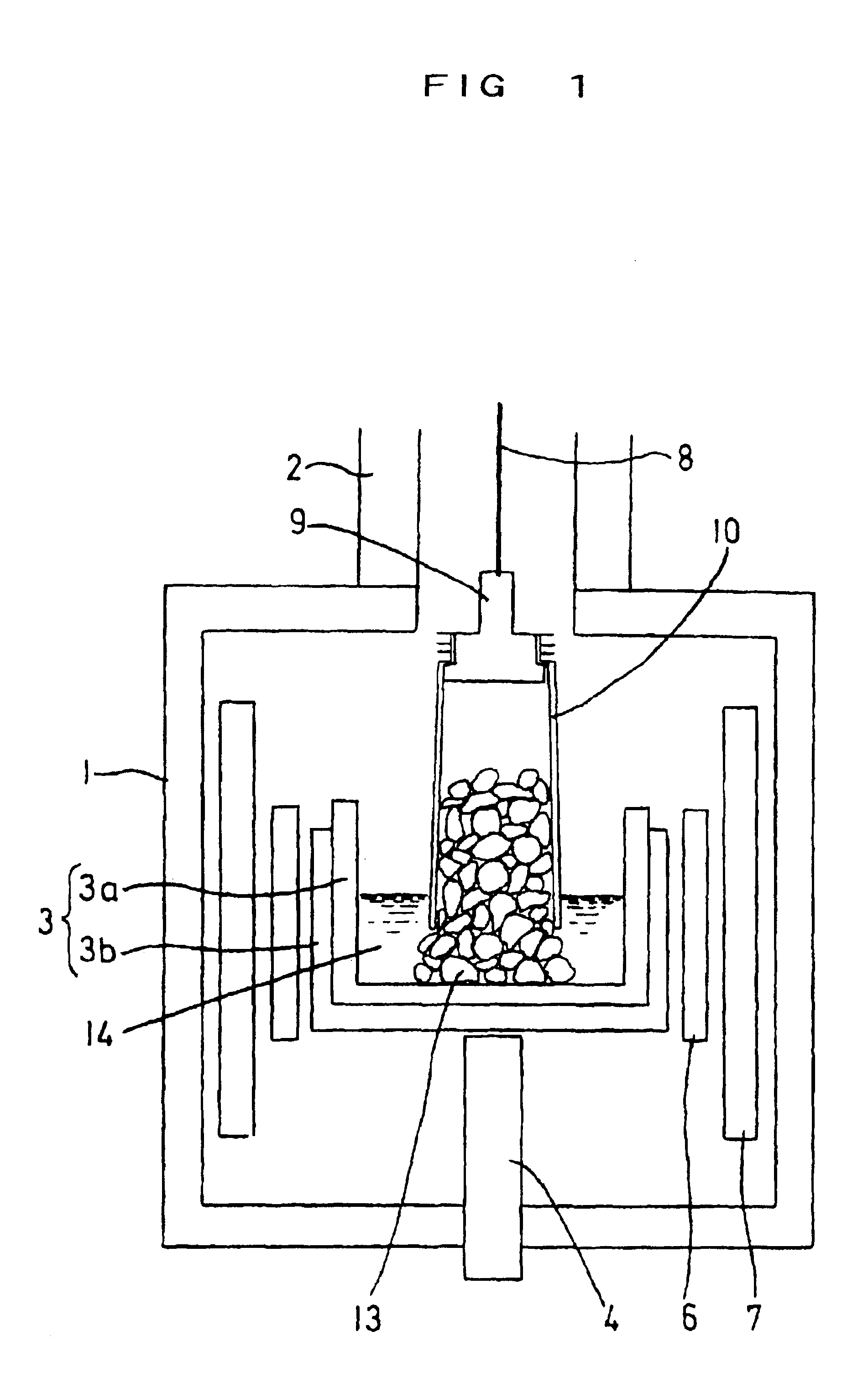

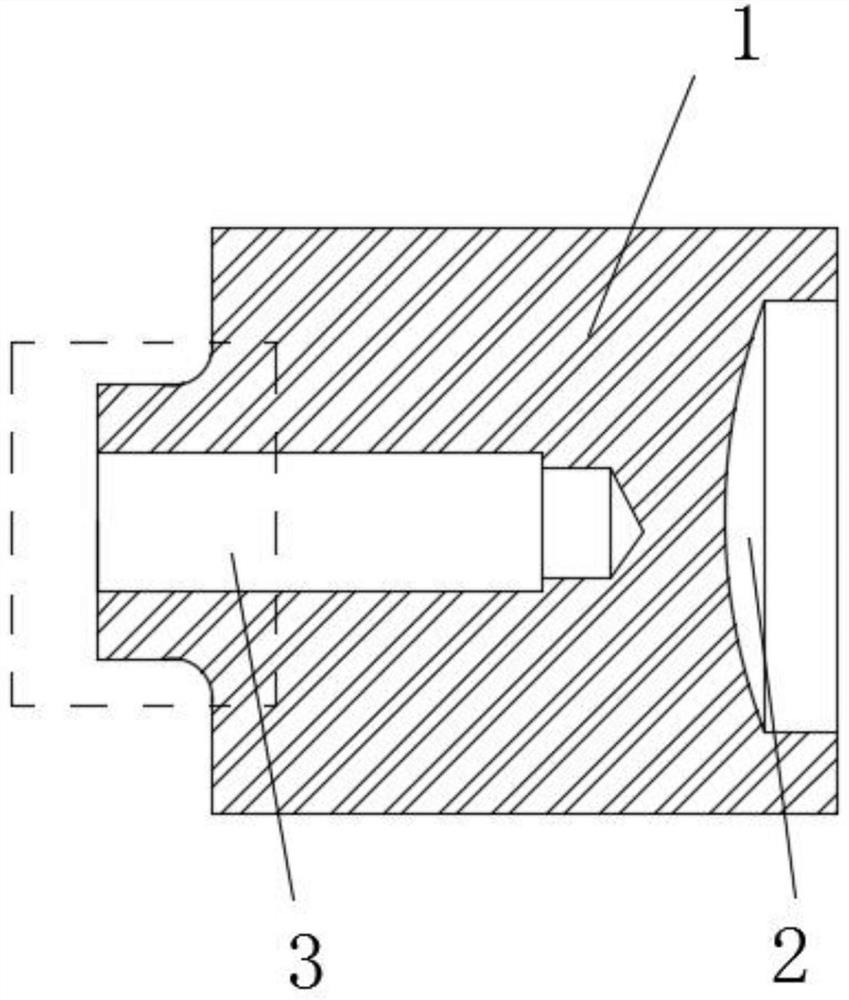

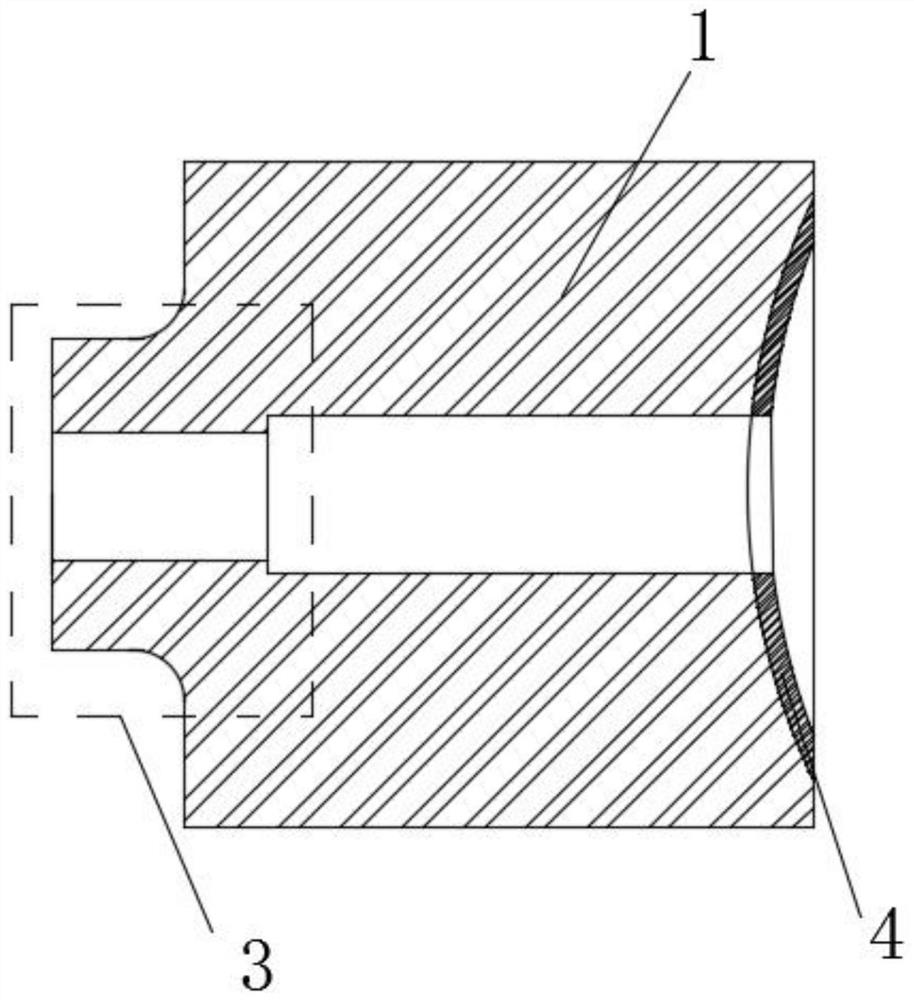

CZ raw material supply method

ActiveUS6908509B2Low raw material costNo risk of crackingPolycrystalline material growthBy pulling from meltCrucibleMaterials science

Additional charge of a solid raw material 13 in the shapes of granules / lumps, low in raw material cost, and with no risk of cracking, is performed into a molten raw material 14 in a crucible in a static manner without solidifying a surface of the molten raw material 14 in the crucible 3. A bottom of a cylindrical raw material vessel 10 made of a material non-meltable when being in contact with the molten raw material 14 in the crucible 3 is closed with a bottom cover 11 made of a material meltable and removable when being in contact with the molten raw material 14 in the crucible 3. The raw material vessel 10 in a state of being filled with the solid raw material 13 in the shapes of granules / lumps is hung down above the crucible 3 to immerse the lower portion thereof into the molten raw material 14 in the crucible 3. The bottom cover 11 is molten and removed by putting the bottom cover 11 into contact with the molten raw material 14 in the crucible 3 to thereby charge the solid raw material 13 in the raw material vessel 10 into the molten raw material 14 in the crucible 3.

Owner:SUMITOMO MITSUBISHI SILICON CORP

Building decoration paster and manufacturing method thereof

InactiveCN105019624AOn-site construction is simpleLittle impact from weatherCovering/liningsSynthetic resin layered productsMaterials sciencePrefabrication

The invention provides a building decoration paster and a manufacturing method thereof. The building decoration paster comprises a reinforced mesh layer, a waterproof layer is arranged on the reinforced mesh layer, a moulding coating layer is arranged on the waterproof layer, and a top facing layer is arranged on the moulding coating layer. The invention further comprises the manufacturing method of the building decoration paster. The building decoration paster can be obtained through industrialized prefabrication production, moulding is conducted through moulds, and the expressive force of moulding and color matching is strong; the building decoration paster is used for replacing painting of building coating on the wall surface on site, on-site construction is easy, and influence of weather is small; influence of on-site construction conditions does not exist, when the construction is conducted, protection is not needed, and adjacent parts which do not need to be painted are not polluted; due to the fact that a workshop is formed through maintenance, noxious odour is not emitted on site, and the workshop can be put in use immediately.

Owner:CHANGSHA YIJING BUILDING MATERIALS TECH CO LTD

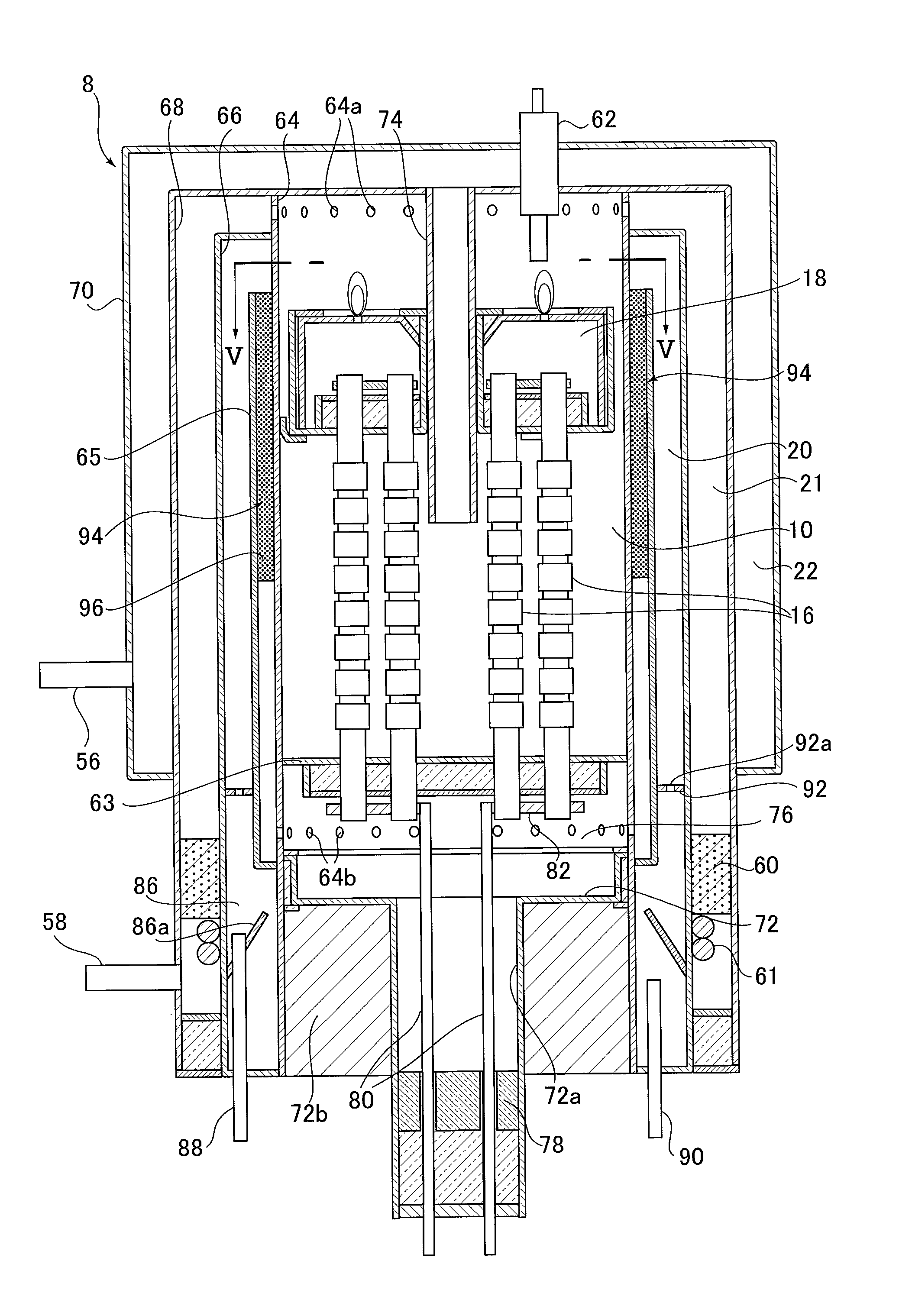

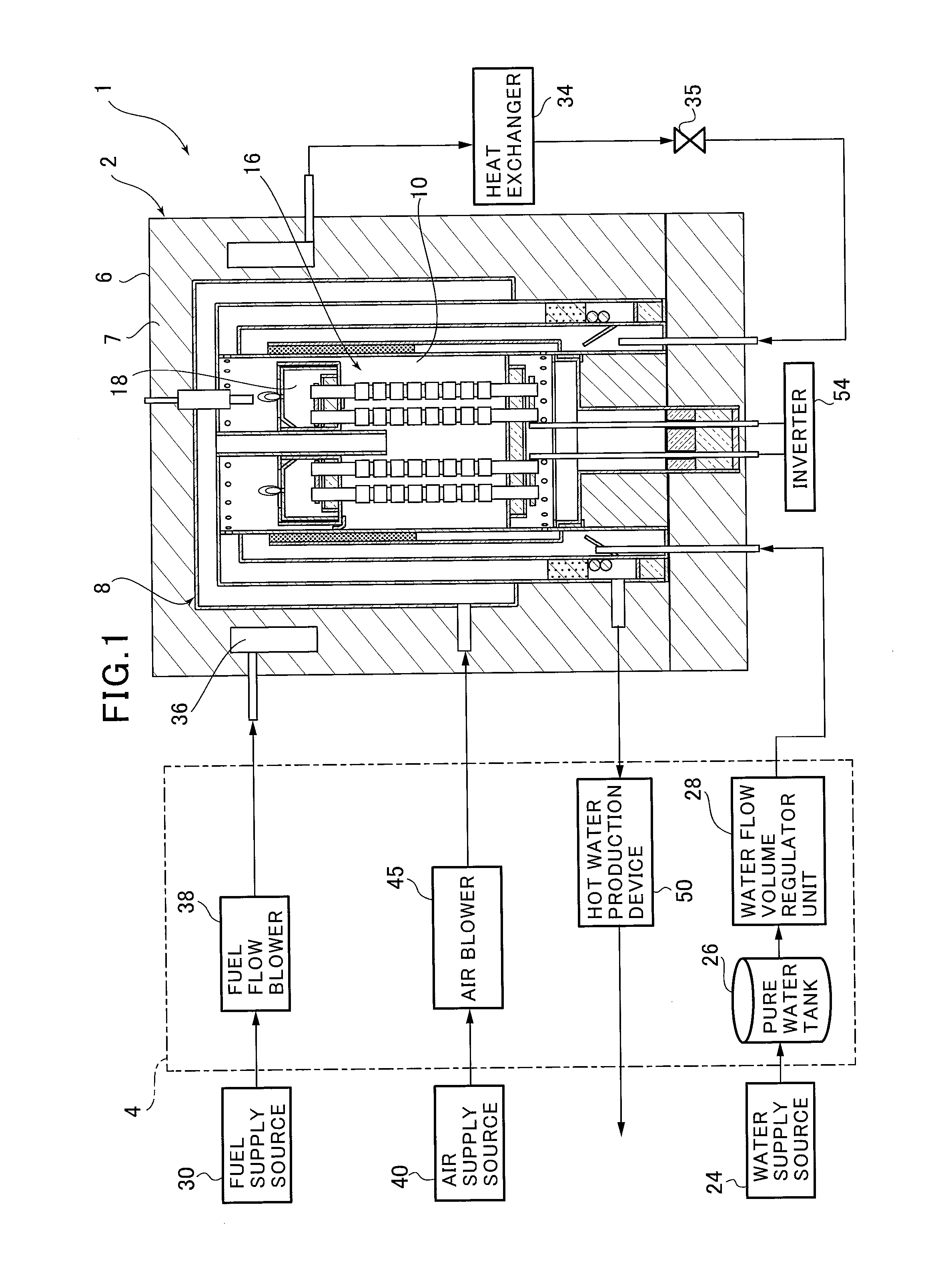

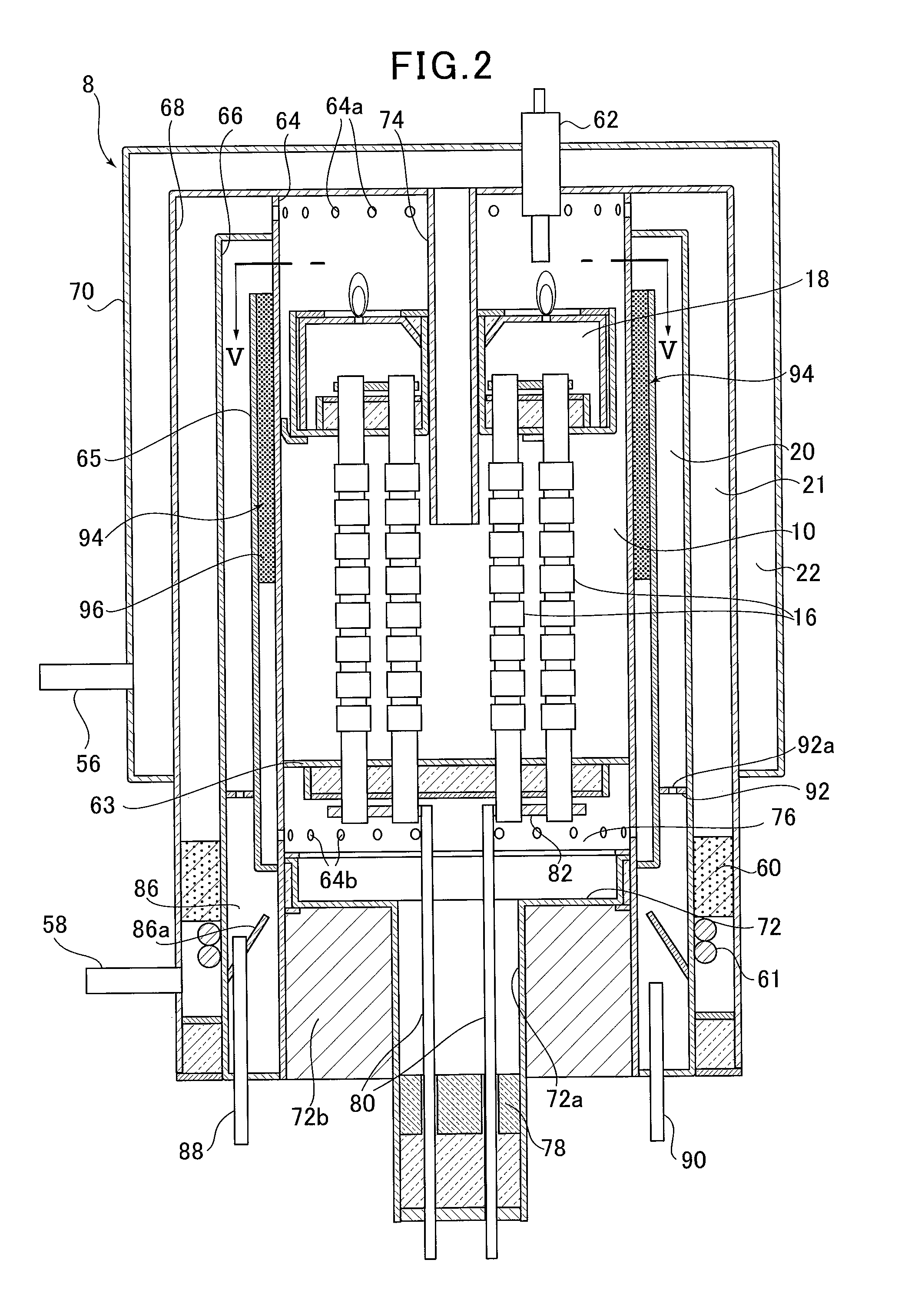

Solid oxide fuel cell and manufacturing method and manufacturing apparatus for same

InactiveUS20150004518A1Shorten production timeSmall volumeLiquid surface applicatorsFuel cells groupingFuel cellsAdhesive

The present invention is a method for manufacturing a solid oxide fuel cell apparatus for generating electricity by supplying fuel and oxidant gas to fuel cells housed in a fuel cell module, comprising: an adhesive application step for applying ceramic adhesive to the joint portions of constituent members so that the flow path carrying fuel or oxidant gas inside the fuel cell module are formed in an airtight manner; a workable hardening step for hardening the applied ceramic adhesive to a state capable of implementing the next manufacturing process; and a solvent elimination and hardening step wherein, after multiple repetitions of the adhesive application step and the workable hardening step, ceramic adhesive hardened in the workable hardening steps is dried to a state capable of withstanding temperatures during electrical generation.

Owner:TOTO LTD

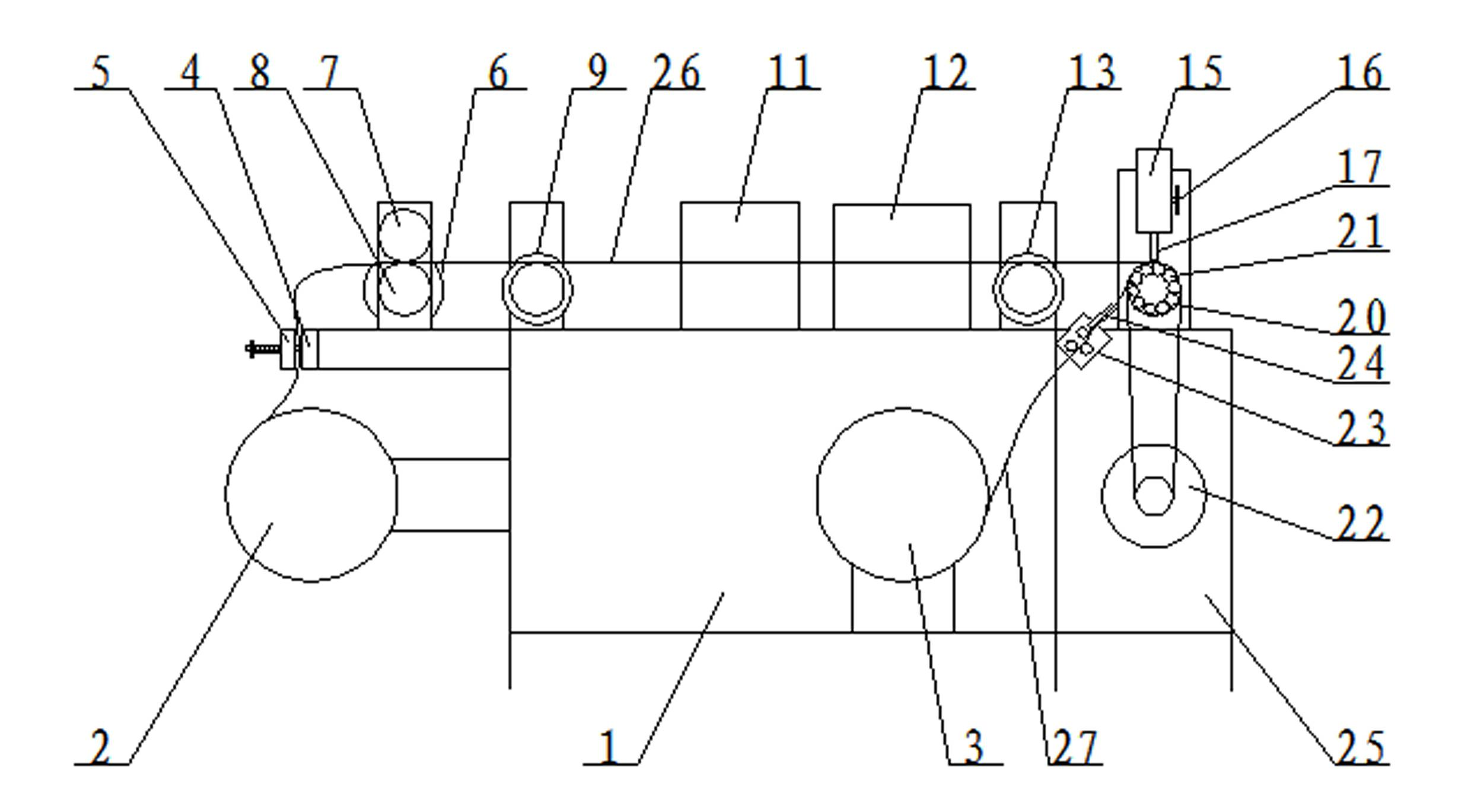

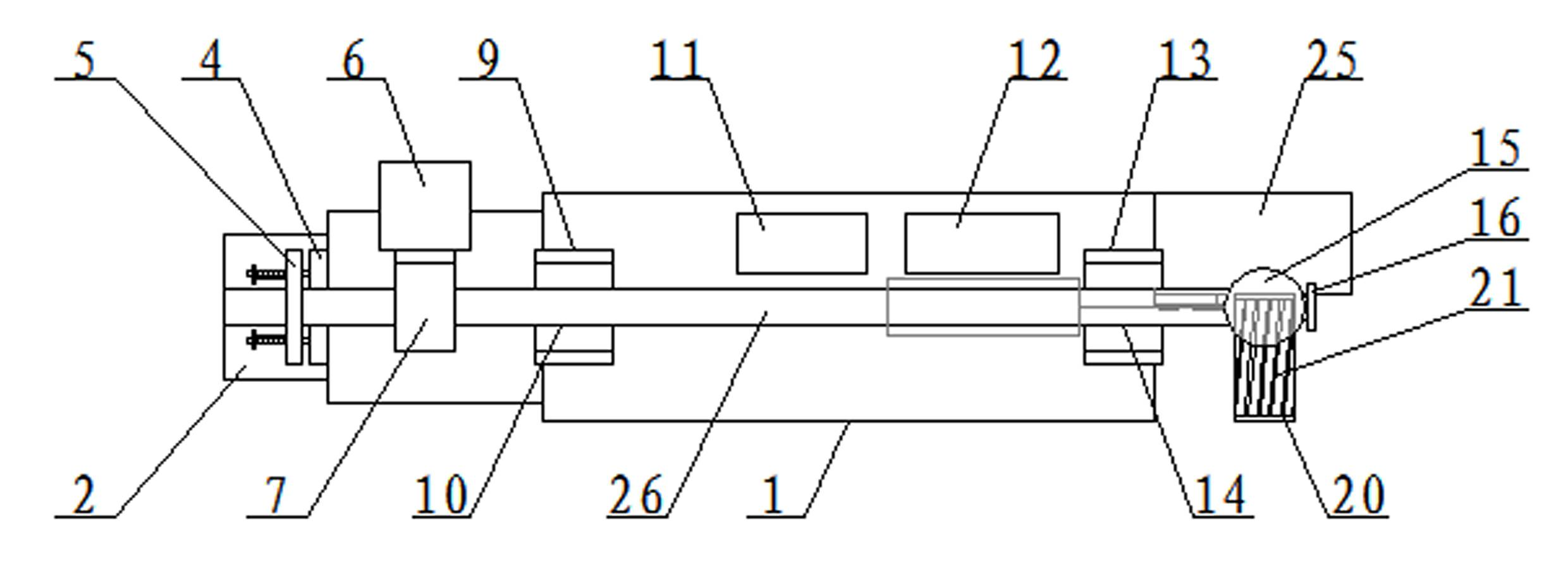

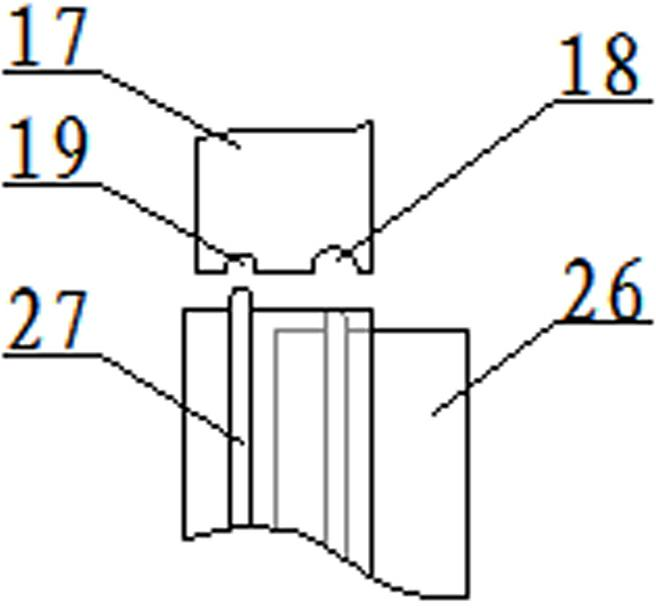

Ultrasonic welding equipment for porous sound attenuation air inlet tube of non-woven fabric helical air filter

The invention relates to ultrasonic welding equipment for a porous sound attenuation air inlet tube of a non-woven fabric helical air filter. The equipment comprises an electric control box, a winding rotating device, a feeding traveling device and a sizing device which are all arranged on a machine frame; the feeding traveling device is connected with a non-woven fabric roll and a nylon yarn roll; the winding rotating device is controlled by the electric control box to rotate; the feeding traveling device is controlled by the electric control box to travel along the direction of the winding rotating device and feeds non-woven fabric strips and nylon yarns into the winding rotating device to rotate and wind the non-woven fabric strips and the nylon yarns from inside to outside; and the sizing device is used for synchronously sizing the non-woven fabric strips wound on the winding rotating device. The non-woven fabric strips and the hard nylon yarns are adopted to be uniformly and slantingly wound on a core rod at intervals and are sized, adhered and formed in a matched mode. The ultrasonic welding equipment has a simple and compact structure, is convenient to operate, and has simple processes and a short forming period. The requirement on a certain rigidity required when an automobile engine and the air filter need to be randomly bent in the abutting process under different assembly working conditions can be met. The ultrasonic welding equipment has a long service life, can be recycled and has no waste pollution.

Owner:JIANGSU XINGCHENXING AUTO ACCESSORIES

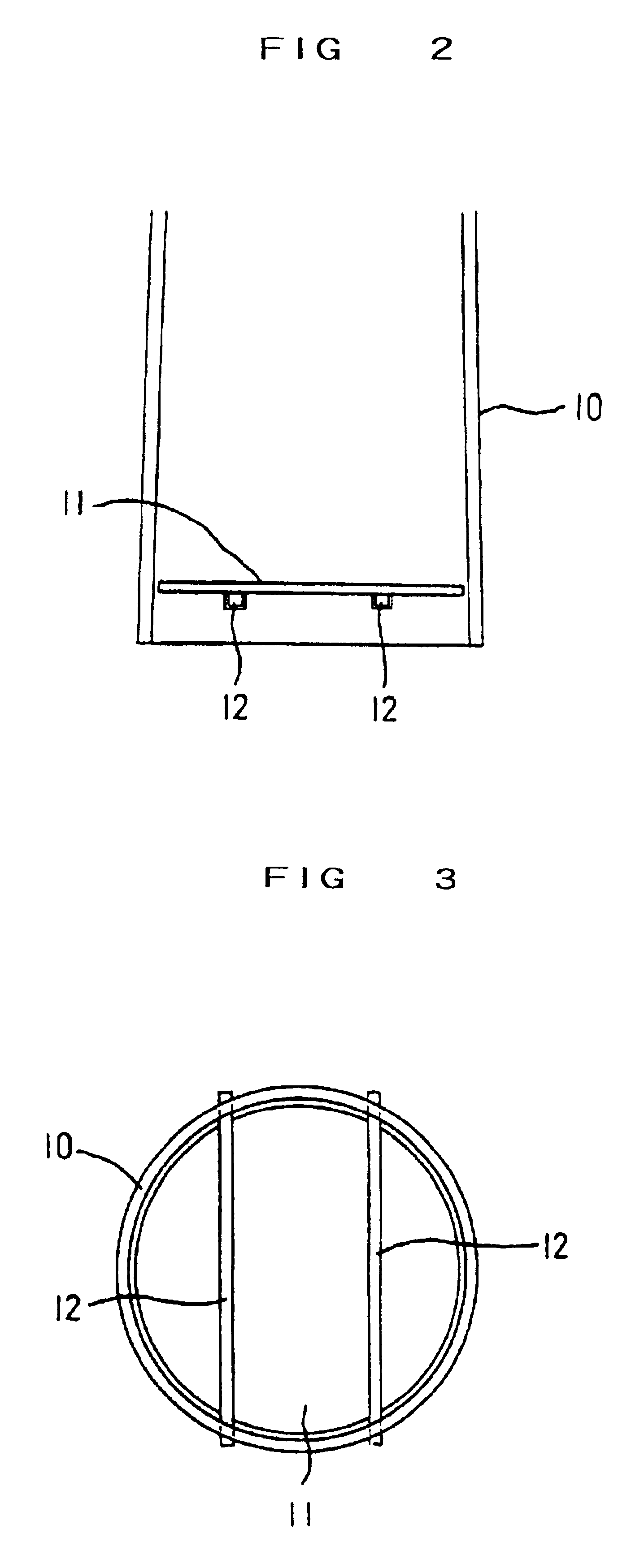

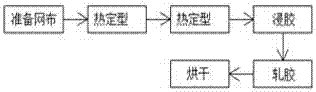

Double-surface coating process of cylindrical screen cloth

InactiveCN106958150AEasy to produceIncrease productivityLiquid surface applicatorsHeating/cooling textile fabricsTextile fiberEngineering

The invention discloses a double-surface coating process of cylindrical screen cloth. The double-surface coating process comprises the following steps of subjecting integrally molded cylindrical screen cloth to heat setting treatment for twice in sequence, then subjecting the cylindrical screen cloth to gum dipping and gum rolling treatment, and finally carrying out oven-drying treatment on the cylindrical screen cloth. By using the double-surface coating process, the convenience is provided for the subsequent production of a product using cylindrical coating screen cloth; the production efficiency is greatly improved; the cost of the product is decreased; the cylindrical screen cloth is subjected to heat setting at different temperatures for twice in sequence; internal stress generated by a textile fiber in a stretching process is eliminated by utilizing different heat power; the slackness of a macromolecule is enabled to basically reach the most balance; therefore, the cylindrical screen cloth is enabled to be more stable in structure and be good in toughness; the cylindrical coating screen cloth is integrally cylindrical, and compared with a cylindrical product which is sewed by common open-width screen cloth, as subsequent sewing processing does not exist, has no risk that a sewed position is easily cracked; the quality of the product is improved; meanwhile, the appearance is also more attractive.

Owner:贾芳纪

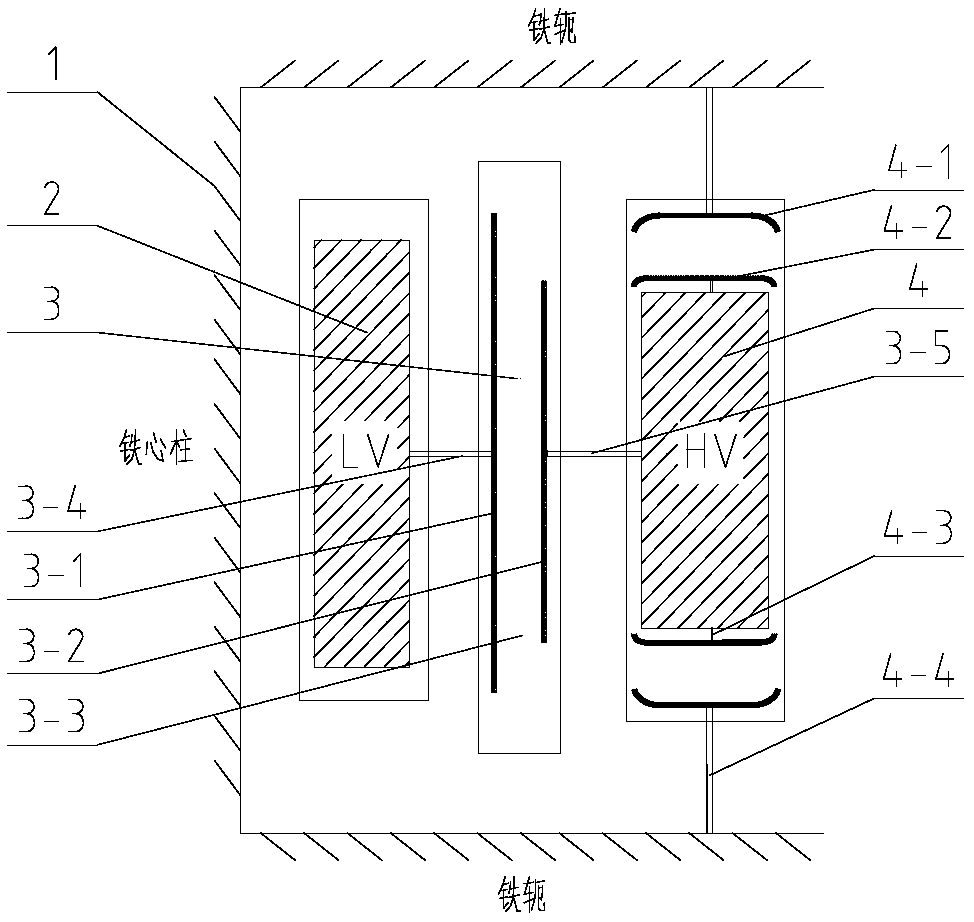

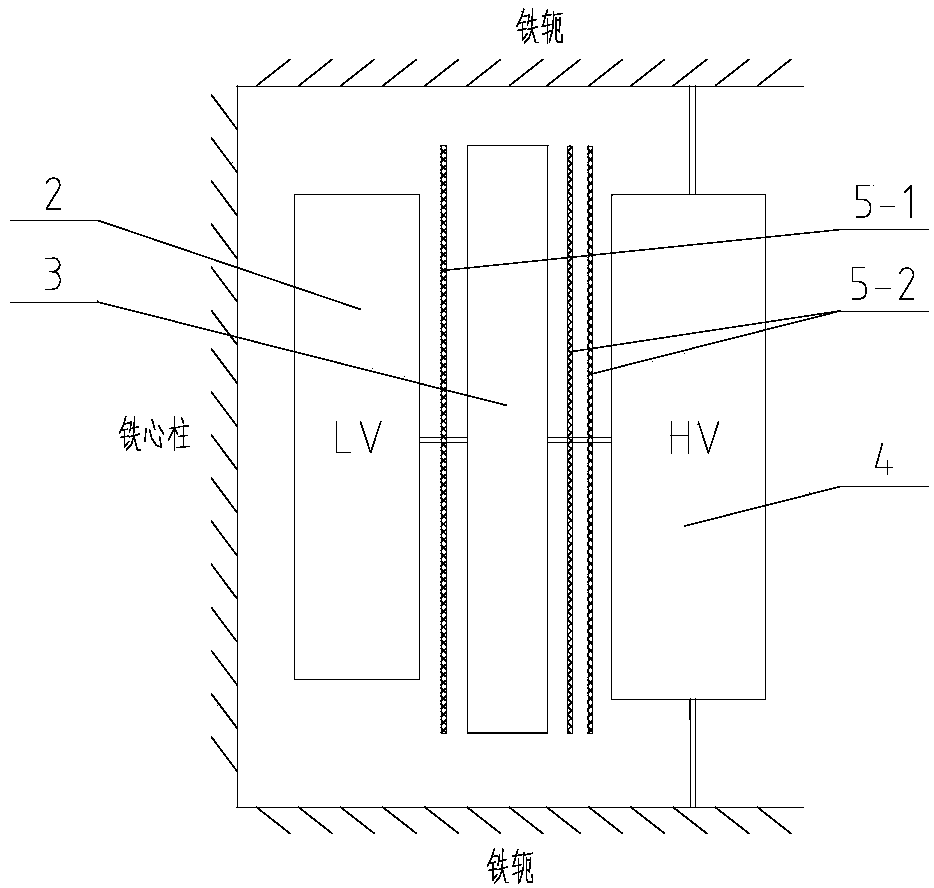

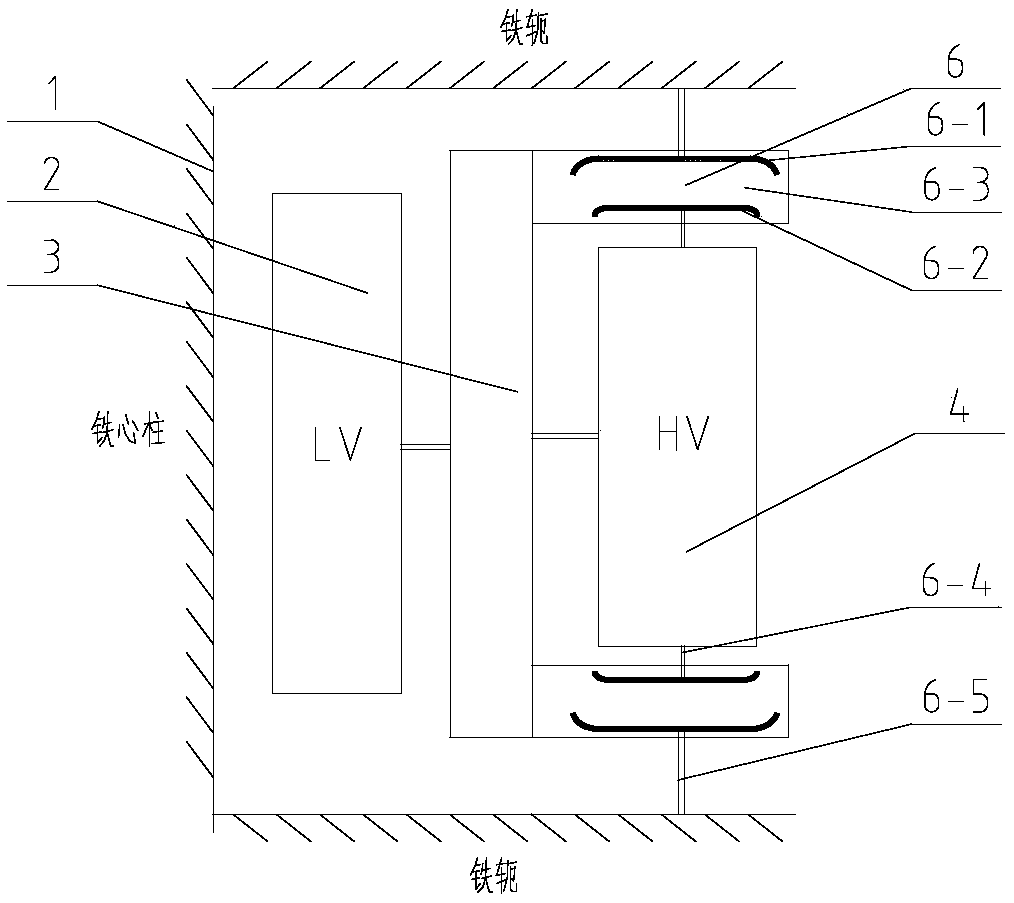

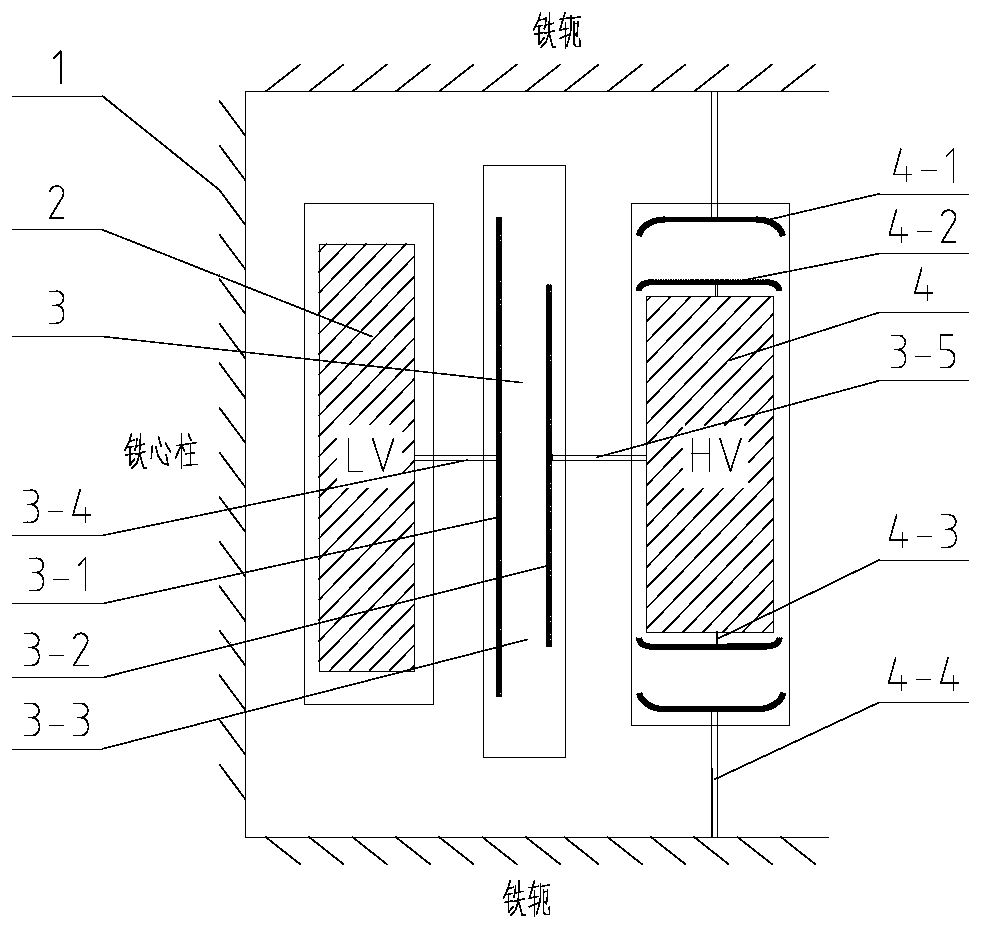

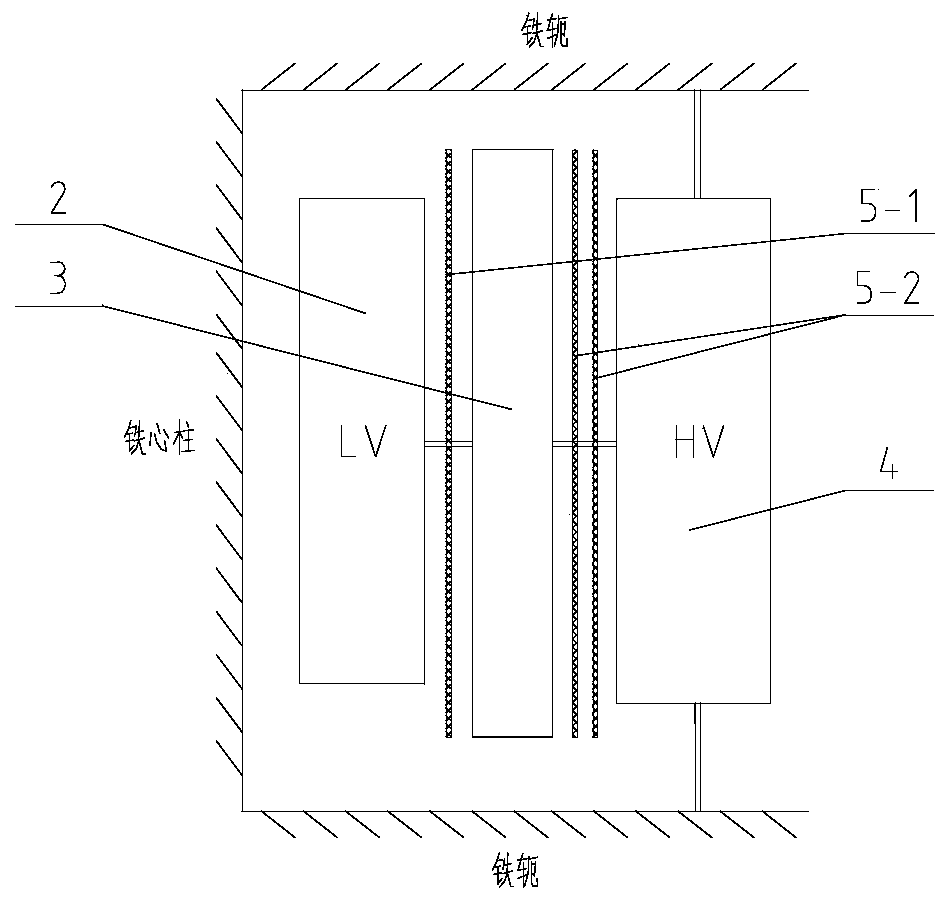

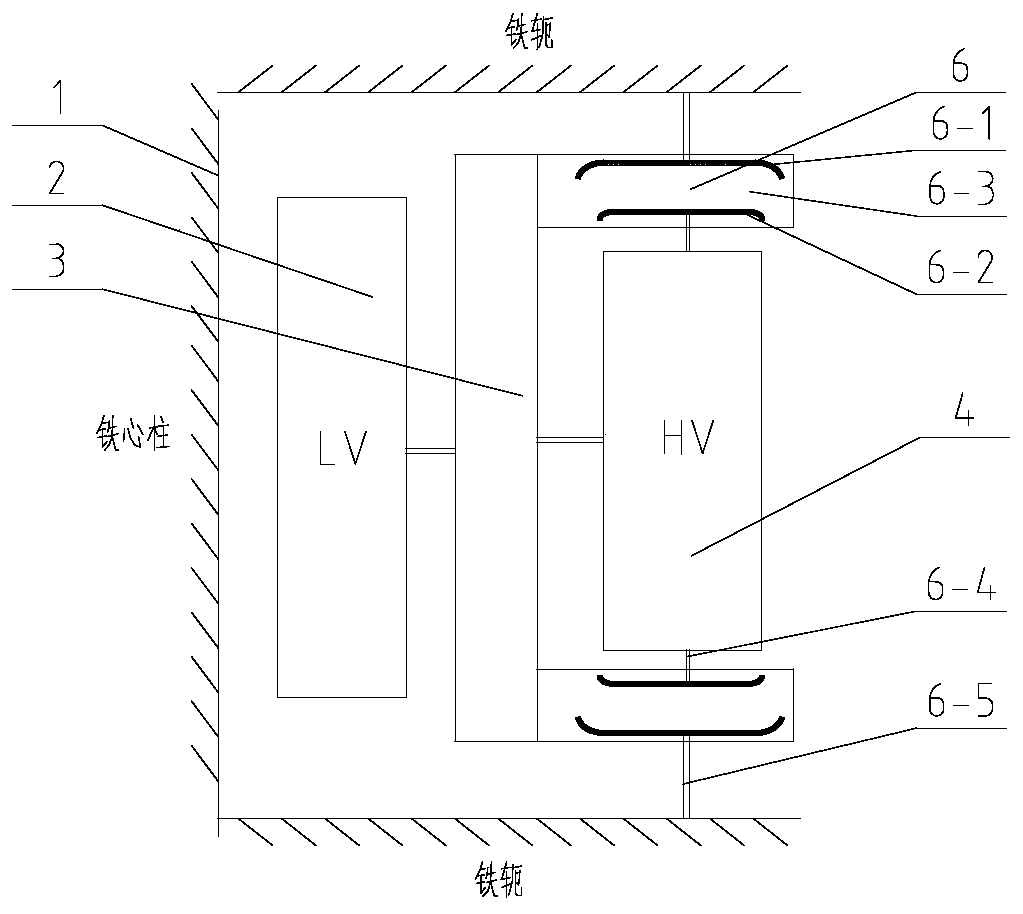

Insulation structure for dry-type transformer

ActiveCN108831716AImprove reliabilityReduce volumeTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionTransformerLow voltage

The invention discloses an insulation structure suitable for a dry-type transformer with the voltage grade of 35 kV or above. A first cylindrical insulation device is arranged between a low-voltage winding and a high-voltage winding of the dry-type transformer, and a second annular cake-shaped second insulation device is also arranged at the end of the high-voltage winding. Shielding layers are arranged on the portions, close to the inner wall and the outer wall, of the first insulation device respectively, and the shielding layers are connected with the middle of the low-voltage winding and the middle of the high-voltage winding respectively to form equipotential. Shielding layers are arranged on the portions, close to the upper wall and the lower wall, of the second insulation device respectively, and the shielding layers are connected with the high-voltage winding and an iron yoke of an iron core respectively to form equipotential. Therefore, the second insulation device becomes a main bearing unit of the voltage at the end of the high-voltage winding. The insulation structure solves the problems that according to the structure of a high-voltage dry-type transformer, the main air channel distance is large, insulation is not reliable due to the fact that air serves as a main insulation medium, and cracking is likely to occur because the thickness of a resin layer of a windingis too large, and has the advantages of being good in practicability and reliability and capable of reducing the cost.

Owner:JIANGSU HONGYUAN ELECTRIC +2

Drawing stamping die and hyperactive drawing technology thereof

InactiveCN105964791ANoveltySolve the problem of insufficient formingShaping toolsEconomic benefitsEngineering

The invention discloses a drawing stamping die and its multi-motion drawing process. The drawing stamping die includes an upper die and a lower die base. Multi-action drawing forming mechanism for step-by-step drawing forming from deep to deep. The drawing and stamping die of the present invention realizes multiple formings in one process, solves the problem of drawing and forming of such parts, and saves investment in die development caused by additional processes. It is conducive to improving the level of mold design and manufacturing, and at the same time can reduce production costs for the automobile industry and bring considerable economic benefits.

Owner:FUJI RAYHOO TECH WUHU

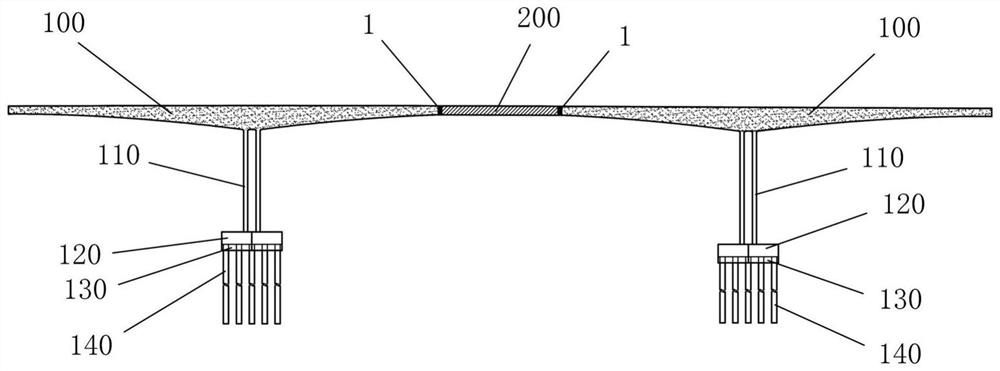

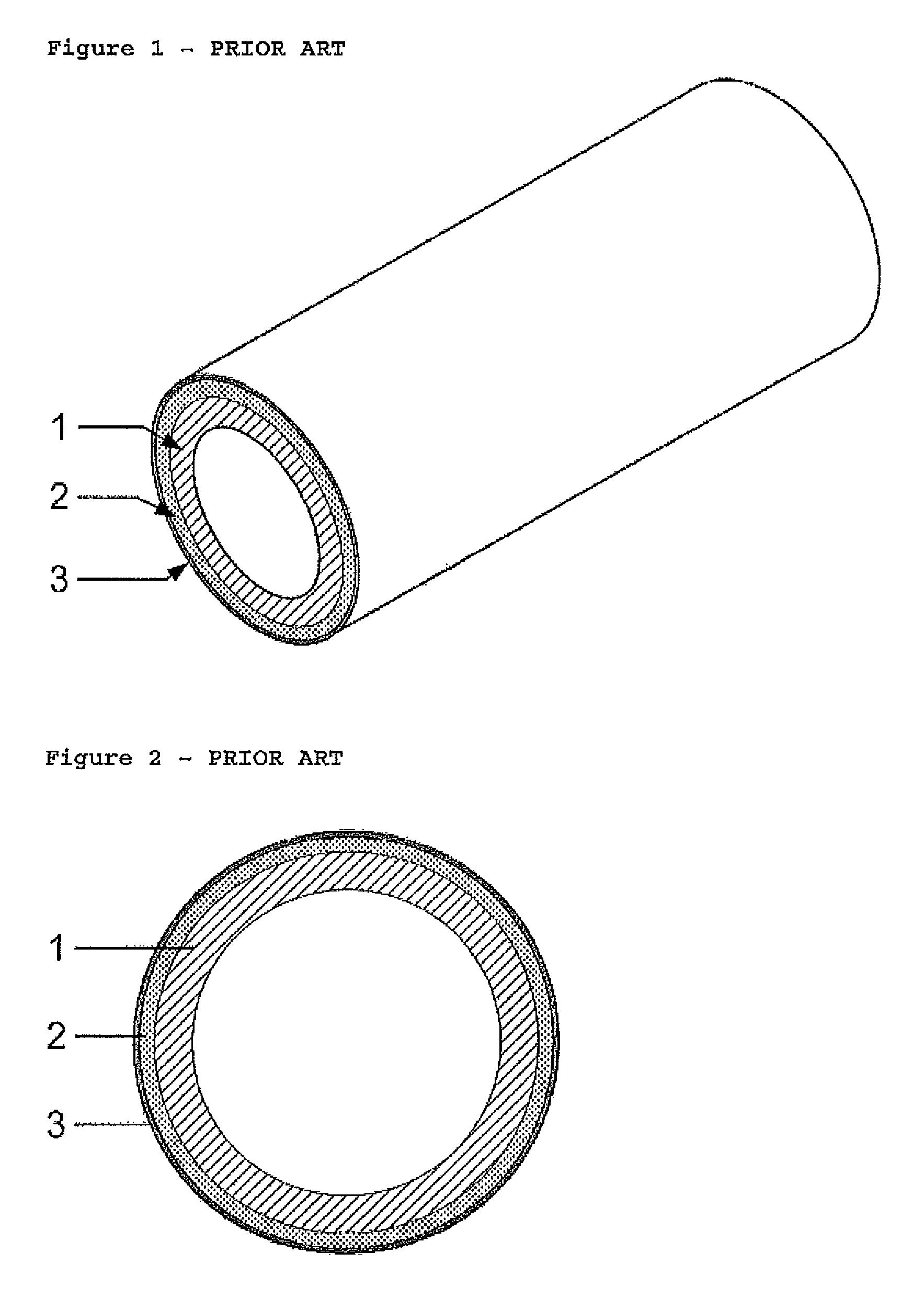

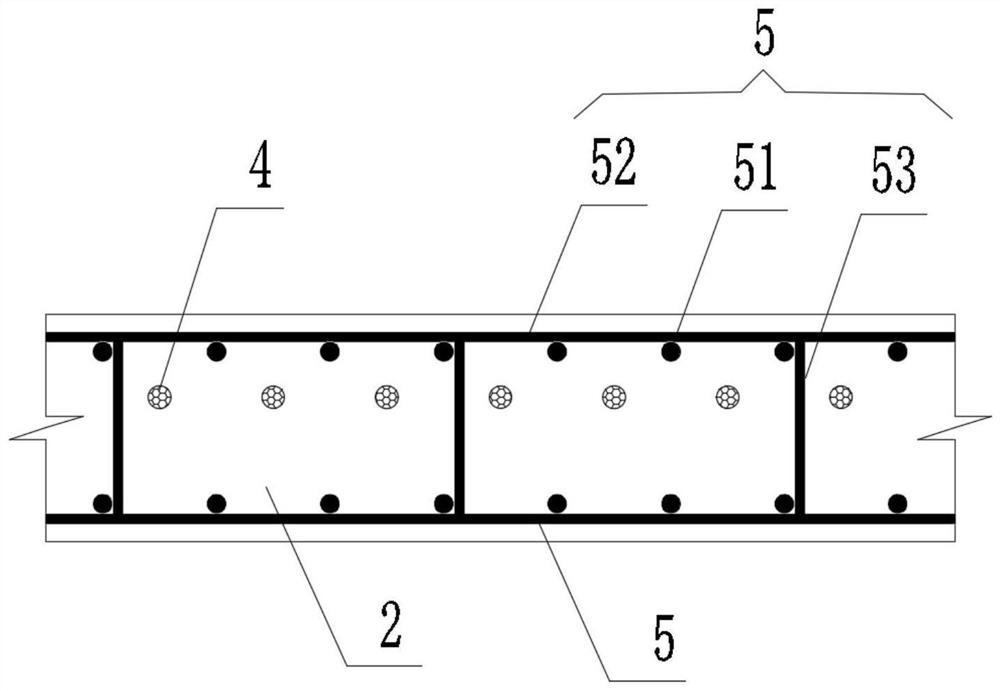

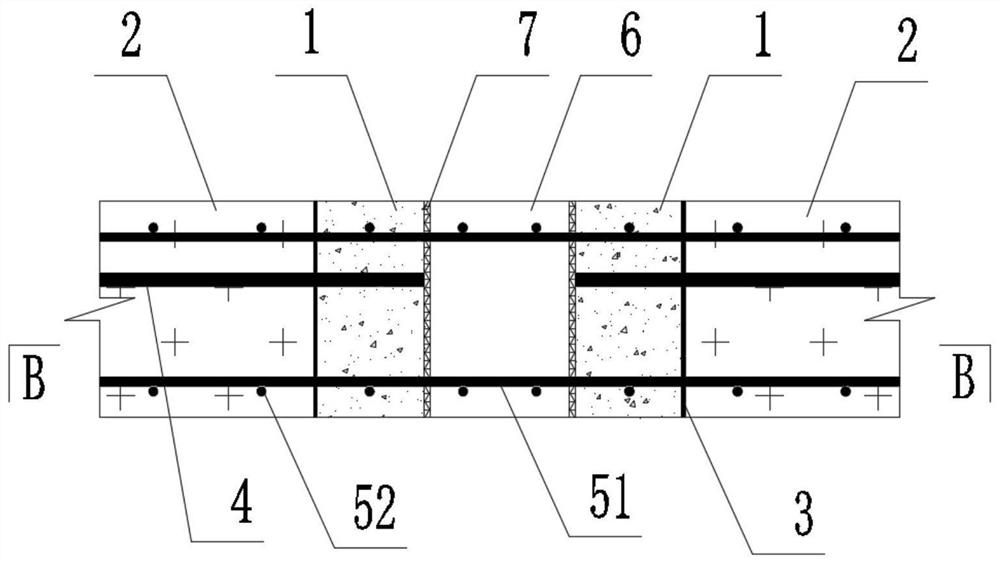

Joint structure of NC-UHPC hybrid rigid frame bridge, hybrid rigid frame bridge and construction method of hybrid rigid frame bridge

PendingCN113047161AQuick dockingEasy constructionBridge structural detailsBridge erection/assemblyConcrete beamsArchitectural engineering

The invention discloses a joint structure of an NC-UHPC hybrid rigid frame bridge, the hybrid rigid frame bridge and a construction method of the hybrid rigid frame bridge. The hybrid rigid frame bridge comprises common concrete beam sections and ultra-high performance concrete beam sections, the ultra-high performance concrete beam sections are midspan beam sections, and the two ends of each ultra-high performance concrete beam section are connected with the corresponding common concrete beam section through the joint structure; the joint structure comprises a first connecting steel plate assembly, a second connecting steel plate assembly and a wet joint, and one end of the first connecting steel plate assembly is embedded in the end of a common concrete beam section and extends out of the end of the common concrete beam section; and one end of the second connecting steel plate assembly is embedded in the end of the ultra-high-performance concrete beam section and extends out of the end of the ultra-high-performance concrete beam section to be connected with the first connecting steel plate assembly. The hybrid rigid frame bridge solves the problems of midspan downwarping and web cracking of a common concrete large-span continuous rigid frame bridge, complex stress of a steel-concrete combined section of a common concrete-steel hybrid rigid frame bridge, and difficult maintenance of a steel box girder section.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

Water heater pipeline antifreeze control method, system and water heater

Provided are a water heater pipeline anti-freezing control method and system and a water heater. The method includes acquiring environment temperature and water temperature and water level of a water tank of the water heater; comparing the environment temperature and the preset environment temperature; when the environment temperature is lower than the preset environment temperature, executing the circulation heating water producing mode where water in a water inlet pipe and a water outlet pipe of the water heater flows in a circulation mode according to the water temperature and the water level of the water tank of the water heater; when the water heater is applied under the condition that the environment temperature is lower than the preset environment temperature, entering the circulation heating water producing mode enabling the water in the water inlet pipe and the water outlet pipe of the water heater to flow in the circulation mode. Flowing water passes through both the cold water inlet pipe and the circulation water inlet pipe of the water heater, the requirement for hot water usage can be met, and the pipeline has no freezing risks.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD

Grey gold alloy

ActiveUS20180171436A1Without reducing deformability propertyImprove grey gold alloysBraceletsWrist-watch strapsChromium freeIndium

A grey gold alloy which is nickel-free, cobalt-free, iron-free, silver-free, zirconium-free, niobium-free, chromium-free, indium-free, gallium-free and manganese-free and includes, expressed in weight percent, from 75.0 to 76.5% of Au, from 15 to 23% of Pd, from 1 to 7% of Cu, and from 0 to 5% of at least one of the alloying elements Ir, Ru, B and Re, the respective percentages of all the elements of the alloy adding up to 100%.

Owner:MONTRES BREGUET

Grey gold alloy

ActiveUS20160273077A1Good deformabilityImprove grey gold alloysClockwork casesBraceletsChromium freeNiobium

A grey gold alloy which is nickel-free, cobalt-free, iron-free, silver-free, copper-free, zirconium-free, niobium-free, chromium-free and manganese-free, including, expressed in weight percent, from 75.0 to 76.5% of Au, from 15 to 23% of Pd, from 0.5 to 5% of Rh, from 0 to 7% of Pt, and from 0 to 5% of at least one of the alloying elements Ir, Ru, Ti, In, Ga, B and Re, the respective percentages of all the alloying elements adding up to 100%.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

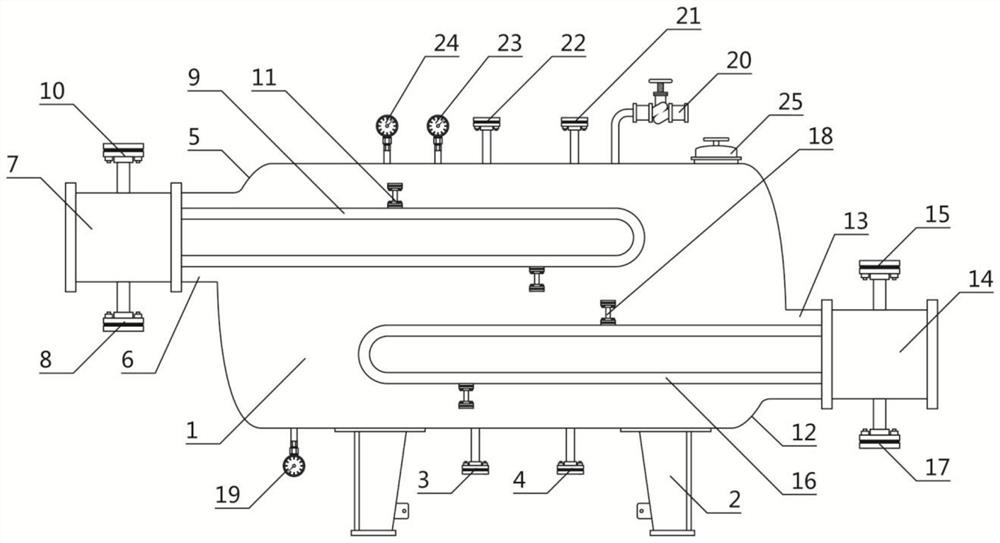

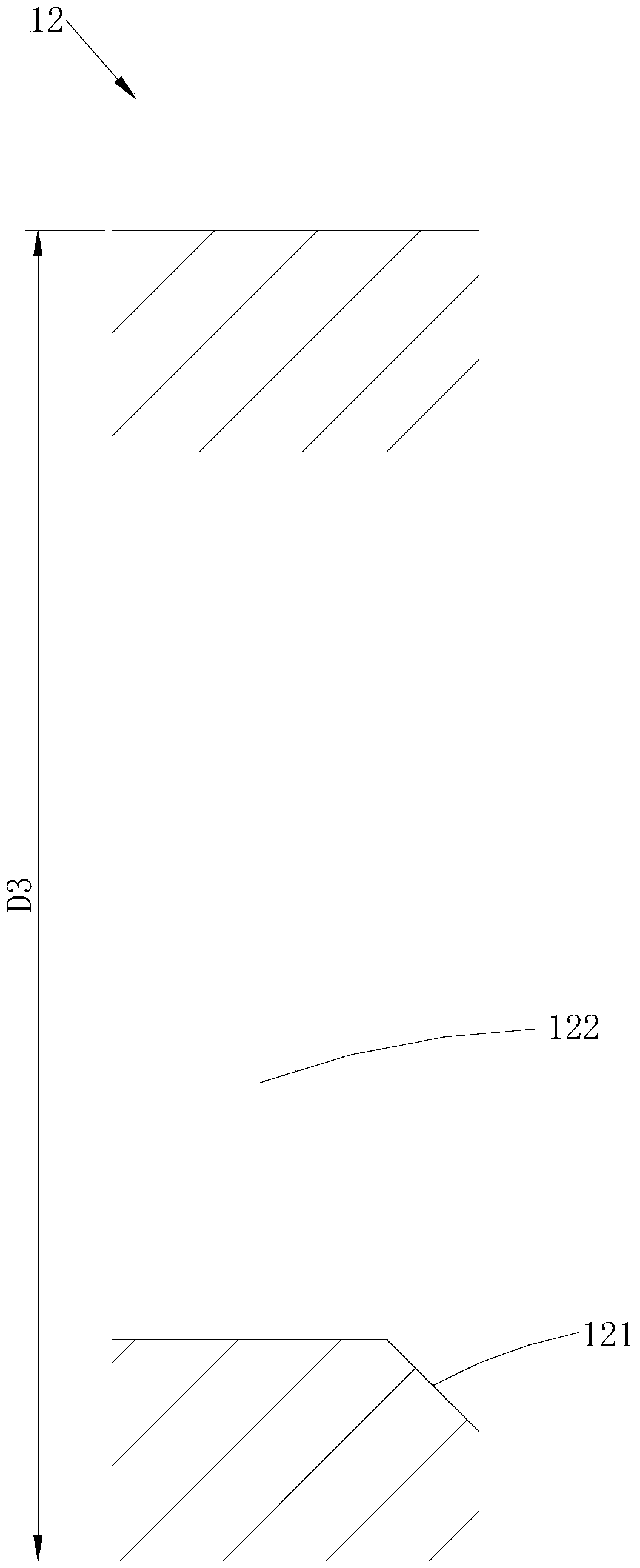

Heater for low-temperature ethylene unloading and working method thereof

PendingCN114018068ANo risk of crackingLow costSteam/vapor condensersSafety valveIndustrial engineering

The invention aims to provide a heater for low-temperature ethylene unloading and a working method of the heater. The heater is characterized by comprising a shell pass cylinder, a supporting skirt, a methanol injection port, a drain outlet, a first seal head, an ethylene reinforced cylinder section, an ethylene side pipe box, a first heat exchange pipe bundle, a second seal head, a steam reinforced cylinder section, a steam side pipe box, a second heat exchange pipe bundle, a first detection instrument, a safety valve port, an emptying interface, a liquid level detection interface and a second detection instrument, a detection instrument and a man hole; the ethylene side pipe box is provided with an ethylene injection port and an ethylene outlet, and the steam side pipe box is provided with a steam injection port and a condensate outlet. The whole set of device adopts a double-heat-exchanger structural design, the medium of one group of heat exchange pipe bundles is low-temperature ethylene, the medium of the other group of heat exchange pipe bundles is water vapor, the medium in the cylinder is methanol, and the steam and the low-temperature ethylene exchange heat indirectly, so that the purpose of rising the temperature of the ethylene is achieved. The heater is compact in overall structure, good in heat transfer effect, is energy-saving and environment-friendly, is low in cost, and is safe and reliable.

Owner:天津奥利达环保设备有限公司

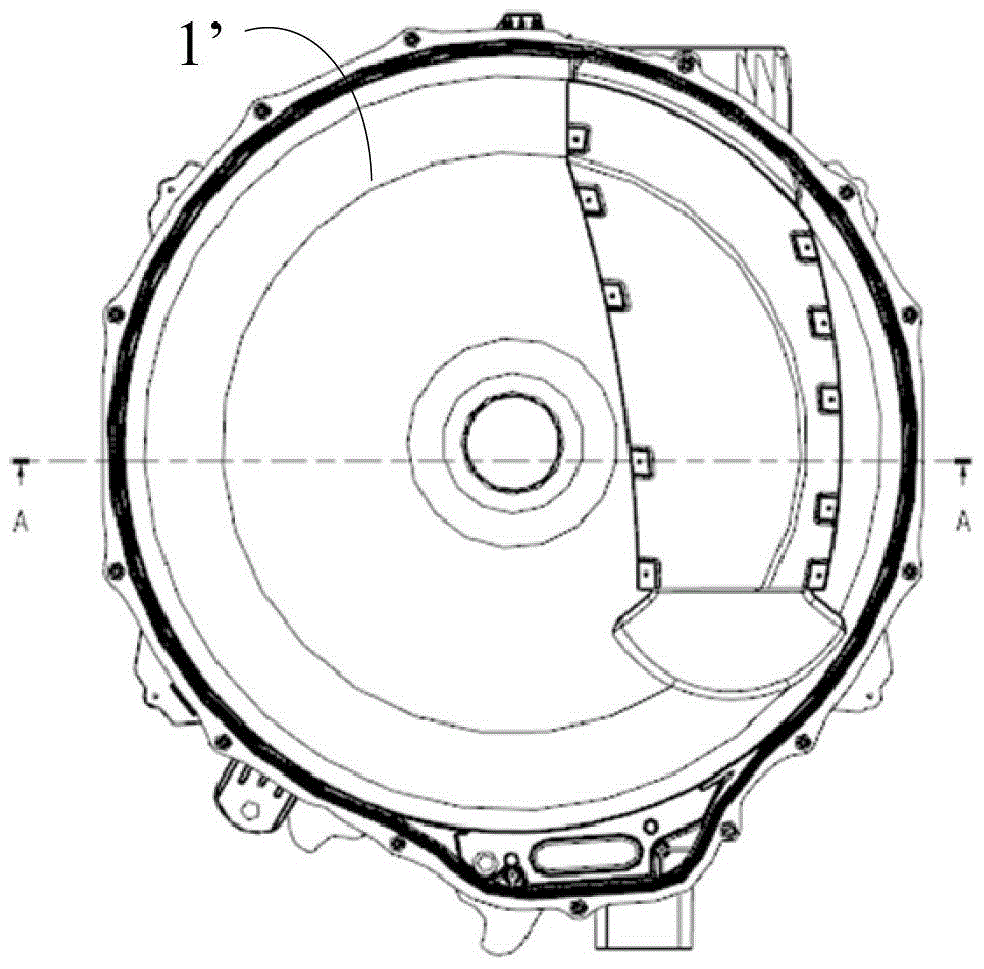

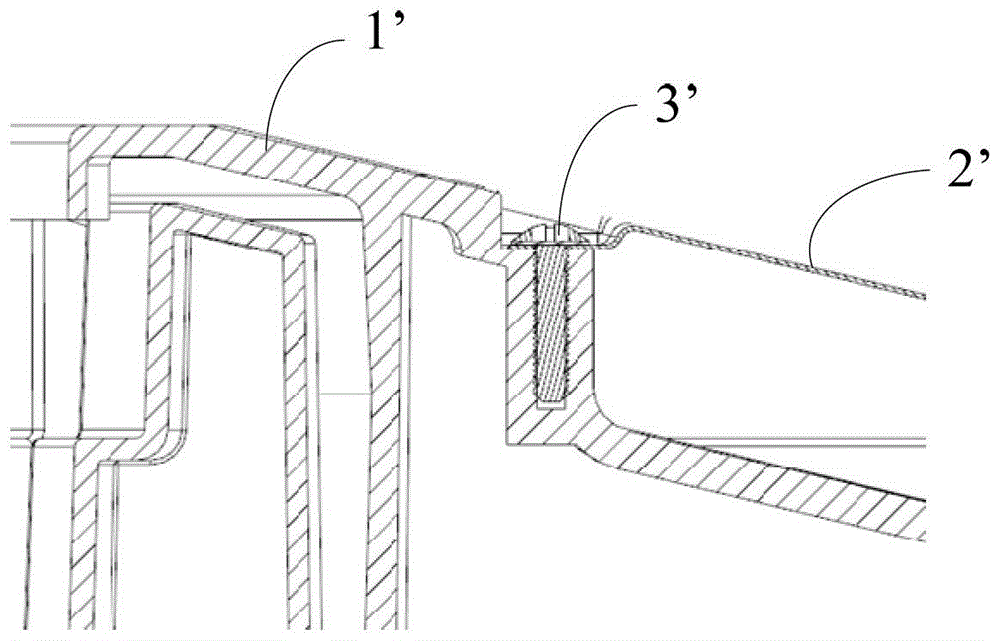

Cover plate mounting structure of condenser

ActiveCN104074037AEasy to installSimple installation structureTextiles and paperLaundry driersStress concentrationEngineering

The invention discloses a cover plate mounting structure of a condenser. The cover plate mounting structure comprises a back drum, wherein a condenser cavity is formed in the back drum, and comprises a condenser cavity bottom wall, a plurality of condenser cavity side walls and a condenser cover plate positioned above the condenser cavity; a plurality of cover plate mounting parts are arranged at the periphery of the condenser cover plate; at least one of the condenser cavity side walls is provided with grooves parallel to the condenser cavity bottom wall; and the corresponding cover plate mounting parts are fixedly inserted in the grooves. The cover plate mounting structure of the condenser has the advantages of simple structure, simple installation and good positioning effect; and after the condenser cover plate is inserted, the high-frequency vibration stress of the back drum is absorbed by the inserted part, so that the stress concentration generated by such rigid fixed connection modes as screws is not caused, and the cracking risk of the condenser cover plate is not occurred.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

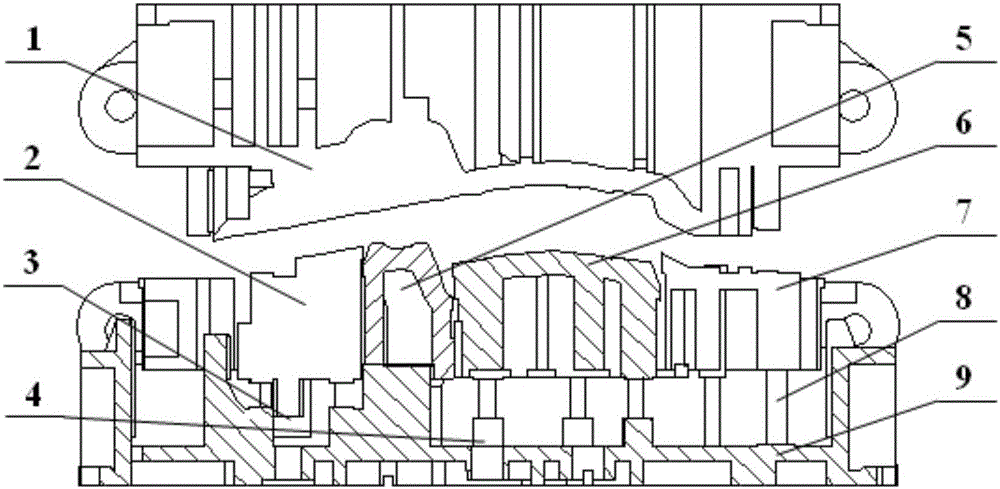

Assembled platy commutator processing method

InactiveCN103001401AReduce manufacturing costSimple processManufacturing dynamo-electric machinesEngineeringRoughcast

The invention relates to a motor commutator processing method. The commutator processing method sequentially includes the steps: processing a commutator bar provided with an insertion portion; adopting a support with an inner round hole, and forming a component for arranging the commutator bar on the side wall of the inner round hole; arranging the commutator bar on the support to enable the component and the commutator bar to be fixedly matched so that a composite part is obtained; placing the composite part into a corresponding mould so that the composite part forms an insulating base body by injection molding; performing heat treatment for a formed blank; and finishing so that a finished product is obtained. The commutator processing method has the advantages of lower commutator processing cost, fewer commutator processing procedures and the like.

Owner:SHENZHEN KAIZHONG PRECISION TECH CO LTD

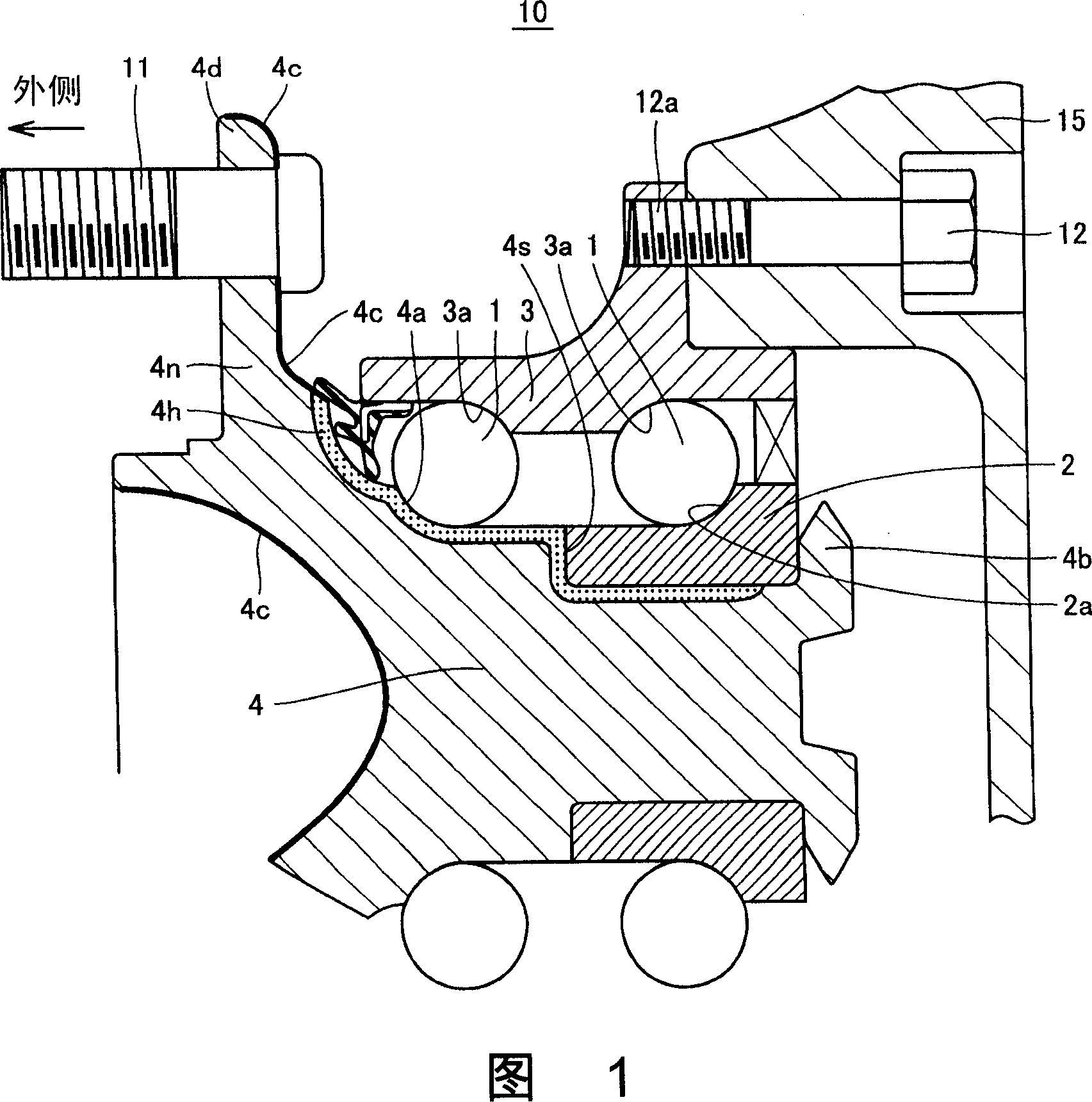

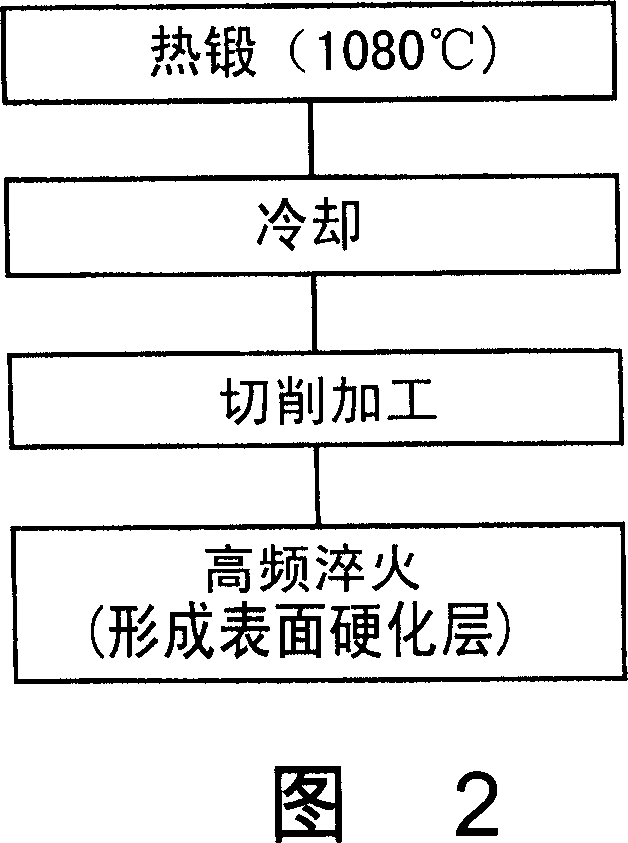

Bearing device for wheel

Owner:NTN CORP

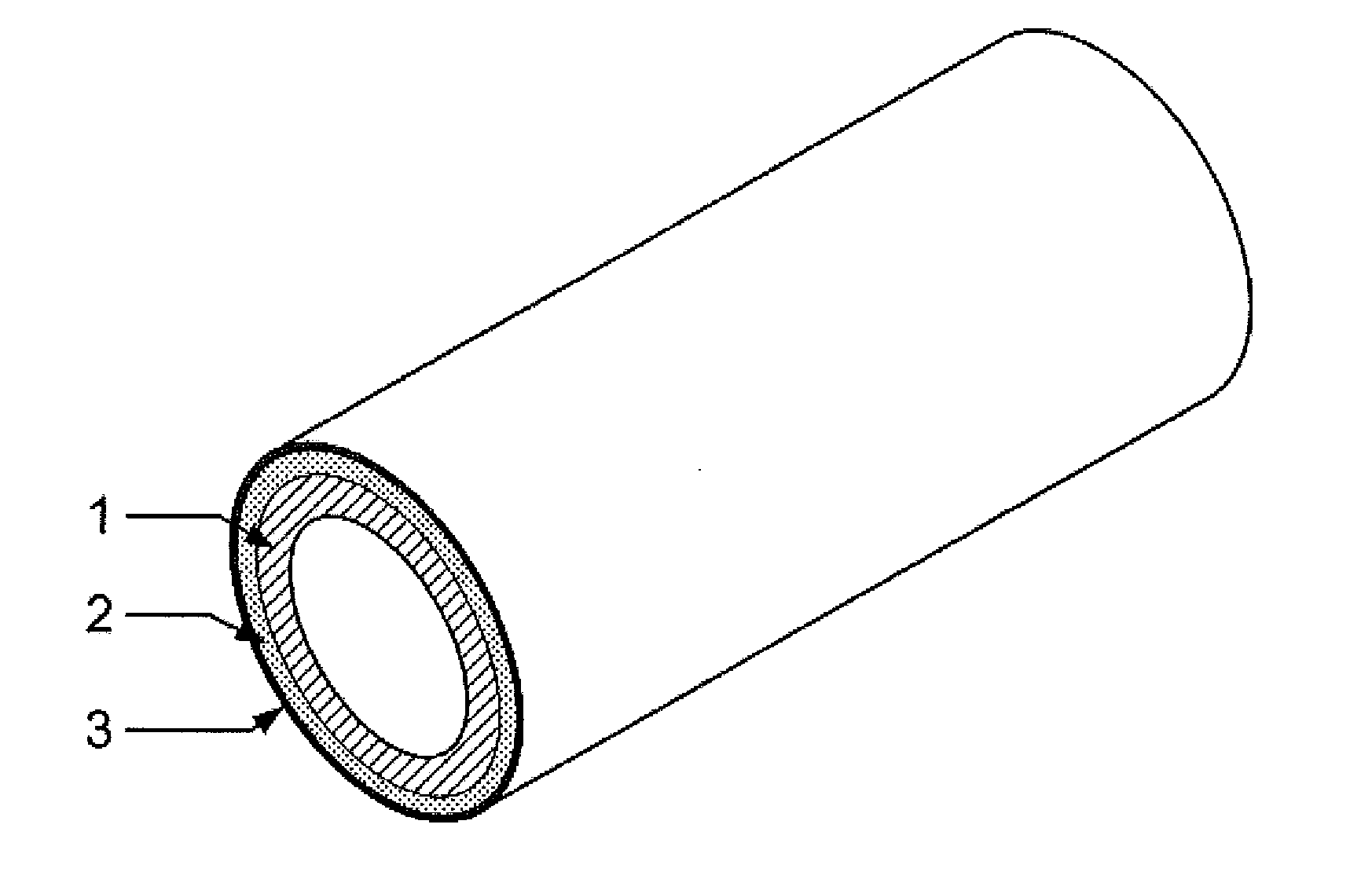

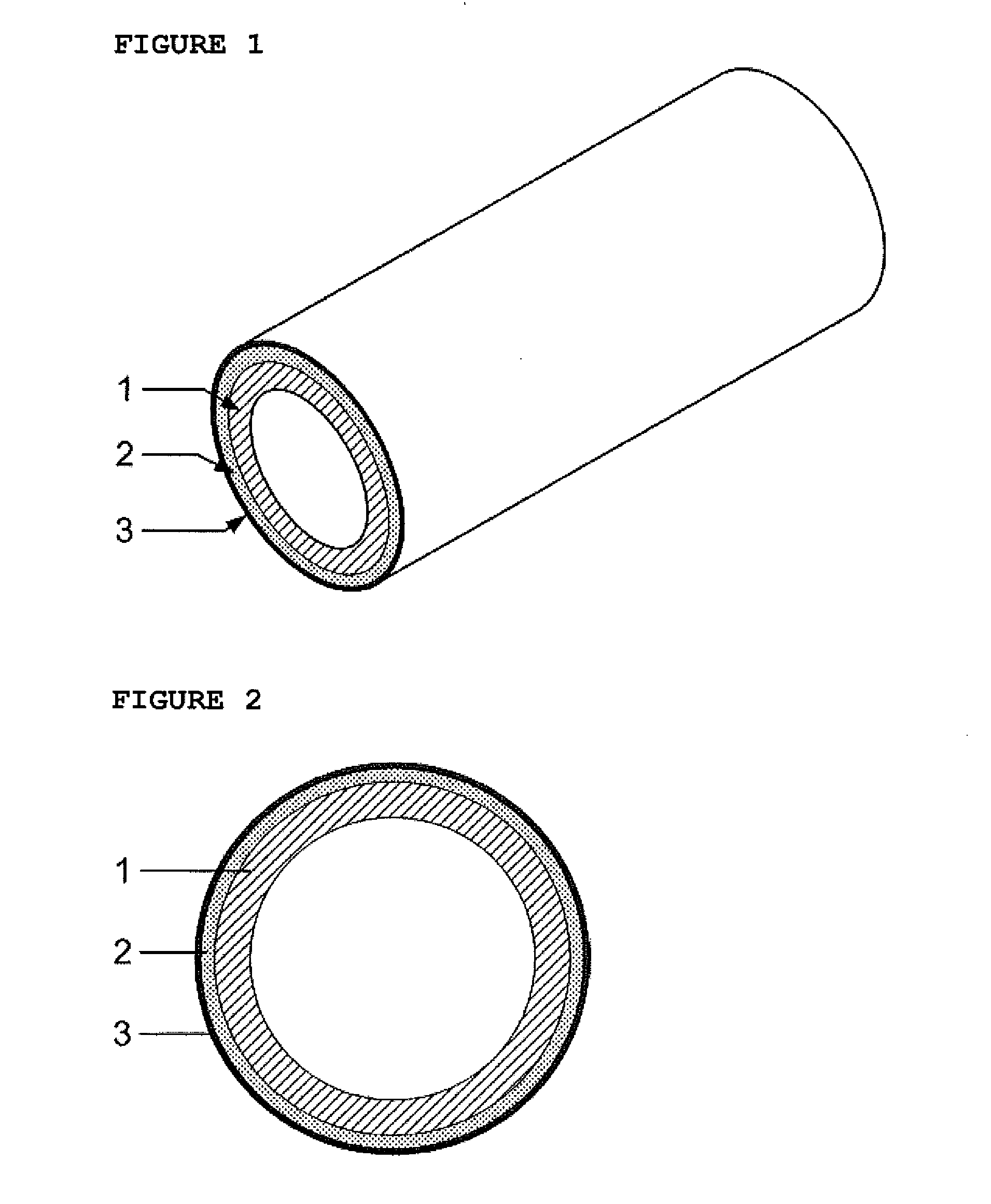

Method of refurbishing rotogravure cylinders, rotogravure cylinders and their use

ActiveUS20150336414A1Improve adhesionReduce brittlenessLiquid surface applicatorsPlate printingCopperZinc

The rotogravure cylinder comprising a rotary gravure base and thereon a copper engraving layer is refurbished to contain a zinc layer between a gravure base and a layer package suitable for engraving and printing. This layer package for instance comprises a metallic support layer, a copper engraving layer and suitably a protection layer. Deposition of the zinc layer may be tuned for thickness variation, in combination with deposition of the layer package in a fixed thickness.

Owner:ICR IOANNOU SA

A dry-type transformer insulation structure

ActiveCN108831716BImprove reliabilityReduce volumeTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionTransformerLow voltage

The invention discloses an insulation structure suitable for a dry-type transformer with the voltage grade of 35 kV or above. A first cylindrical insulation device is arranged between a low-voltage winding and a high-voltage winding of the dry-type transformer, and a second annular cake-shaped second insulation device is also arranged at the end of the high-voltage winding. Shielding layers are arranged on the portions, close to the inner wall and the outer wall, of the first insulation device respectively, and the shielding layers are connected with the middle of the low-voltage winding and the middle of the high-voltage winding respectively to form equipotential. Shielding layers are arranged on the portions, close to the upper wall and the lower wall, of the second insulation device respectively, and the shielding layers are connected with the high-voltage winding and an iron yoke of an iron core respectively to form equipotential. Therefore, the second insulation device becomes a main bearing unit of the voltage at the end of the high-voltage winding. The insulation structure solves the problems that according to the structure of a high-voltage dry-type transformer, the main air channel distance is large, insulation is not reliable due to the fact that air serves as a main insulation medium, and cracking is likely to occur because the thickness of a resin layer of a windingis too large, and has the advantages of being good in practicability and reliability and capable of reducing the cost.

Owner:JIANGSU HONGYUAN ELECTRIC +2

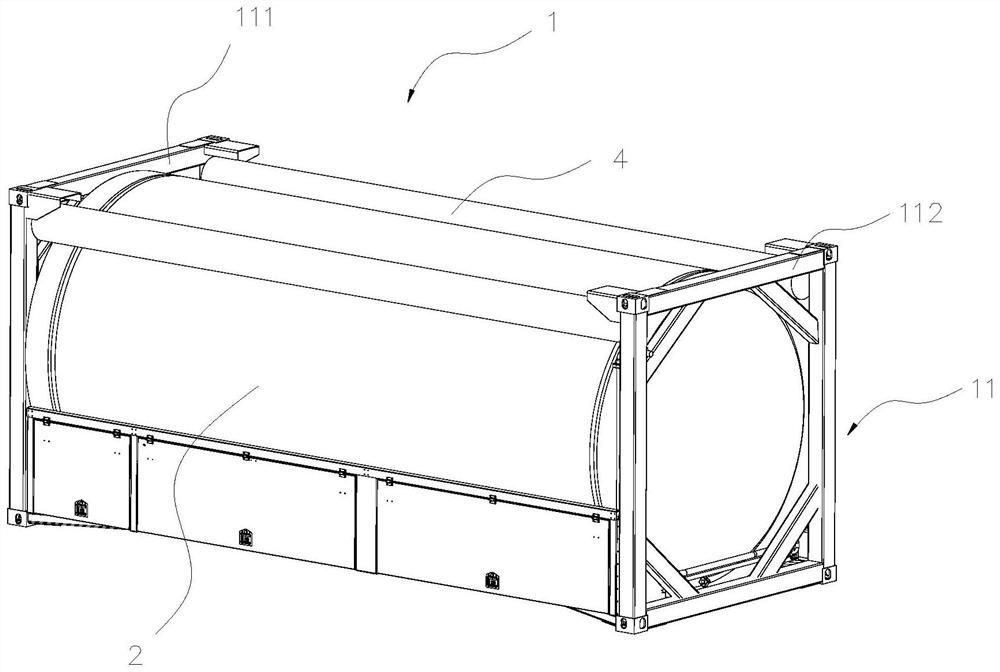

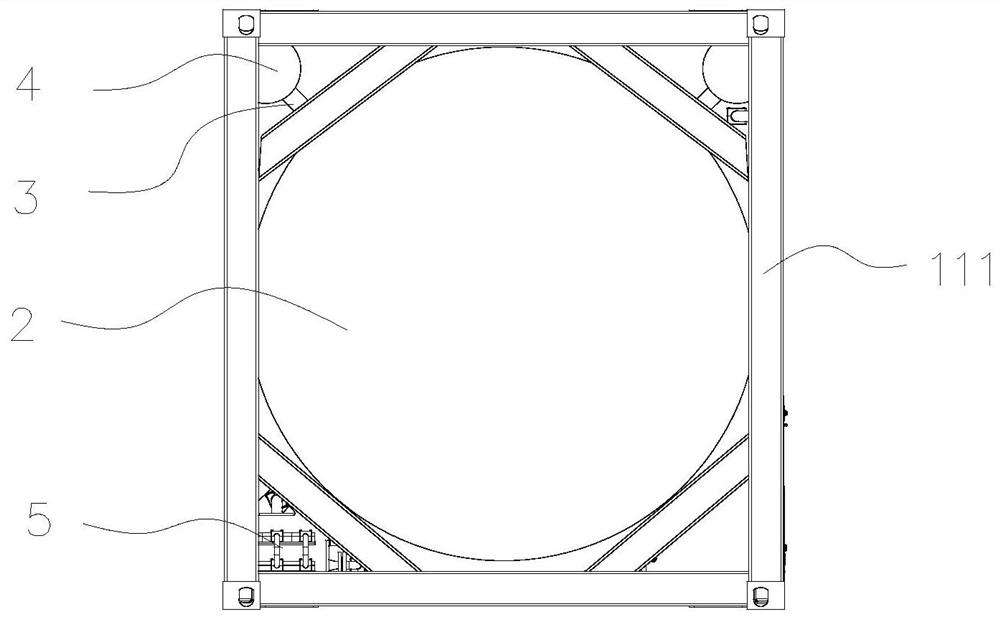

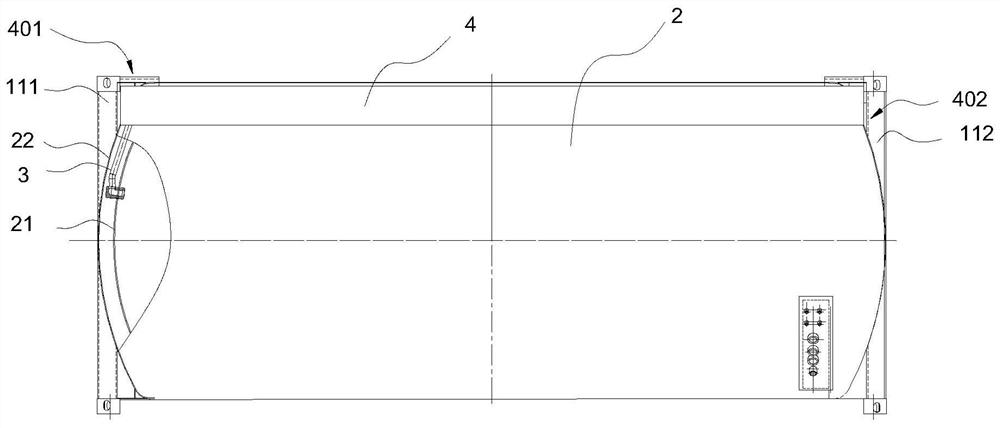

Low-temperature tank container

PendingCN113551150ASolve the discharge problemLow densityVessel mounting detailsVessel geometry/arrangement/sizeTank containerMechanics

The invention provides a low-temperature tank container. The low-temperature tank container comprises a frame and a tank body horizontally arranged in the frame. The tank body is used for storing low-temperature liquid. The low-temperature tank container further comprises a connecting pipe, a gasification heat exchange pipe and a discharge pipeline system; the connecting pipe penetrates through the tank body and extends into the tank body so as to communicate with the gas phase space of the tank body; the gasification heat exchange pipe is fixedly arranged on the tank body; the gasification heat exchange pipe extends in the axial direction of the tank body and does not exceed the outer side of the frame; an inlet and an outlet are formed in the two ends, in the axial direction, of the gasification heat exchange pipe correspondingly, and the inlet is connected and communicates with the end, exposed out of the tank body, of the connecting pipe; and the discharge pipeline system is connected and communicates with the outlet of the gasification heat exchange pipe. The gasification heat exchange pipe is located in the atmospheric environment, low-temperature media flowing through the interior of the pipe can participate in heat exchange with the outside atmosphere, then absorb heat and are gasified into gas, the gas is discharged through the discharge pipeline system, and the temperature of the gas is relatively high so that the risk of frost cracking cannot be generated to adjacent containers and ships.

Owner:NANTONG CIMC ENERGY EQUIP CO LTD +2

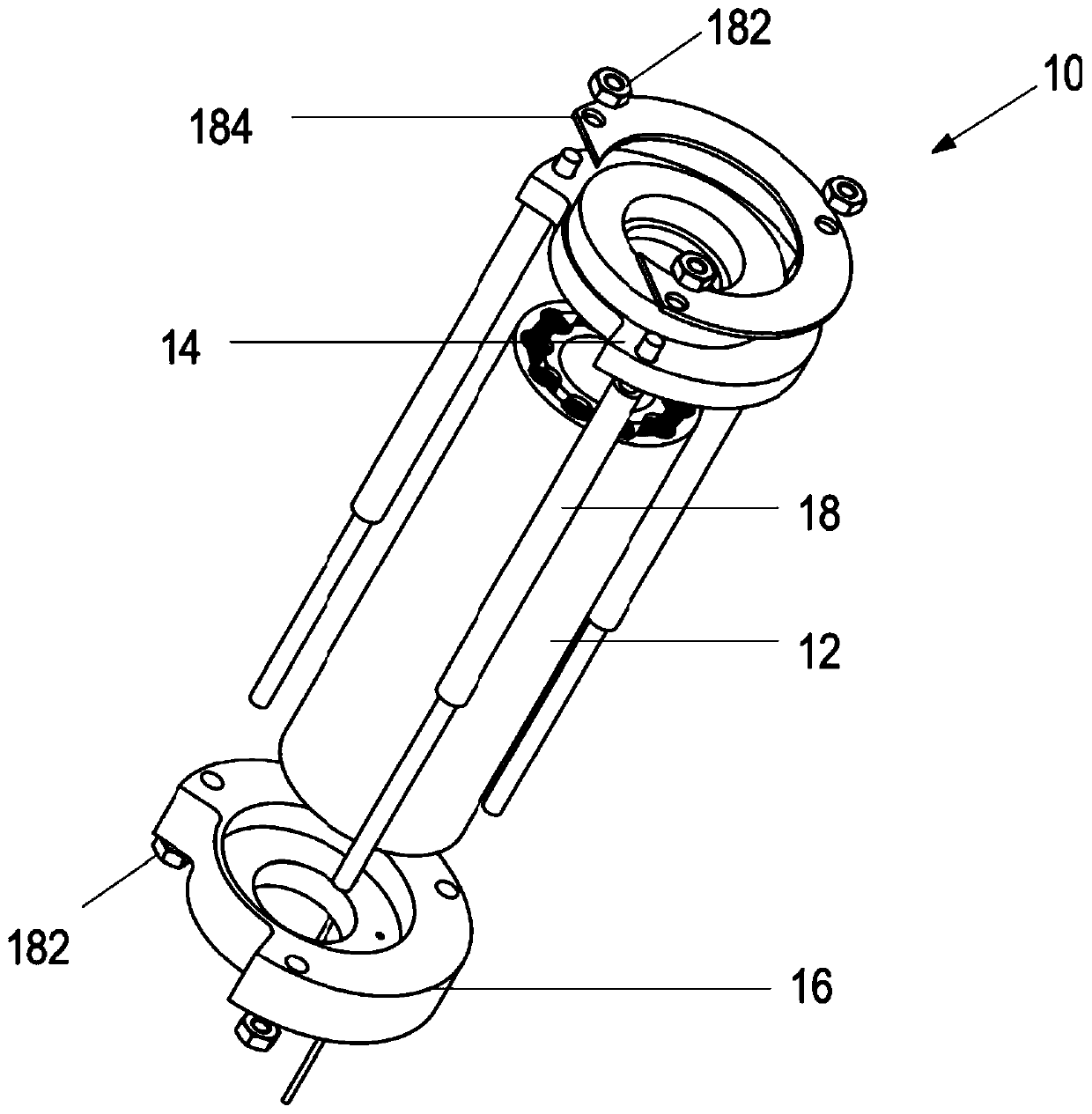

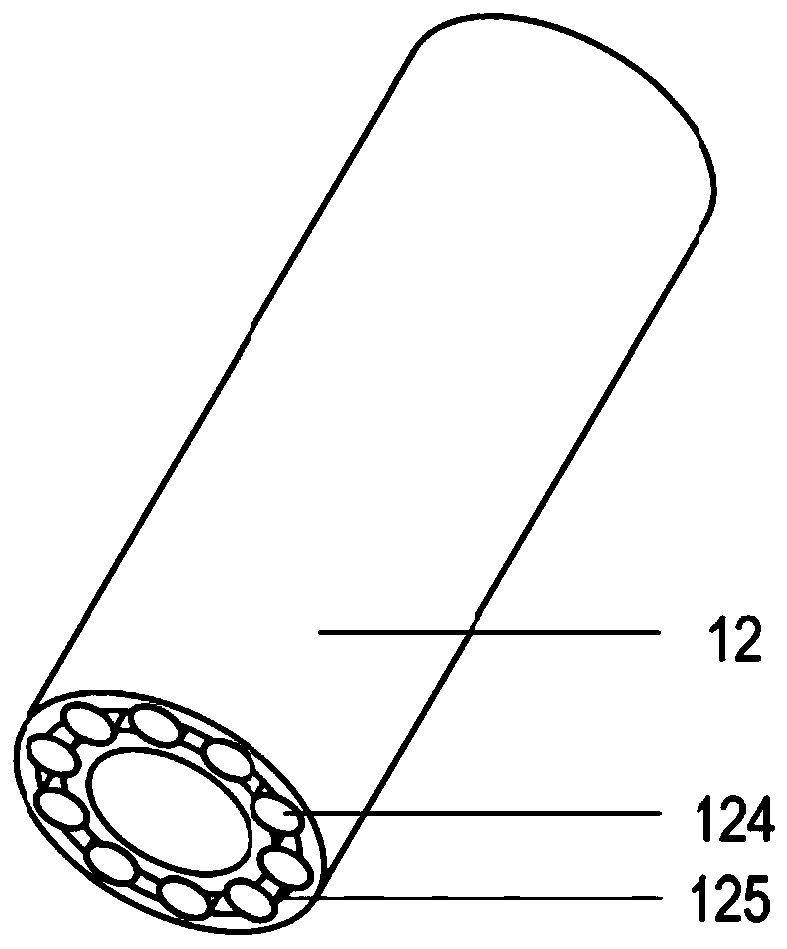

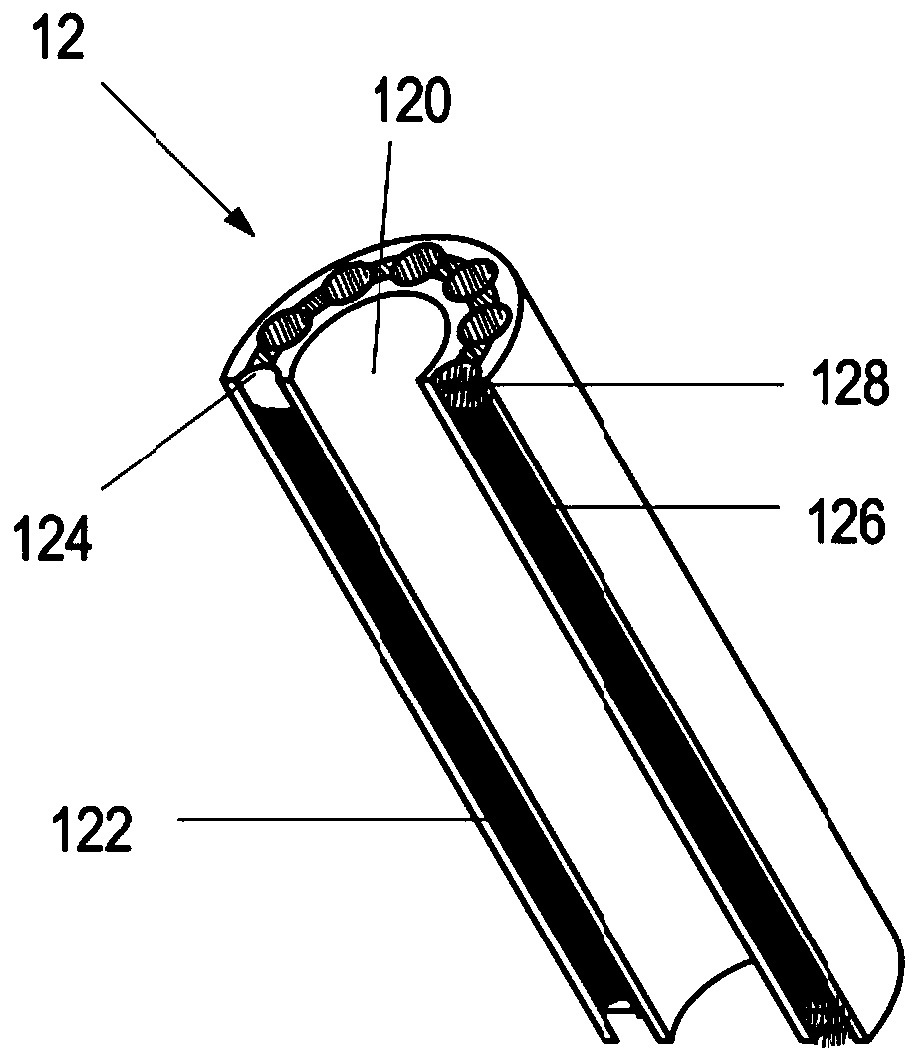

Zirconium oxide oxygen analyzer heating furnace

ActiveCN110411216AExtended service lifeHas high temperature insulation propertiesFurnace typesElectric heating for furnacesWater basedFilling materials

The invention provides a zirconium oxide oxygen analyzer heating furnace. The zirconium oxide oxygen analyzer heating furnace comprises a furnace core tube, a first end plate, a second end plate and aconnecting rod piece, wherein a heating wire is arranged in the furnace core tube and is used for heating a zirconium oxide oxygen sensitive element positioned in an inner cavity of the furnace coretube; the first end plate is used for supporting a first end part of the furnace core tube; the second end plate is used for supporting a second end part of the furnace core tube; the connecting rod piece is used for fastening the first end plate and the second end plate together, so that the furnace core tube is clamped between the first end plate and the second end plate. A heating cavity of theheating wire of the furnace core tube provided with the heating wire is filled with a filling material, the first end part and the second end part of the furnace core tube are sealed through a sealing material, the filling material and the sealing material are all prepared by mixing a liquid material and a solid material, the liquid material comprises a water-based high-temperature insulating coating capable of resisting high temperature of 1250 DEG C or above for a long time, and the solid material comprises sericite powder. The adopted filling material and sealing material have long-time high-temperature stability, the chemical and physical changes are not easy to occur, and the service life of the heating furnace is prolonged.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

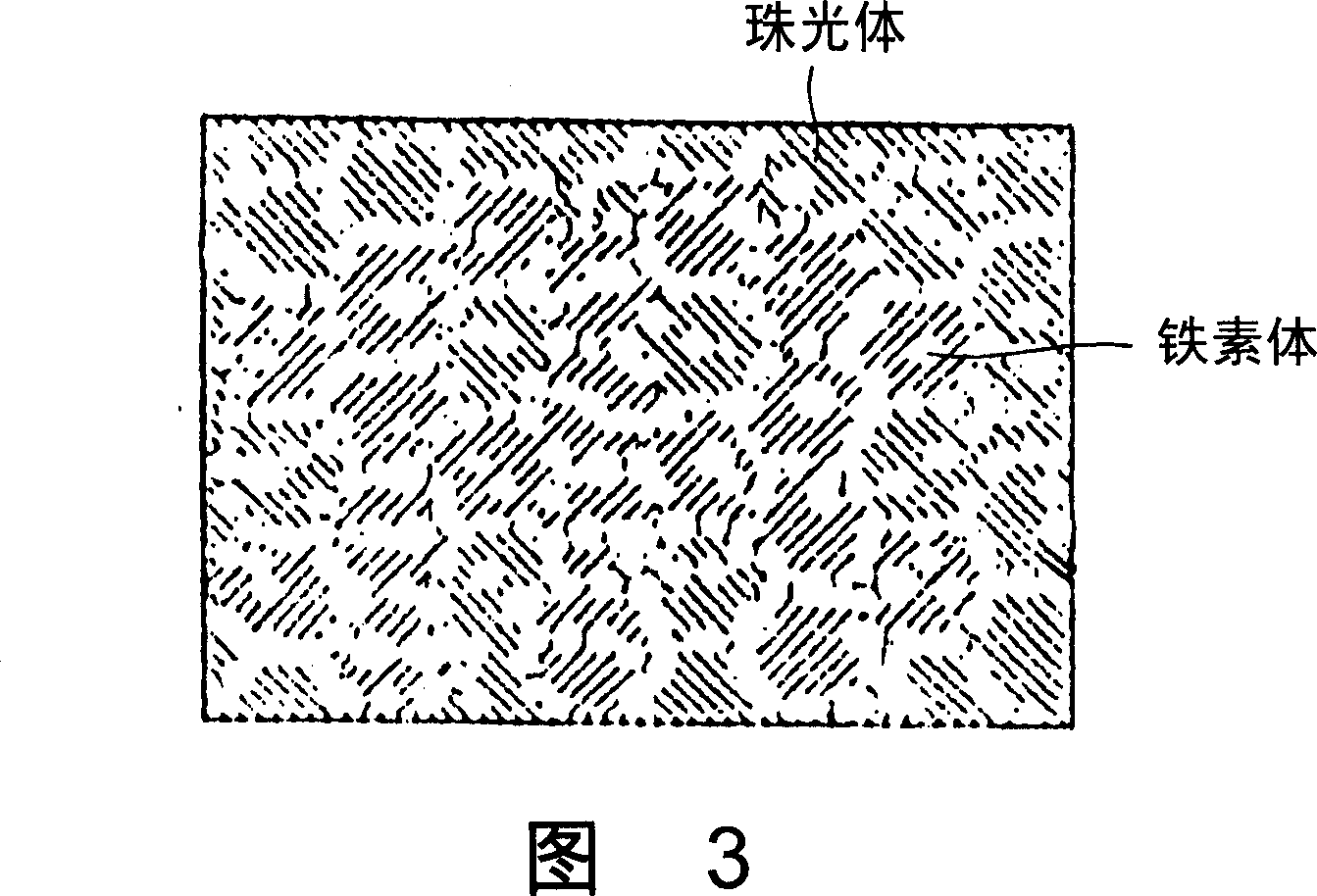

Bimetal spiral steel pipe and manufacturing method thereof

The invention discloses a bimetal spiral steel pipe and a manufacturing method thereof. The steel pipe comprises a pipe body, wherein the pipe body surface extends outwards to form a convex rib which is spirally arranged around the outer wall of the pipe body; the convex rib forms a groove with the pipe body surface and is provided with an auxiliary inner steel band capable of covering the groove notch; and a hollow cavity is formed between the groove and auxiliary inner steel band, and is filled with concrete. The convex rib on the outer wall of the pipe body and the pipe body are integrally formed without any welding seam, and thus, can resist the dynamic load fatigue when bearing the dynamic load. The pipe body inner wall is provided with the auxiliary inner steel band made of a specific metal material, thereby enhancing the corrosion resistance and wear resistance of the steel pipe, avoiding the fluid pollution, reducing the thickness of the steel pipe main body and lowering the material cost. The pipe can be used in the occasions for delivering water or other special media, such as supply or discharge of water, high-corrosivity media, media with higher requirements for purity, high-temperature media and the like, and greatly lowers the manufacturing cost.

Owner:南京大得钢管有限公司

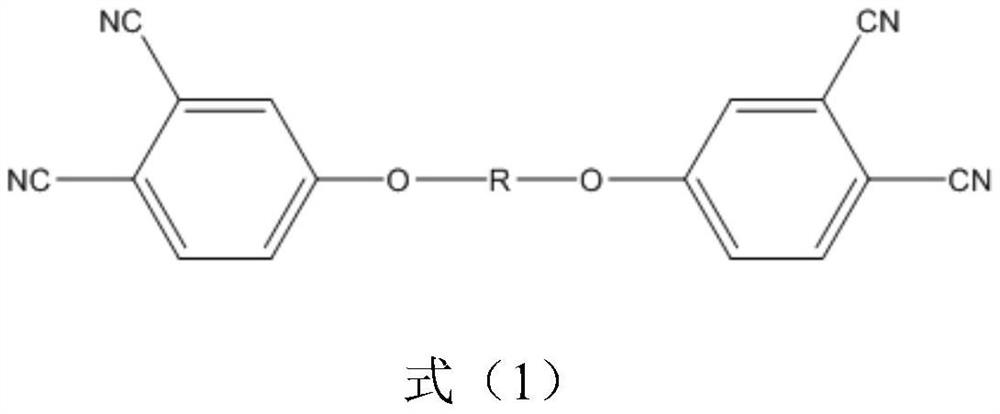

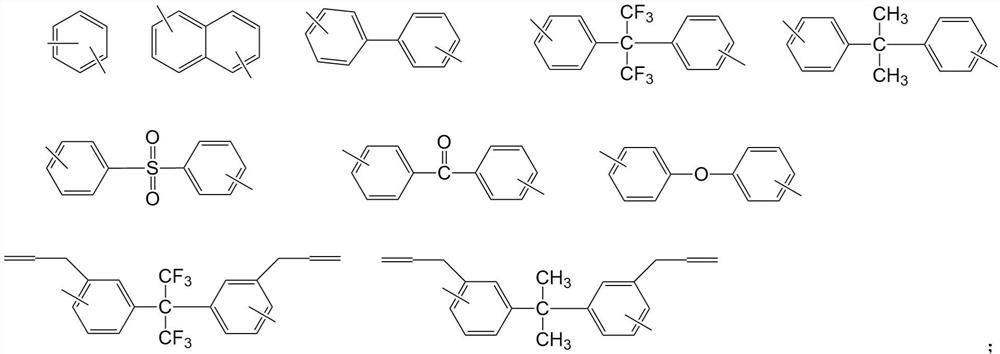

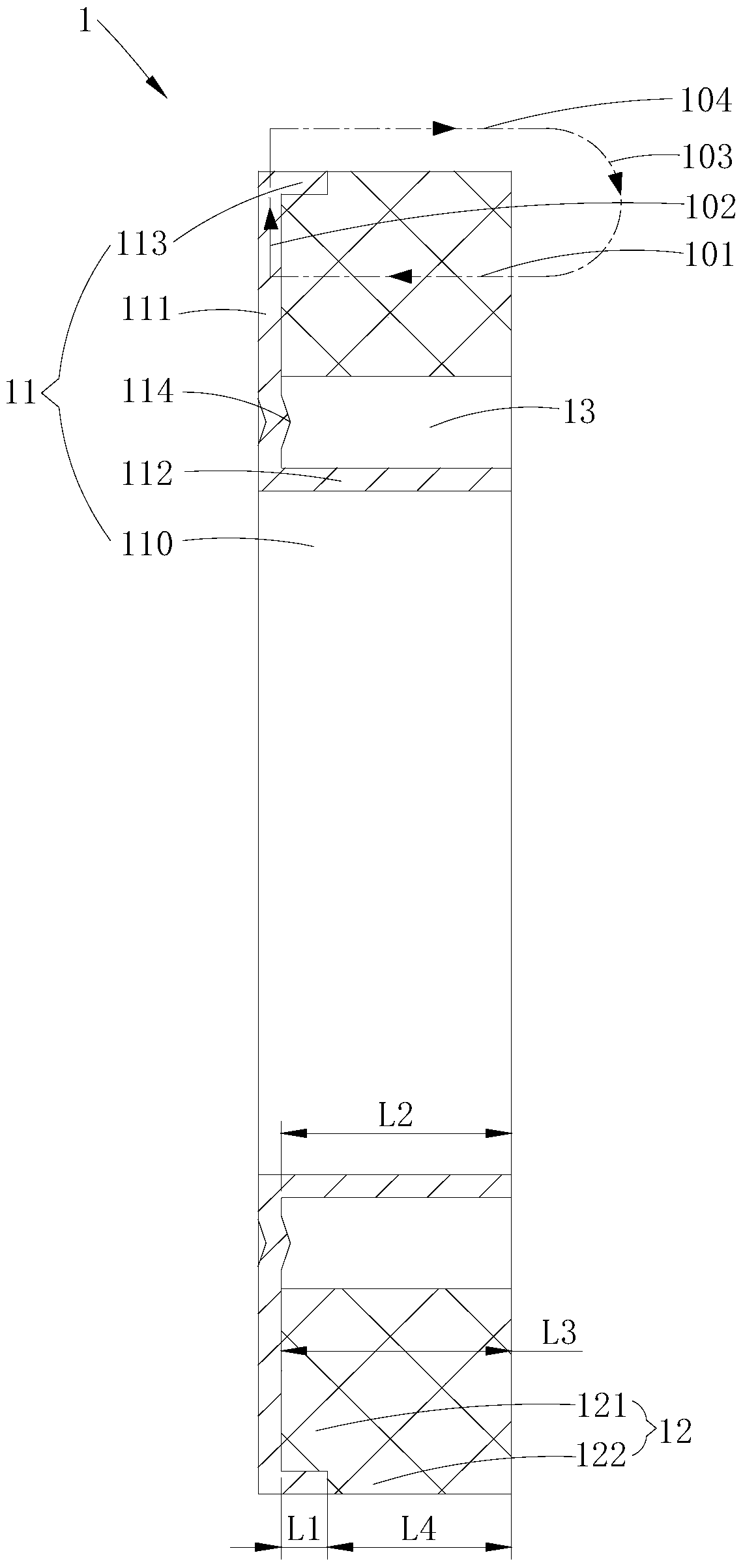

Phthalonitrile-based composite material and preparation method and application thereof

ActiveCN113263755ACoefficient of thermal expansion matchingAblation resistance mechanical propertiesSynthetic resin layered productsGlass/slag layered productsPhthalonitrileCompositermes

The invention discloses a phthalonitrile-based composite material and a preparation method and application thereof. The phthalonitrile-based composite material comprises an integrally formed structure consisting of a heat-proof layer and a structural layer coated with the heat-proof layer, or comprises an integrally formed sandwich structure formed by stacking heat-proof layers and a structural layer; in the sandwich structure, the heat-proof layers serve as an upper layer and a bottom layer, and the structural layer serves as a middle layer; and the heat-proof layers are selected from a phthalonitrile resin premix and / or a phthalonitrile resin prepreg, and the structural layer is selected from a phthalonitrile resin prepreg. The composite material is obtained through one-time mold pressing curing molding. The process complexity that a structure sample piece and a functional sample piece of the composite material are separately pressed and subjected to secondary forming is overcome, and a structure ablation integrated phthalonitrile composite material component which is resistant to ablation and excellent in mechanical property can be industrially produced; and the composite material can be widely applied to the aerospace technology.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method of refurbishing rotogravure cylinders, rotogravure cylinders and their use

ActiveUS9539844B2Improve adhesionNo risk of crackingPlate printingRotary pressesCopperProtection layer

The rotogravure cylinder comprising a rotary gravure base and thereon a copper engraving layer is refurbished to contain a zinc layer between a gravure base and a layer package suitable for engraving and printing. This layer package for instance comprises a metallic support layer, a copper engraving layer and suitably a protection layer. Deposition of the zinc layer may be tuned for thickness variation, in combination with deposition of the layer package in a fixed thickness.

Owner:ICR IOANNOU SA

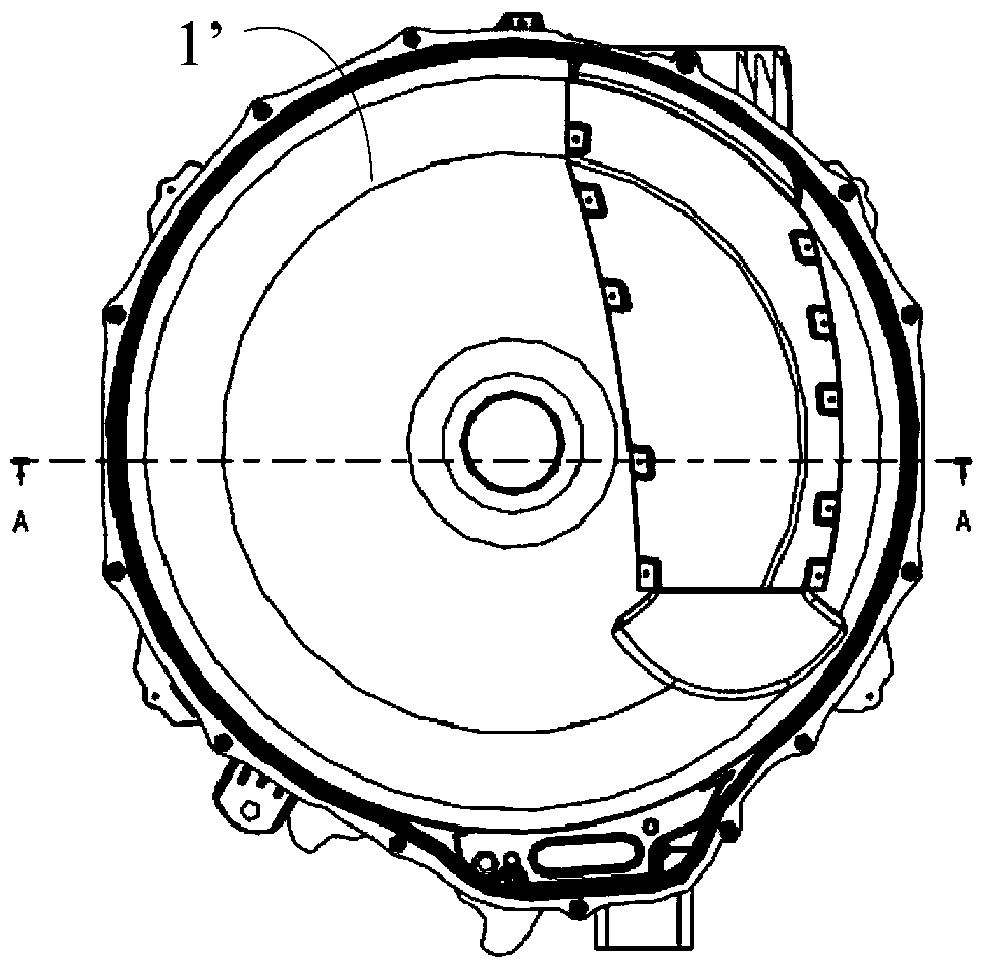

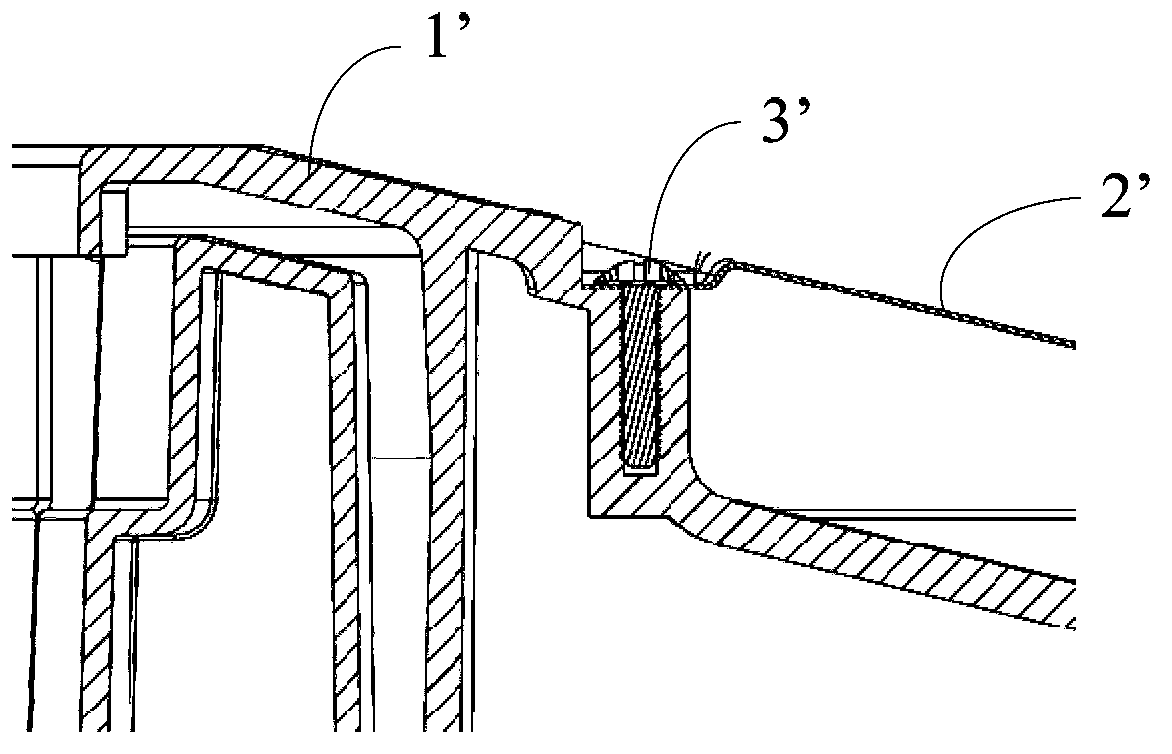

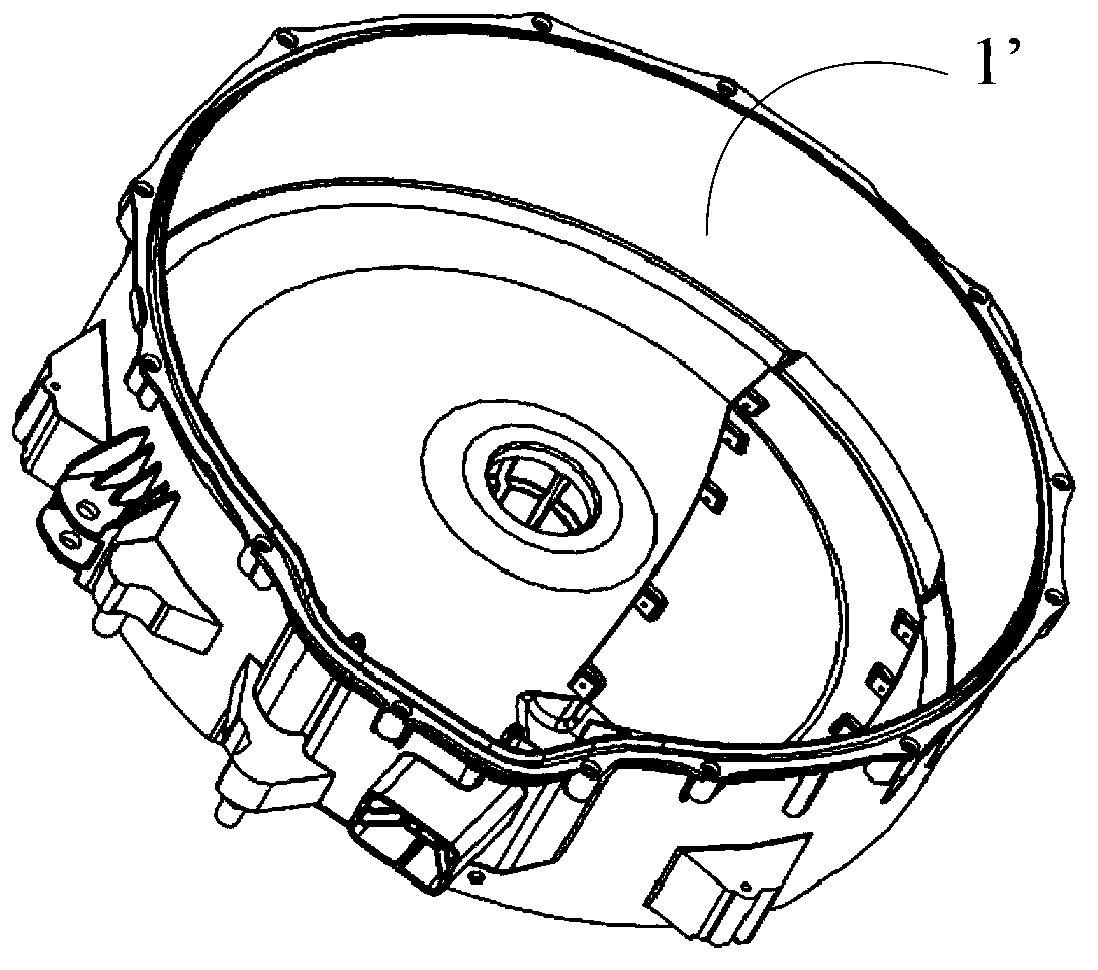

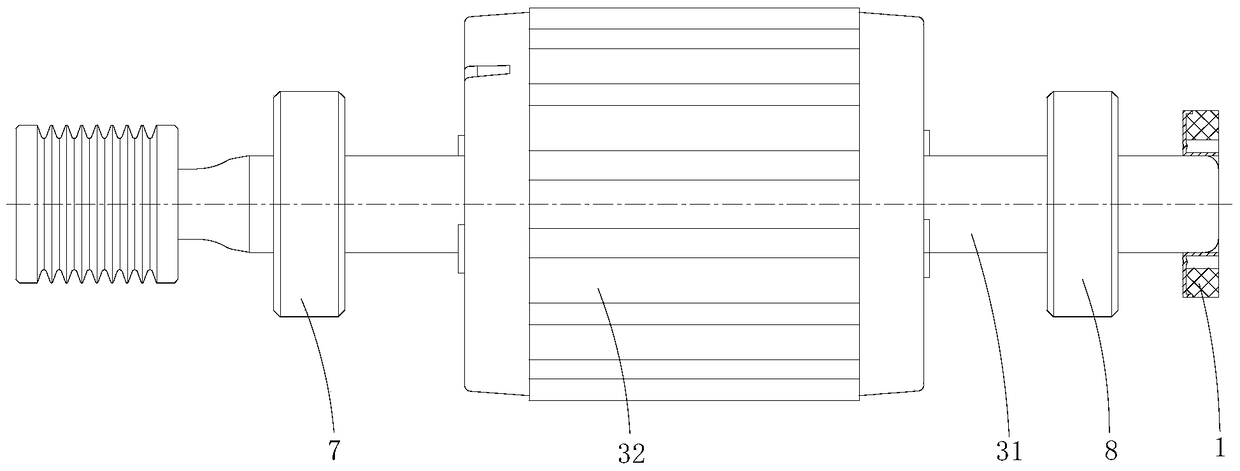

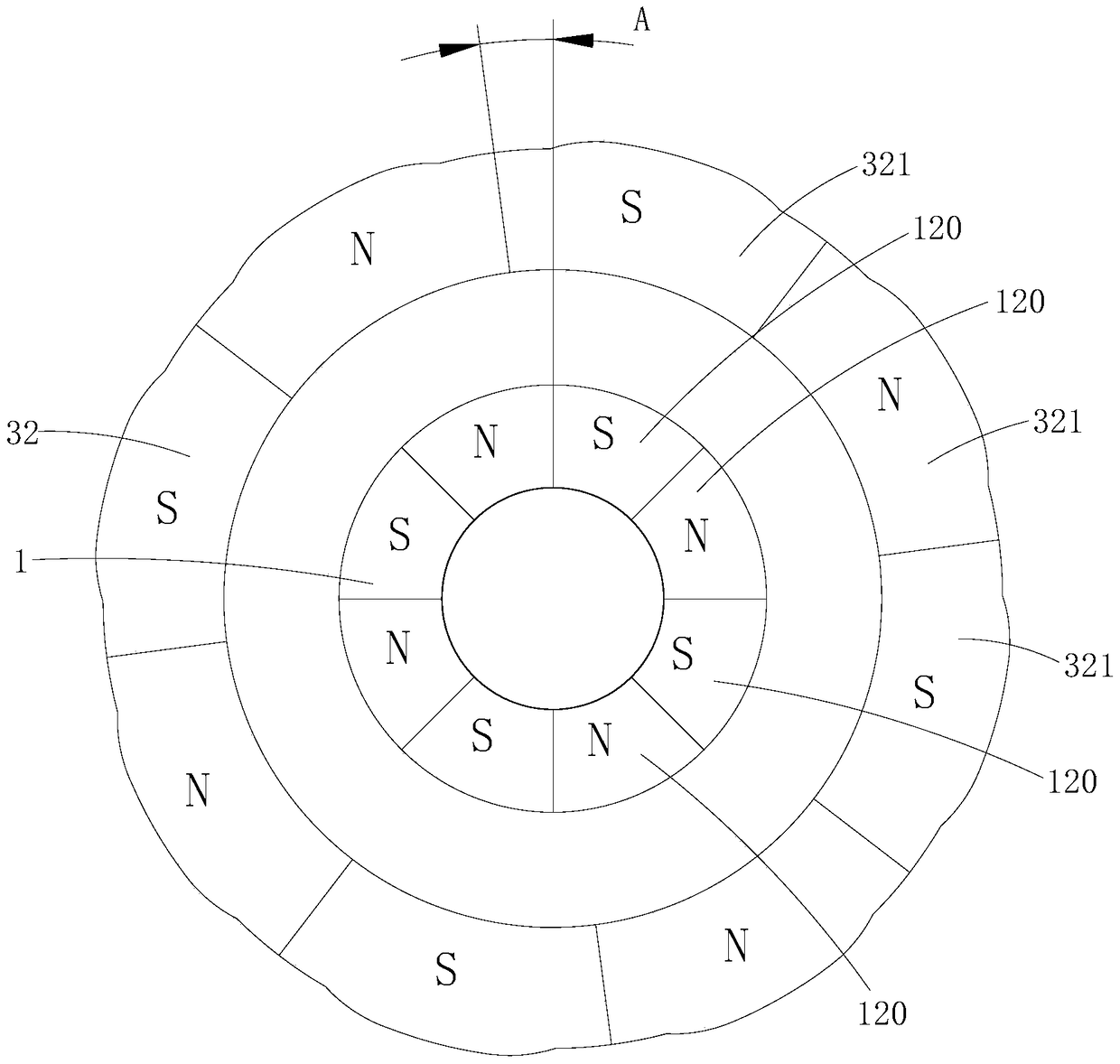

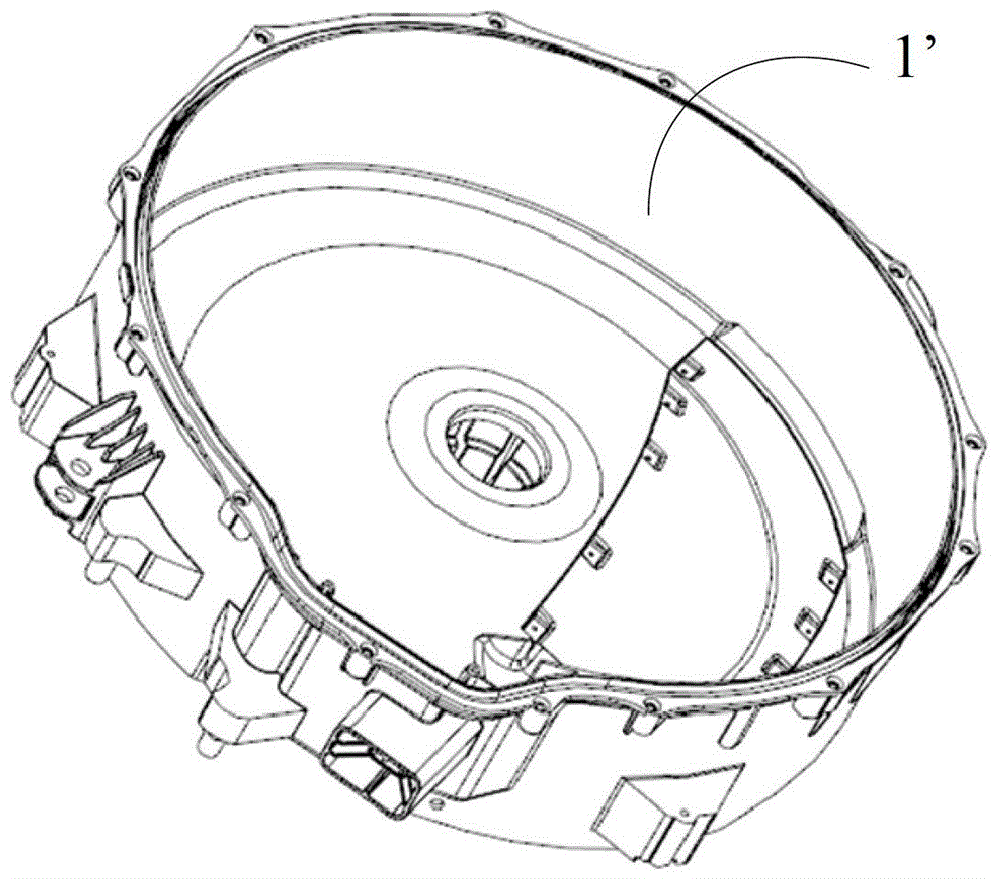

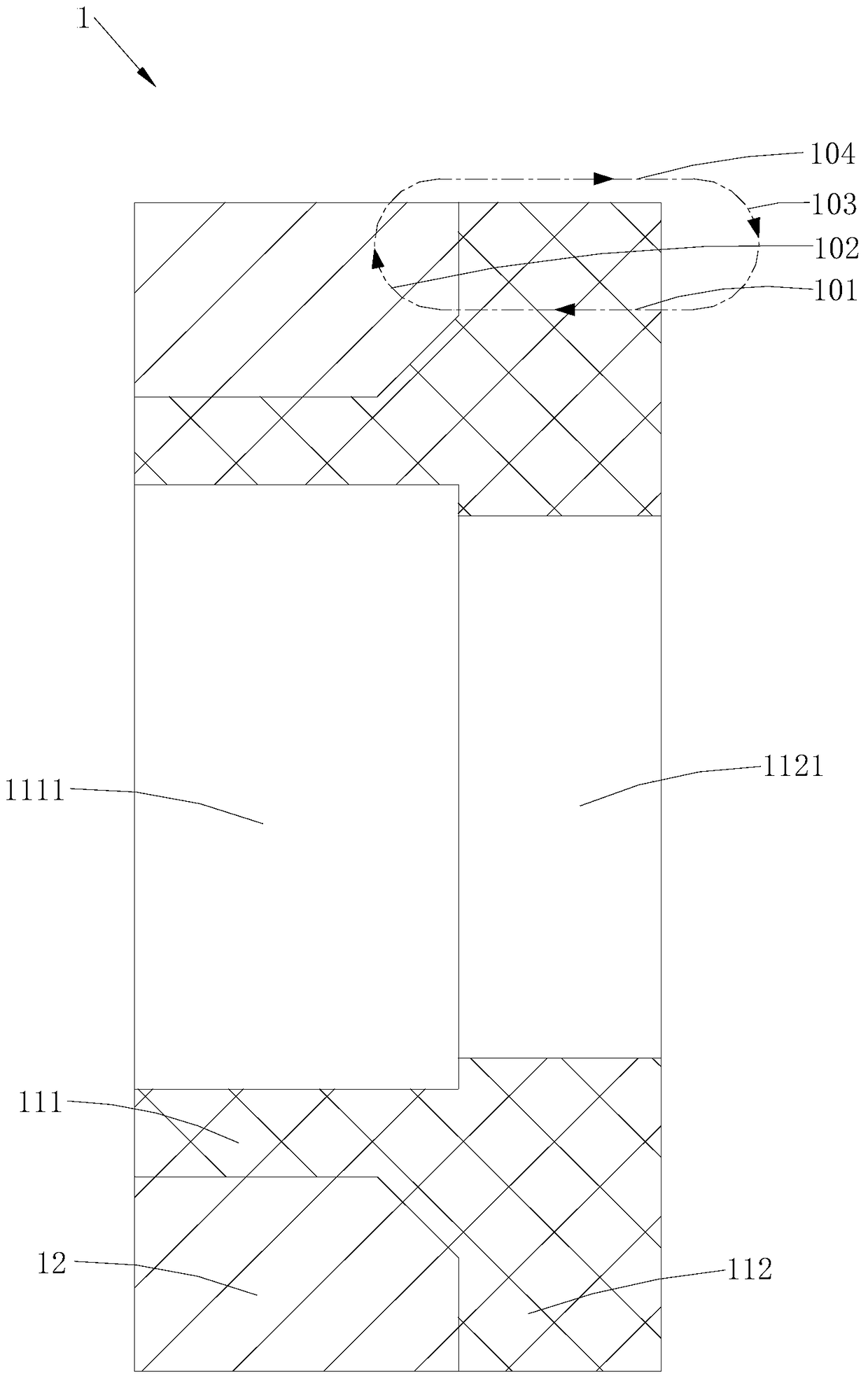

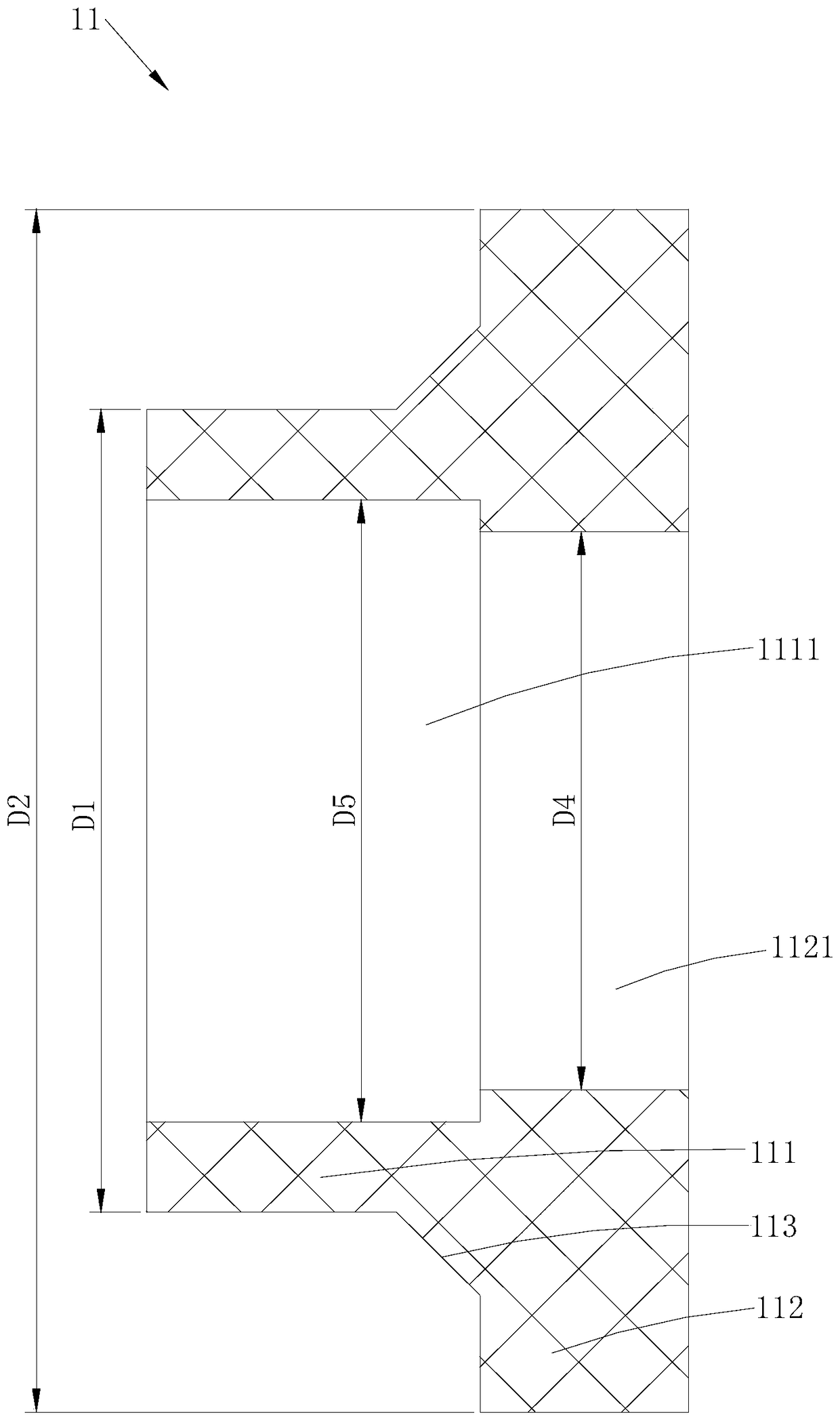

Motor magnetic ring, motor and washing machine

ActiveCN104979969BPrevent non-working situationsHigh bonding strengthPermanent magnetsStructural associationLaundry washing machineElectric machine

The invention belongs to the field of motors and particularly discloses a motor magnetic ring, a motor and a washing machine. The motor magnetic ring is composed of a hollow inner hole, a metal bracket fittingly matched with a rotating shaft, and a non-metallic magnetic ring formed on the metal bracket through the injection molding process. The metal bracket comprises a substrate, a sleeve convexly arranged at the middle part of the substrate, and an annular convex edge convexly arranged at the outer edge of the substrate. The hollow inner hole penetrates through the sleeve and the substrate. The non-metallic magnetic ring is formed on the annular convex edge and the substrate through the injection molding process. According to the technical scheme of the invention, the non-metallic magnetic ring and the rotating shaft do not directly match each other. Meanwhile, the non-metallic magnetic ring is formed on the annular convex edge and the substrate through the injection molding process. In this way, when the motor magnetic ring is to be installed onto the rotating shaft, no outwardly expanding stress is applied onto the non-metallic magnetic ring. Therefore, the non-metallic magnetic ring is free from cracking. During the rotating process of the rotating shaft, the centrifugal force applied onto the non-metallic magnetic ring is transferred onto the annular convex edge. As a result, the condition that the motor does not run due to the cracking / shedding state of the non-metallic magnetic ring is avoided.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Condenser cover installation structure

ActiveCN104074037BNo risk of crackingNo stress concentrationTextiles and paperLaundry driersStress concentrationEngineering

The invention discloses a cover plate mounting structure of a condenser. The cover plate mounting structure comprises a back drum, wherein a condenser cavity is formed in the back drum, and comprises a condenser cavity bottom wall, a plurality of condenser cavity side walls and a condenser cover plate positioned above the condenser cavity; a plurality of cover plate mounting parts are arranged at the periphery of the condenser cover plate; at least one of the condenser cavity side walls is provided with grooves parallel to the condenser cavity bottom wall; and the corresponding cover plate mounting parts are fixedly inserted in the grooves. The cover plate mounting structure of the condenser has the advantages of simple structure, simple installation and good positioning effect; and after the condenser cover plate is inserted, the high-frequency vibration stress of the back drum is absorbed by the inserted part, so that the stress concentration generated by such rigid fixed connection modes as screws is not caused, and the cracking risk of the condenser cover plate is not occurred.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

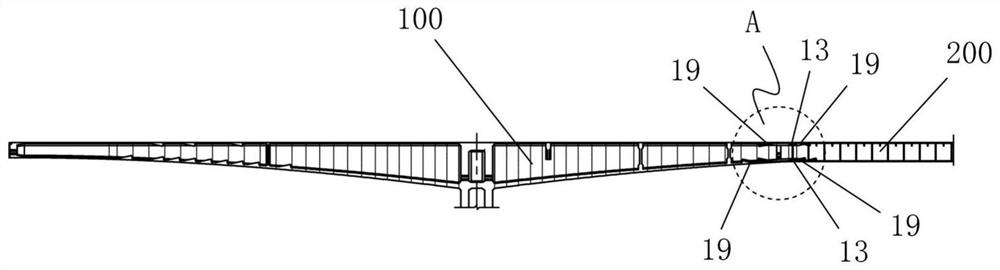

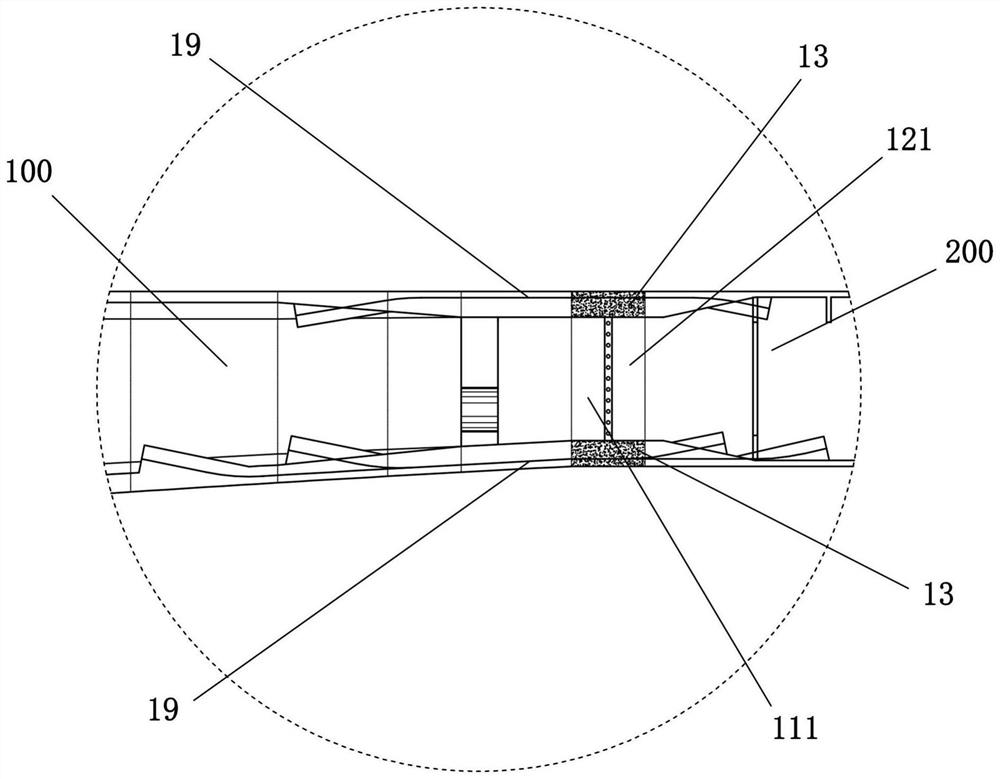

Construction method of bridge deck slab, bridge deck slab and bridge

PendingCN114753248ANo risk of crackingMake up for retractionCeramic shaping apparatusBridge structural detailsComposite structurePre stress

The invention discloses a bridge deck construction method, a bridge deck and a bridge, and relates to the field of design and construction of composite structure bridges. The bridge deck is a UHPC-NC bridge deck slab provided with two UHPC sections and one NC section, and the NC section is located between the two UHPC sections. In the manufacturing process of the UHPC-NC bridge deck slab, UHPC and NC are poured synchronously, so that the boundary of the two materials is properly fused and has no cracking risk, the problem that the UHPC-NC bridge deck slab is prone to cracking can be solved, the overall comfort of a bridge is improved, and the service life of the bridge is prolonged. In addition, the UHPC sections are located at the two ends of the UHPC-NC bridge deck slab, due to the fact that the strength of the UHPC sections is high, the problem of retraction of the prestressed tendons can be solved, and therefore the overall structural stability of the UHPC-NC bridge deck slab is guaranteed.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

Strengthening method for bimetal cylinder body spline of hydraulic plunger pump

InactiveCN112725567AShorten the processing cycleReduce manufacturing costFurnace typesHeat treatment furnacesTemperingEngineering

The invention discloses a strengthening method for a bimetal cylinder body spline of a hydraulic plunger pump, relates to a machining method of the bimetal cylinder body spline of the hydraulic plunger pump, and discloses the strengthening method for the bimetal cylinder body spline of the hydraulic plunger pump. Strengthening treatment is performed, specifically, when a cylinder body blank is slowly cooled to 850 DEG C, quenching liquid is adopted for rapid cooling, after the temperature of the cylinder body blank is lower than 200 DEG C, the cylinder body blank stays in a cooling area for a period of time; and tempering treatment and discharging are performed, specifically, different tempering temperatures are selected according to the hardness requirement of a part for tempering, and discharging is performed after heat preservation is performed for a certain time. After a spline of the cylinder body is subjected to strengthening treatment, the subsequent nitriding treatment or medium-high frequency treatment procedure of the cylinder body can be replaced, the machining period of a cylinder body finished product is shortened, and procedures are reduced. The spline is pulled after the spline area of the cylinder body is subjected to strengthening treatment, so that the problems of spline deformation and spline cracking in the nitriding or medium-high frequency process are solved. In addition, after the spline area of the cylinder body is subjected to strengthening treatment, good comprehensive performance is achieved, and better impact resistance is achieved.

Owner:六安鑫成材料科技有限公司

Grey gold alloy

ActiveUS10458002B2Without reducing deformability propertyImprove grey gold alloysBraceletsWrist-watch strapsChromium freeIndium

A grey gold alloy which is nickel-free, cobalt-free, iron-free, silver-free, zirconium-free, niobium-free, chromium-free, indium-free, gallium-free and manganese-free and includes, expressed in weight percent, from 75.0 to 76.5% of Au, from 15 to 23% of Pd, from 1 to 7% of Cu, and from 0 to 5% of at least one of the alloying elements Ir, Ru, B and Re, the respective percentages of all the elements of the alloy adding up to 100%.

Owner:MONTRES BREGUET

Motor magnetic ring, motor and washing machine

ActiveCN104979968BPrevent non-working situationsNo risk of crackingPermanent magnetsStructural associationLaundry washing machineElectric machinery

The invention is applicable to the field of motors, and discloses a motor magnetic ring, a motor and a washing machine, wherein the motor magnetic ring includes a non-metallic magnetic ring sleeved on a rotating shaft and a metal sleeve sleeved on the non-metallic magnetic ring, and the non-metallic magnetic ring It includes a mounting part for matching with the rotating shaft sleeve and a magnetic ring working part located at one axial end of the mounting part and used to generate a magnetic field for detection by the control circuit board. The metal sleeve is sleeved on the mounting part. In the present invention, the non-metallic magnetic ring is axially divided into two parts: the installation part and the magnetic ring working part, and the installation of the non-metallic magnetic ring on the rotating shaft is realized through the installation part, and the magnetic field is generated by the magnetic ring working part for detection by the control circuit board In this way, the position of the magnetic poles of the rotor can be determined; at the same time, by installing a metal sleeve outside the installation part, there is no risk of cracking at the installation part of the non-metallic magnetic ring and the working part of the magnetic ring, thereby preventing the damage caused by the non-metallic magnetic ring. If the ring breaks or falls off, the motor will not work.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com