Drawing stamping die and hyperactive drawing technology thereof

A stamping die and process technology, which is applied in the field of stamping and forming dies for automobile panels and their drawing processes, can solve problems such as affecting the mold manufacturing cycle, increasing development costs, reducing the quality of automobile panel products, and improving the level of mold design and manufacturing. , Prevent cracking, save the effect of mold development investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

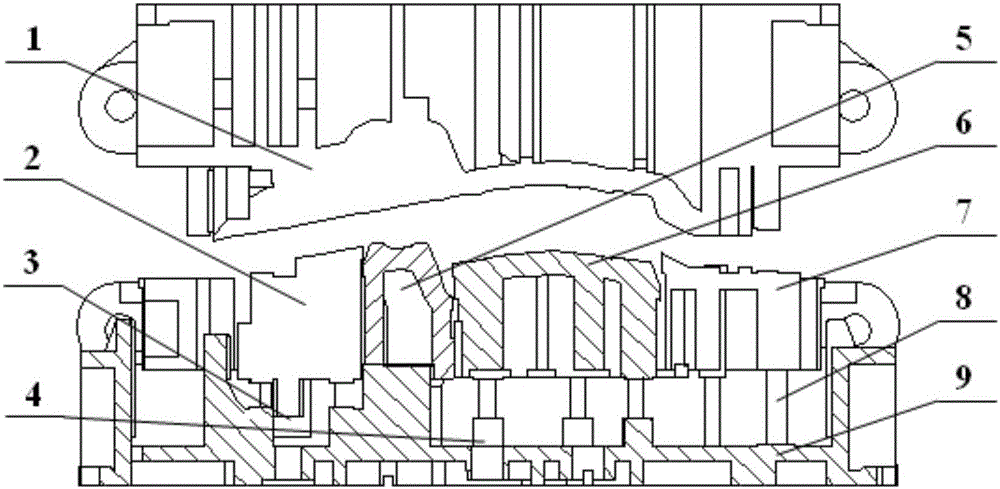

[0032] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

[0033] Such as figure 1 As shown, the present invention specifically relates to a drawing stamping die, including an upper die 1 and a lower die base 9, and the lower die base 9 is provided with a step-by-step drawing forming process from shallow to deep through cooperation with the upper die 1. The multi-action drawing forming mechanism. Through the multi-action drawing forming mechanism, when the pressed product is drawn and stamped with different drawing depths, it can be drawn and formed step by step from shallow to deep, so as to avoid insufficient forming and product quality problems.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com