Steel-concrete combined structure pipeline with spiral reinforcing ring and manufacturing method of steel-concrete combined structure pipeline

A technology of combined structure and production method, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of hidden danger of cracking, large dependence, thickening of pipe walls, etc., to enhance the overall structural strength and reduce stress. Concentrate the point, enhance the effect of hoop strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

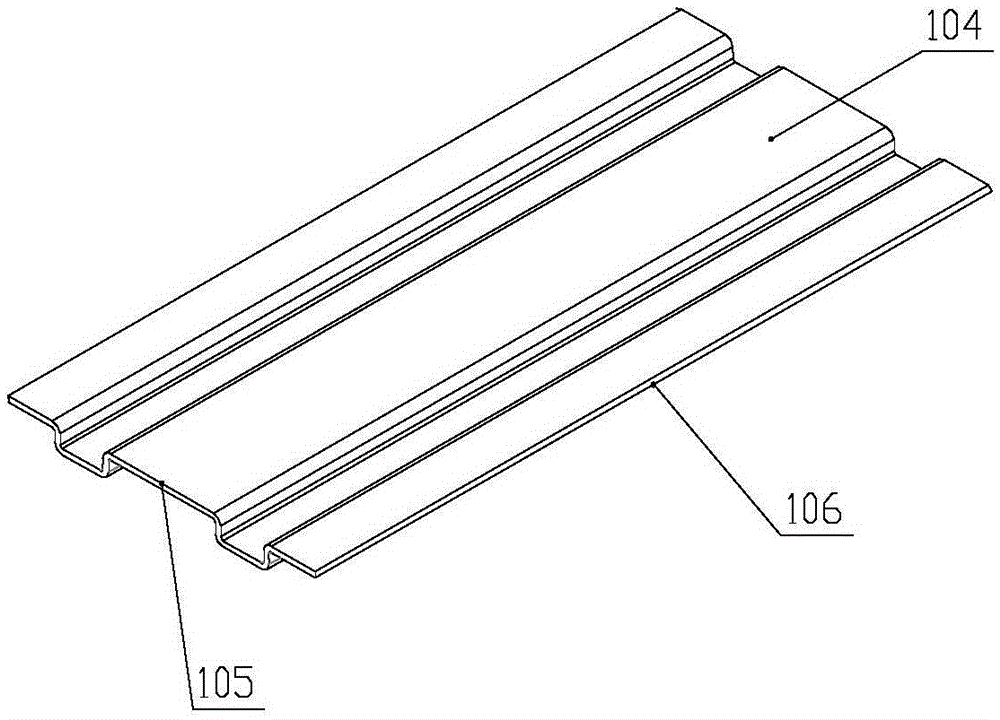

[0067] Embodiment 1 The implementation scheme of the steel-concrete composite structure pipeline with the spiral reinforcement ring made with the inline plugging steel strip

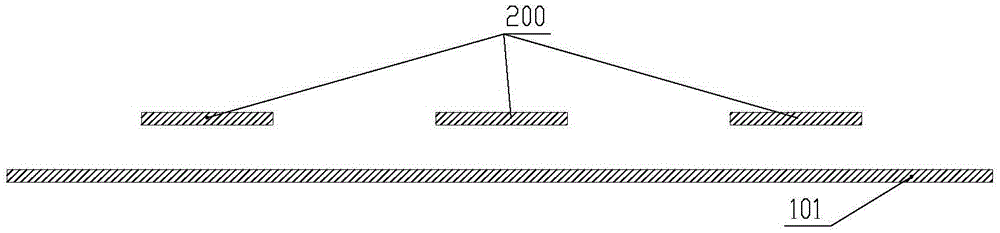

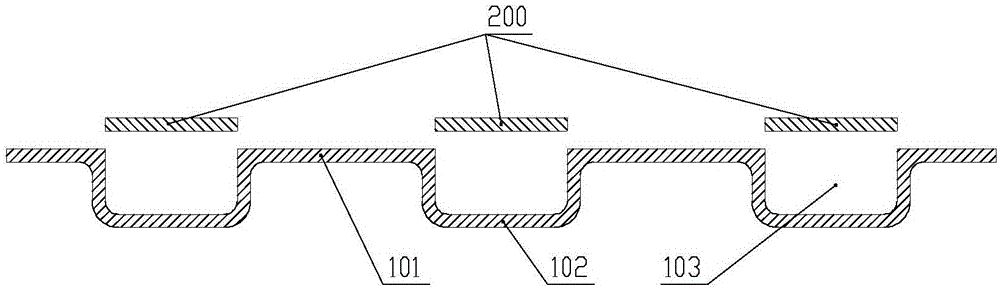

[0068] Adjust the forming angle of the spiral forming machine to an appropriate value according to the diameter of the produced spiral welded steel pipe. The main steel strip and the plugging steel strip, the quantity of the plugging steel strip is determined according to the actual production situation, and after unwinding, leveling, trimming and other processes, they are placed according to the production location, such as figure 1 As shown; the main steel belt is placed on the unwinding machine below the sealing steel belt, the main steel belt is processed into continuous ribs by the forming mechanism, and the sealing steel belt is processed by the forming mechanism into a sealing steel belt with a straight end face ,Such as image 3 As shown; under the action of the pressure roller, the plugging ste...

Embodiment 2

[0069] Embodiment 2 The embodiment scheme of the steel-concrete composite structure pipe with spiral reinforcement ring made of short groove type plugging steel strip

[0070] Adjust the forming angle of the spiral forming machine to an appropriate value according to the diameter of the produced spiral welded steel pipe. The main steel strip and the plugging steel strip, the quantity of the plugging steel strip is determined according to the actual production situation, and after unwinding, leveling, trimming and other processes, they are placed according to the production location, such as figure 1 As shown; the main steel strip is placed on the unwinding machine below the plugging steel strip, the main steel strip is processed into continuous convex ribs by the forming mechanism, and the plugging steel strip is processed by the forming mechanism into a short-grooved plugging steel strip Such as Figure 4 As shown; under the action of the pressure roller, the plugging steel ...

Embodiment 3

[0071] Example 3 The implementation scheme of the steel-concrete composite structure pipeline with spiral reinforcement ring made of long groove type plugging steel strip

[0072] Adjust the forming angle of the spiral forming machine to an appropriate value according to the diameter of the produced spiral welded steel pipe. The main steel strip and the plugging steel strip, the quantity of the plugging steel strip is determined according to the actual production situation, and after unwinding, leveling, trimming and other processes, they are placed according to the production location, such as figure 1 As shown; the main steel strip is placed on the unwinding machine below the plugging steel strip, the main steel strip is processed into continuous convex ribs by the forming mechanism, and the plugging steel strip is processed by the forming mechanism into a plugging steel strip whose end face is a long groove ;Such as Figure 5 As shown; under the action of the pressure roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com