Bearing device for wheel

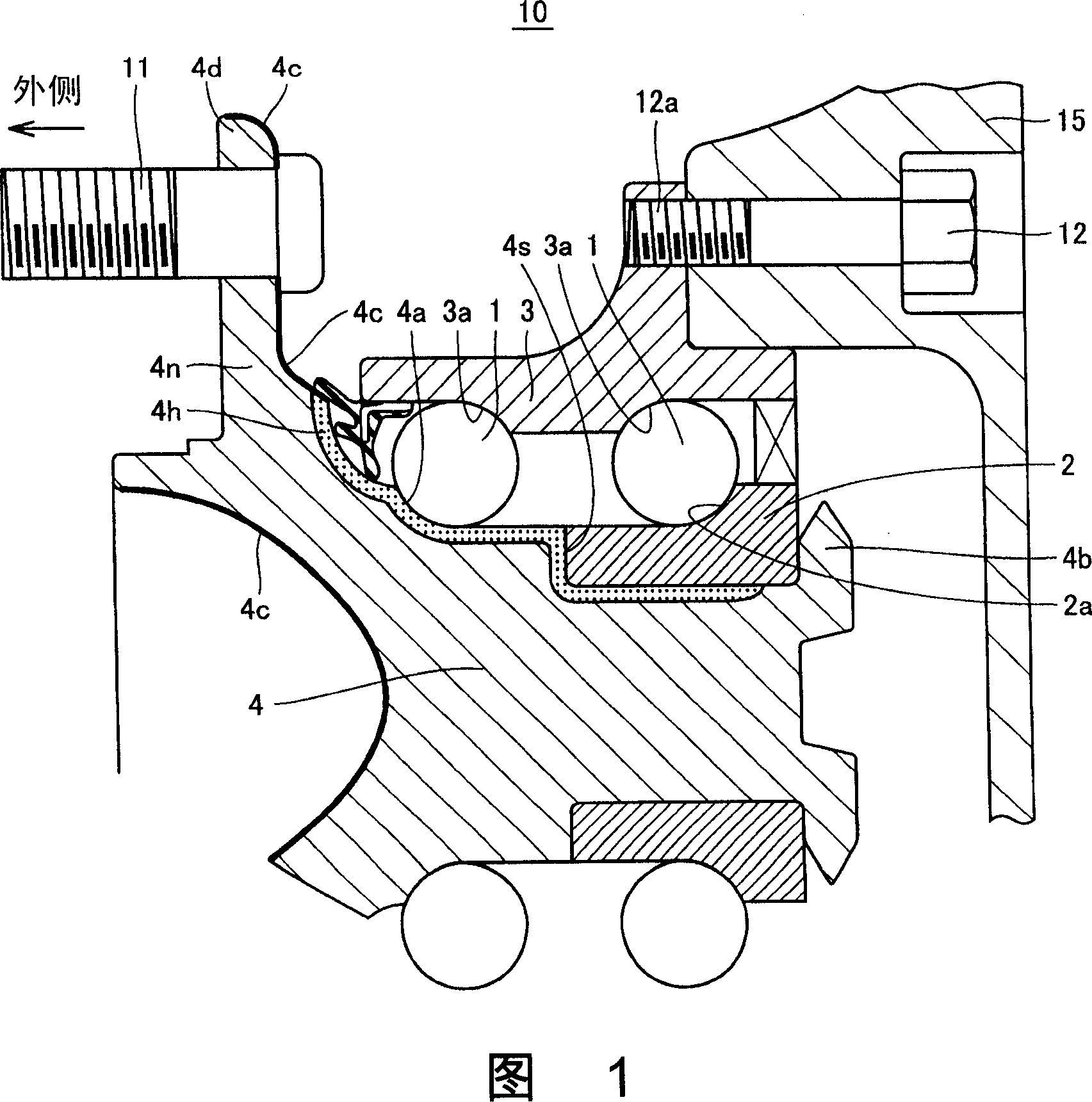

一种轴承装置、车轮的技术,应用在轴承、车轴、车轮等方向,能够解决难轻量化、断裂、耐久性下降等问题,达到质量容易管理的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The results of actual studies on the mechanical properties and microstructure will be described below. Table 1 shows the composition of steel materials used in Example 1 of the present invention. The steels in the examples of the present invention are improved on the basis of S53C, and the characteristics of the composition are as follows. The characteristic point in Examples 3 and 4 of the present invention is that V and the like are contained in addition to low Mn.

[0059] (Example 1 of the present invention) S53C corresponds to +V: 0.08% by mass

[0060] (Example 2 of the present invention) S53C corresponds to +Ti0.07% by mass

[0061] (Example 3 of the present invention) Low Mn (0.25% by mass)+V: 0.09% by mass

[0062] (Example 4 of the present invention) Low Mn (0.24 mass%)+V: 0.04 mass%+Ti0.06 mass%

Embodiment 2

[0084] Next, a durability test was performed using the steel used for the manufacture of the hub ring and the outer ring of the wheel bearing device. This test can be called a test for verifying the life of repeated stress from the hub bolt hole eccentric position of the hub rim against the root of the flange or the arm. The steel used as an example of the present invention contains 0.6% by mass of C, 0.57% by mass of Si, 0.8% by mass of Mn, 0.015% by mass of P, 0.017% by mass of S, 0.25% by mass of Cr and 0.15% by mass of V. mass % of steel. As the steel used in the comparative example, commercially available carbon steel S53C for machine structures specified in JIS G4051 was used.

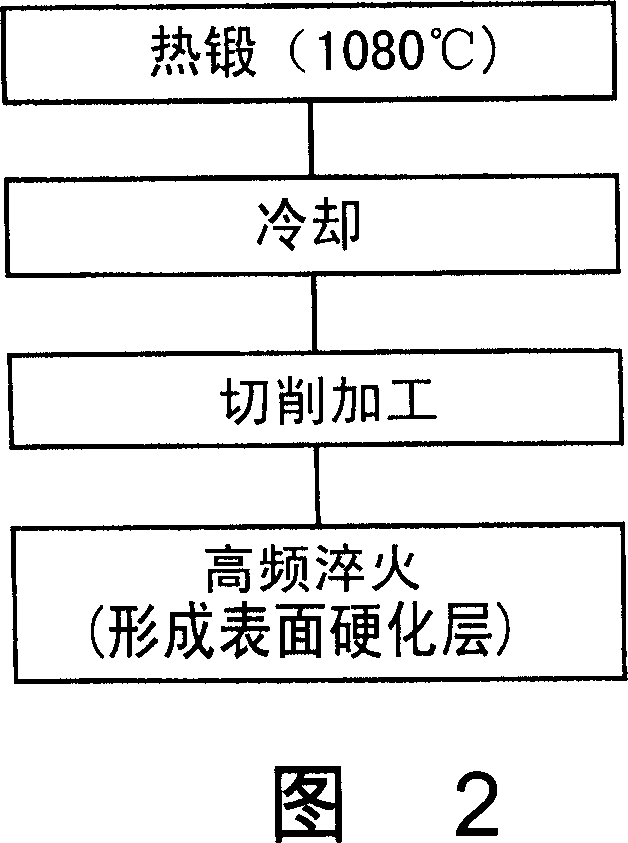

[0085] As shown in FIG. 2 , the steel materials of the above-mentioned examples of the present invention and the steel materials of the comparative example were hot forged to produce cooled test pieces, and neither of them was normalized.

[0086] In the test, the shrinkage workability was eval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com