Cover plate mounting structure of condenser

A technology of installation structure and condenser, which is applied in the direction of washing equipment, textiles and papermaking, household appliances, etc., can solve the problems of shedding, safety hazards, stress concentration, etc., and achieve the effect of simple installation, simple installation structure and good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

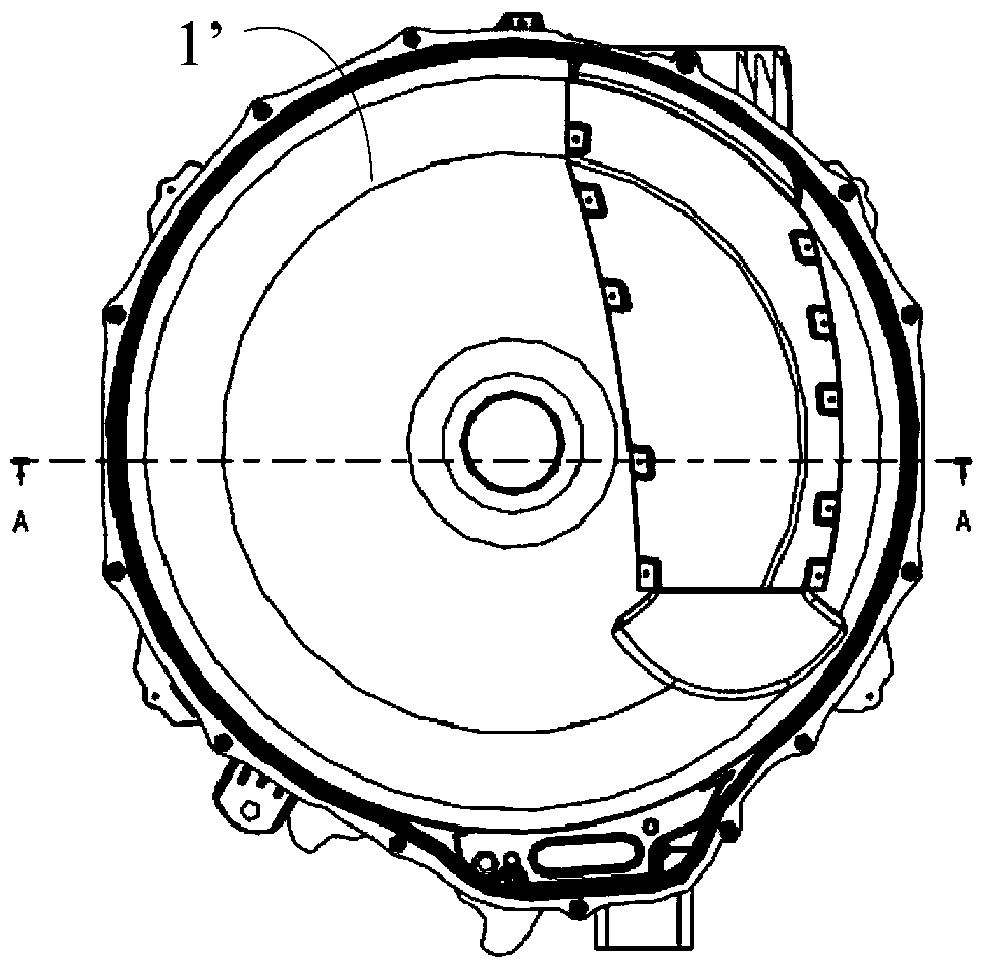

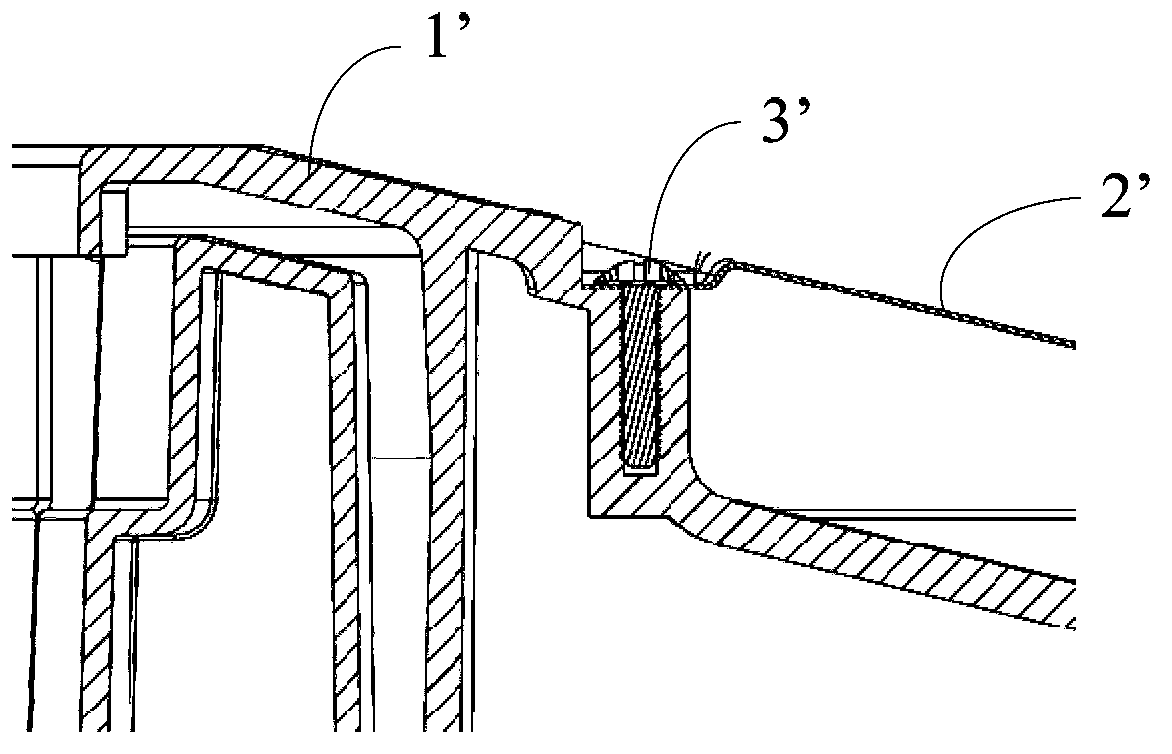

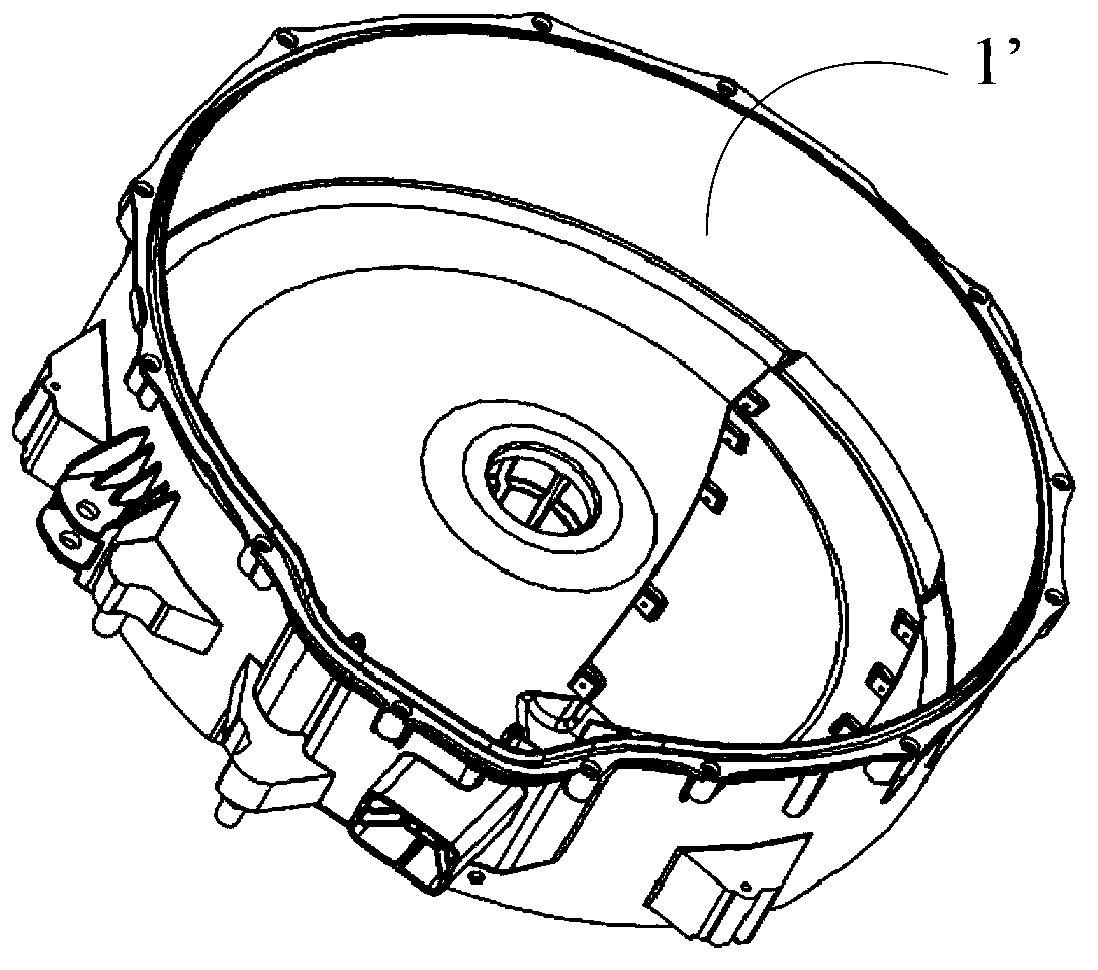

[0031] The invention discloses a condenser cover plate installation structure, which comprises a rear bucket, and a condenser chamber is arranged in the rear bucket, and the condenser chamber includes a bottom wall of the condenser chamber, a plurality of side walls of the condenser chamber and a The condenser cover above the condenser chamber, the periphery of the condenser cover includes several cover installation parts, at least one side wall of the condenser chamber is provided with a groove parallel to the bottom wall of the condenser chamber, and the corresponding cover is installed The part is fixedly plugged in the groove.

[0032] Further, the side wall of the condenser chamber includes a first side wall and a second side wall correspondingly arranged on the same side of the center of the rear tub, and the distance between the first side wall and the center of the rear tub is smaller than the distance between the second side wall and the center of the rear tub. distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com