Bimetal spiral steel pipe and manufacturing method thereof

A technology of spiral steel pipe and manufacturing method, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of increasing the rigidity of the pipe body, hidden dangers of cracking, cracking of welds, etc., to increase the circumferential moment of inertia, reduce Corrosion, the effect of a large increase in cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: The inner wall completely covers the pipe body with the auxiliary inner steel belt

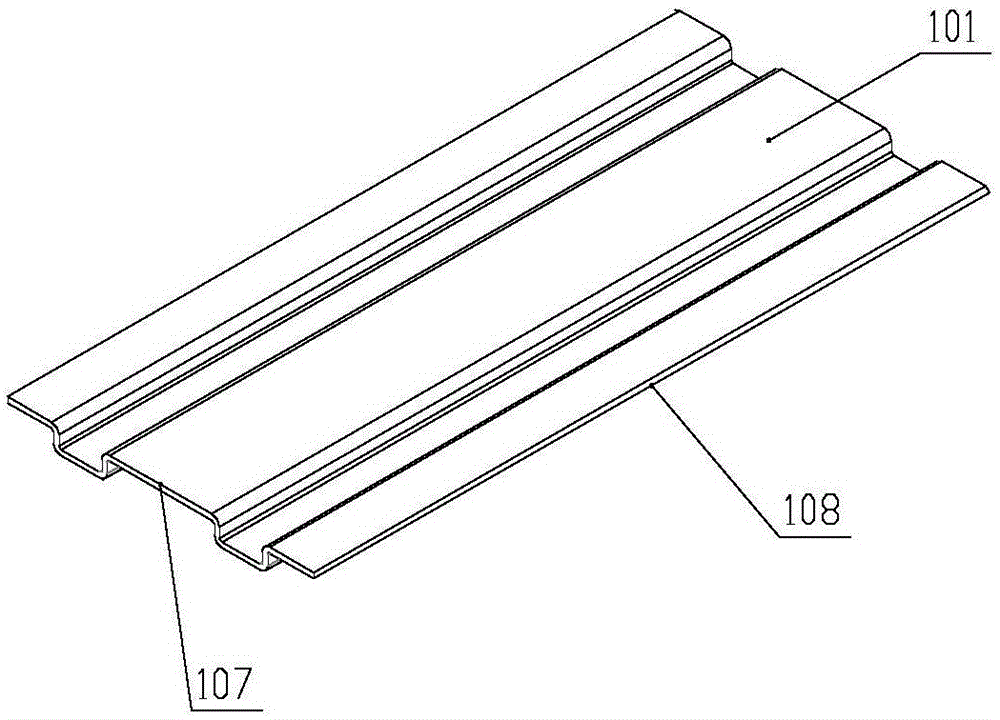

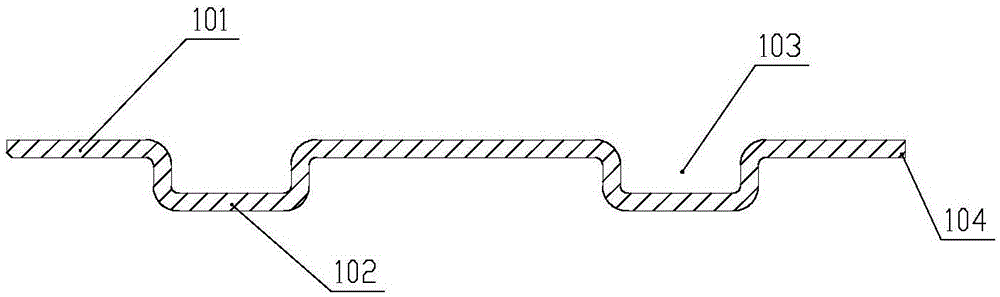

[0059] First, adjust the spiral tube forming machine to a suitable forming angle according to the diameter of the spiral welded steel pipe to be produced. Secondly, after the main steel strip 101 is derusted and shot-peened, it is rolled into a cross-sectional shape with a certain spacing and regular downward protrusions (number and size are set according to actual conditions) through a forming unit. Referred to as "beads 102", correspondingly, grooves 103 are formed above the ribs 102, and then welding slits 104 are processed on both sides of the main steel strip, such as Figure 1-3 shown. Then, a certain amount of plugging steel strips 500 are laid on the notch position of the groove 103 after the main steel strips have been formed, and the two are welded together to form a closed hollow cavity 300, such as Figure 4 shown. On the upper surface of the main steel strip 1...

Embodiment 2

[0060] Example 2: The inner wall partially covers the pipe body with the auxiliary inner steel belt

[0061] First, adjust the spiral tube forming machine to a suitable forming angle according to the diameter of the spiral welded steel pipe to be produced. Secondly, after the main steel strip 101 is derusted and shot-peened, it is rolled into a cross-sectional shape with a certain spacing and regular downward protrusions (number and size are set according to actual conditions) through a forming unit. It is called "bead 102", correspondingly, a groove 103 is formed above the rib 102, and then welding cutouts 104 are processed on both sides of the main steel strip. Next, a certain number of plugging steel strips 500 are laid on the notch position of the formed groove 103 of the main steel strip, and the two are welded together to form a closed hollow cavity 300, thus obtaining a composite steel strip. The composite steel strip formed above is sent into the rolling mechanism 700...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com