Phthalonitrile-based composite material and preparation method and application thereof

A technology of phthalonitrile-based and phthalonitrile resins, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problem of complex secondary processing and secondary molding processes, which are not conducive to Promote the use of other issues to achieve the effect of matching the mechanical properties of ablation resistance and thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Phthalonitrile resin prepreg, which is made of glue by mixing phthalonitrile resin and acetone at a weight ratio of 100:150. The viscosity of the glue is about 800mPa.s, and then the glue is mixed evenly and coated Cover on 120 parts of glass fiber plain weave cloth (brand SW-280), the number of times of brushing is 2 times, and fully air until the weight content of acetone drops below 4%, to obtain the phthalonitrile resin glass fiber prepreg.

[0067] When preparing another prepreg, mix the above-mentioned glue solution evenly and apply it on 120 parts of high-silica fiber plain weave cloth. The number of times of brushing is 2 times, and it is fully aired until the weight content of acetone drops below 4%. Phthalonitrile resin high silica fiber plain weave prepreg.

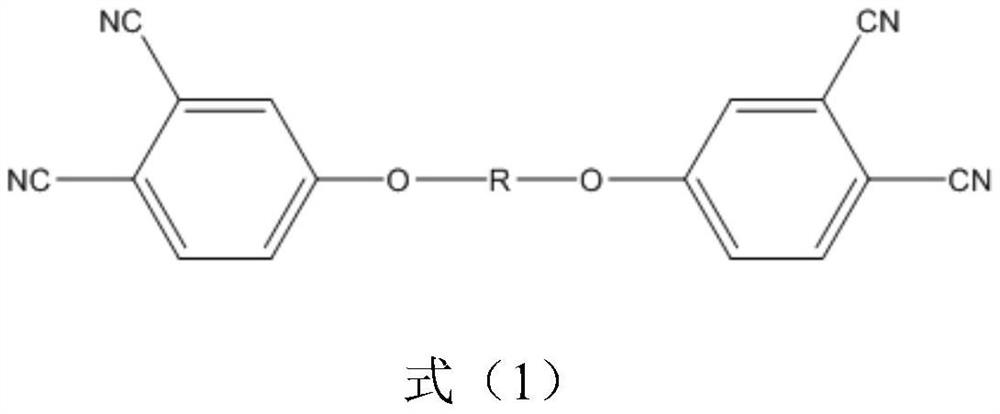

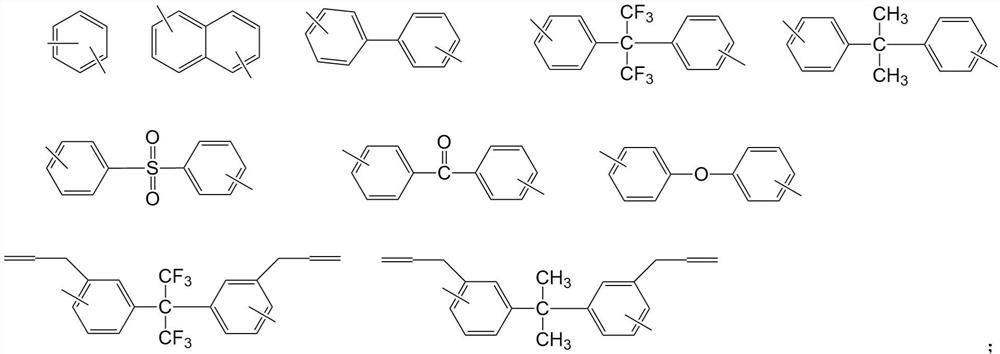

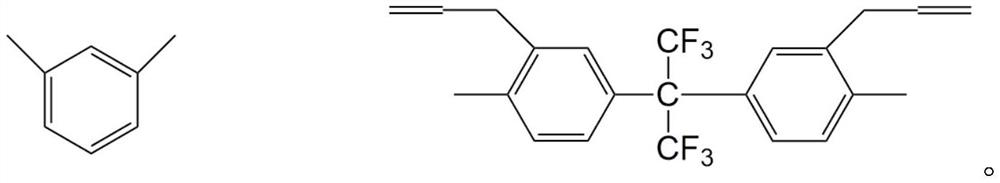

[0068] Among them, the phthalonitrile resin glass fiber prepreg is the same as the phthalonitrile resin in the phthalonitrile resin high-silica fiber plain cloth prepreg, which consists of phthalonitrile...

Embodiment 2

[0077] Phthalonitrile resin prepreg, which is made of glue by mixing phthalonitrile resin and acetone at a weight ratio of 100:185. The viscosity of the glue is about 900mPa.s, and then the glue is mixed evenly and coated Coating on 12 parts of T700 carbon fiber, the number of times of brushing is 2 times, and fully airing until the weight content of acetone drops below 4%, to obtain a phthalonitrile resin prepreg.

[0078] Phthalonitrile resin premix, which is made of glue by mixing phthalonitrile resin and acetone in a weight ratio of 100:160, the viscosity of the glue is about 800mPa.s, and then 120 parts of chopped high The silicone fiber and the mixed glue solution are poured into a mixer, mixed evenly, spread out and left standing until the acetone volatilizes until the weight content is less than 4%, and the phthalonitrile resin premix is obtained.

[0079] Wherein, the phthalonitrile resin prepreg is the same as the phthalonitrile resin in the phthalonitrile resin pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire ablation rate | aaaaa | aaaaa |

| Mass ablation rate | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com