Tungsten/silicon nitride/tungsten symmetrical laminated gradient composite material as well as rapid preparation method and application thereof

A composite material and layered technology, which is applied in the field of W/Si3N4/W symmetrical layered gradient composite material and its rapid preparation, can solve the problems of high sintering temperature, low strength and poor air tightness in the sintering process. Excellent high temperature mechanical properties, reducing residual internal stress, and the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

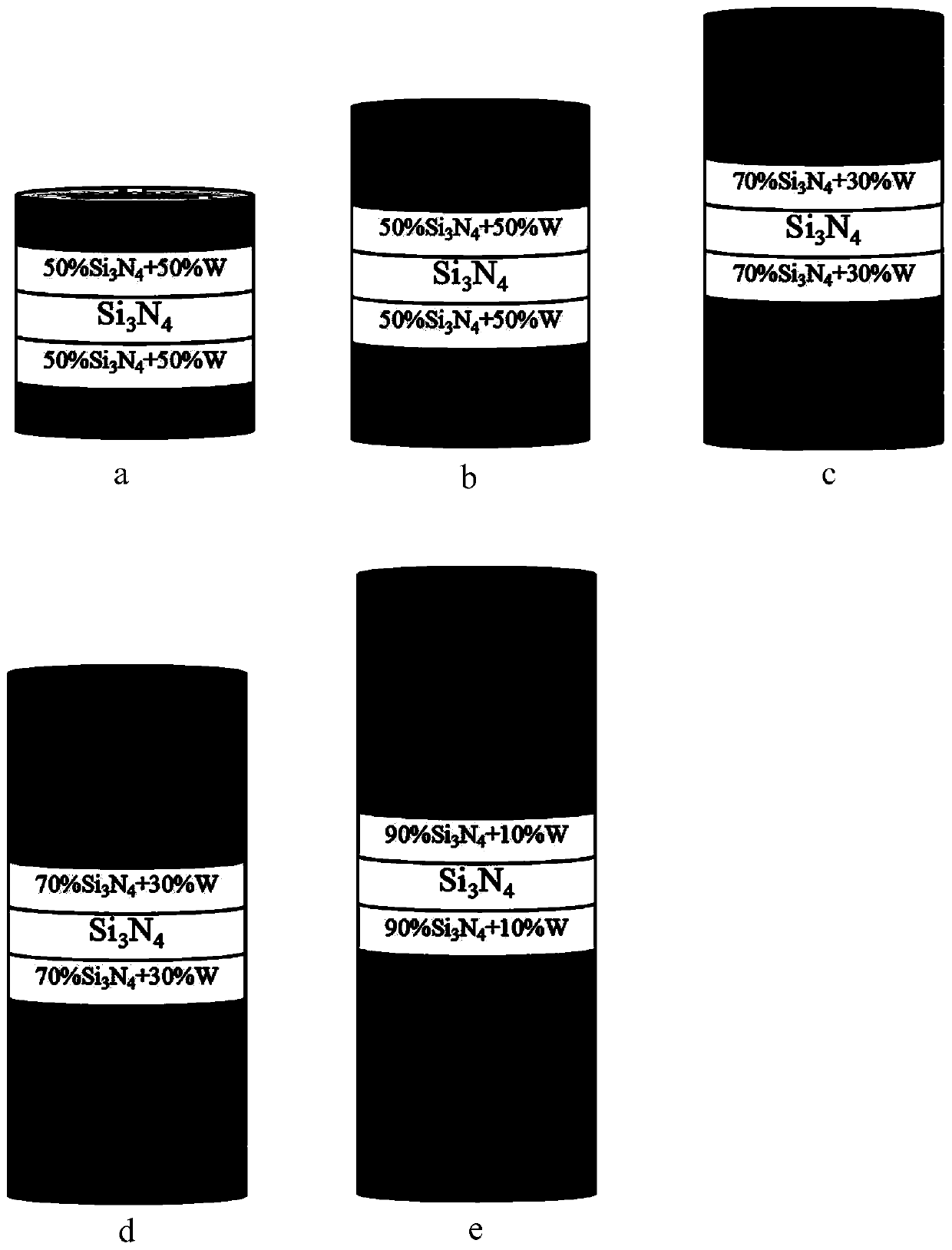

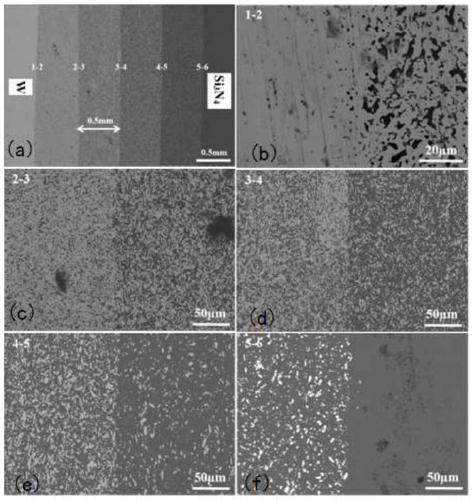

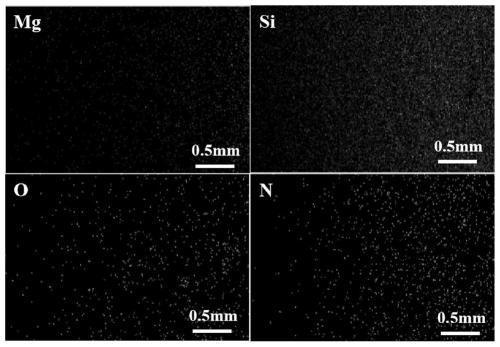

[0032] Choose W powder, Si 3 N 4 Powder and corresponding sintering aids are the original powder materials, and 5-layer gradient materials are prepared by SPS sintering.

[0033] W powder, Si 3 N 4 Powder and corresponding sintering aids are mixed according to the designed volume fraction, and ethanol solvent is added for wet milling, and the ball milling time is 24 hours; the mixed powder required for each layer is mixed according to the following formula figure 1 As shown in middle a, place layers and press in graphite molds in turn, each layer thickness is 2mm, then install upper and lower graphite indenters and coat graphite carbon felt to complete the mold loading work; place the mold with the sample to be sintered in spark plasma sintering In the furnace of the system, vacuumize to no higher than 0.01Pa. Under the axial pressure of 35MPa, the temperature is raised to 1300°C at a rate of 300°C / min, and then raised to 1500°C at a rate of 100°C / min and kept for 7 minutes...

Embodiment 2

[0035] Choose W powder, Si 3 N 4 Powder and corresponding sintering aids are the original powder materials, and 7-layer gradient materials are prepared by SPS sintering.

[0036] W powder, Si 3 N 4 Powder and corresponding sintering aids are mixed according to the designed volume fraction, and ethanol solvent is added for wet milling, and the ball milling time is 24 hours; the mixed powder required for each layer is mixed according to the following formula figure 1 As shown in middle b, place layers and press in graphite molds in turn, each layer thickness is 1mm, then install upper and lower graphite indenters and coat graphite carbon felt to complete the mold loading work; put the mold with the sample to be sintered in spark plasma sintering In the furnace of the system, vacuumize to no higher than 0.01Pa, under the axial pressure of 65MPa, raise the temperature to 1300°C at a rate of 200°C / min, and then raise the temperature to 1600°C at a rate of 120°C / min and keep it f...

Embodiment 3

[0038] Choose W powder, Si 3 N 4 Powder and corresponding sintering aids are the original powder materials, and 9-layer gradient materials are prepared by SPS sintering.

[0039] W powder, Si 3 N 4 Powder and corresponding sintering aids are mixed according to the designed volume fraction, and ethanol solvent is added for wet milling, and the ball milling time is 24 hours; the mixed powder required for each layer is mixed according to the following formula figure 1 As shown in middle c, laying and pressing in the graphite mold in turn, the thickness of each layer is 1mm, and then install the upper and lower graphite indenters and coat the graphite carbon felt to complete the mold loading work; put the mold with the sample to be sintered in spark plasma sintering In the furnace of the system, vacuumize to no higher than 0.01Pa. Under the axial pressure of 50MPa, the temperature is raised to 1400°C at a rate of 150°C / min, and then raised to 1650°C at a rate of 150°C / min and k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com