Anodic bonding method and anodic bonding device for vacuum glass sealing

A vacuum glass, anodic bonding technology, applied in glass forming, glass remolding, glass manufacturing equipment and other directions, can solve the problems of material physical properties mismatch, complex process, harsh welding conditions, etc., to achieve thermal expansion coefficient matching , the preparation process is simple, the effect of high sealing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

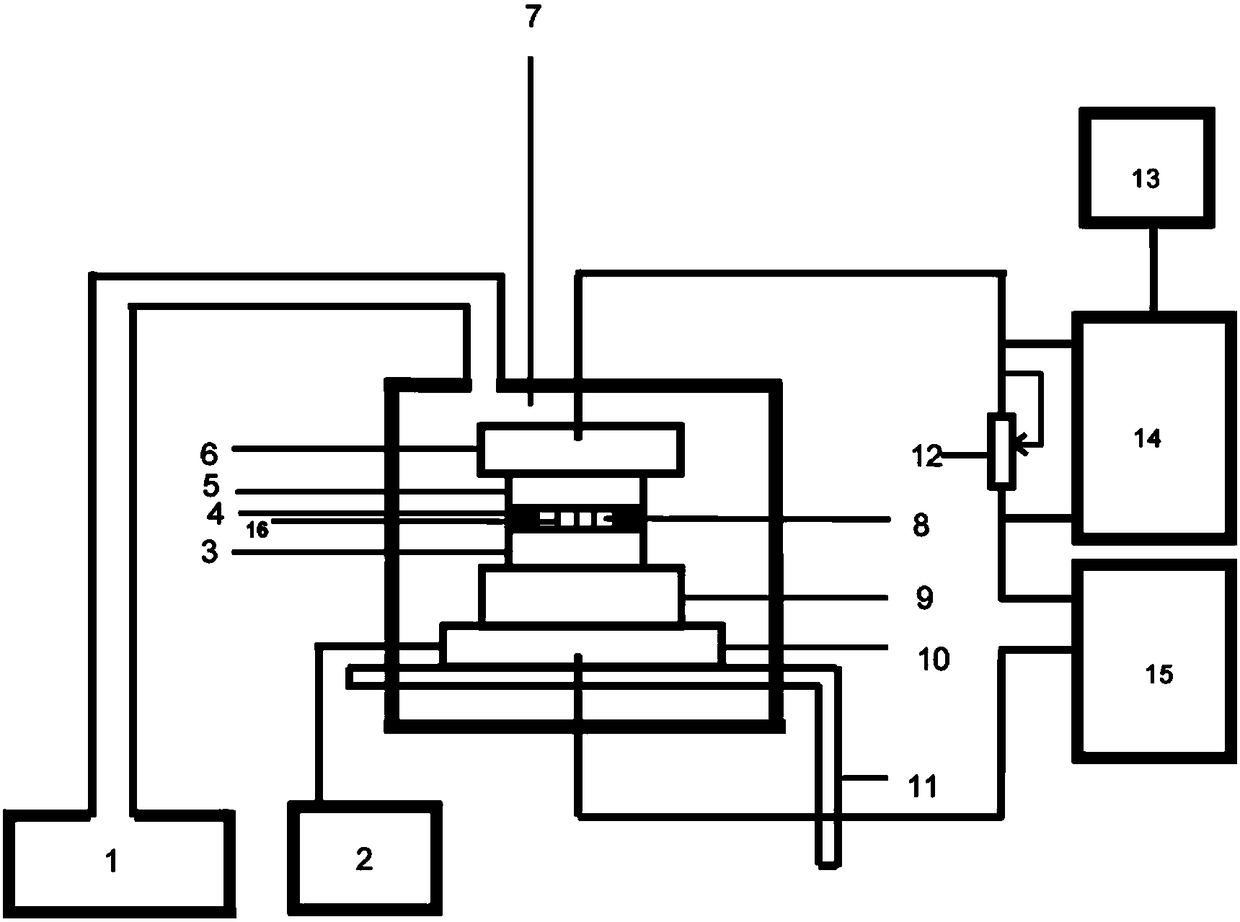

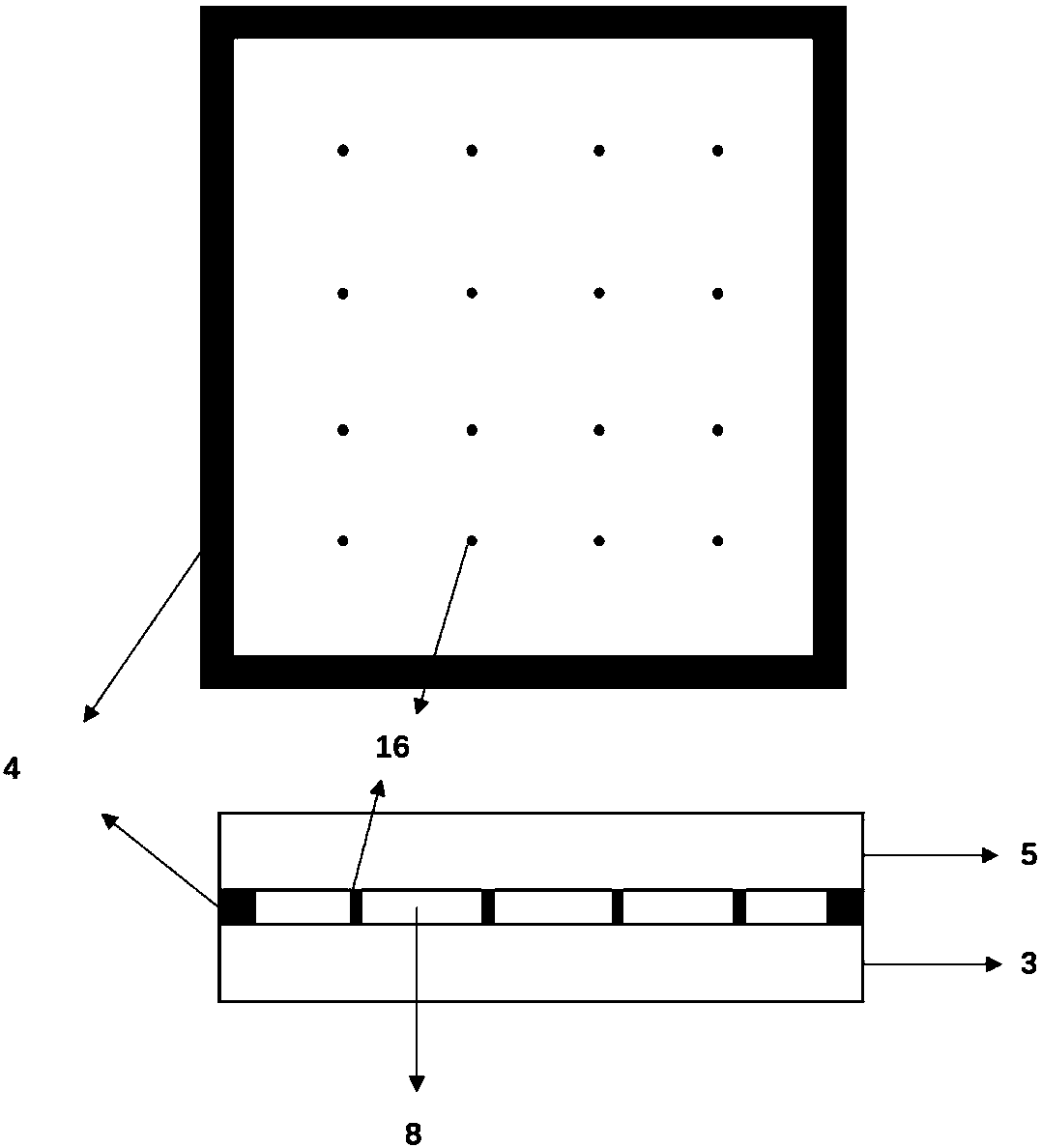

[0036] An anodic bonding method for vacuum glass sealing, which completes the vacuuming and sealing of vacuum glass at one time in the anodic bonding device for vacuum glass sealing; the specific steps are:

[0037] 1) Prepare an anodic bonding device for vacuum glass sealing;

[0038] 2) Preparation of low melting point glass powder

[0039] Weigh the basic glass raw material according to mole percentage: TeO 2 15%, ZnO 30%, B 2 o 3 40%, Na 2 O is 15%, and the weighed raw materials are fully mixed to make a mixture. The obtained glass batches were heated up to 900°C at a rate of 3°C / min, and then held for 70 minutes; then poured into a graphite mold for molding, and annealed at 350°C for 1 hour, the prepared glass blocks were broken, ground for 2 hours, and then passed 500 mesh sieve to obtain low melting point glass powder.

[0040]

[0041]

[0042] 3) Preparation of low melting point glass paste:

[0043] Be 94:6 by the mass ratio of terpineol and ethyl cellul...

Embodiment 2

[0048] An anodic bonding method for vacuum glass sealing, which completes the vacuuming and sealing of vacuum glass at one time in the anodic bonding device for vacuum glass sealing; the specific steps are:

[0049] 1) Prepare an anodic bonding device for vacuum glass sealing;

[0050] 2) Preparation of low melting point glass powder

[0051] Weigh the basic glass raw material according to mole percentage: TeO 2 15%, ZnO 40%, B 2 o 3 30%, Li 2 O is 15%, and the weighed raw materials are fully mixed to make a mixture. The obtained glass batches were heated up to 1000°C at a rate of 5°C / min, and then held for 40 minutes; then poured into a graphite mold for molding, and annealed at 350°C for 1 hour, the prepared glass blocks were broken, ground for 2 hours, and then passed 500 mesh sieve to obtain low melting point glass powder.

[0052]

[0053] 3) Preparation of low melting point glass paste:

[0054] Be 96:4 by the mass ratio of terpineol and ethyl cellulose, mix (s...

Embodiment 3

[0059] An anodic bonding method for vacuum glass sealing, which completes the vacuuming and sealing of vacuum glass at one time in the anodic bonding device for vacuum glass sealing; the specific steps are:

[0060] 1) Prepare an anodic bonding device for vacuum glass sealing;

[0061] 2) Preparation of low melting point glass powder

[0062] Weigh the basic glass raw material according to mole percentage: TeO 2 75%, ZnO 20%, Na 2 O is 5%, and the weighed raw materials are fully mixed to make a mixture. The obtained glass batches were heated to 870°C at a rate of 5°C / min, and then kept for 50 minutes; then poured into water and quenched into glass pieces, and the prepared glass pieces were further broken, ground for 3 hours, and passed through a 500-mesh sieve. Obtain low melting point glass powder.

[0063]

[0064] 3) Preparation of low melting point glass paste:

[0065] Be 98:2 by the mass ratio of terpineol and ethyl cellulose, mix (stir) terpineol and ethyl cellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com