Electrode of flexible CIGS solar cell and manufacturing method

A solar cell and electrode technology, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of small contact area between metal wires and AZO layers, easy disconnection of top electrodes, cumbersome manufacturing methods, etc., to improve cleanliness and surface The effect of activity, photocurrent collection efficiency improvement, and simplification of component packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

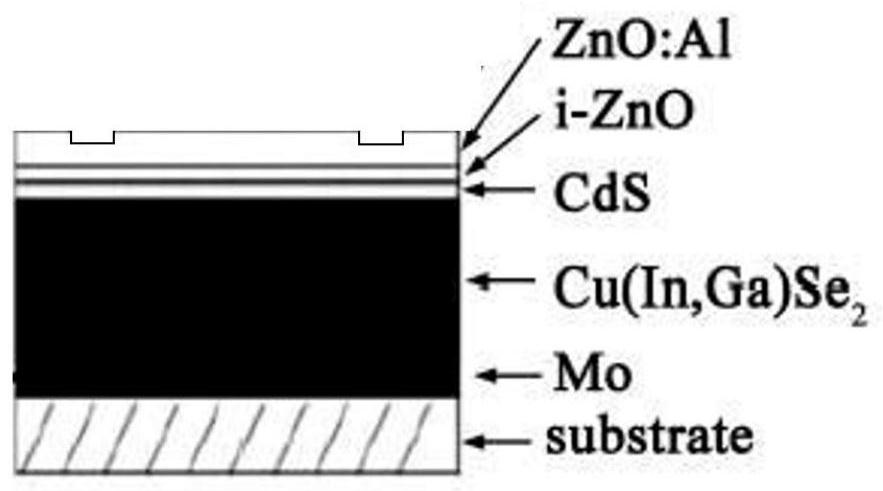

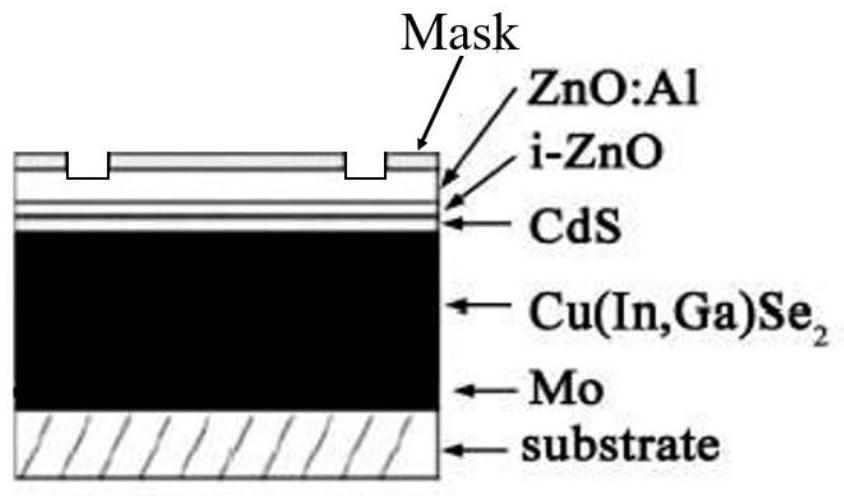

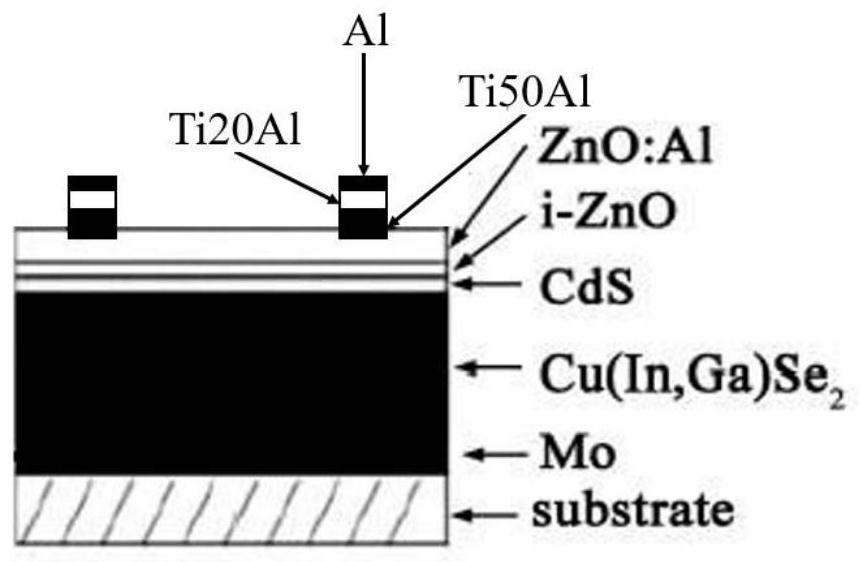

[0048] Such as Figure 1~3 As shown, an electrode of a flexible CIGS solar cell, since the CIGS top window layer is Al-doped ZnO, the film layer is an n-type semiconductor. Metal materials are generally used for electrodes requiring high conductivity. According to semiconductor theory, a potential barrier exists when a metal and a semiconductor come into contact. The size of the potential barrier is related to the properties of metal and semiconductor materials, work function, interface state and other factors. Therefore, in order to reduce the resistance between the semiconductor and metal electrodes, the Schottky barrier height at the metal and semiconductor interface should be small. For n-type semiconductors, metals with a small work function are more conducive to ohmic contact. In addition, annealing will cause the metal and ZnO interface to react to form new phases, such as TiO(111), TiO(110). A large number of oxygen vacancies are accumulated at the interface, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com