Double-surface coating process of cylindrical screen cloth

A double-sided coating, cylindrical technology, applied in the device, coating, fabric surface trimming and other directions of coating liquid on the surface, can solve the problems of raw material waste, product cost increase, environmental pollution of corner waste, etc. The effect of reducing product cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

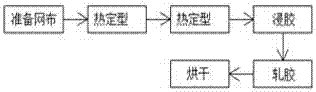

Image

Examples

Embodiment 1

[0024] A double-sided coating process for cylindrical mesh cloth, comprising the following steps:

[0025] 1) Use a double-needle bed warp knitting machine to directly weave into an integrated cylindrical mesh;

[0026] 2a), send the cylindrical mesh into the heat setting machine for heating, the heating temperature is 190 degrees, and the heating time is 20 seconds;

[0027] 2b) Cool the cylindrical mesh cloth after the first heat treatment, and send it to the heat setting machine for heating again, the heating temperature is 100 degrees, and the heating time is 30 seconds;

[0028] 3a), the heat-set cylindrical mesh is completely cooled and flattened into a double-layer structure, and then immersed in a liquid coating additive under the action of a pulling roller, so that the mesh is completely immersed in the additive;

[0029] 3b) After dipping, the mesh cloth passes through the padding car in open width, and is extruded by the rolling car to squeeze out the excess additi...

Embodiment 2

[0032] A double-sided coating process for cylindrical mesh cloth, comprising the following steps:

[0033] 2) Use a double-needle bed warp knitting machine or a weft knitting machine to directly weave an integral cylindrical mesh;

[0034] 2a), send the cylindrical mesh into the heat setting machine for heating, the heating temperature is 200 degrees, and the heating time is 30 seconds;

[0035] 2b) The cylindrical mesh cloth after the first heat treatment is cooled and sent to the heat setting machine for heating again, the heating temperature is 120 degrees, and the heating time is 60 seconds;

[0036] 3a), the heat-set cylindrical mesh is completely cooled and flattened into a double-layer structure, and then immersed in a liquid coating additive under the action of a pulling roller, so that the mesh is completely immersed in the additive;

[0037] 3b) After dipping, the mesh cloth passes through the padding car in open width, and is extruded by the rolling car to squeeze ...

Embodiment 3

[0040] A double-sided coating process for cylindrical mesh cloth, comprising the following steps:

[0041] 3) Use a double-needle bed warp knitting machine or weft knitting machine to weave directly into an integrated cylindrical mesh;

[0042] 2a), send the cylindrical mesh into the heat setting machine for heating, the heating temperature is 195 degrees, and the heating time is 25 seconds;

[0043] 2b) After the first heat treatment, the cylindrical mesh is cooled and sent to the heat setting machine for heating again, the heating temperature is 110 degrees, and the heating time is 50 seconds;

[0044] 3a), the heat-set cylindrical mesh is completely cooled and flattened into a double-layer structure, and then immersed in a liquid coating additive under the action of a pulling roller, so that the mesh is completely immersed in the additive;

[0045] 3b) After dipping, the mesh cloth passes through the padding car in open width, and is extruded by the rolling car to squeeze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com