Assembled platy commutator processing method

A technology of assembly and processing method, which is applied in the direction of electric components, manufacturing motor generators, electrical components, etc., can solve the problems of increasing the process, the impact of carbon brush wear, and increasing the cost of the commutator, so as to reduce the manufacturing cost, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

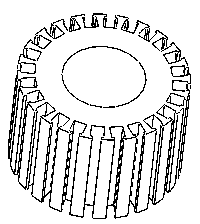

[0036] The core purpose of the present invention is to provide a commutator processing method with simple molding process and difficult cracking of the insulating matrix.

[0037] The core technical solution of the present invention will be described below in conjunction with the accompanying drawings, see Figure 10 ,Such as Figure 10 As mentioned above, an embodiment of the core technical solution of the present invention provides a method for manufacturing an assembled lamellar commutator, which includes the following steps in sequence:

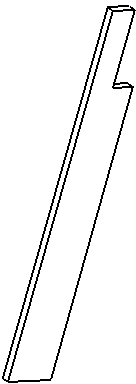

[0038] A. Process a commutator segment 1 (see Figure 5 ), the commutator segment 1 has a plug-in part;

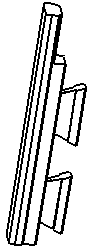

[0039] B. Using a bracket 2 (see Image 6 ), here, the bracket 2 is cylindrical, and the inner wall of the bracket 2 is formed with a component 3 for the commutator segment 1, and the component 3 includes a number of components evenly distributed on the inner wall of the bracket 2 The convex strip 4, the convex strip 4 extends in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com