Heater for low-temperature ethylene unloading and working method thereof

A low-temperature ethylene and heater technology, which is applied in the chemical industry, can solve the problems of easy cracking of the storage cylinder of the storage container, great damage to the storage equipment, and rapid freezing of the storage equipment, etc., and achieves clear structural ideas, low cost, and simple and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

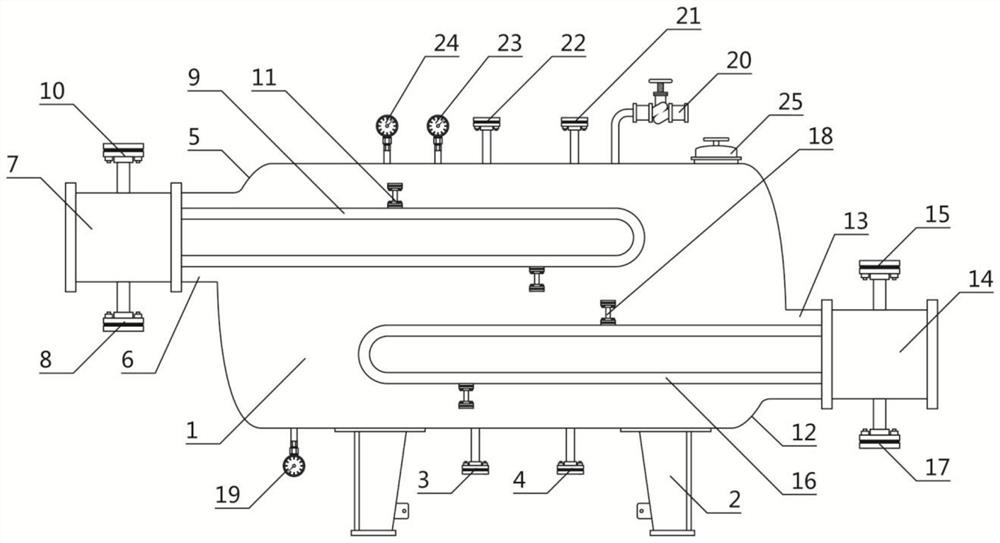

[0028] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0029] Such as figure 1A heater for low-temperature ethylene unloading is shown, which is characterized in that it includes a shell-side cylinder 1, a support skirt 2, a methanol injection port 3, a sewage outlet 4, a first head 5, an ethylene reinforced cylinder section 6, Ethylene side tube box 7, first heat exchange tube bundle 9, second head 12, steam reinforced tube section 13, steam side tube box 14, second heat exchange tube bundle 16, first detection instrument 19, safety valve port 20, exhaust Air interface 21, liquid level detection interface 22, second detection instrument 23, third detection instrument 24 and manhole 25, the support skirt 2 is located at the lower part of the shell side cylinder 1, the support skirt 2 and the shell side The cylinder 1 is fixedly connected, the methanol injection port 3 and the sewage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com