Continuous regeneration adsorption purification process of trimethylolpropane trioleate

A trimethylolpropane oleate and process technology, which is applied in the field of continuous regeneration adsorption purification process of trimethylolpropane oleate, can solve the problem that the adsorbent cannot be reused, the production cost of the product is increased, and the processing cost is increased And other problems, to achieve superior oxidation stability and anti-emulsification performance, reduce product loss, the effect of environmentally friendly production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

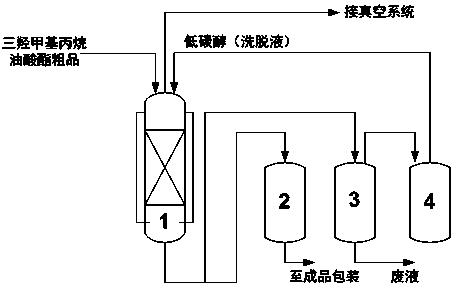

[0038] Embodiment 1 Adsorption purification of trimethylolpropane oleate

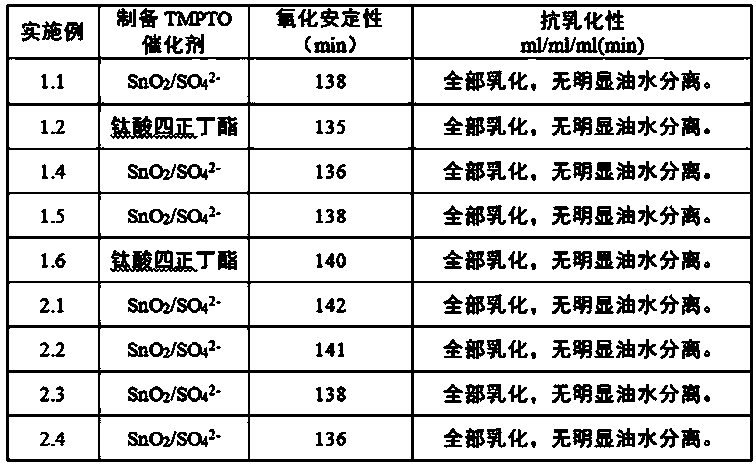

Embodiment 11

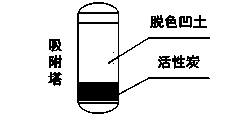

[0040] Load 220kg of decolorized soil (Anhui Mingmei Mineral Co., Ltd.) into an adsorption tower (ф450×2850) with insulation. 14 tons of trimethylolpropane oleate crude product (by trimethylolpropane and oleic acid in solid superacid SnO 2 / SO 4 2- Catalyzed esterification) preheated to 77°C, pumped into the adsorption tower from the top of the tower at a speed of 78kg / min; the oil after adsorption treatment directly enters the finished product receiving tank, and samples are taken to test the oxidation stability and resistance of the oil Emulsification, and compared with the performance of the crude product before treatment.

Embodiment 12

[0042] It is basically the same as Example 1, but with the following changes: the crude trimethylolpropane oleate is prepared by esterification of trimethylolpropane and oleic acid under the catalysis of tetra-n-butyl titanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com