Patents

Literature

43results about How to "Increase agitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

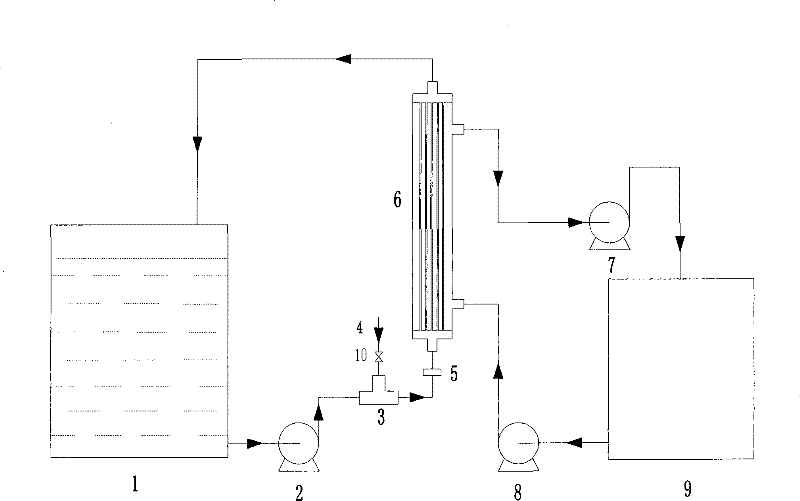

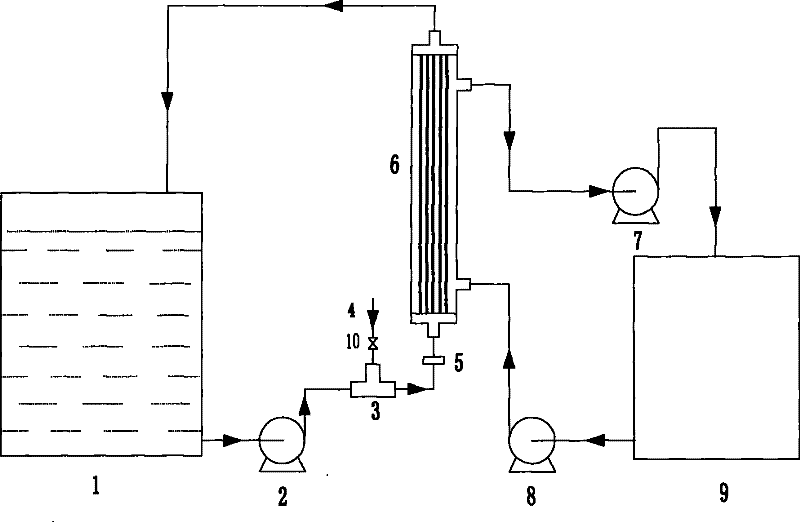

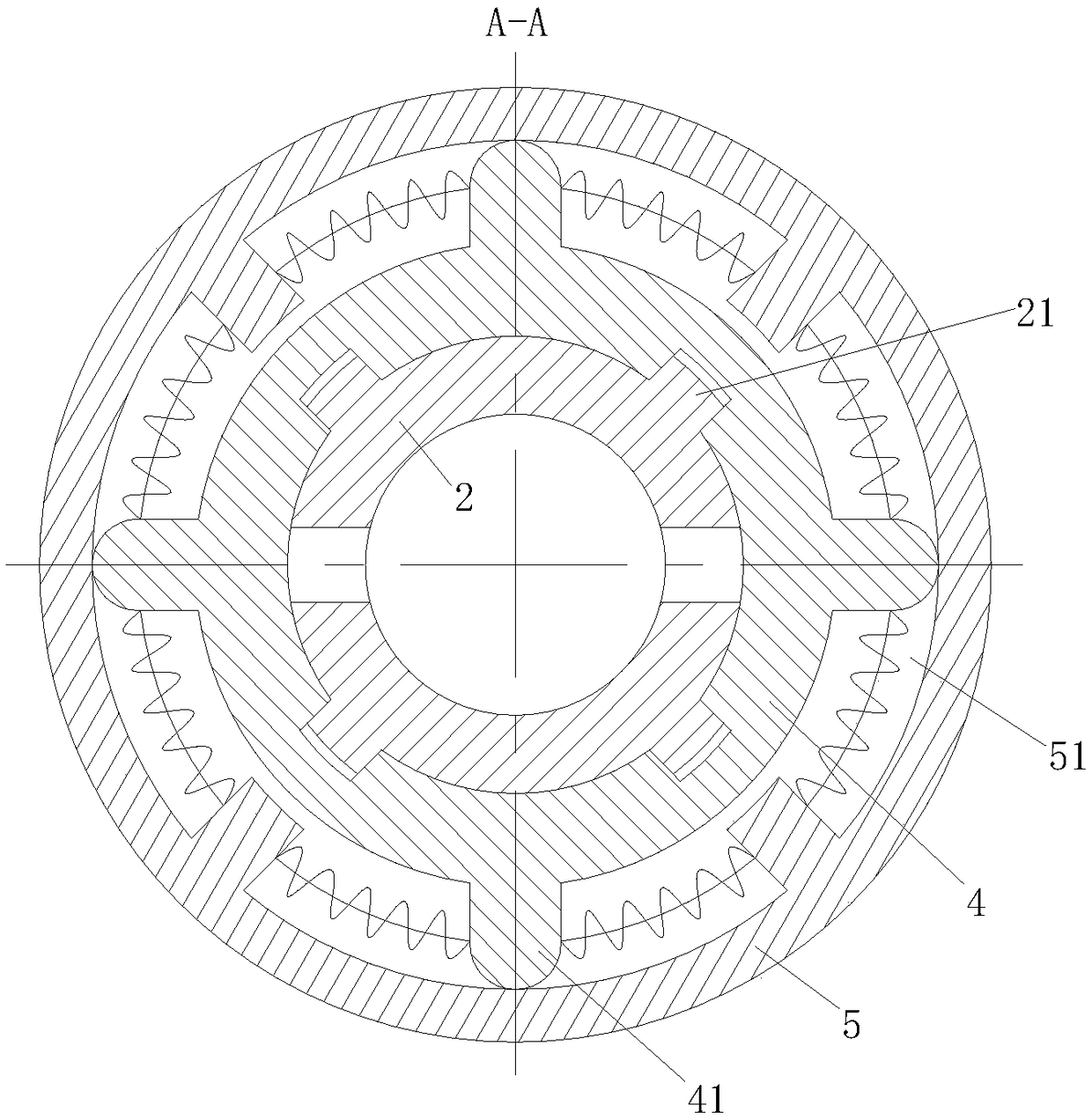

Method and apparatus of impulse fluid jet type membrane bioreactor

ActiveCN101293705APollution controlImprove energy efficiencySustainable biological treatmentBiological water/sewage treatmentMembrane surfaceEngineering

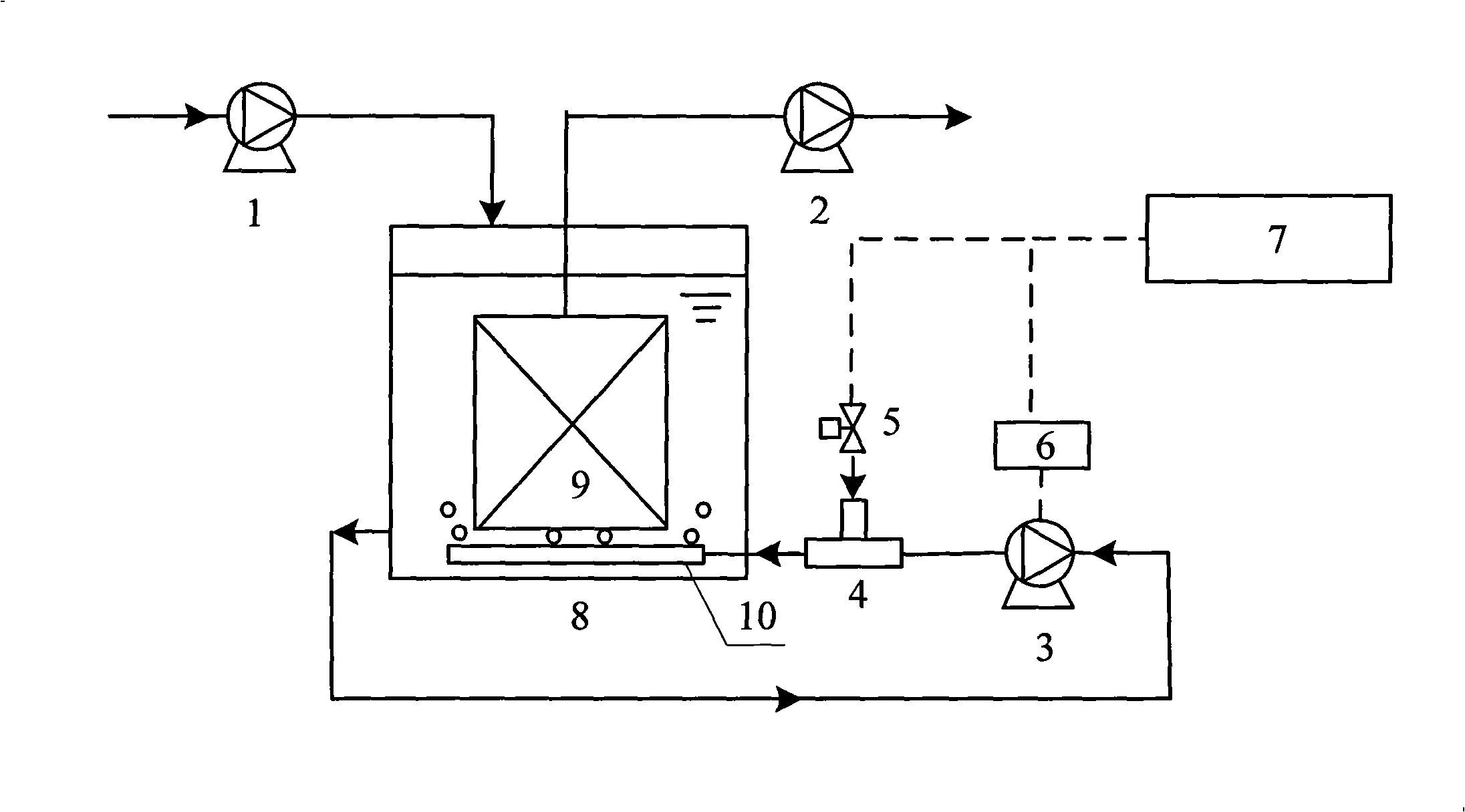

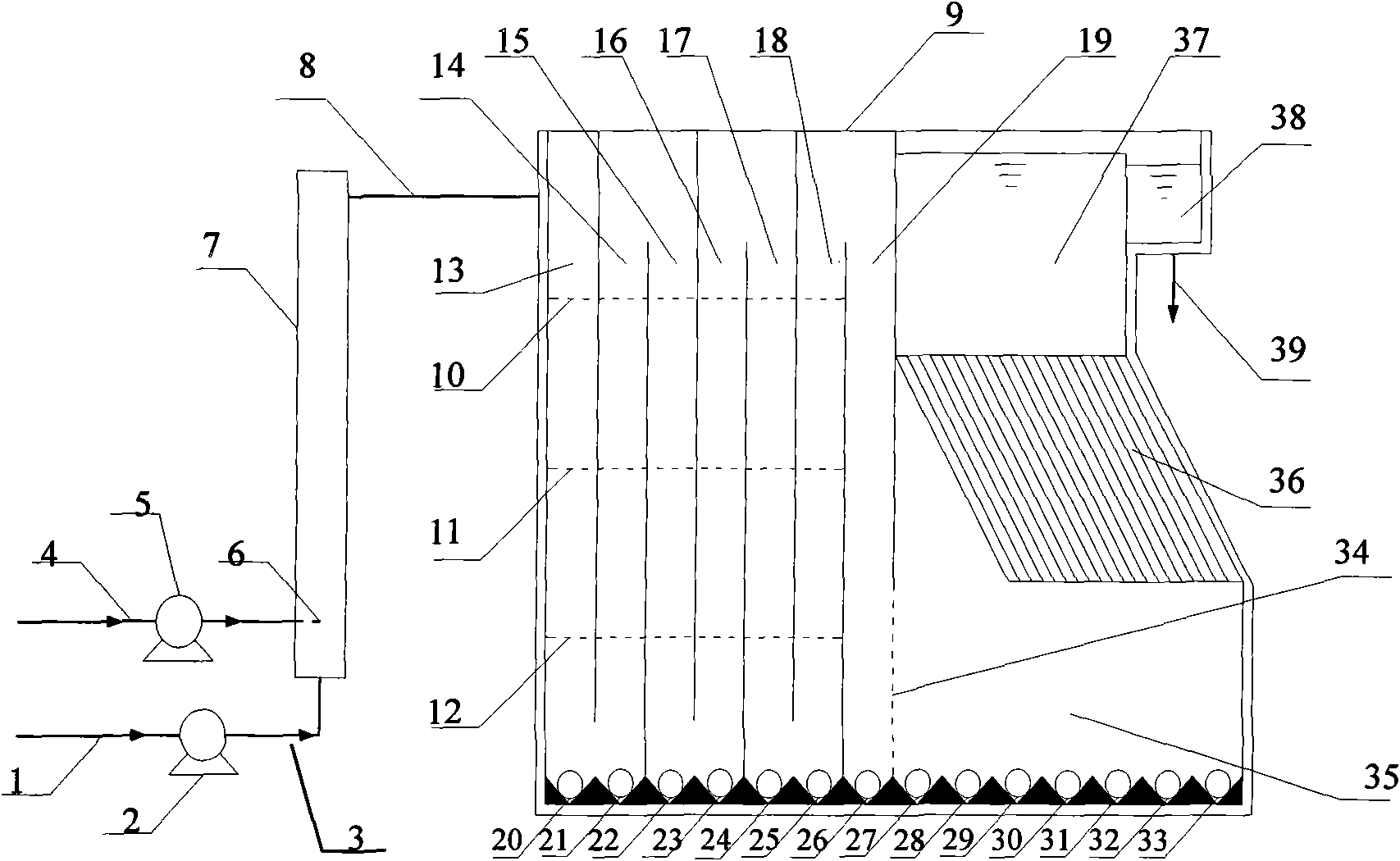

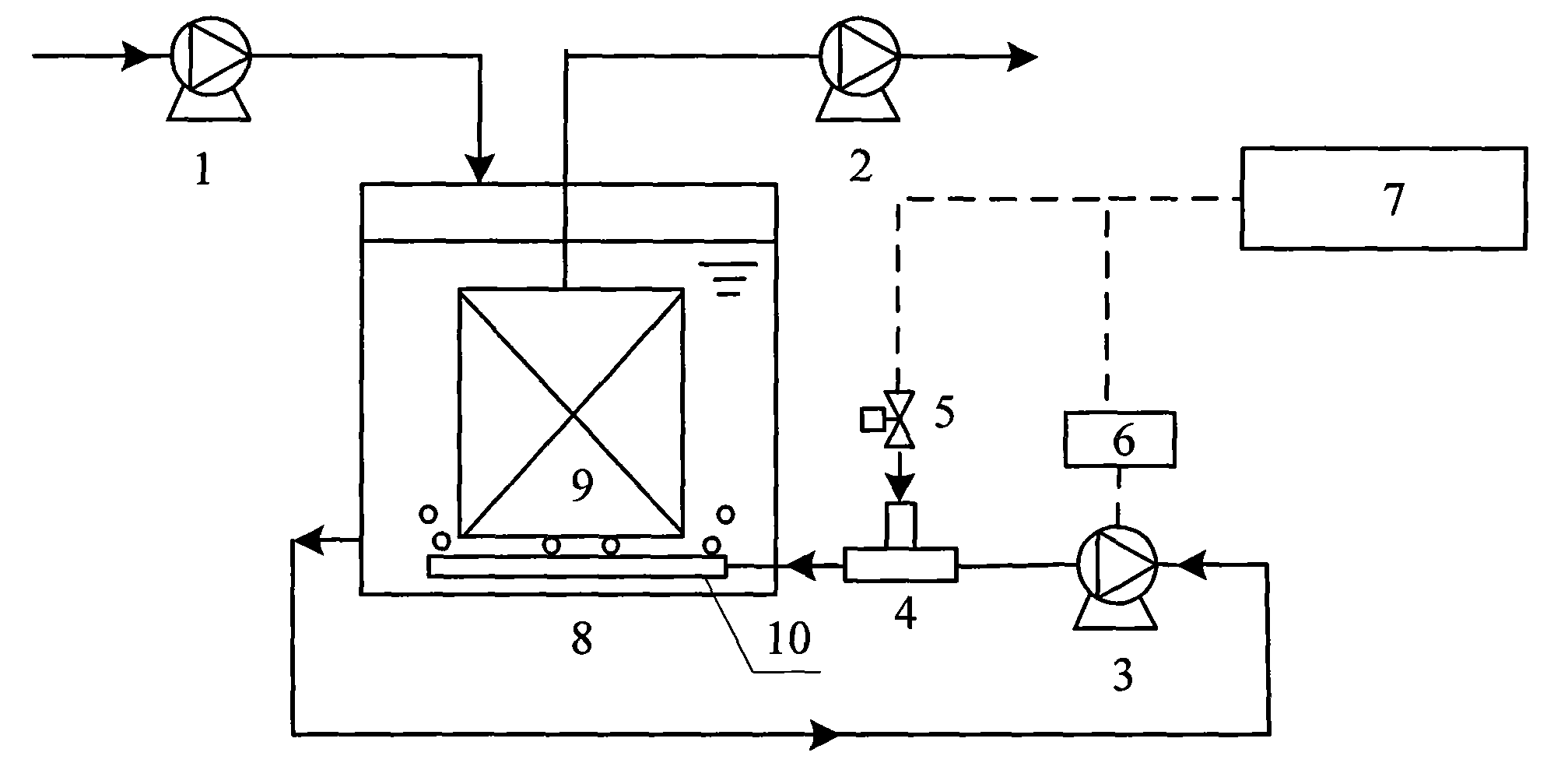

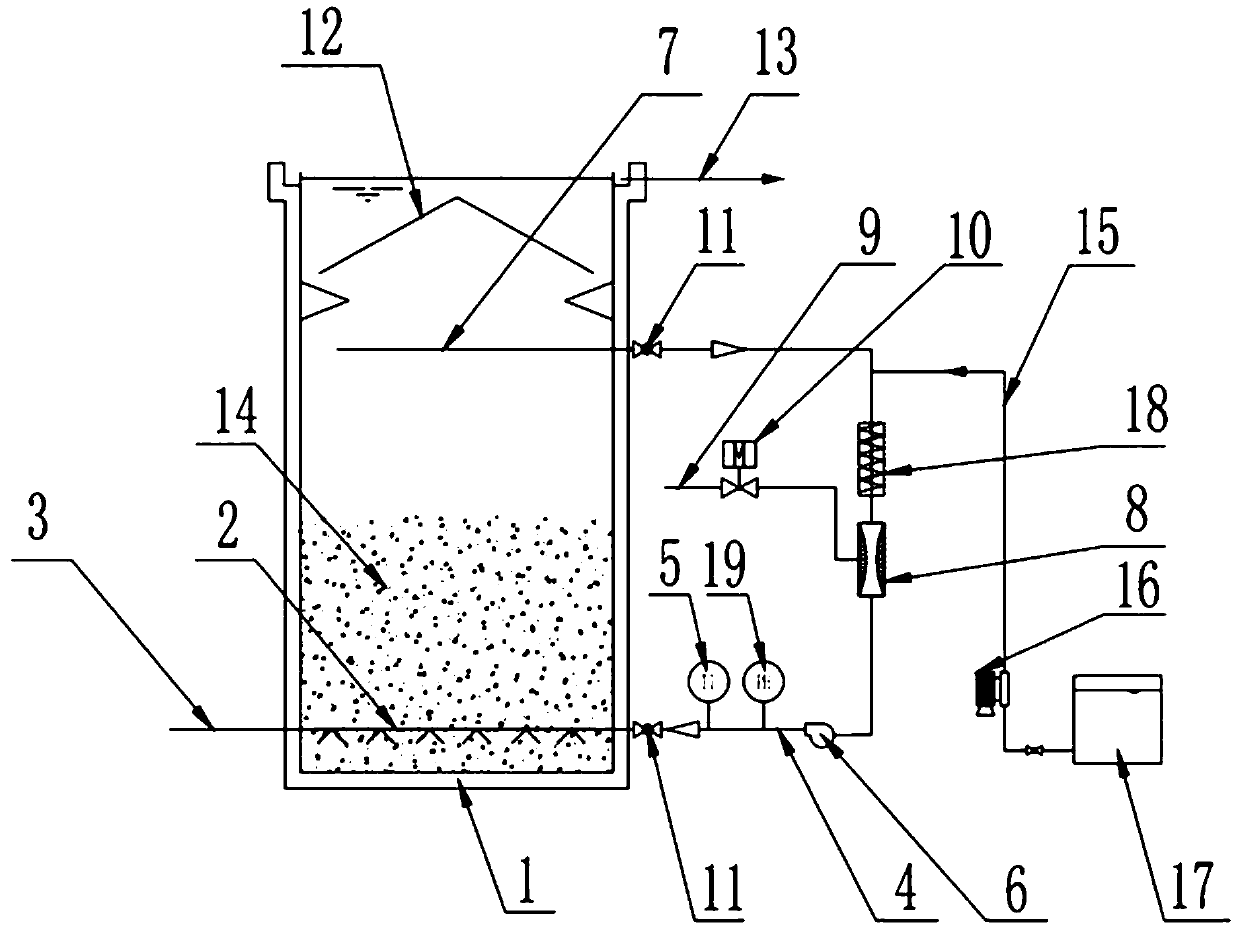

The invention provides a method of a pulse-jet membrane bioreactor and a device for realizing the method. The method adopts a jet aerator to replace a traditional blower to realize the cross-flow scouring effect of membrane components; wherein, circulating fluid flows through the jet aerator at high speed; air enters the jet aerator in a pulse way by a valve controlled by PLC and jets at the bottom through a gas spreading distributor; the PLC system regulates the cross-flow state of gas-liquid two-phase flow on the membrane surface by changing circulation flow rate and pulse frequency, so as to improve the scouring effect of the air to the membrane surface, to further control membrane pollution, to improve the energy utilization efficiency of a circulating pump and to reserve energy. The use of the jet aerator also increases the utilization efficiency of oxygen and improves sludge degradation effect. The device has the advantages of low operation energy consumption and low operation noise, slight membrane pollution, less early investment in equipment, simple structure of the device, small occupation area, simple and convenient operation and convenience in automatic running and control.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

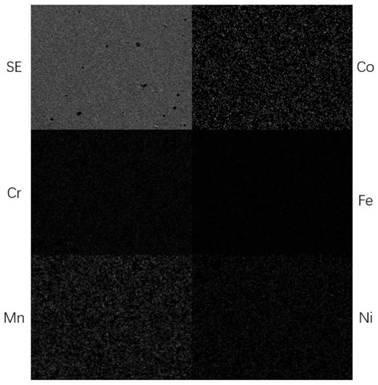

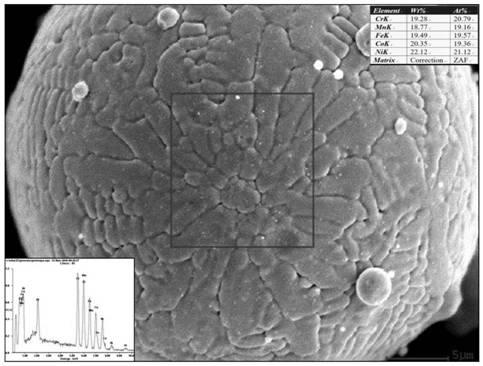

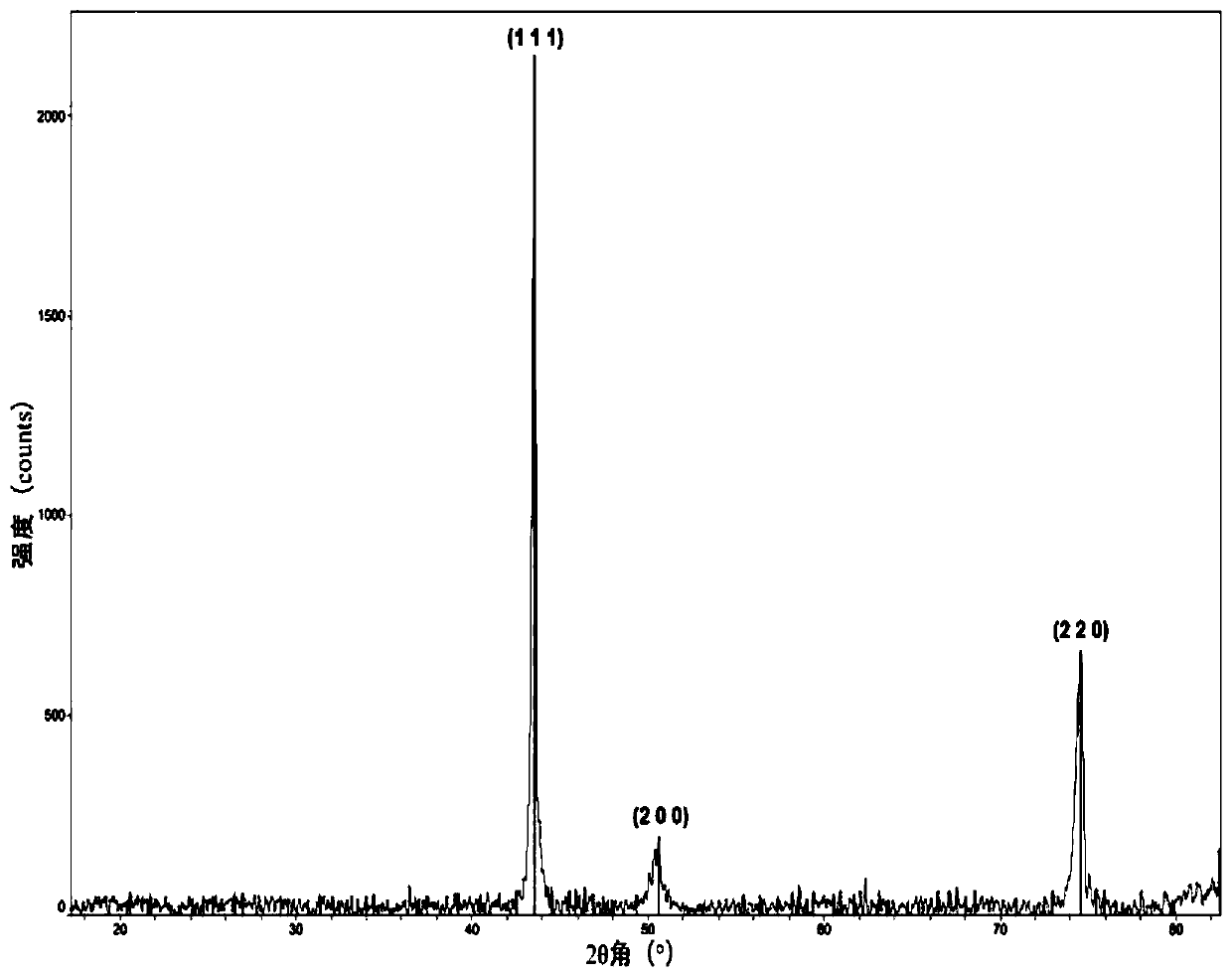

High-entropy alloy CoCrFeMnNi and atomization powder making method manufacturing technique

The invention relates to a high-entropy alloy CoCrFeMnNi and an atomization powder making method manufacturing technique. The atomization powder making method manufacturing technique comprises the steps that 1, Fe, Co, Ni, Cr and Mn elementary substance small pieces with the same substance amount are smelted with a medium-frequency induction furnace to obtain a CoCrFeMnNi alloy rod material; 2, the CoCrFeMnNi alloy rod material is made into CoCrFeMnNi high-entropy alloy powder with an electrode induction melting gas atomization method; the finally manufactured high-entropy alloy CoCrFeMnNi does not have micro-segregation; the average particle size is 36 mu m; the particle size ranges from 15 to 53 mu m; the whole appearance is round and smooth; a single FCC phase is presented; and the sphericity is good, and no obvious powder adhesion occurs. The technique is simple; product performance is excellent; and the problems of the high-entropy CoCrFeMnNi manufactured with a current techniqueof being nonuniform in impurity, having micro-segregation, being large in particle size, being large in particle size deviation, being poor in sphericity, having partial powder adhesion and the like are solved.

Owner:SHANGHAI UNIV OF ENG SCI

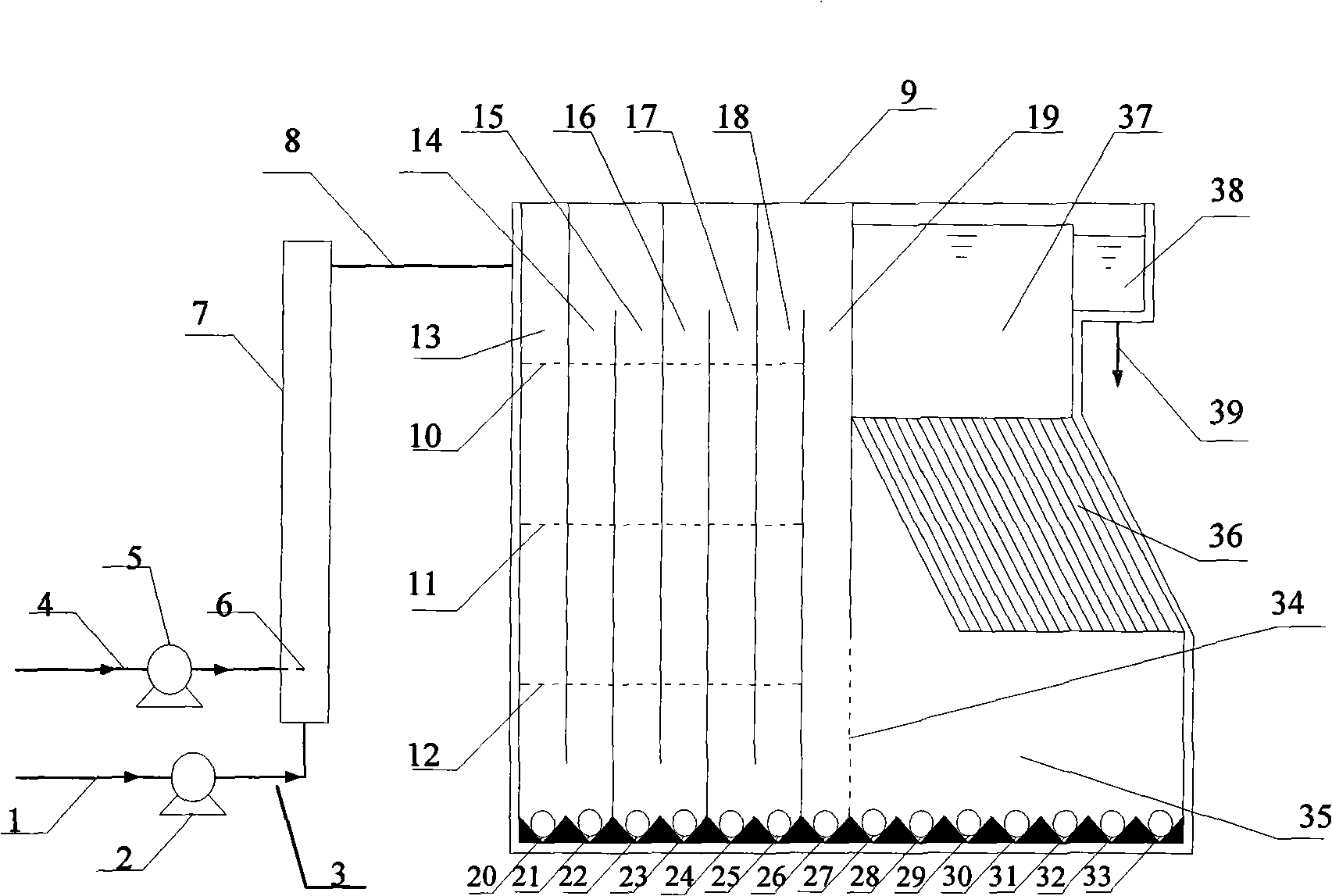

Pretreatment process method and device for removing aniline in wastewater through potassium ferrate

InactiveCN101570371AImprove biochemical treatment efficiencyAvoid secondary pollutionWater contaminantsMultistage water/sewage treatmentPotassiumAliphatic hydrocarbon

The invention relates to a pretreatment process method and a device for removing aniline in wastewater through potassium ferrate. The method comprises the following steps: intensively mixing the wastewater to be treated and potassium ferrate in a tubular mixer, and setting the rate of flowing water in the tube to 0.8 to 1.0m / s; leading the intensively mixed wastewater into a tableflap type coagulating basin for 30min of reaction; and leading the reacted wastewater into a precipitation pool for precipitation, setting upward flowing rate in the precipitation pool to 10 to 15 mm / s, and leading the output water into a conventional biochemical system after precipitation. The method makes use of the strong oxidizing property of potassium ferrate to oxidize hardly degradable aniline into a series of aliphatic hydrocarbons, thereby improving the biochemical treatment efficiency of a subsequence process, and solving the problem of secondary pollution universally lying in other processes. In addition, a grid-shape holder plate is arranged in a coagulation area so as to shorten the reaction time and improve the reaction efficiency. A transition area is arranged between the coagulation area and the precipitation area and a grid-shaped baffle plate is also added to improve the precipitation effect.

Owner:DONGHUA UNIV

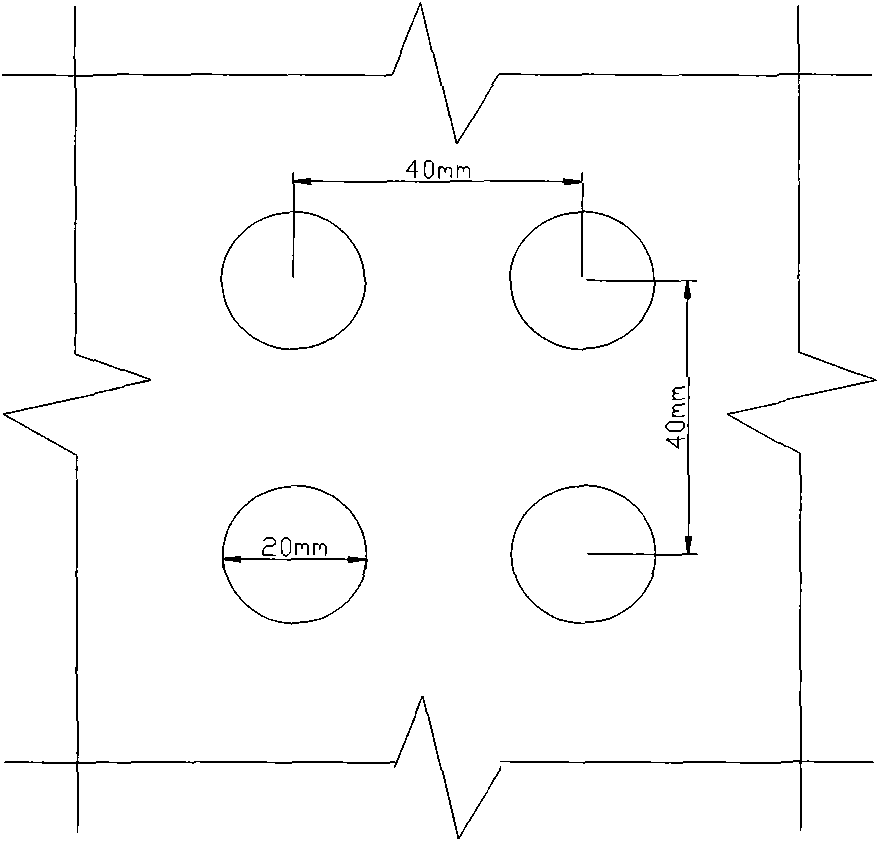

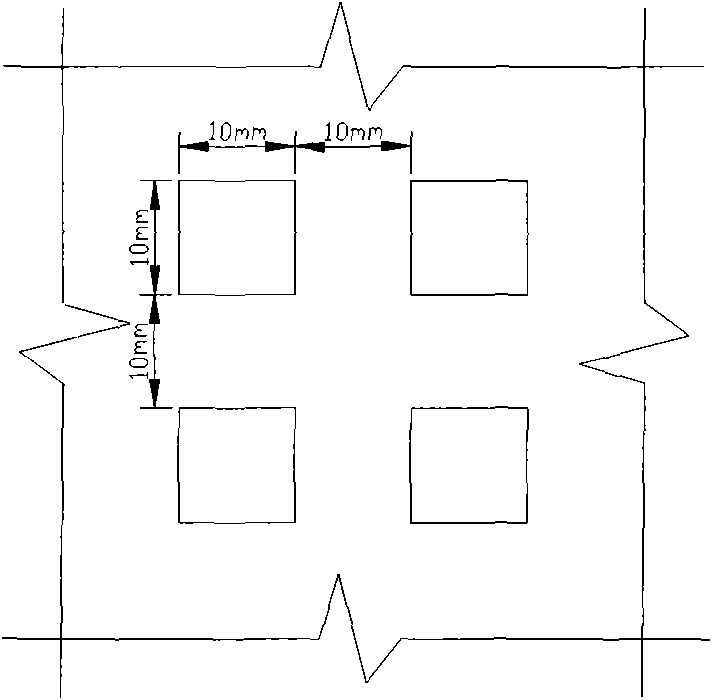

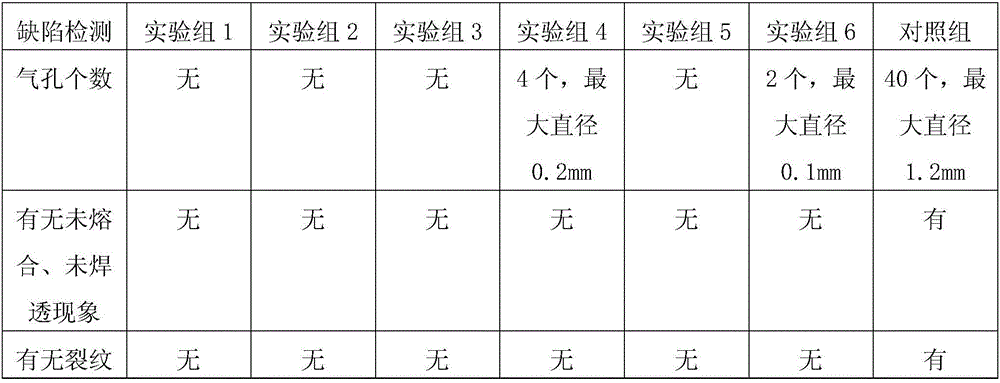

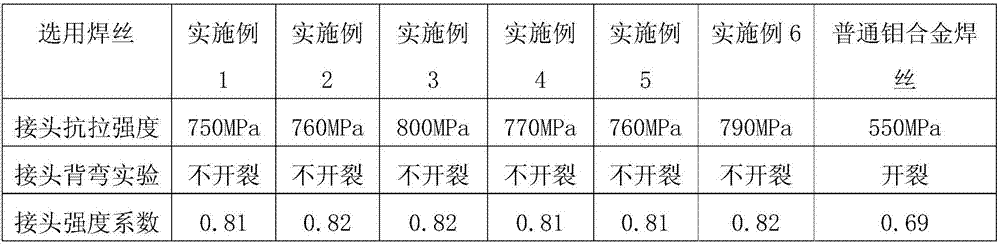

Aluminum alloy welding process

InactiveCN106825871AHigh tensile strengthDoes not affect aestheticsArc welding apparatusWelding/cutting media/materialsSlagMegasonic cleaning

The invention discloses an aluminum alloy welding process and belongs to the technical field of metal welding. The aluminum alloy welding process comprises the following steps: (1) a welding area of the surface of an aluminum alloy plate is put into a cleaning fluid for ultrasonic cleaning and then dried; (2) the welding area of the to-be-welded aluminum alloy plate is heated to 150-200 DEG C; (3) the welding area of the to-be-welded aluminum alloy plate is heated to 750-830 DEG C, a degasifier is sprayed to the welding area of the aluminum alloy plate, and the aluminum alloy plate is welded with a special aluminum alloy welding wire; (4) the welded part of the aluminum alloy plate is subjected to solid solution at the temperature of 300-450 DEG C, and the aluminum alloy plate is subjected to degasification treatment through ultrasonic waves; (5) the welded part of the aluminum alloy plate after solid solution treatment is transferred to cold water and cooled to the room temperature; (6) clearing and removal of welding powder or slag are performed. With the adoption of the aluminum alloy welding process, the pore problem can be effectively solved, and incomplete fusion, incomplete penetration and cracking phenomena are unlikely to occur.

Owner:玉林博飞商贸有限公司

Method for welding molybdenum alloy

ActiveCN106862732AInhibition of sensitization tendencySmall mechanical propertiesArc welding apparatusWelding/cutting media/materialsActive agentDirect current

The invention discloses a method for welding molybdenum alloy, belonging to the technical field of metal welding. The method comprises the steps: (1) after cleaning, drying the welding area of molybdenum alloy; (2) manufacturing a special welding wire for the molybdenum alloy; (3) degassing at high temperature; (4) taking out a molybdenum alloy workpiece, spraying an active agent until the thickness is 0.2-0.8mm on the he welding area of molybdenum alloy, heating the special welding wire for the molybdenum alloy to dry, and then welding the molybdenum alloy workpiece, wherein the welding method adopts TIG wire filling welding, adopts a direct-current straight polarity power supply and determines welding process parameters; (5) cooling; (6) inspection. The method can reduce the quantity of joint holes, improve weldability, reduce cracks, refine parent crystalline grains so as to improve the tensile property of welded joints, and obtain good welding quality.

Owner:宝鸡市蕴杰金属制品有限公司

Aluminum alloy degasifier and preparation method thereof

The invention relates to an aluminum alloy degasifier and a preparation method thereof. The aluminum alloy degasifier consists of the components by mass percent: 13-15% of ammonium carbonate, 22-25% of activated carbon and the balance of calcium carbonate. Ammonium carbonate is decomposed at a high temperature and is reacted with hydrogen and oxygen in aluminum alloy liquid, and then carbon dioxide, nitrogen dioxide, steam, ammonia gas, a small amount of methane and other gases are released; and because the steam is generated, the stirring degree of molten aluminum alloy is improved and the gas release and floating of aluminum slag are improved.

Owner:黄宣斐

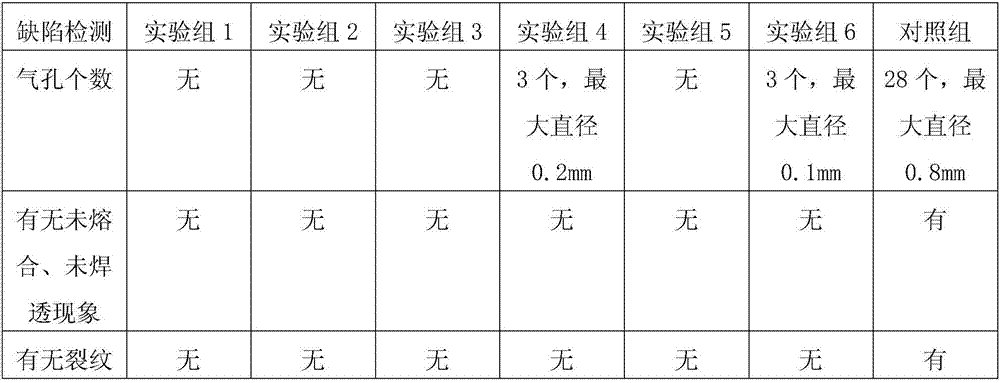

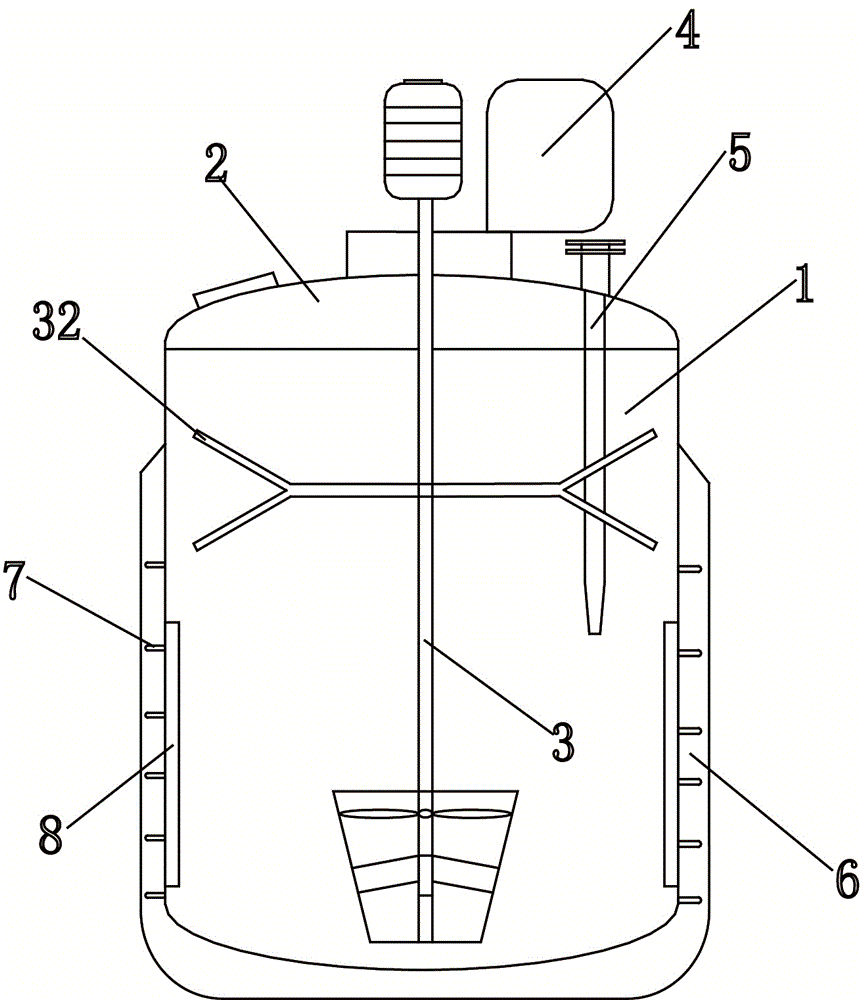

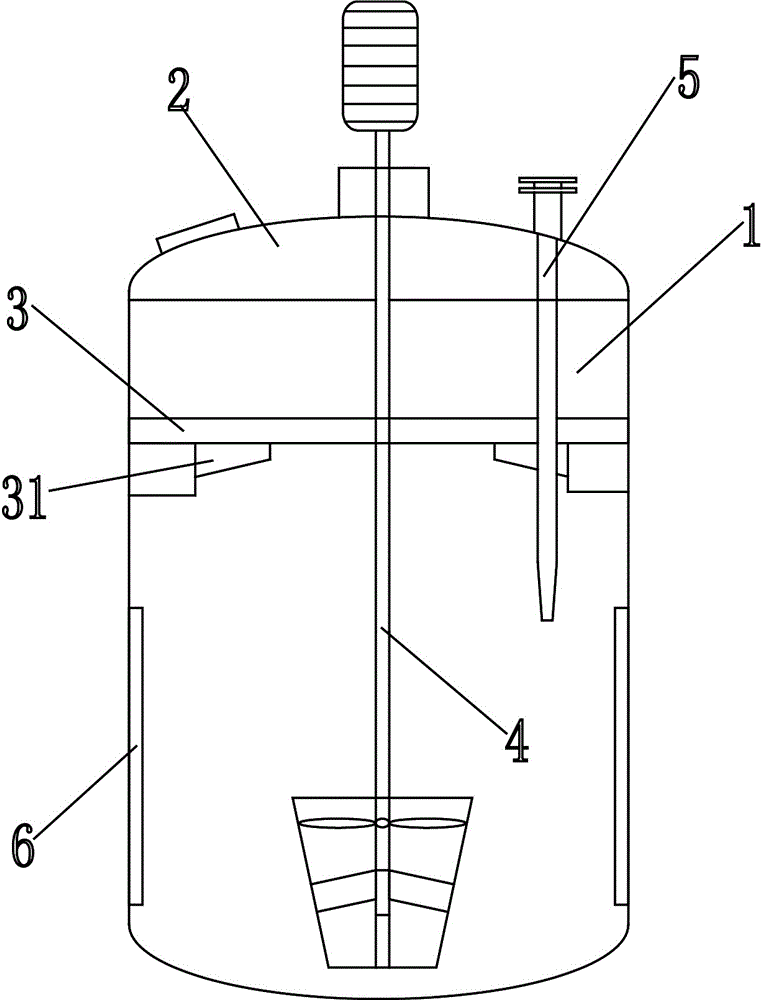

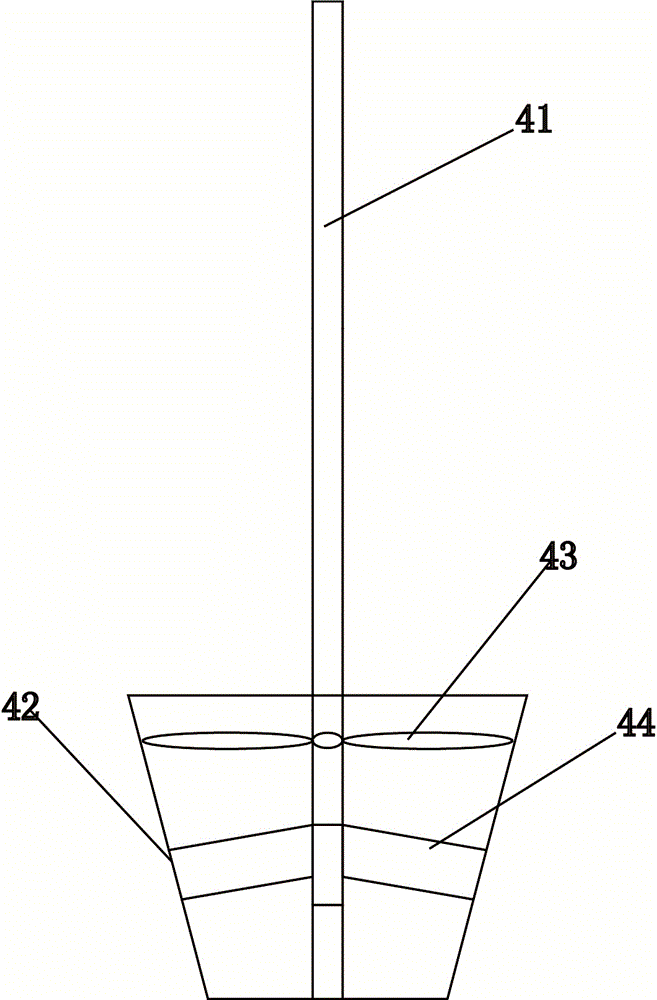

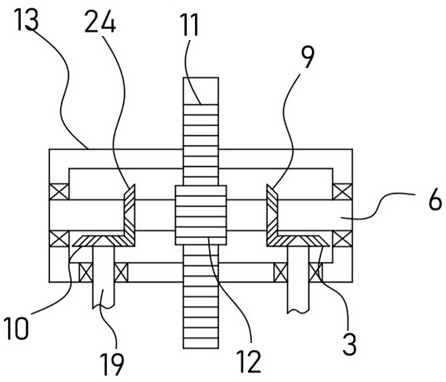

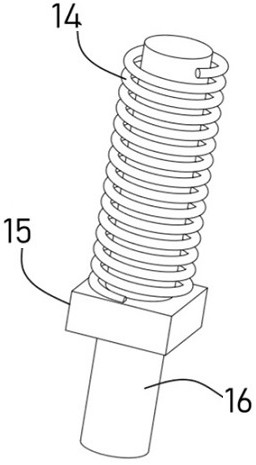

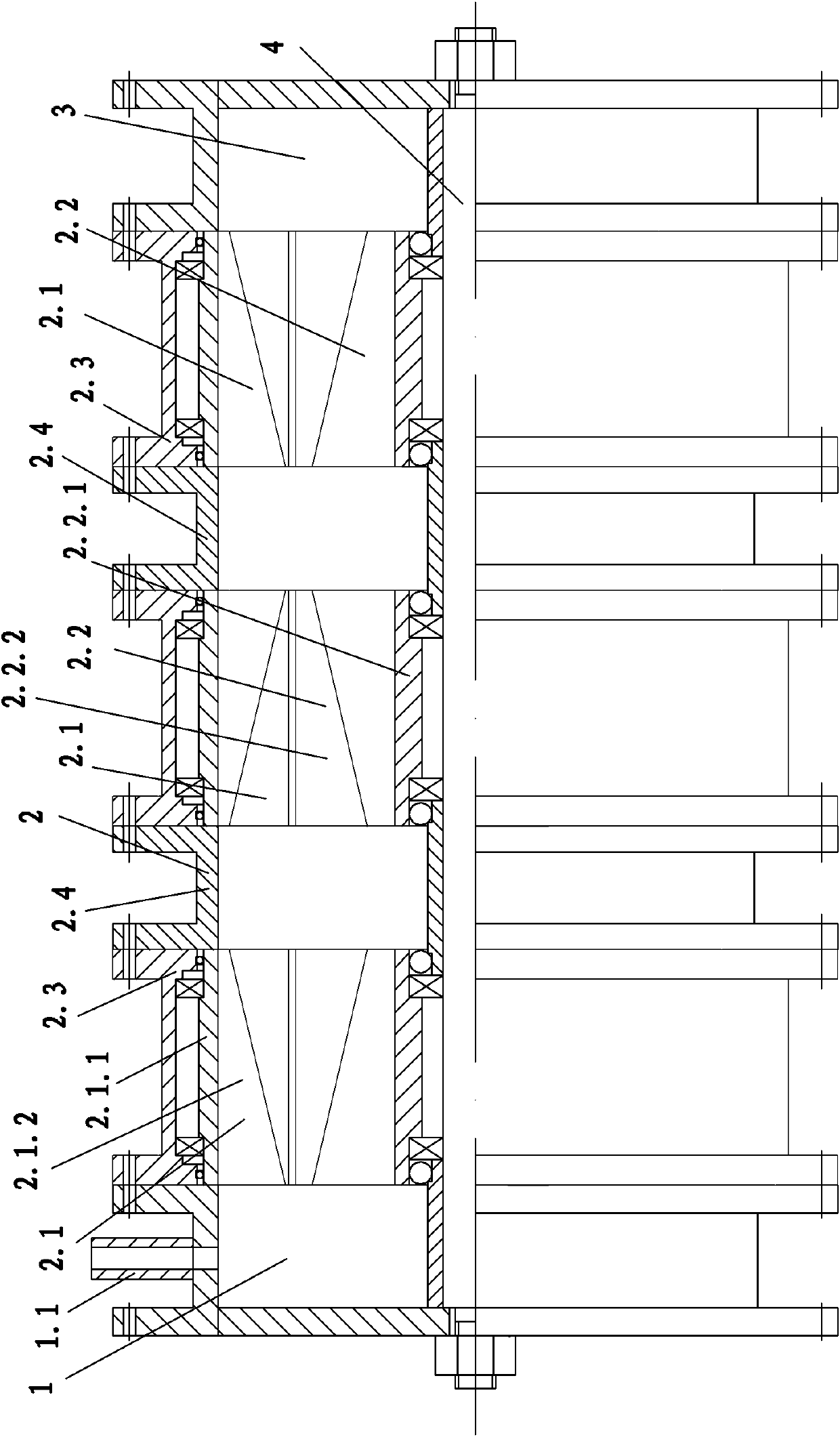

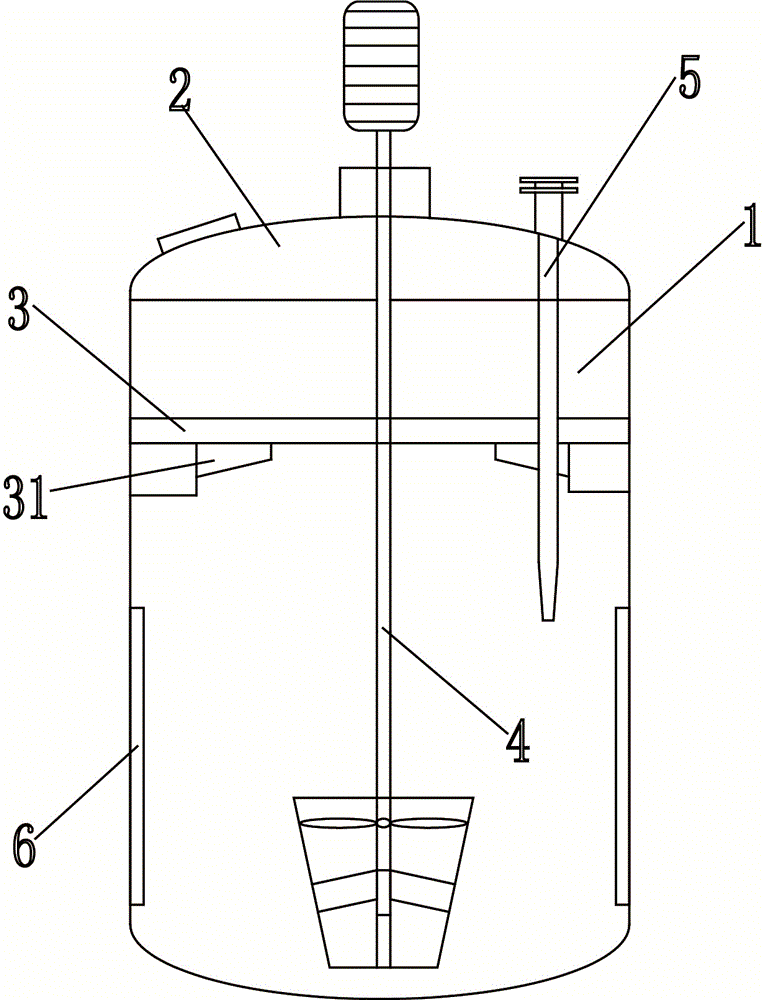

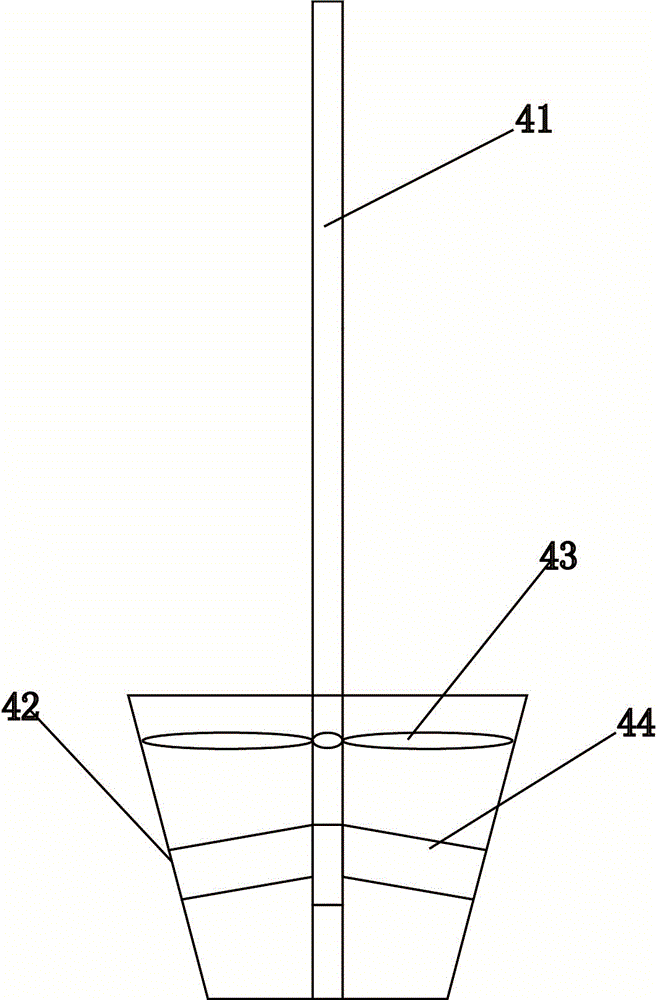

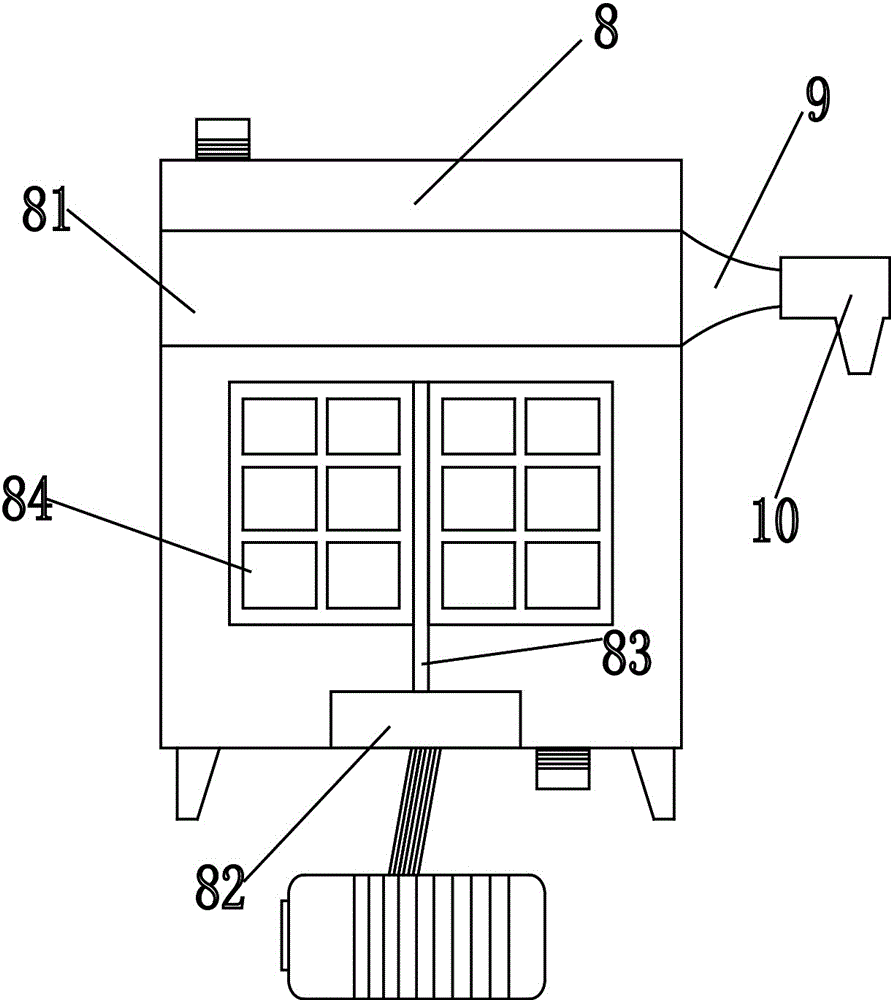

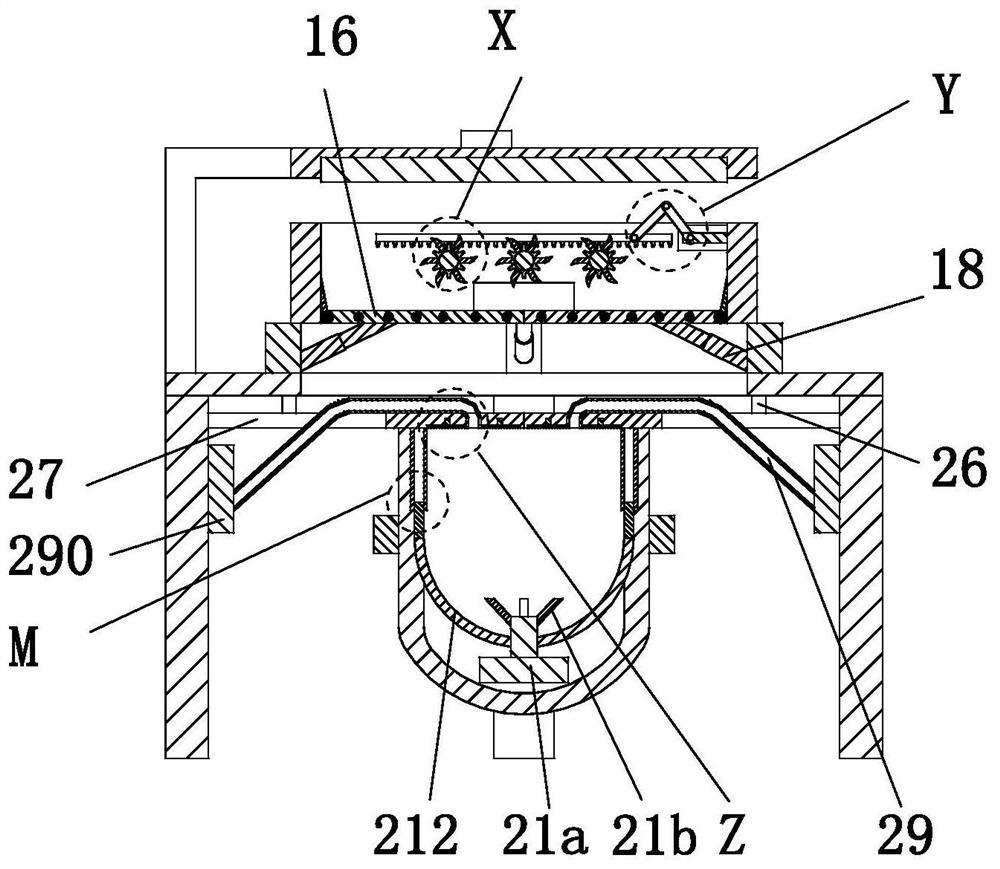

Wear prevention reaction kettle

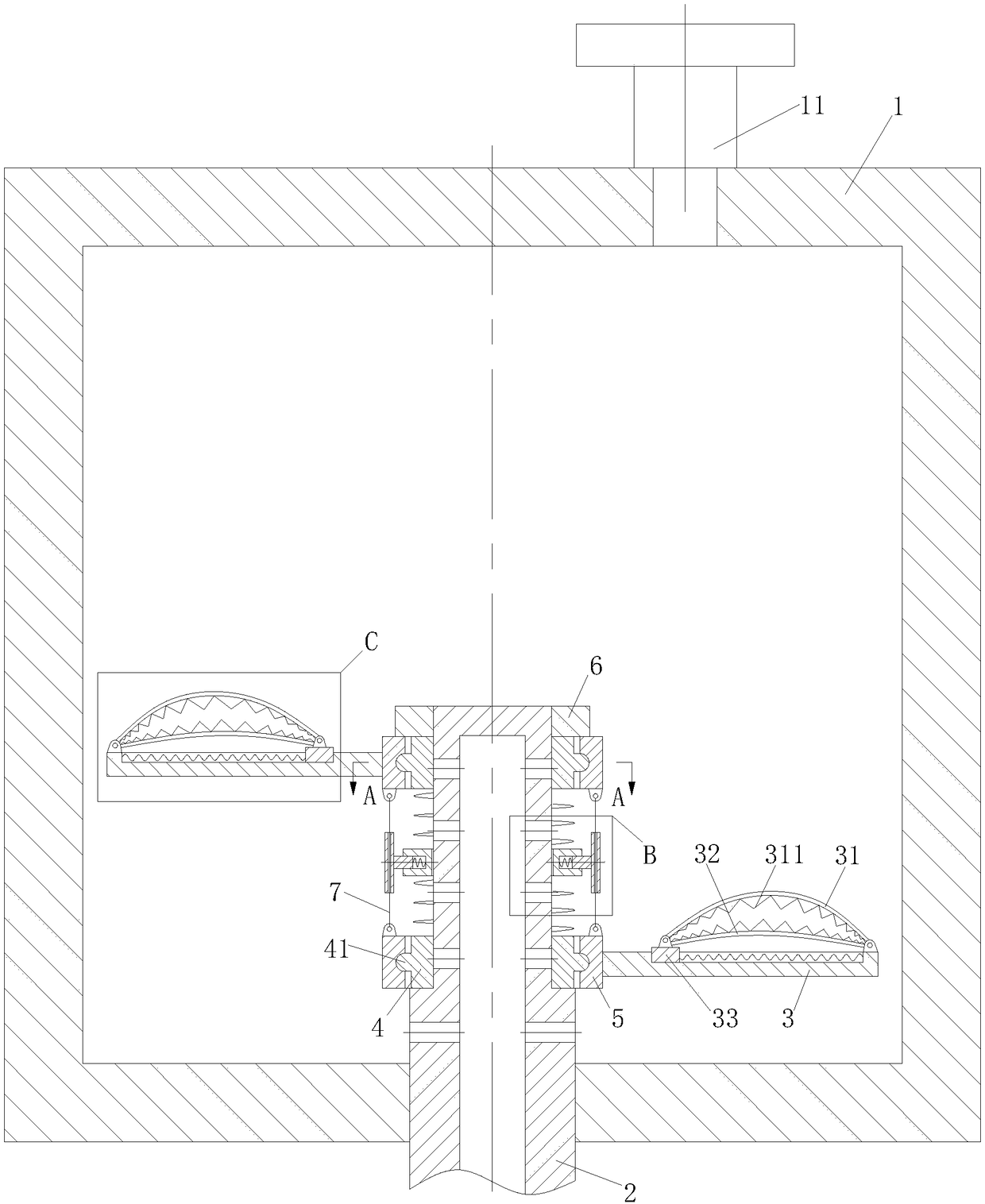

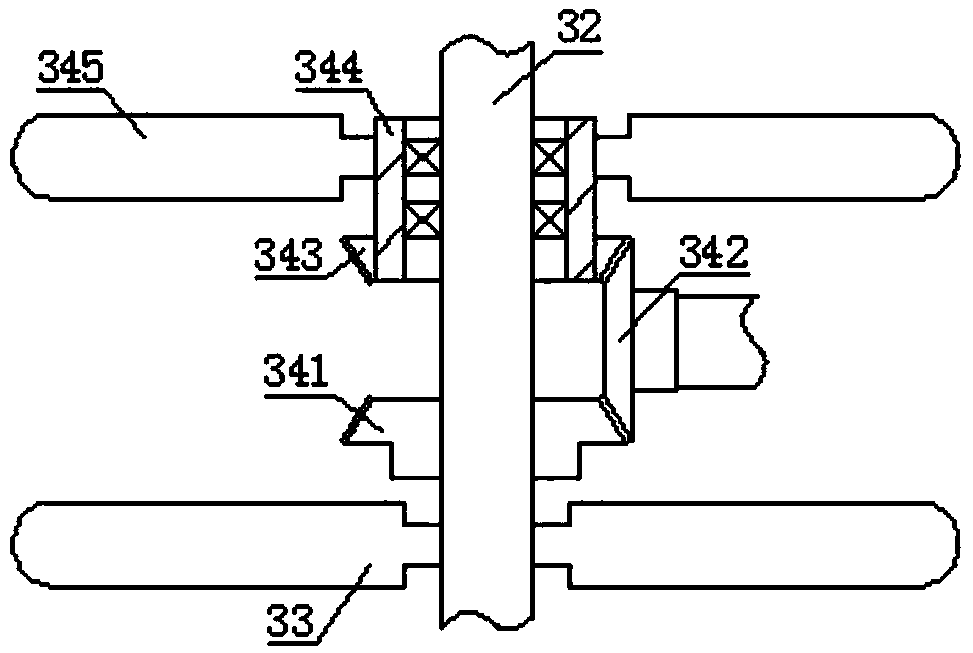

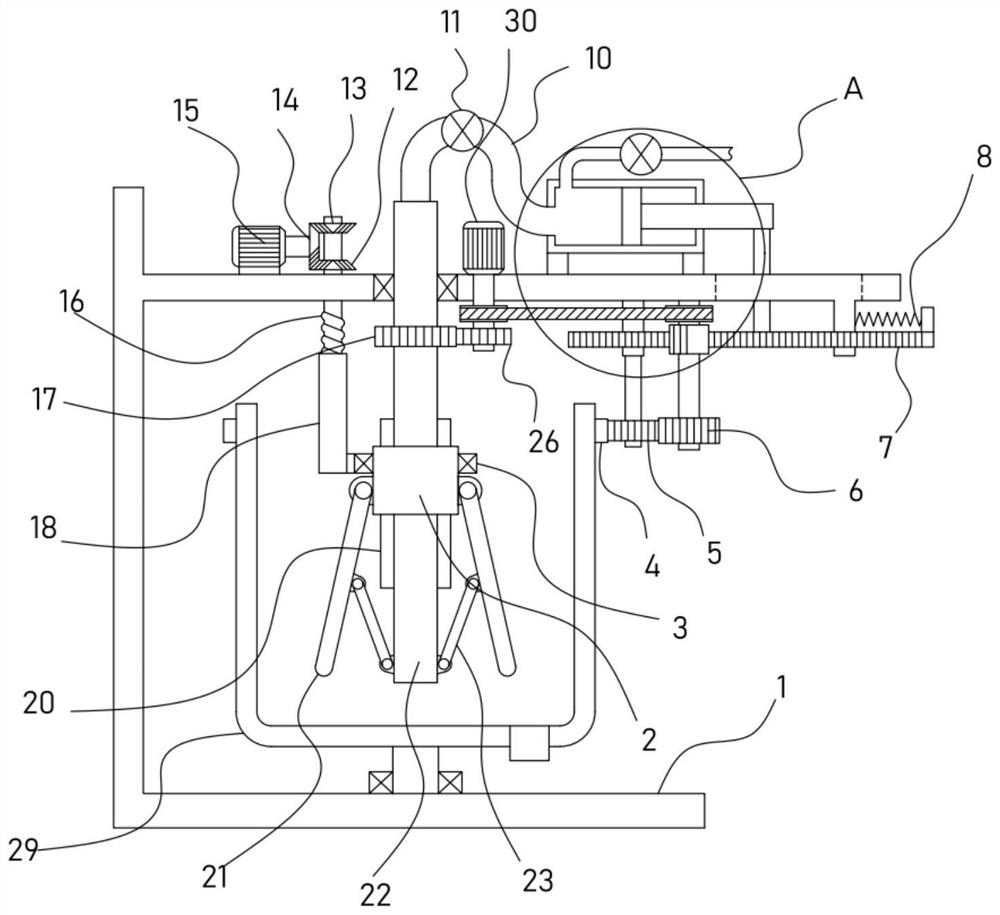

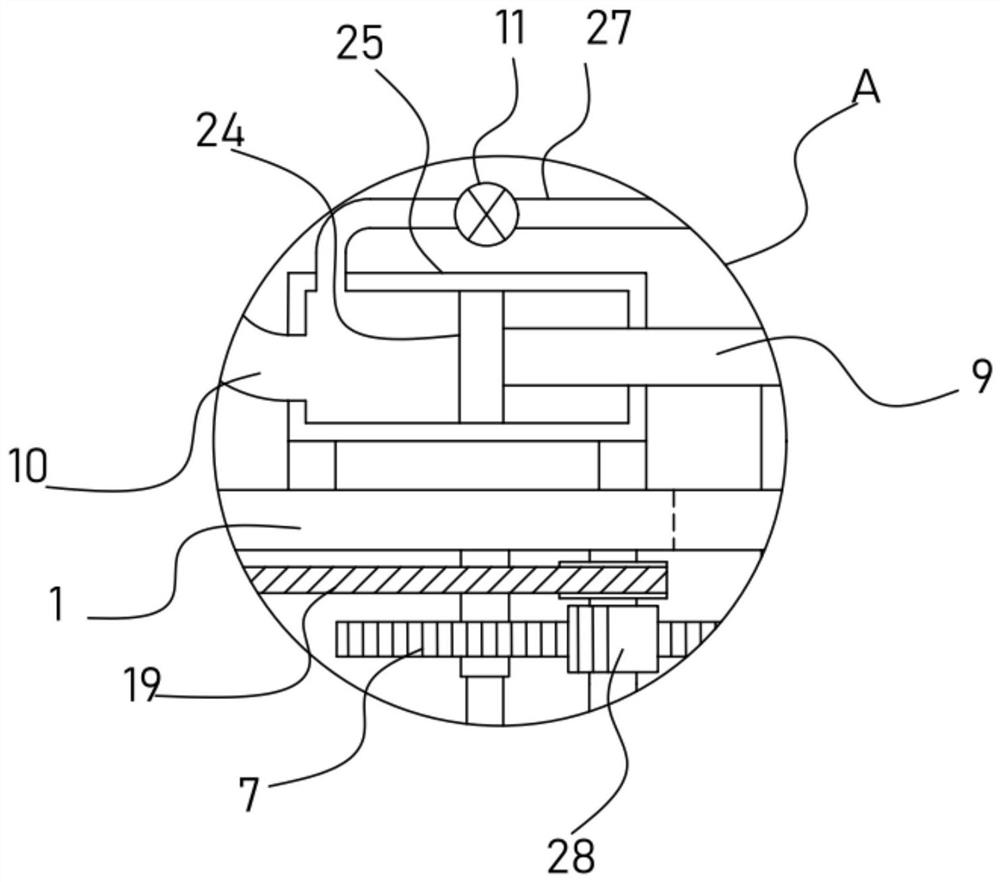

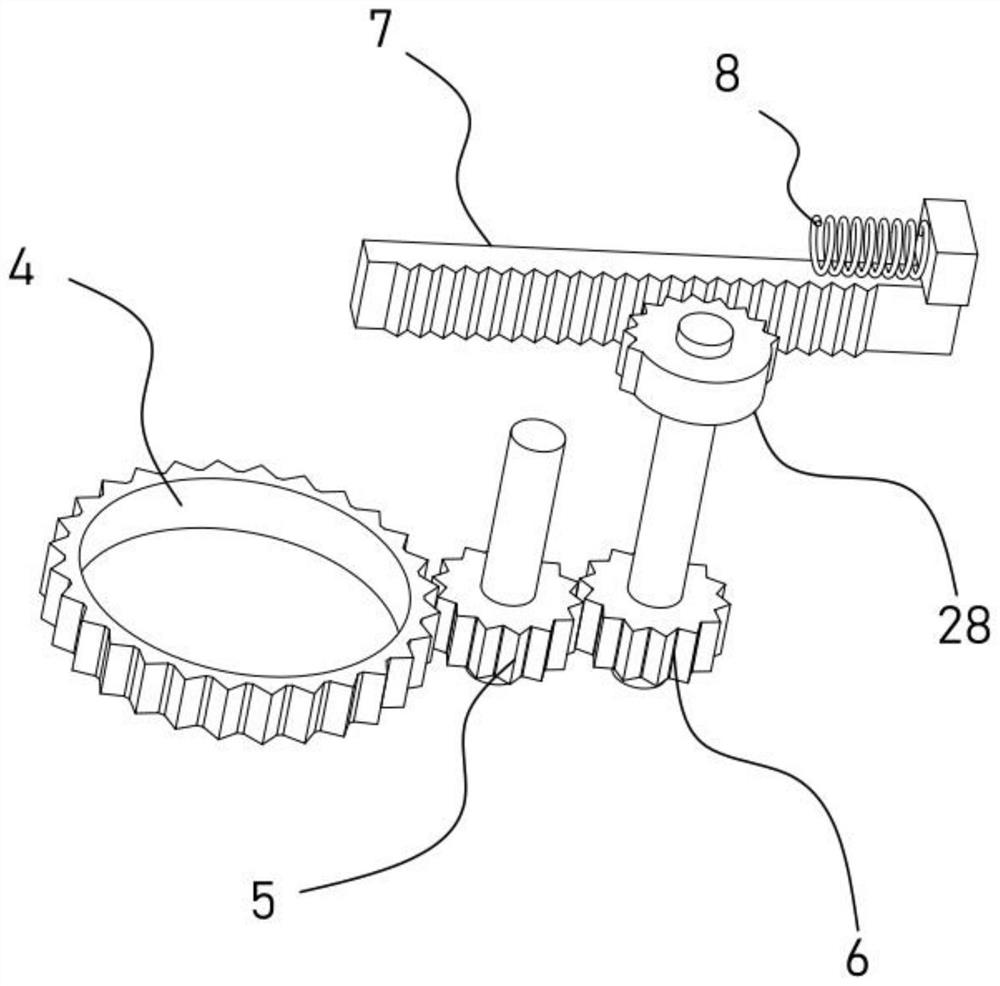

InactiveCN104437311AIncrease agitationImprove the mixing effectChemical/physical/physico-chemical stationary reactorsThermometerStator

The invention discloses a wear prevention reaction kettle which comprises a kettle body, a kettle cover, a U-shaped jacket and a stirring device, wherein the stirring device comprises a stirrer, a transmission device, an air pump, a shaft seal and a supporting seat; the stirrer is positioned inside the kettle body; the air pump, the shaft seal and the supporting seat are positioned on the kettle cover and are connected with the stirrer by virtue of the transmission device; a thermometer well stretches into the kettle body, and the upper end of the thermometer well is fixedly arranged on the kettle cover; the stirrer comprises a stirring shaft, a Y-shaped gas ejector pipe, a ring duct, a stator and a rotor; the air pump is connected with the Y-shaped gas ejector pipe by virtue of a hose; the stator is positioned behind the rotor; the kettle comprises a cylinder and an elliptical lower seal head; the cylinder and the elliptical lower seal head are encircled by the U-shaped jacket; and a spirally ascending batten is wound around the outer wall of the cylinder. According to the wear prevention reaction kettle disclosed by the invention, the adsorbate accumulated on the inner wall of the kettle body can be removed so as not to damage the kettle body; and moreover, bubbles can be reduced during stirring, and full contact between the mixtures is maintained.

Owner:NINGBO YUANOU FINE CHEM

Aluminum alloy degasifying agent

The invention relates to an aluminum alloy degasifying agent which consists of the following components in percentage by weight: 13-15 percent of ammonium carbonate, 22-25 percent of activated carbon and the balance of calcium carbonate. The ammonium carbonate is decomposed at high temperature and reacts with hydrogen and oxygen in an aluminum alloy liquid, and thus gases such as carbon dioxide, nitrogen dioxide, water vapor, ammonia gas and small amount of methane are filtered. Due to the generation of the water vapor, the stirring degree of the melt aluminum alloy liquid is improved and the escape of the gases and the floating of aluminum slag are improved.

Owner:黄宣斐

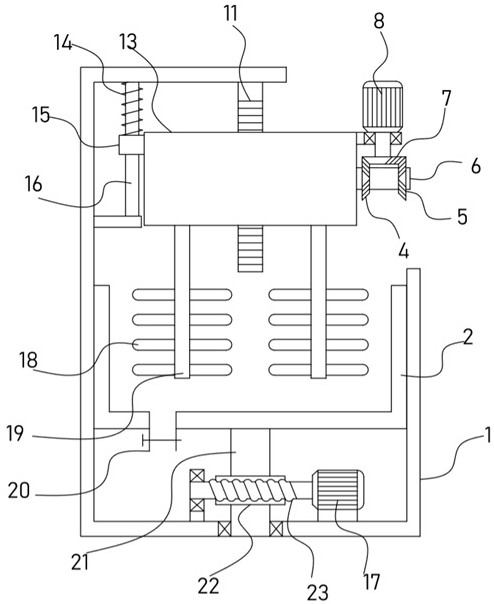

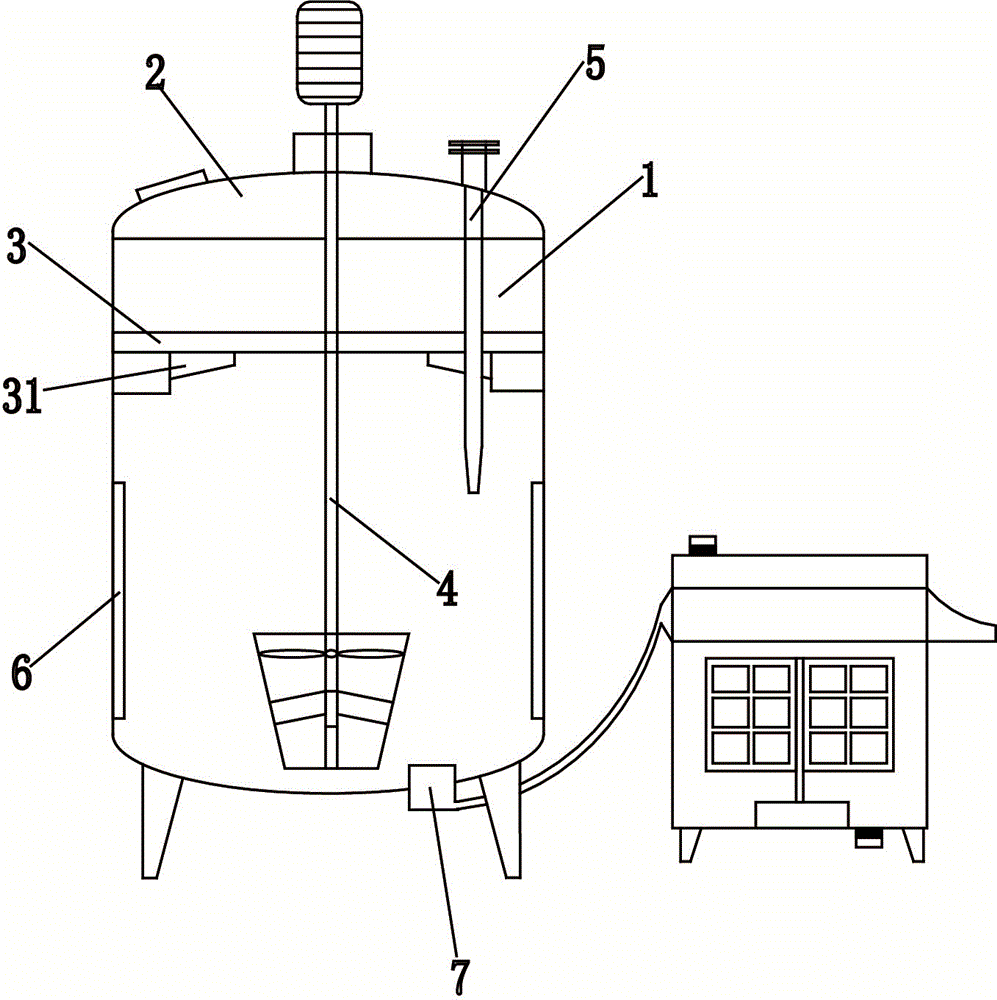

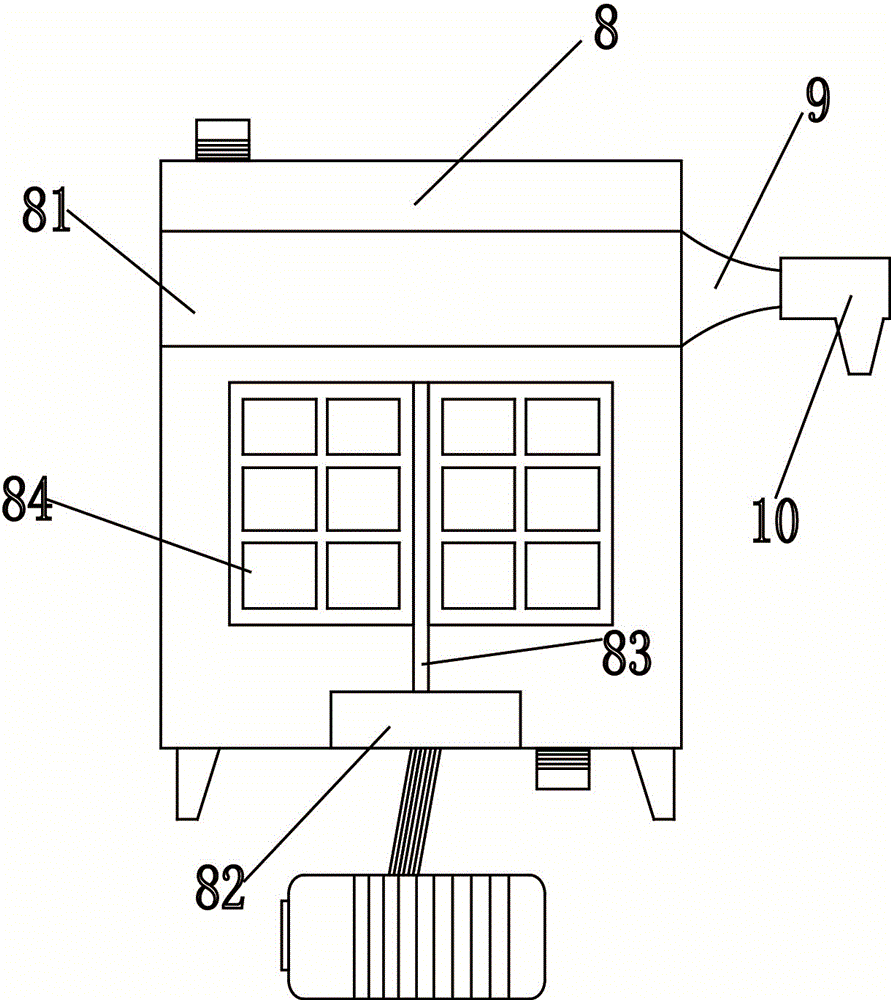

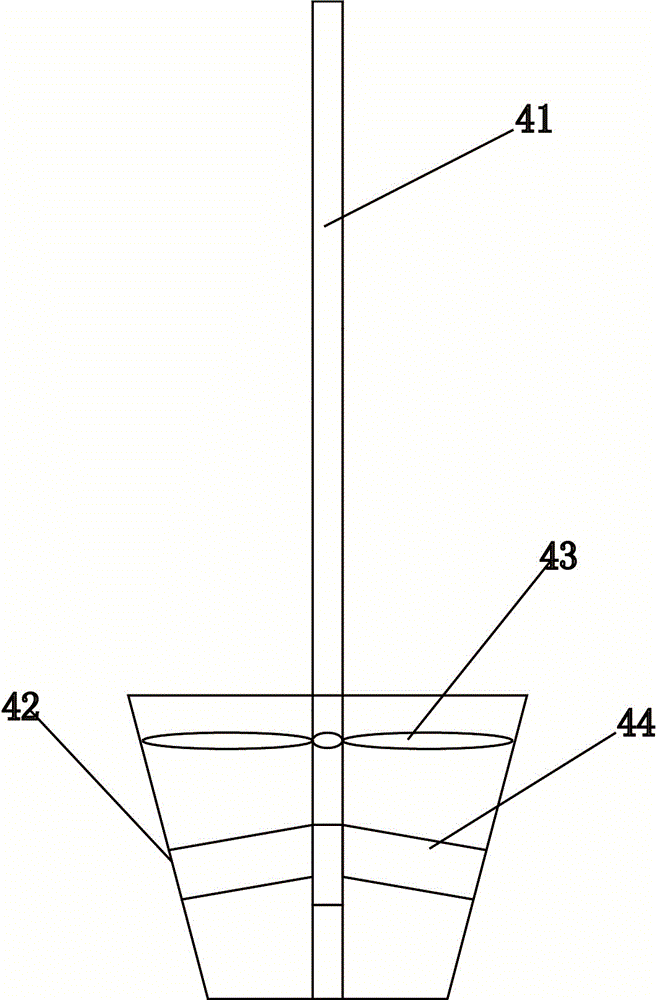

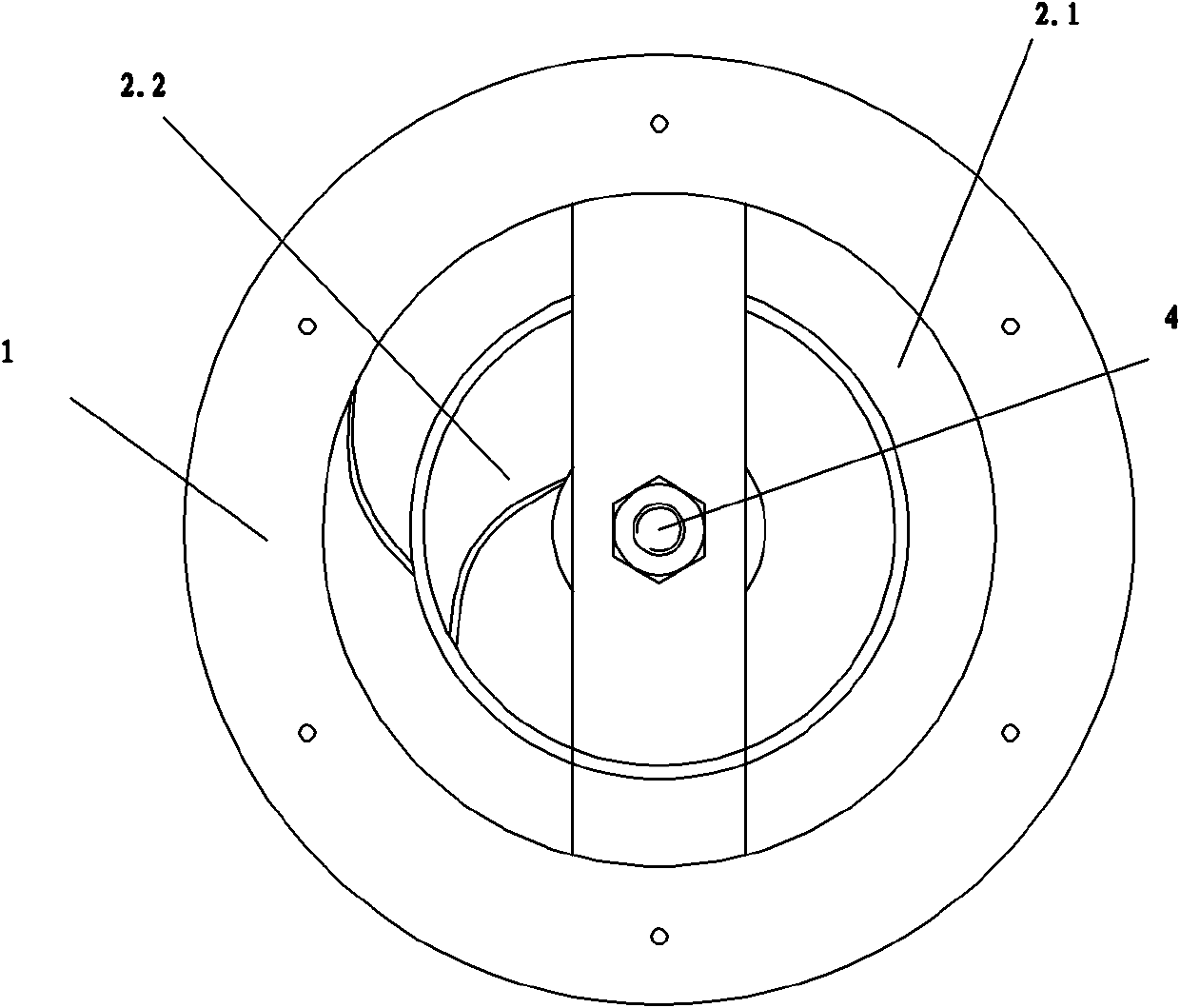

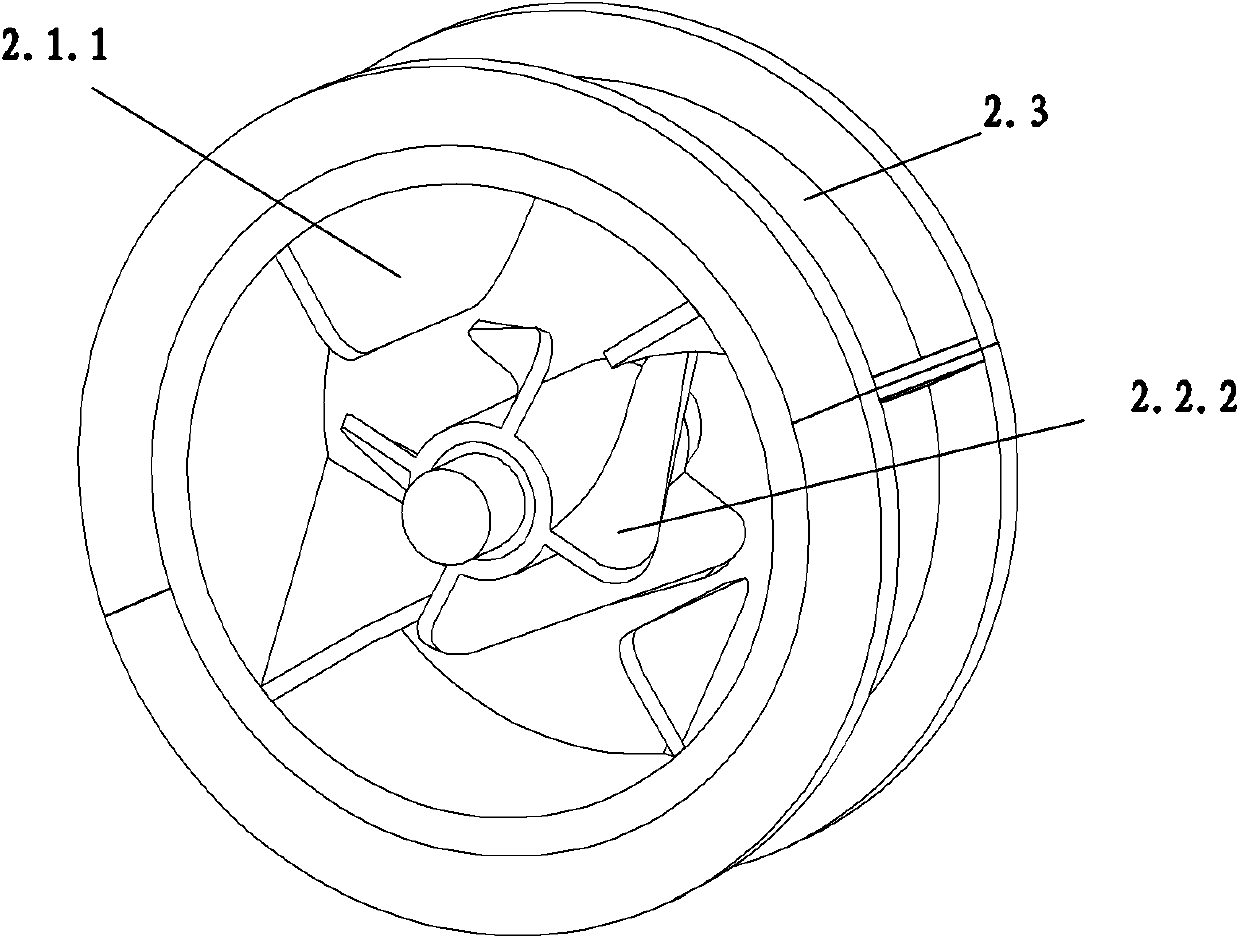

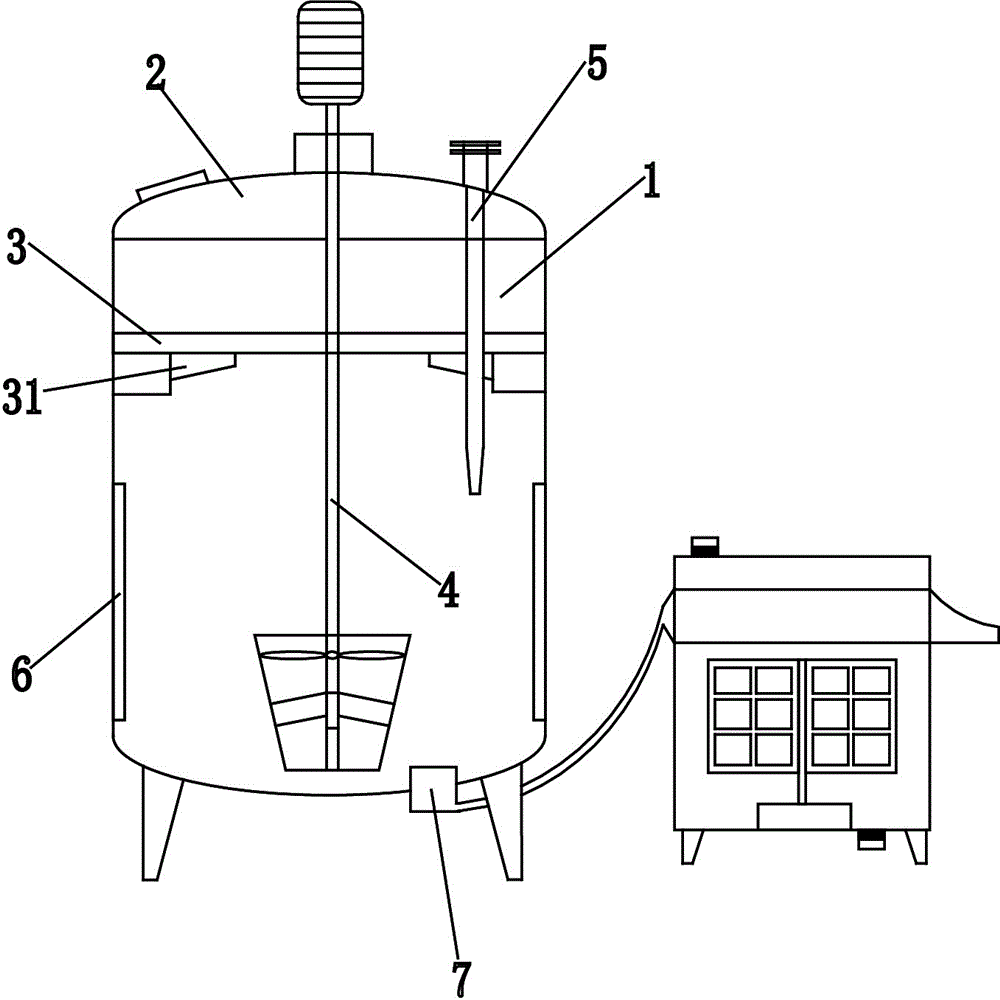

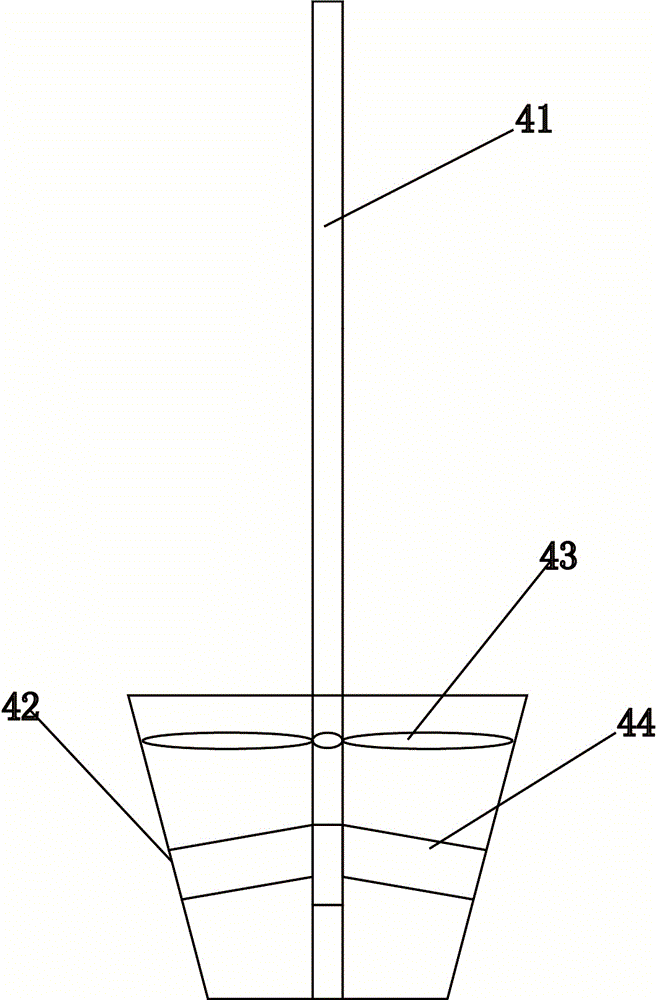

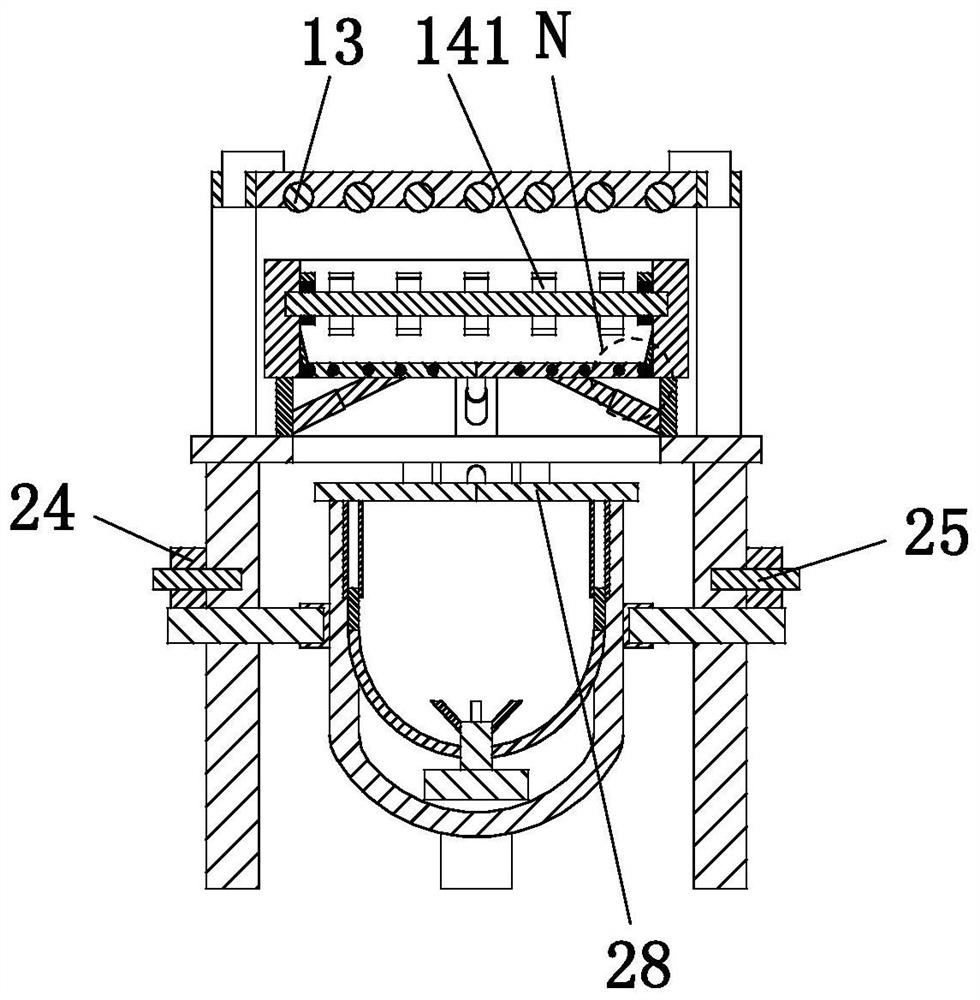

a reaction kettle

ActiveCN104474995BReasonable structural designNovel ideaChemical/physical/physico-chemical stationary reactorsControl engineeringMixed materials

The invention discloses a reaction kettle. The reaction kettle comprises a kettle body, a kettle cover and a mixing device, wherein a lug boss is arranged on the inner wall of the kettle body, a pressure cover plate is arranged in the kettle body and positioned on the lug boss, a through hole is formed in the center of the pressure cover plate, and a scraping knife is arranged at the lower end surface of the pressure cover plate and close to the inner wall of the kettle body; the mixing device comprises a mixer, a transmission device, a shaft seal and a support, the mixer is positioned in the kettle body, the shaft seal and the support are positioned on the kettle cover and connected with the mixer through the transmission device, and plug holes are funnel-shaped and uniformly formed in the kettle cover; a thermometer sleeve tube extends into the kettle, the upper end of the thermometer is fixed on the kettle cover, and a thermometer is arranged in the thermometer sleeve tube; the mixer comprises a mixing shaft, a ring-shaped guide tube, a stator and a rotor; and diversion battens are radially arranged and circumferentially, uniformly distributed on the inner wall of the kettle body, and extend along the axial direction. The reaction kettle disclosed by the invention can reduce the generation of air bubbles during mixing through the novel mixing device, keeps full contact between mixed materials, and improves the mixing effect.

Owner:NINGBO YUANOU FINE CHEM

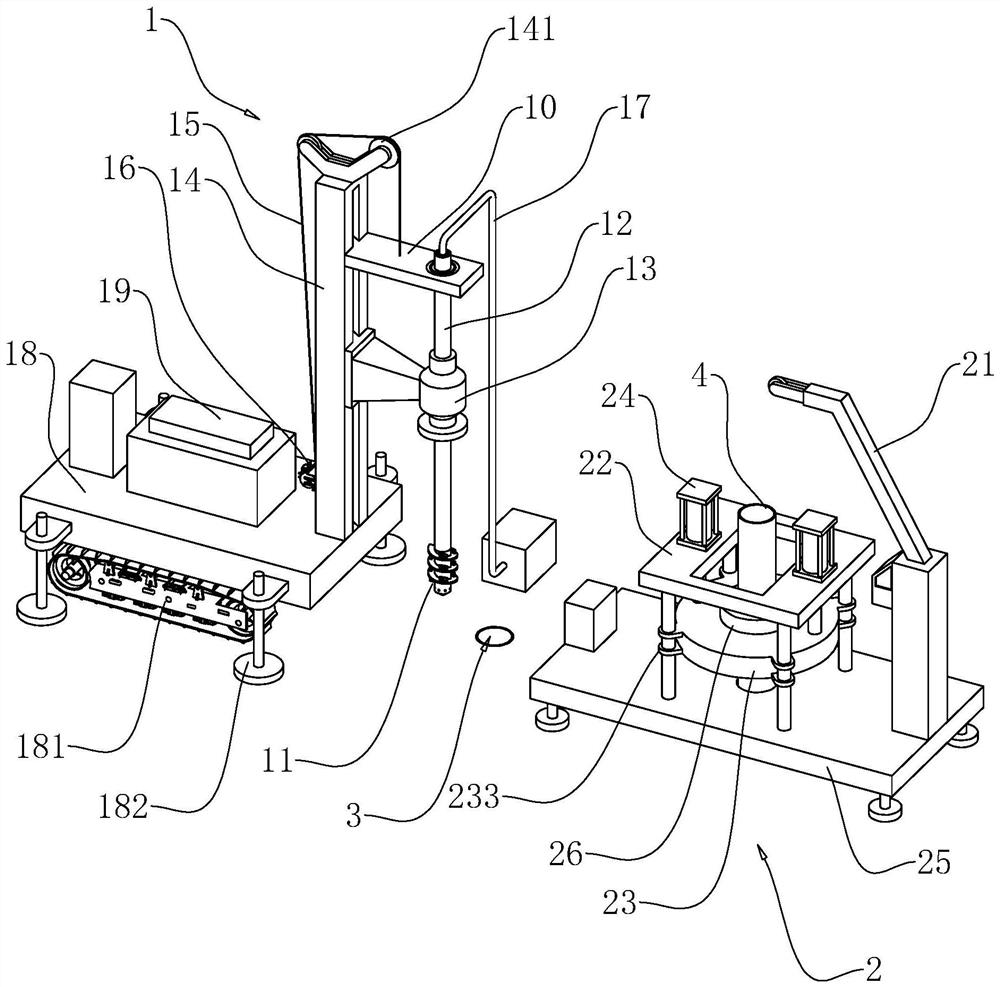

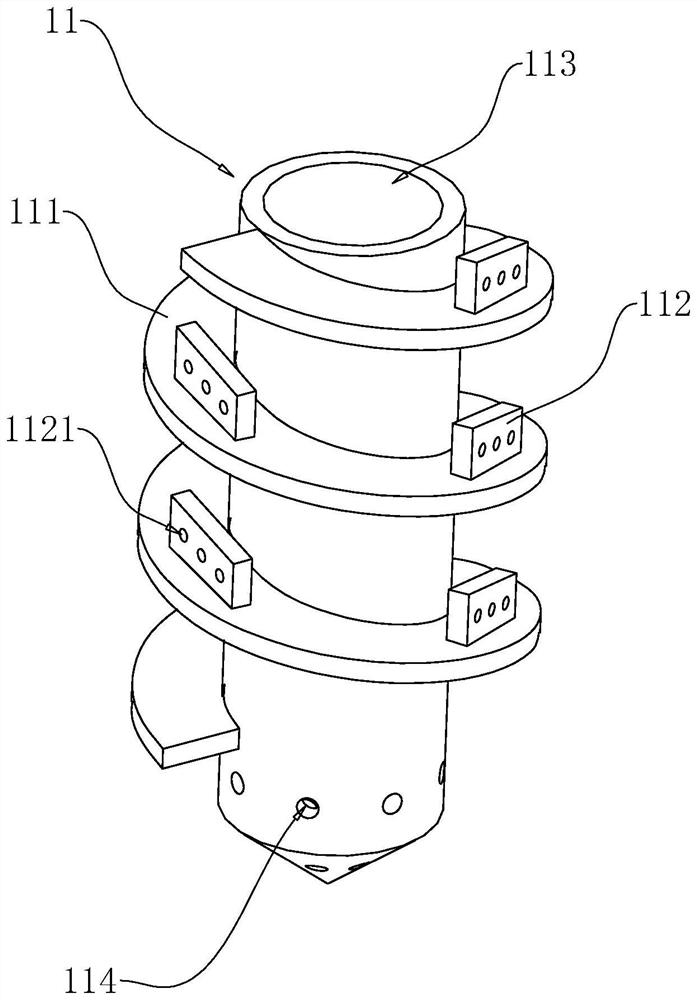

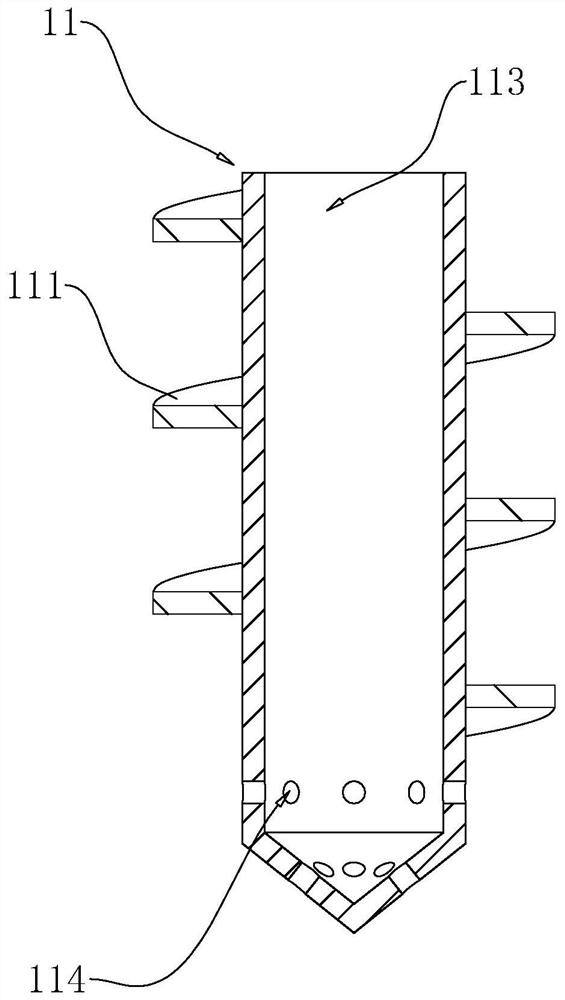

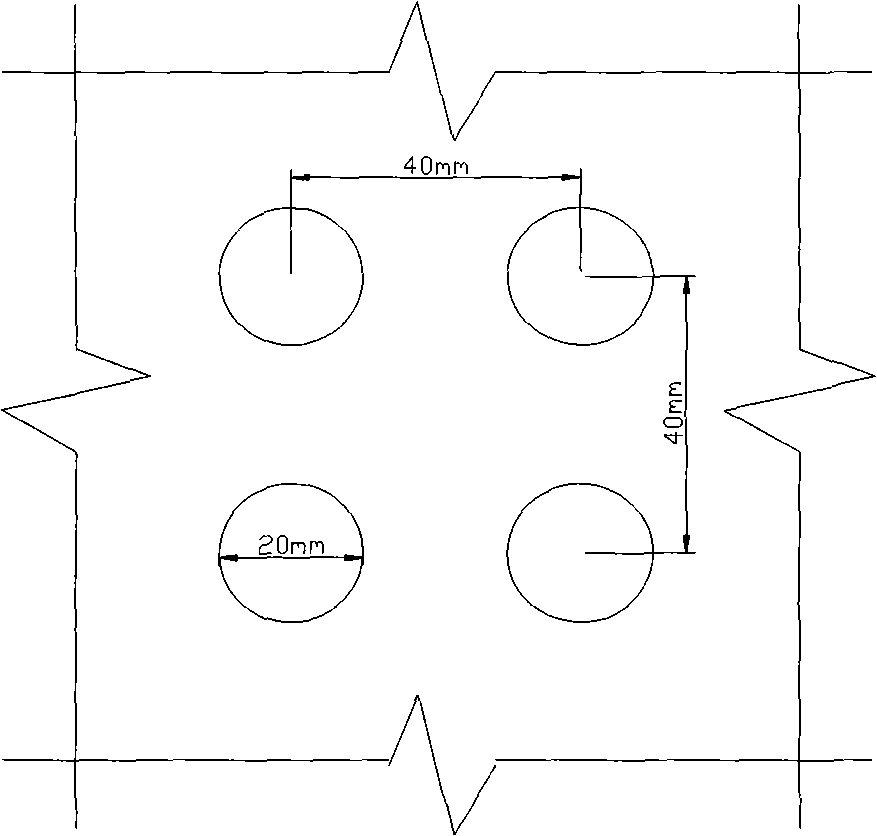

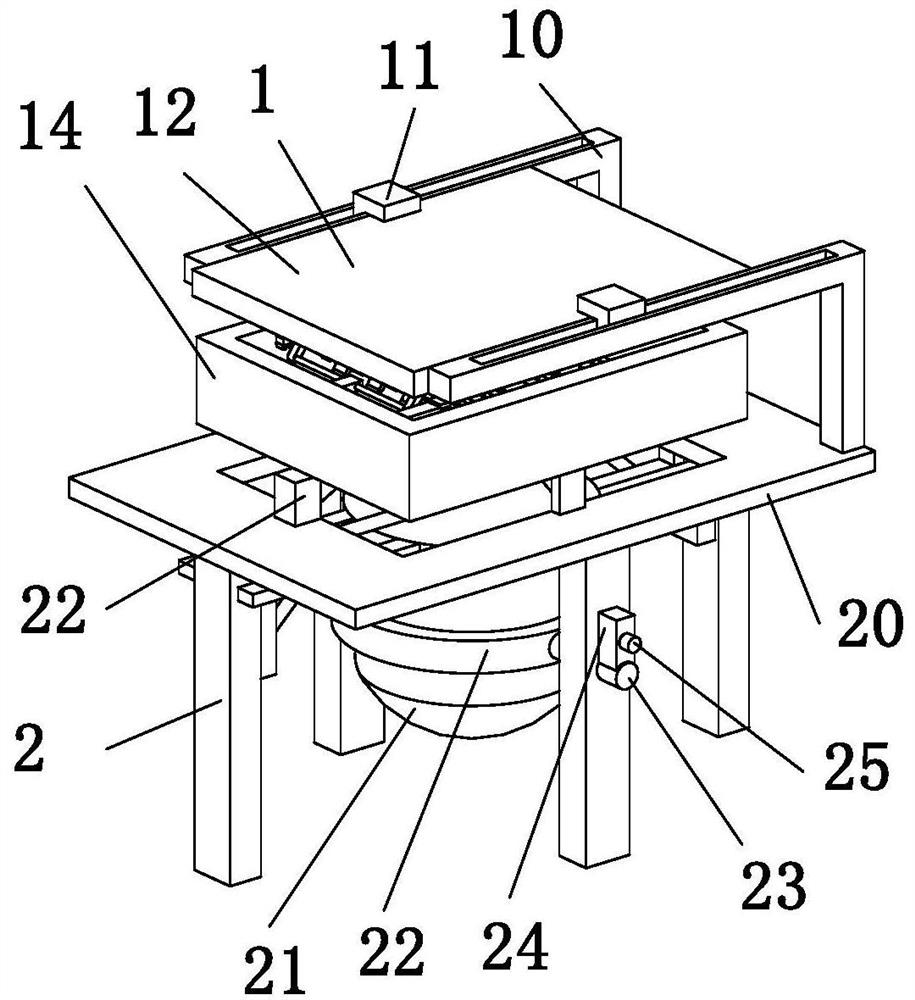

Hole guiding and pile planting equipment and construction method

PendingCN113309088AIncrease agitationReduces the problem of premature solidificationDrill bitsDerricks/mastsCement compositesArchitectural engineering

The invention relates to the field of building construction, in particular to hole guiding and pile planting equipment and a construction method. The hole guiding and pile planting equipment comprises a hole guiding mechanism used for forming a drill hole in a construction site and a pile planting mechanism used for pressing a preset pipe pile into the drill hole. The hole guiding mechanism comprises a drill bit; a main blade is connected with the peripheral face of the drill bit; a plurality of branch blades are connected with the blade face of the main blade; and an included angle between each branch blade and the main blade ranges from 30 degrees to 90 degrees. The construction method adopting the hole guiding and pile planting equipment includes the steps of construction preparation, drilling and hole forming, cement pile manufacturing, core pile inserting and the like. According to the hole guiding and pile planting equipment and the construction method, through the mutual cooperation of the main blades and the branch blades, the stirring degree of cement paste is improved, so that the composition of the cement paste and mixing between the cement paste and soil particles in the drill hole are more sufficient, the cement paste is more uniform, the problem that the cement paste is locally solidified too early is solved, and a finally formed cement composite pile has better quality.

Owner:江苏乐建建设有限公司

Gravel mixing device for constructional engineering

InactiveCN111974284ARealize the effect of rotating and stirringRealize the rotating stirring effectShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionClassical mechanics

The invention discloses a gravel material mixing device for constructional engineering, and relates to the technical field of building construction. The device comprises a fixing frame, the fixing frame is provided with a mixing tank used for storing sand and stone materials, a driving motor is fixed to a transmission box, the driving motor is in driving connection with a transmission mechanism located in the transmission box, the transmission mechanism is in driving connection with two stirring shafts vertically extending into the mixing tank, and a plurality of pairs of stirring rods are fixed to the stirring shafts at equal intervals. The transmission mechanism can drive the two stirring shafts to drive the respective stirring rods to rotate in opposite directions, the rotary stirring effect on sand and stone materials in the mixing tank is realized, the arranged stirring rod can vertically reciprocate while rotating along with the stirring shaft, the rotary stirring effect on the sand and stone materials at different vertical positions in the mixing tank is achieved, and the sufficient stirring degree of the sand and stone materials is remarkably improved. Meanwhile, the sand and stone materials in the mixing tank can be driven to rotate relative to the stirring rod, and sufficient and efficient stirring and mixing of the sand and stone materials are achieved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Greenhouse gas collecting device

The invention relates to the technical field of gas collection, in particular to a greenhouse gas collecting device. The device comprises a floating plate used for floating on the surface layer of a water body, a collecting pipe used for collecting gas is arranged on the floating plate in a sliding and penetrating mode, the end, penetrating through the floating plate, of the collecting pipe is located in the water body, a valve is arranged at the end, away from the water body, of the collecting pipe, a driven gear is coaxially arranged on the collecting pipe, a motor is arranged on the floating plate, a driving gear is arranged on a rotating shaft of the motor, and the driving gear is meshed with the driven gear. With the device adopted, the detection accuracy of greenhouse gas diffused in the water body can be improved.

Owner:杭州亚太工程管理咨询有限公司 +1

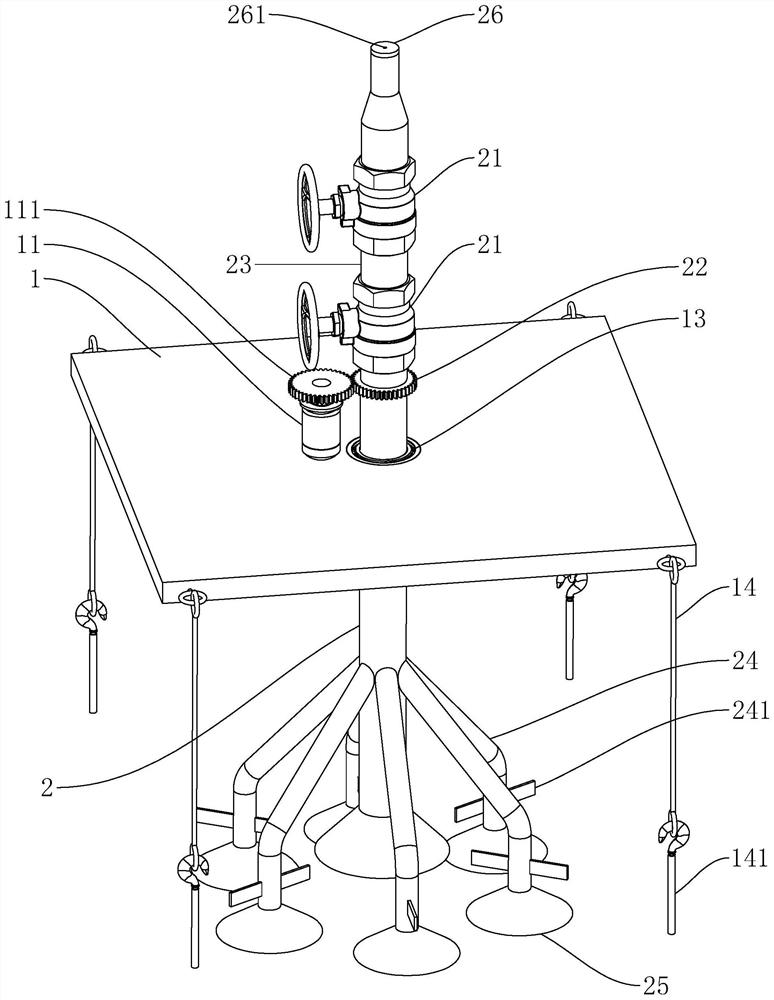

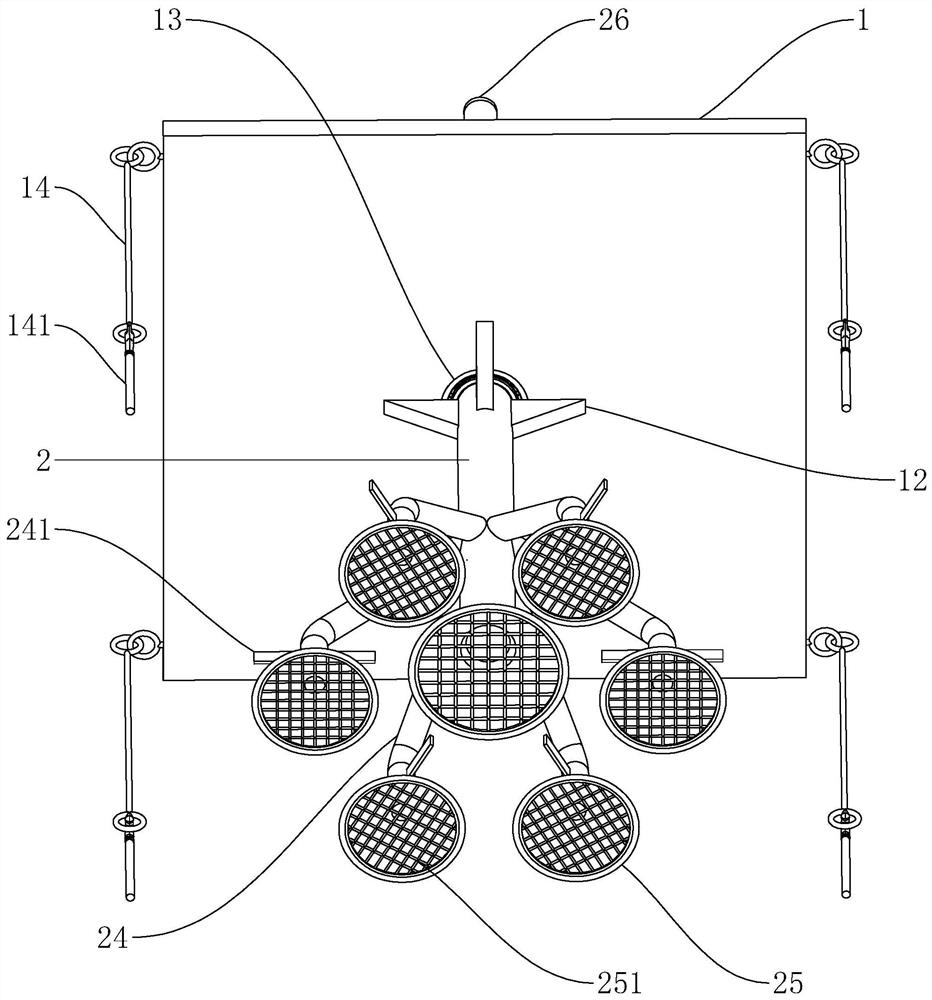

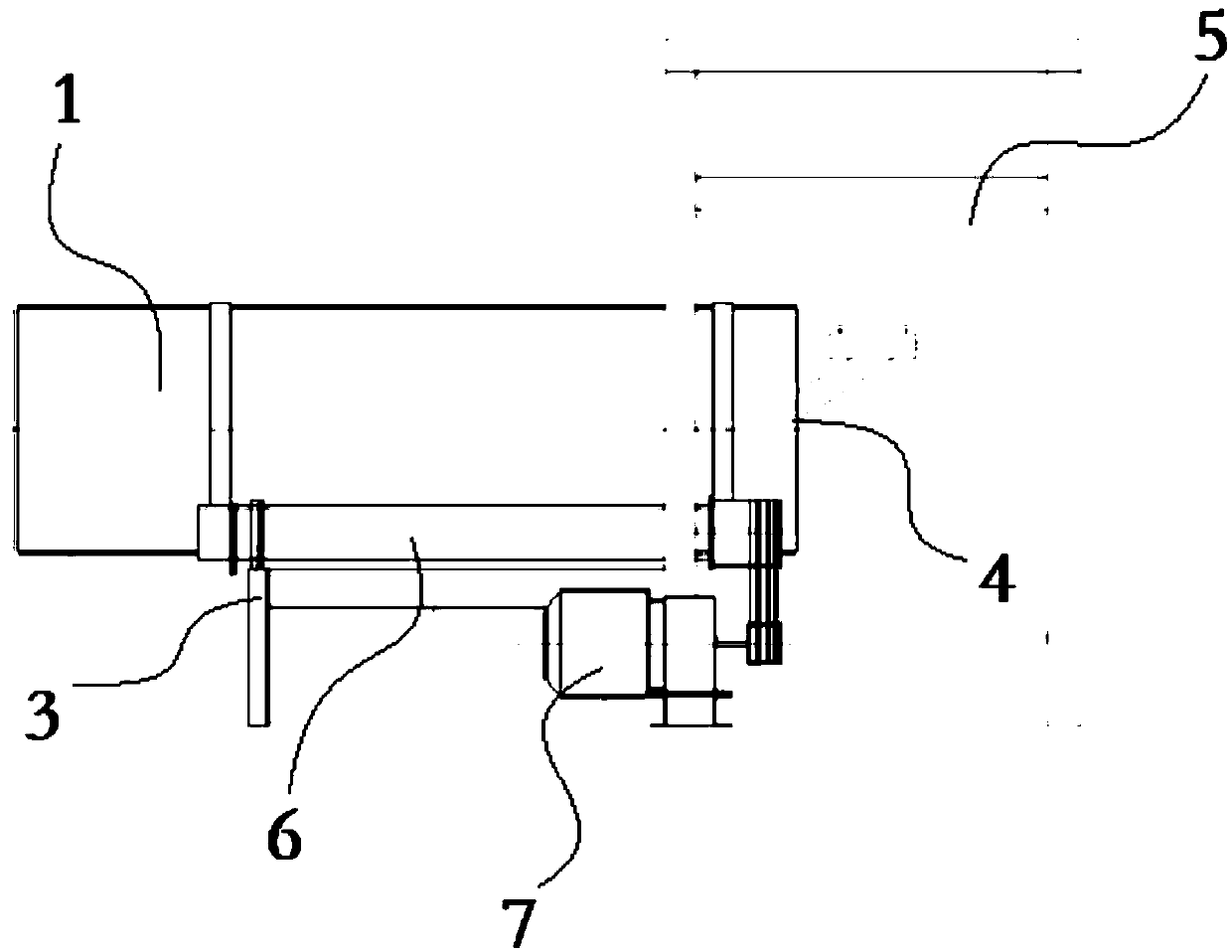

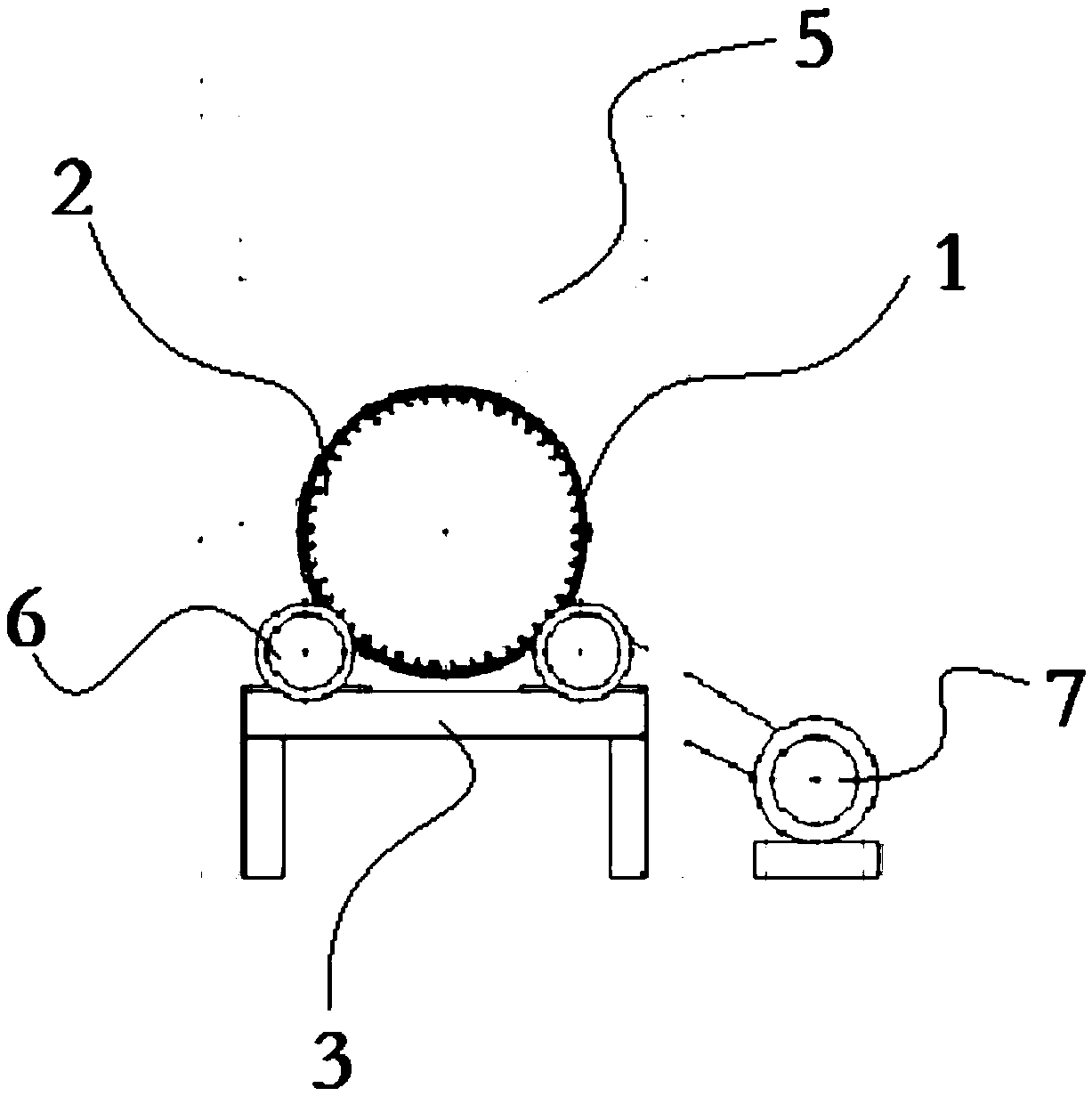

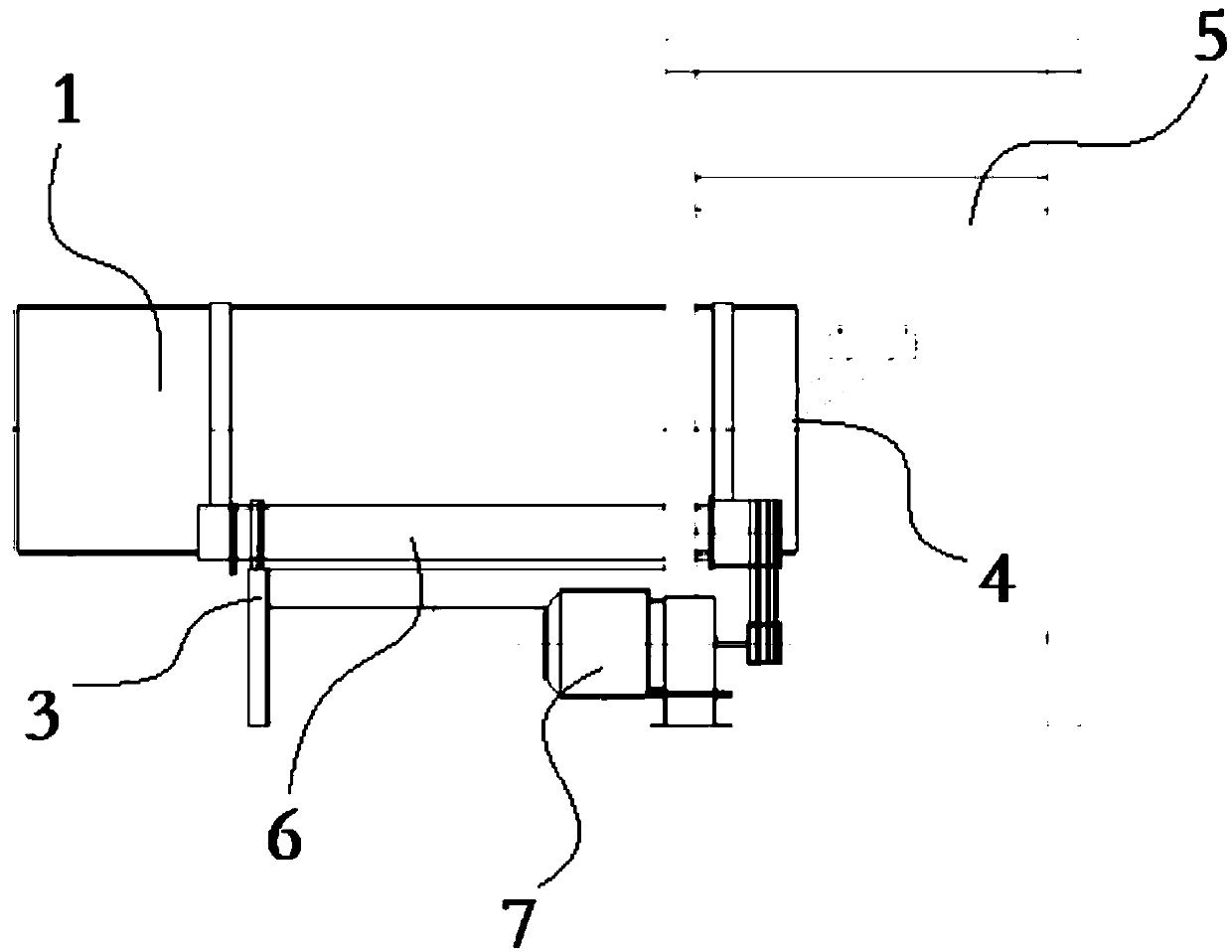

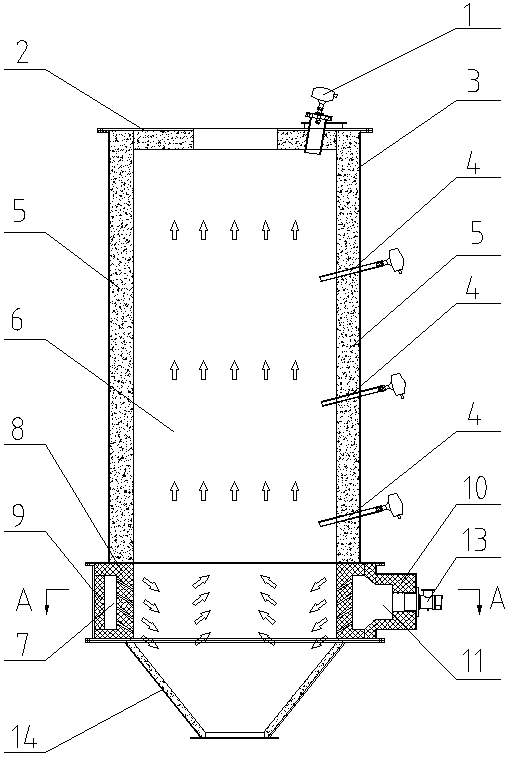

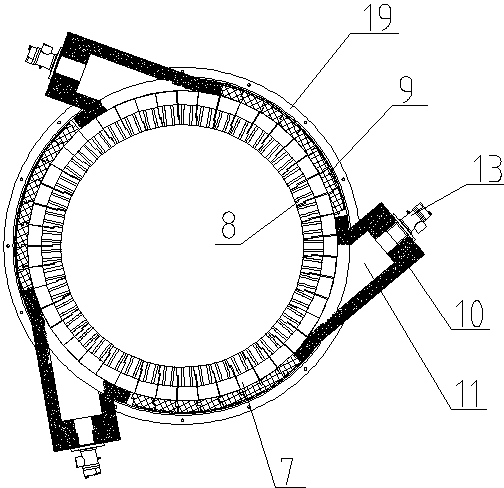

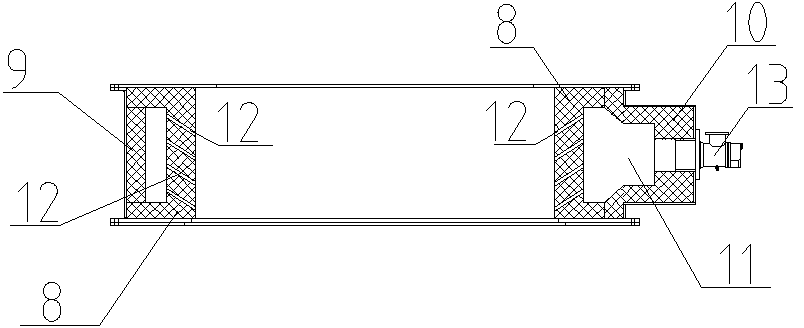

A method and device for a jet-air-lift split membrane bioreactor

ActiveCN101284698BReduce pollutionIncrease agitationSustainable biological treatmentBiological water/sewage treatmentSmall footprintEngineering

The invention provides a method for manufacturing a jet gas-stripping type independent membrane bioreactor as well as a device used for realizing the method. A jet aerator is adopted to replace the traditional blower for realizing the stripping effect of a membrane module, thereby greatly reducing the operational energy. Partial circulation solution in a bio-aeration pool flows through the jet aerator at a high speed to generate negative pressure for sucking air in, a fast mixed gas-liquid two-phase flow which is evenly ejected into the membrane module through a novel water and air distributing device is formed, continuous and effective washing and air bump rinse are carried out, the pollution of the membrane is effectively reduced and the service life of the membrane is prolonged. The violent agitation function produced by the jet aerator also increases the mass-transfer velocity in the mixed solution, so as to speed up the biochemical reaction and improve the treatment efficiency. The operational energy of the method is low, the pollution degree of the membrane is reduced, and the initial investment of the equipment is decreased. The structure of the device is simple, the occupied area is small, the operation is easy, and the automatic operation and the operation control are convenient.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

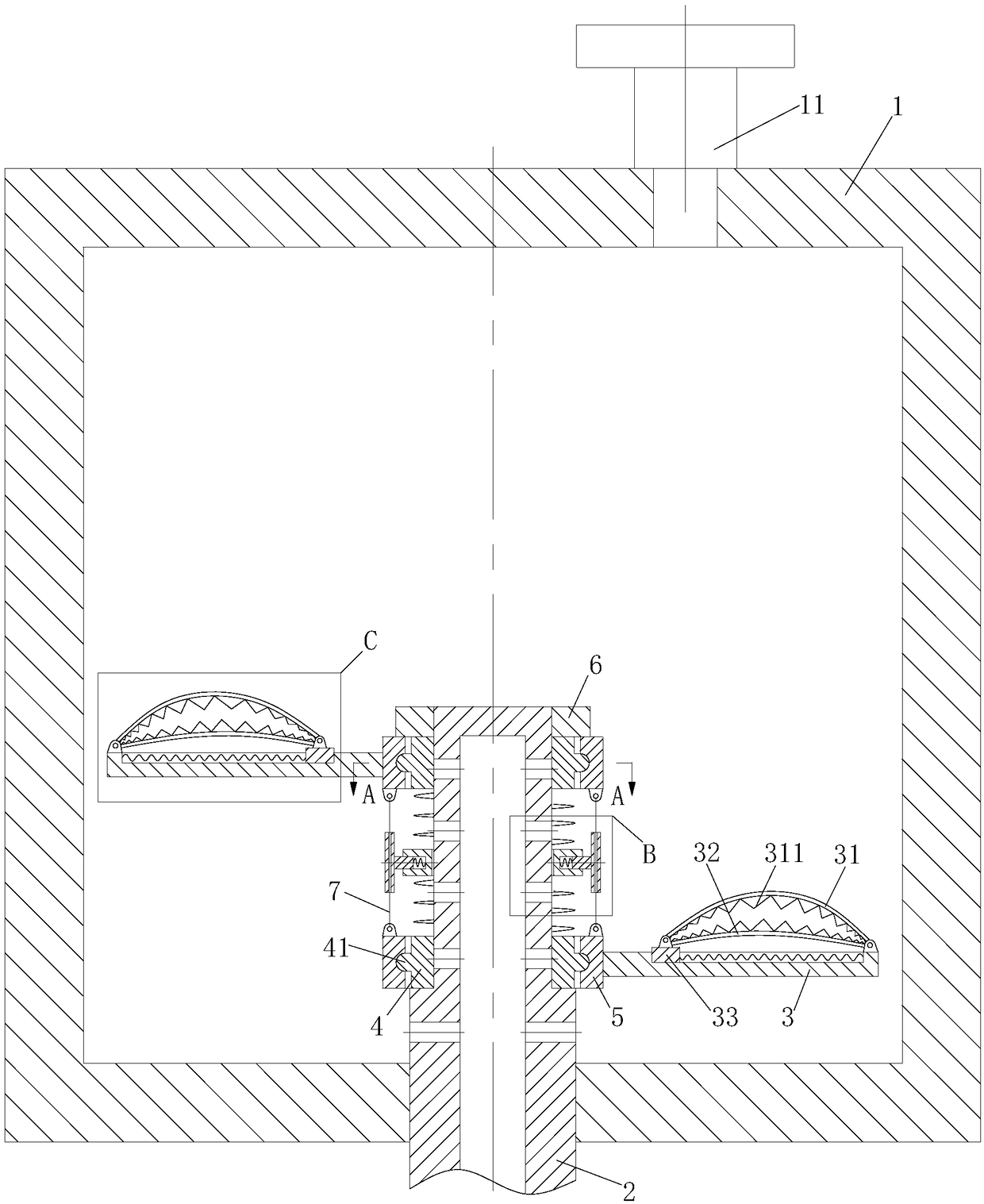

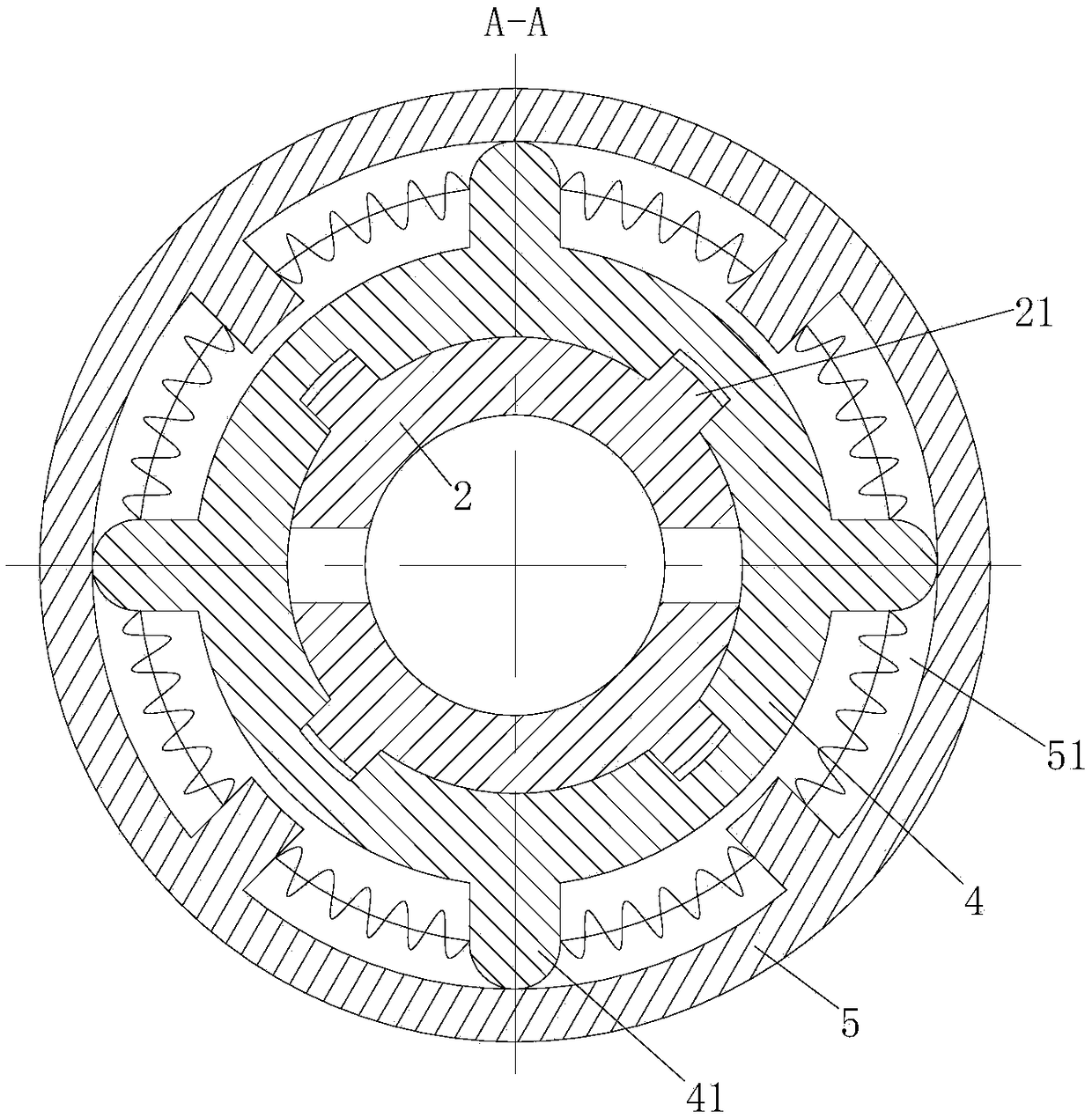

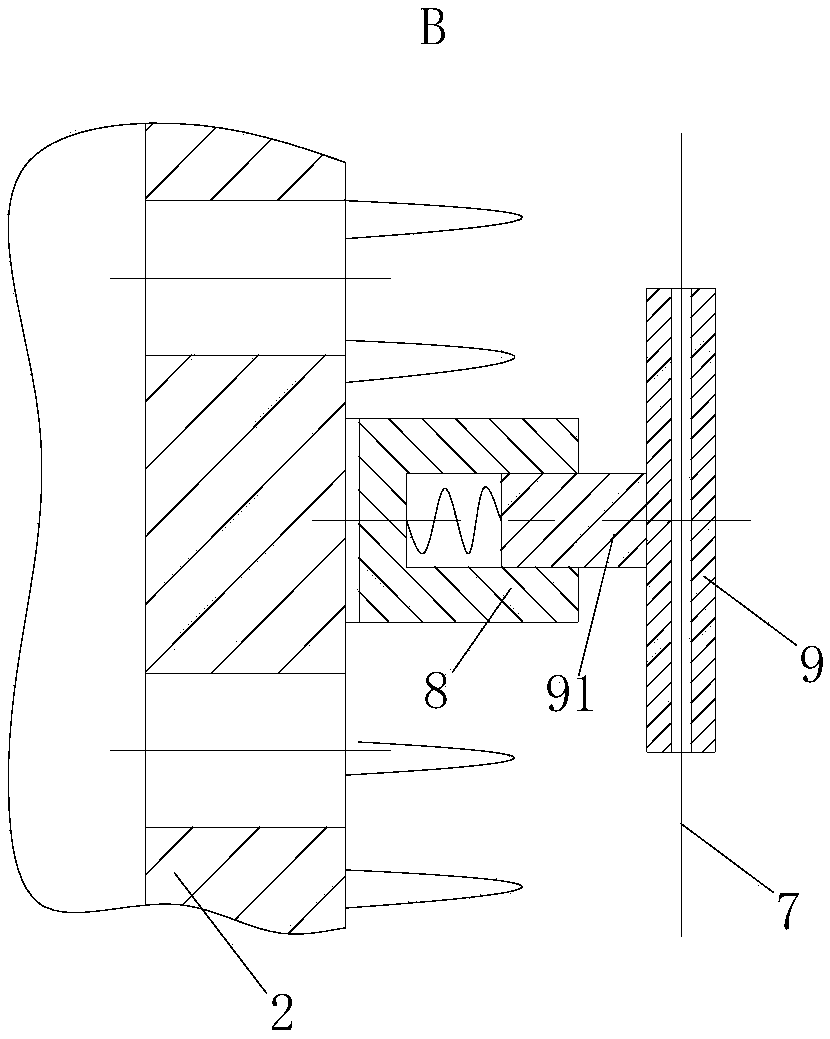

Industrial waste gas treatment device

PendingCN108939884AExtended service lifeReduced chance of fatigue fractureGas treatmentDispersed particle separationBreakage probabilityDrive shaft

The invention belongs to the technical field of industrial waste gas treatment, and particularly relates to an industrial waste gas treatment device, which comprises a washing tank, a driving shaft, astirring rod, a pipe joint, a mobile ring, a torsion ring, a spring and a limiting ring, wherein a group of rectangular strip protrusions are axially arranged on the cylindrical surface of the driving shaft evenly, and the mobile ring, the spring and the torsion ring are respectively arranged on the driving shaft from bottom to top in a sliding manner; a group of rectangular slots are arranged ina central hole of the mobile ring, and a group of ball head cylindrical protrusions are evenly arranged on the cylindrical surface of the mobile ring; a ring type semicircular groove is formed in thecentral hole of the torsion ring, and a group of rectangular protrusions are evenly arranged in the ring type semicircular groove in the torsion ring. The spring is arranged between the mobile ring and the torsion ring, on one hand, the buffering of starting resistance can be realized, and the service life of the driving shaft can be further prolonged; on the other hand, the absorption of external impact can be realized, the breakage probability of the driving shaft due to fatigue can be reduced, and the service life of the driving shaft can be prolonged.

Owner:彭圆

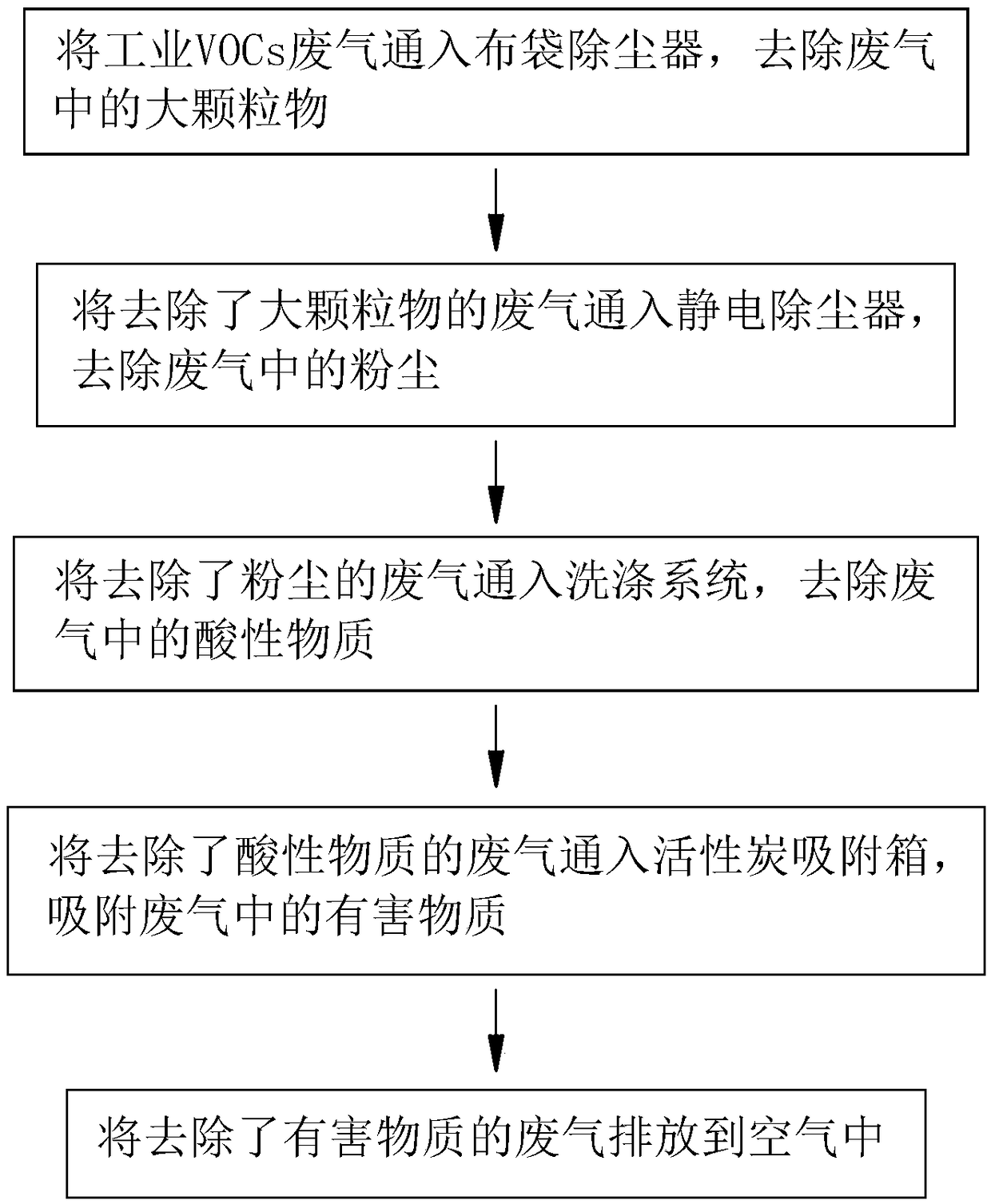

Industrial VOCs waste gas treatment method

ActiveCN108889072AExtended service lifeReduced chance of fatigue fractureCombination devicesGas treatmentDrive shaftProcess engineering

The invention belongs to the technical field of industrial waste gas treatment, and particularly relates to an industrial VOCs waste gas treatment method. A washing system in the method comprises a washing tank, a transmission shaft, a stirring rod, a tube joint, a movable ring, a twisting ring, a spring and a limiting ring, wherein a group of rectangular strip-shaped projections are uniformly arranged on a cylindrical surface of the transmission shaft in the axial direction; a movable ring, springs and another movable ring are separately slidably mounted on the transmission shaft from bottomto top; a rectangular groove is formed in the central hole of each movable ring; a group of ball cylindrical projections are uniformly arranged on the cylindrical surface of each movable ring; a ring-shaped semicircular groove is formed in the central hole of the twisting ring; and a group of rectangular projections are uniformly arranged in the ring-shaped semicircular groove of the twisting ring. Each spring is arranged between the corresponding movable ring and the twisting ring, resistance during buffer starting is realized, and thus, the service life of the transmission shaft is prolonged; and meanwhile, impact force of the outside is absorbed, the probability of fatigue breakage of the transmission shaft is reduced, and the service life of the transmission shaft is prolonged.

Owner:苏州市吴江新宇电工材料有限公司

Pretreatment device for removing nitrobenzene in waste water by potassium ferrate and method

InactiveCN101575137AIncrease agitationShort reaction timeWater contaminantsWater/sewage treatment by flocculation/precipitationNitrobenzeneChemistry

The invention relates to a pretreatment device for removing nitrobenzene in waste water by potassium ferrate and a method. By adopting the device, the waste water containing nitrobenzene is mixed fully with potassium ferrate by a tube-type mixer, and then the mixture passes through a one-piece device for coagulation and precipitation to carry out degradation to the nitrobenzene in the waste water by the synergy of oxidization, coagulation, absorption and the like of potassium ferrate, wherein part of nitrobenzene is removed, and the rest part thereof can be converted into a series of aliphatic hydrocarbon, which can be further degraded completely by the subsequent biological treatment of waste water. The invention solves problem of secondary pollution commonly existing in the conventional nitrobenzene waste water treatment process; a gridding frame plate is added in the coagulating area so as to increase the stirring strength to waste water, strengthen the mass transferring action of substances in waste water, shorten the reaction time, and improve reaction efficiency; and a transitional area is added between the coagulating area and a precipitating area and a gridding-shaped clapboard is additionally arranged so as to improve the precipitating effect.

Owner:DONGHUA UNIV

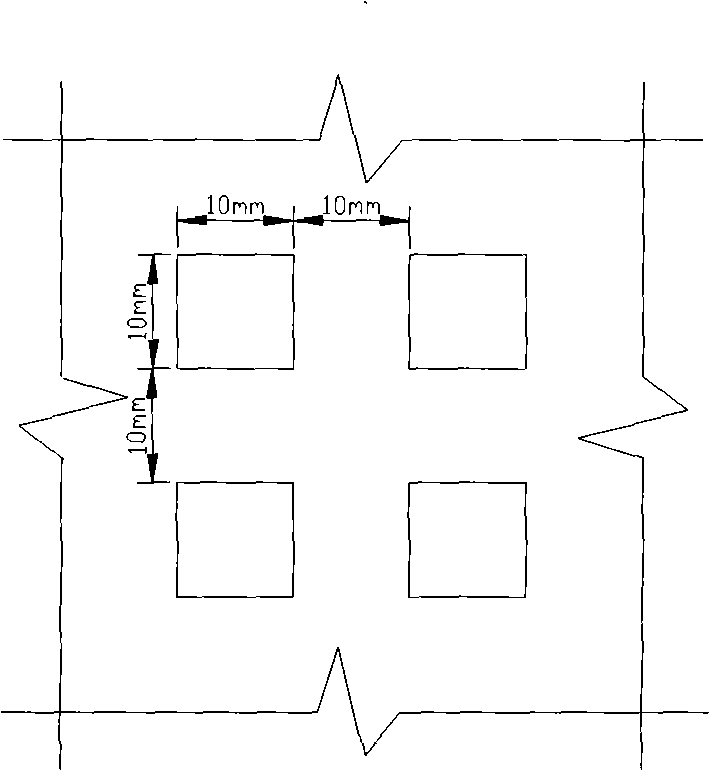

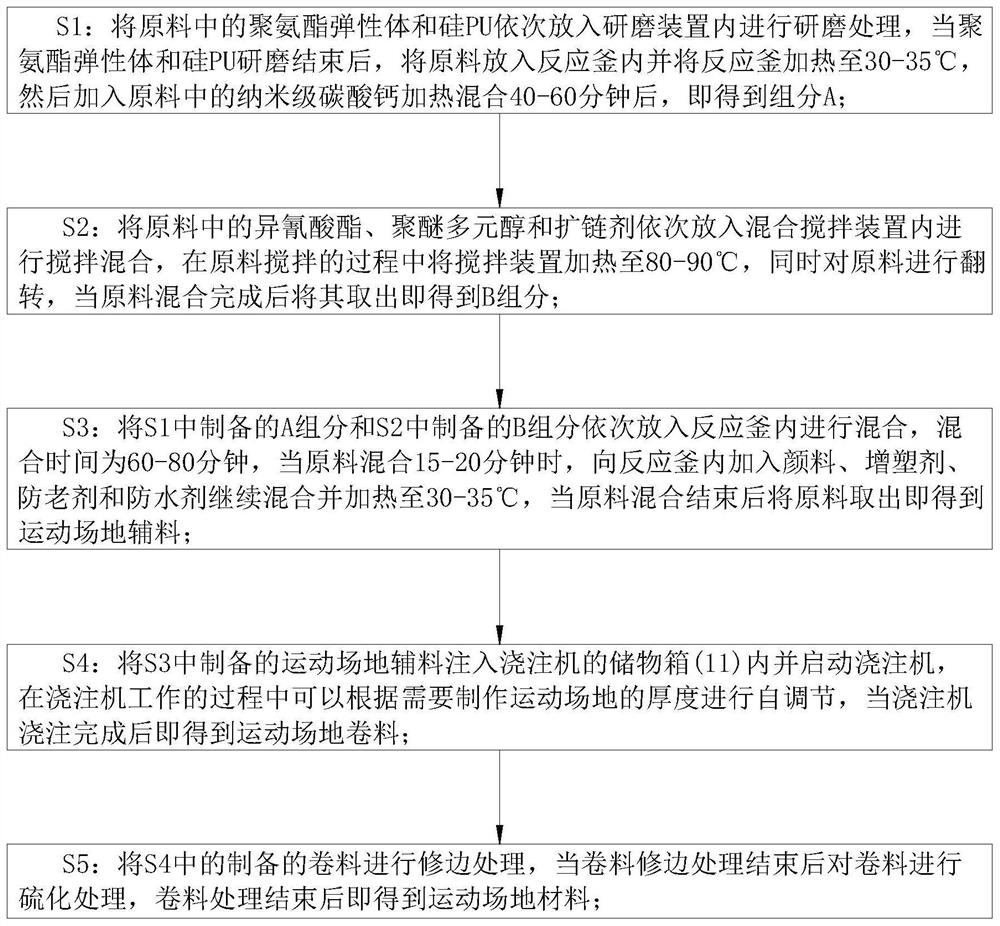

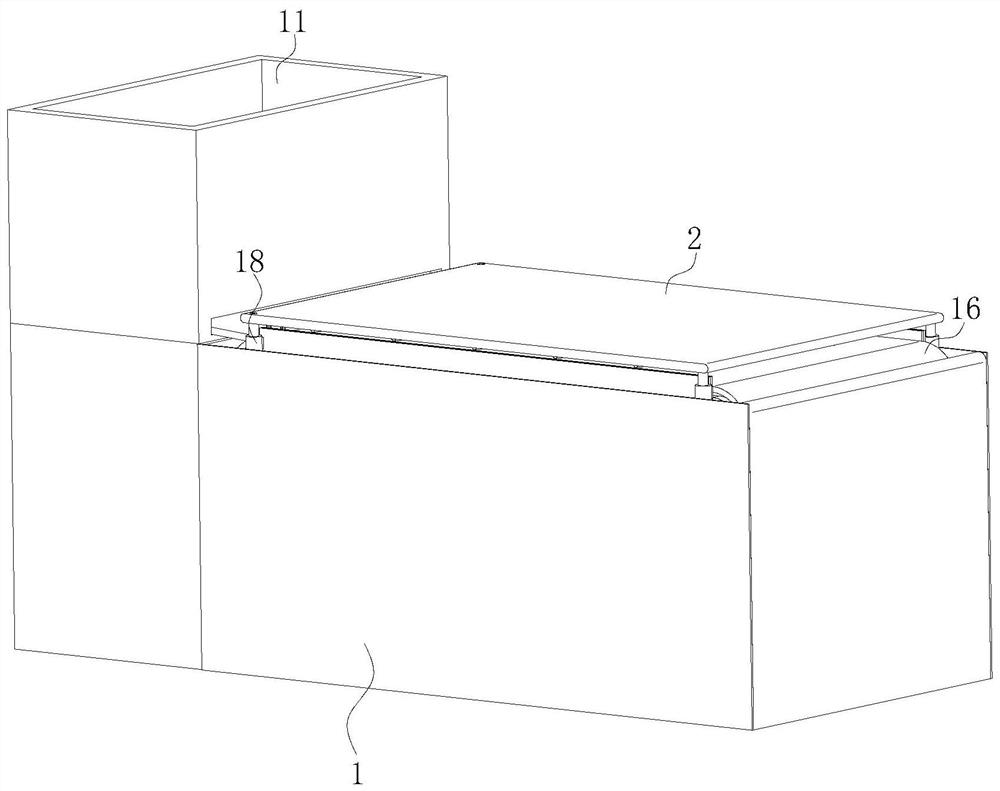

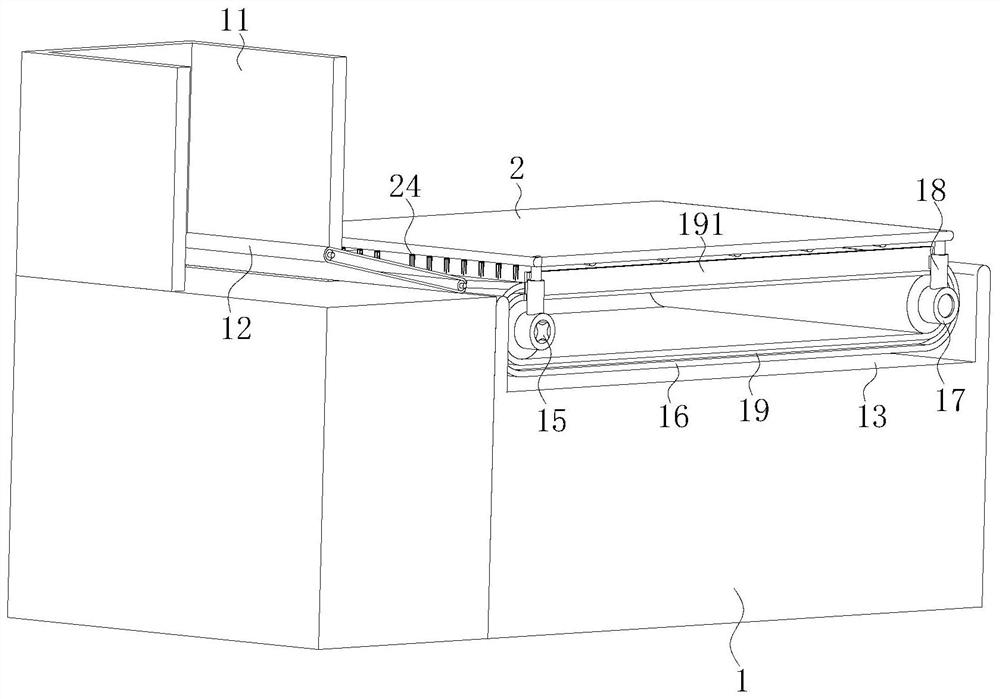

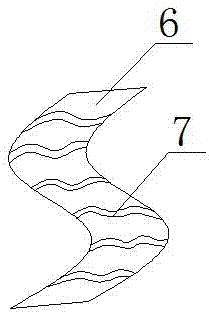

Preparation method of pouring type prefabricated polyurethane elastomer sport field material

ActiveCN111875948AEasy to useExtended service lifeRoads maintainencePolyurethane elastomerMechanical engineering

The invention belongs to the technical field of athletic field materials, and particularly relates to a preparation method of a pouring type prefabricated polyurethane elastomer athletic field material. A casting machine comprises a base and a storage box. A storage box is fixedly connected to the upper surface of the left side of the base; a conveying belt is rotationally connected into the storage box through a motor; a long groove is formed in the inner wall of the storage box on the right side of the conveying belt and penetrates through the inner wall of the right side of the storage box;and a mounting groove is formed in the inner wall of the base on the right side of the storage box. According to the invention, the manufacturing method is mainly used for solving the problems that in the existing sports field material pouring process, due to accumulation of raw materials, the thicknesses of manufactured sports field materials are different; meanwhile, in the sports field material manufacturing process, a water-based adhesive solution is added, so that the product solves the problem that in the raw material pouring process, the raw materials are liable to be bonded and accumulated, the thickness of each part of raw materials is not uniform in the pouring process of the raw materials, and thereby the manufactured sport field materials are uneven.

Owner:HUNAN YOUGUAN SPORTS MATERIAL CO LTD

Reaction kettle with cooling device

InactiveCN104437310AIncrease agitationReduce generationChemical/physical/physico-chemical stationary reactorsEngineeringMixing effect

The invention discloses a reaction kettle with a cooling device. The reaction kettle comprises a kettle body, a kettle cover and a stirring device, wherein a feeding hole is formed in the upper end of the kettle body; a discharge opening A is formed in the lower end of the kettle body; the stirring device comprises a stirrer A, a transmission device, a shaft seal and a supporting seat; the stirrer A is positioned inside the kettle body; the shaft seal and the supporting seat are positioned on the kettle cover and are connected with the stirrer A by virtue of the transmission device; a thermometer well stretches into the kettle body, and the upper end of the thermometer well is fixedly arranged on the kettle cover; a thermometer is arranged in the thermometer well; the stirrer A comprises a stirring shaft A, an annular guide pipe, a stator and a rotor; the discharge opening A is connected with a tank body in which a chamber is formed by virtue of a guide pipe; and a pipeline and cooling liquid are arranged in the chamber. According to the reaction kettle with the cooling device, provided by the invention, materials can stretch into the bottom of the kettle, so that the mixing effect is improved. Moreover, according to a novel stirring device, bubbles can be reduced during stirring, the full contact among mixtures is maintained, and reaction products can be subjected to forced cooling.

Owner:NINGBO YUANOU FINE CHEM

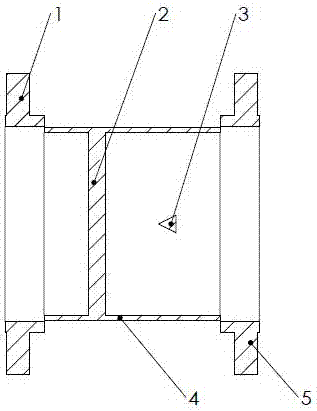

Pipeline mixer

InactiveCN102441333BIncreased turbulenceImprove the mixing effectFlow mixersWater/sewage treatment by flocculation/precipitationFlocculationSpiral blade

The invention relates to the technical field of water treatment, and especially relates to a pipeline mixer which is applied to a flocculation deposition device and is used for fully mixing a flocculating agent with raw water. The pipeline mixer which can solve problems of low water-drug mixing efficiency and bad use reliability existing in the prior art has the advantages of simple structure, high use reliability and high water-drug mixing efficiency. The pipeline mixer which comprises a water-inlet drug-addition tube, a water-drug mixing tube and a water outlet tube is characterized in that: at least two spiral tube and impeller combinations which are promoted by the self power of a water flow are distributed in the channel of the water-drug mixing tube, and each spiral tube and impeller combination comprises a spiral tube and an impeller which is arranged on the spiral tube and is coaxial with the spiral tube; the spiral tube comprises a spiral tube body and several spiral blades fixed on the inner wall of the spiral tube body; the impeller comprises an impeller seat and several impeller blades fixed on the surface of the impeller seat; and the spiral direction of the spiral blades is opposite to the spiral direction of the impeller blades of a same spiral tube and impeller combination.

Owner:ZHEJIANG MARINE DEV RES INST

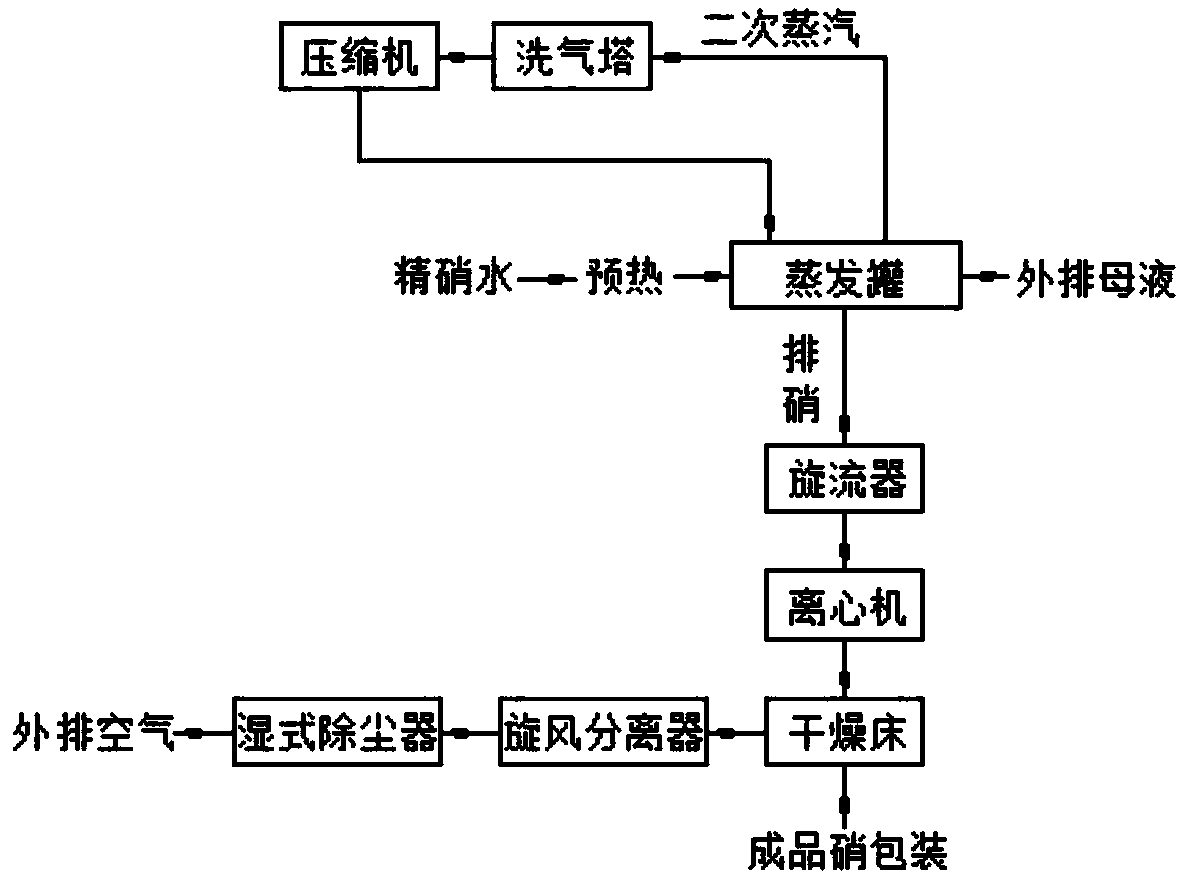

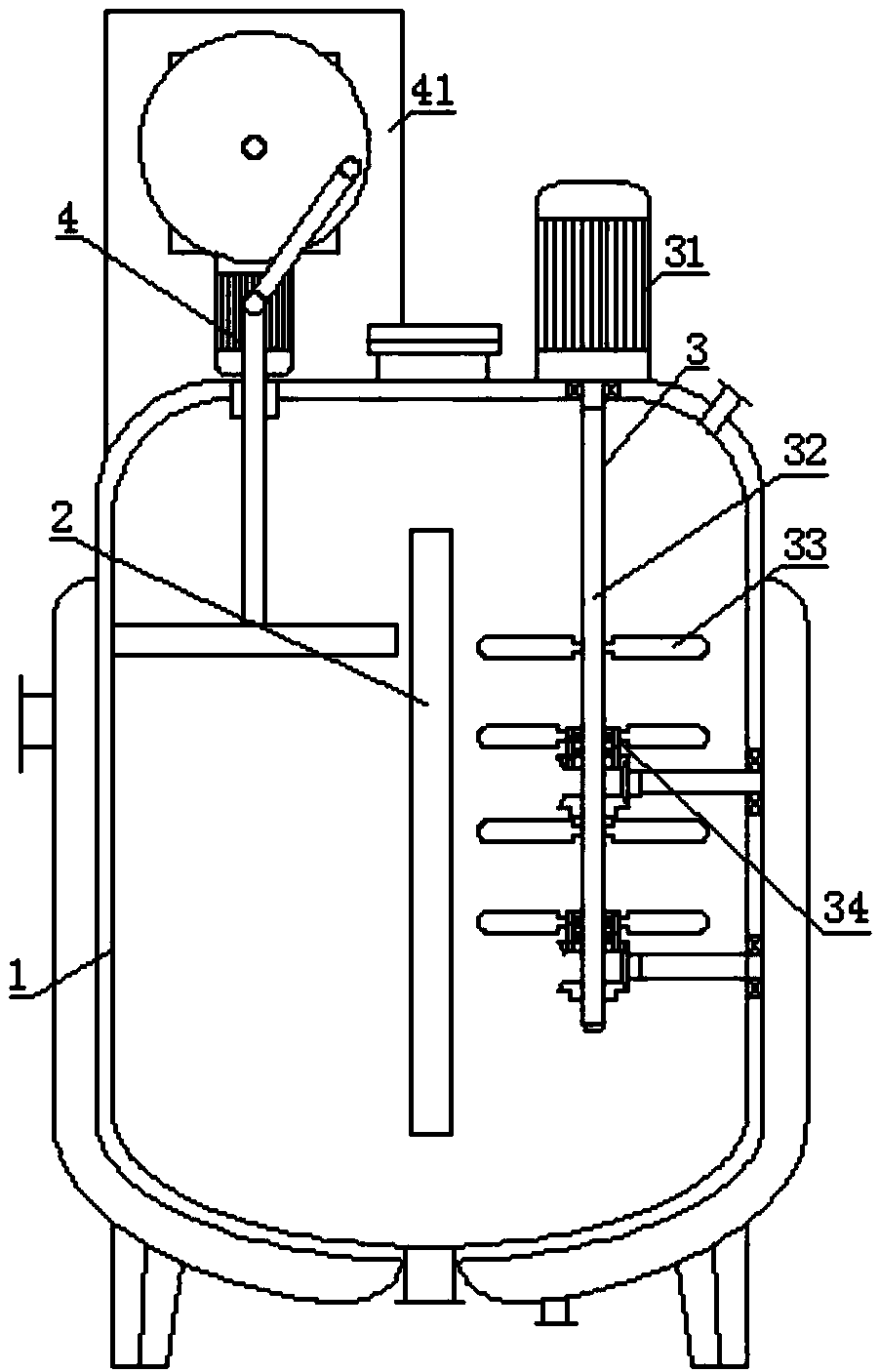

Production system and production method for sodium sulfate by adopting single effect and mechanical thermal compression technology

PendingCN107651696ASimple structureImprove the efficiency of nitrificationAlkali metal sulfite/sulfate dehydrationProcess engineeringSlurry

The invention relates to the field of sodium sulfate production, in particular to a production system and a production method for sodium sulfate by adopting a single effect and mechanical thermal compression technology. The technical scheme provided by the invention is that the production system for the sodium sulfate by adopting the single effect and mechanical thermal compression technology comprises an evaporating system, a drying system and a purifying system, wherein the evaporating system comprises an evaporating tank; the evaporating tank comprises a tank body; a separating board is fixed in the tank body; clearances are reserved between the separating board and upper and lower ends of the tank body; the inner part of the tank body is separated into a stirring cavity and a convection cavity by the separating board; a stirring mechanism is arranged in the stirring cavity; a material pushing mechanism is arranged in the convection cavity. The production method for the sodium sulfate by adopting the single effect and mechanical thermal compression technology comprises the steps of evaporating, drying and purifying tail gases. The invention provides the production system and theproduction method by adopting the single effect and mechanical thermal compression technology, by which nitrate slurry is sufficiently stirred in the evaporating tank so as to improve the evaporationefficiency; the problem of relatively-low evaporation efficiency of the evaporating tank in an existing production system for the sodium sulfate is solved.

Owner:四川省洪雅青衣江元明粉有限公司

A drainage and stirring device for chemical experiments

ActiveCN111744408BRealize the effect of rotating and stirringAchieve stirring effectRotating receptacle mixersShaking/oscillating/vibrating mixersBLENDER/MIXERThermodynamics

Owner:河南财政金融学院

Reaction kettle

ActiveCN104474995AReasonable structural designNovel ideaChemical/physical/physico-chemical stationary reactorsControl engineeringMixed materials

The invention discloses a reaction kettle. The reaction kettle comprises a kettle body, a kettle cover and a mixing device, wherein a lug boss is arranged on the inner wall of the kettle body, a pressure cover plate is arranged in the kettle body and positioned on the lug boss, a through hole is formed in the center of the pressure cover plate, and a scraping knife is arranged at the lower end surface of the pressure cover plate and close to the inner wall of the kettle body; the mixing device comprises a mixer, a transmission device, a shaft seal and a support, the mixer is positioned in the kettle body, the shaft seal and the support are positioned on the kettle cover and connected with the mixer through the transmission device, and plug holes are funnel-shaped and uniformly formed in the kettle cover; a thermometer sleeve tube extends into the kettle, the upper end of the thermometer is fixed on the kettle cover, and a thermometer is arranged in the thermometer sleeve tube; the mixer comprises a mixing shaft, a ring-shaped guide tube, a stator and a rotor; and diversion battens are radially arranged and circumferentially, uniformly distributed on the inner wall of the kettle body, and extend along the axial direction. The reaction kettle disclosed by the invention can reduce the generation of air bubbles during mixing through the novel mixing device, keeps full contact between mixed materials, and improves the mixing effect.

Owner:NINGBO YUANOU FINE CHEM

A vortex mixer

The invention discloses a vortex mixer, which comprises an inlet flange, a vortex generator I, a vortex generator II, a mixer main pipe and an outlet flange, the mixer main pipe is a hollow cylinder structure, and the inlet flange The outlet flange and the outlet flange are respectively welded to the upper and lower ends of the main pipe of the mixer. The vortex generator I and the vortex generator II are both set in a hollow isosceles triangular column structure, and the top angle is facing the direction of the fluid inlet; the vortex generator I and vortex generator II are installed at right angles to each other through the center of the pipe interface. The vortex generator I is welded between the upper and lower end faces of the mixer main tube, and the vortex generator II is welded on the side perpendicular to the axis of the mixer main tube. on the side wall. The pipeline mixer of the present invention has simple structure, high reliability, and remarkable mixing enhancement effect, which is beneficial to the generation of eddy current, improves the agitation degree of fluid, improves the mixing effect, and is used for liquid-liquid, gas-gas rapid mixing reaction, and is suitable for wide range.

Owner:QINGDAO HEADWAY TECH

A reaction kettle with a cooling device

InactiveCN104437310BIncrease agitationReduce generationChemical/physical/physico-chemical stationary reactorsEngineeringMixing effect

The invention discloses a reaction kettle with a cooling device. The reaction kettle comprises a kettle body, a kettle cover and a stirring device, wherein a feeding hole is formed in the upper end of the kettle body; a discharge opening A is formed in the lower end of the kettle body; the stirring device comprises a stirrer A, a transmission device, a shaft seal and a supporting seat; the stirrer A is positioned inside the kettle body; the shaft seal and the supporting seat are positioned on the kettle cover and are connected with the stirrer A by virtue of the transmission device; a thermometer well stretches into the kettle body, and the upper end of the thermometer well is fixedly arranged on the kettle cover; a thermometer is arranged in the thermometer well; the stirrer A comprises a stirring shaft A, an annular guide pipe, a stator and a rotor; the discharge opening A is connected with a tank body in which a chamber is formed by virtue of a guide pipe; and a pipeline and cooling liquid are arranged in the chamber. According to the reaction kettle with the cooling device, provided by the invention, materials can stretch into the bottom of the kettle, so that the mixing effect is improved. Moreover, according to a novel stirring device, bubbles can be reduced during stirring, the full contact among mixtures is maintained, and reaction products can be subjected to forced cooling.

Owner:NINGBO YUANOU FINE CHEM

Method and stirring device for preparation of composite colored silica sand used for water permeable bricks

PendingCN109833808AIncrease flipFree from destructionRotating receptacle mixersTransportation and packagingBrickSilicon

The invention relates to the technical field of water permeable brick preparation, in particular to a method and stirring device for preparation of composite colored silica sand used for water permeable bricks. The preparation method includes putting a variety of single color silica sand in the stirring device for mixing, the stirring device has a rotatable horizontal stirring bin and has no stirring paddle, the inner wall of the horizontal stirring bin is equipped with a plurality of stirring bulges, and the stirring method includes placing of the variety of single color silica sand in the stirring device for mixing. According to the method and stirring device for preparation of composite colored silica sand used for water permeable bricks provided by the invention, the prepared water permeable bricks have the characteristics of high water permeation rate and good water seepage effect.

Owner:BEIJING RECHSAND SCI & TECH GRP

Method and apparatus of impulse fluid jet type membrane bioreactor

ActiveCN101293705BPollution controlImprove utilization efficiencySustainable biological treatmentBiological water/sewage treatmentMembrane surfaceEngineering

The invention provides a method of a pulse-jet membrane bioreactor and a device for realizing the method. The method adopts a jet aerator to replace a traditional blower to realize the cross-flow scouring effect of membrane components; wherein, circulating fluid flows through the jet aerator at high speed; air enters the jet aerator in a pulse way by a valve controlled by PLC and jets at the bottom through a gas spreading distributor; the PLC system regulates the cross-flow state of gas-liquid two-phase flow on the membrane surface by changing circulation flow rate and pulse frequency, so as to improve the scouring effect of the air to the membrane surface, to further control membrane pollution, to improve the energy utilization efficiency of a circulating pump and to reserve energy. The use of the jet aerator also increases the utilization efficiency of oxygen and improves sludge degradation effect. The device has the advantages of low operation energy consumption and low operation noise, slight membrane pollution, less early investment in equipment, simple structure of the device, small occupation area, simple and convenient operation and convenience in automatic running and control.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

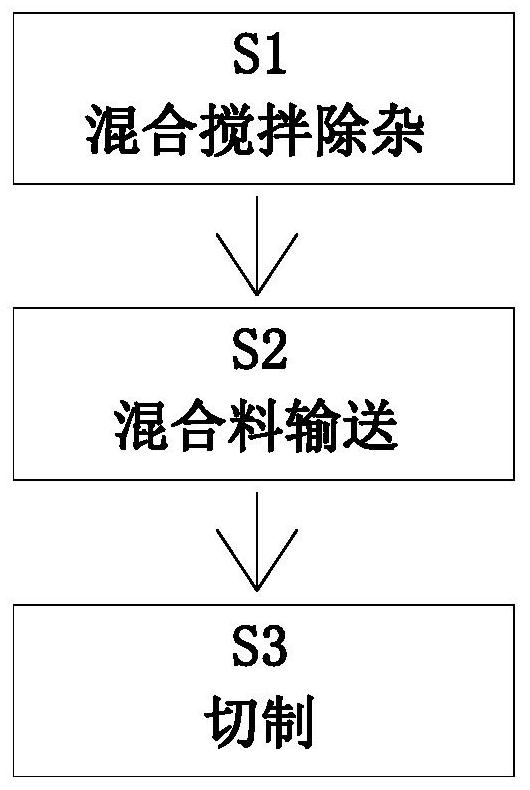

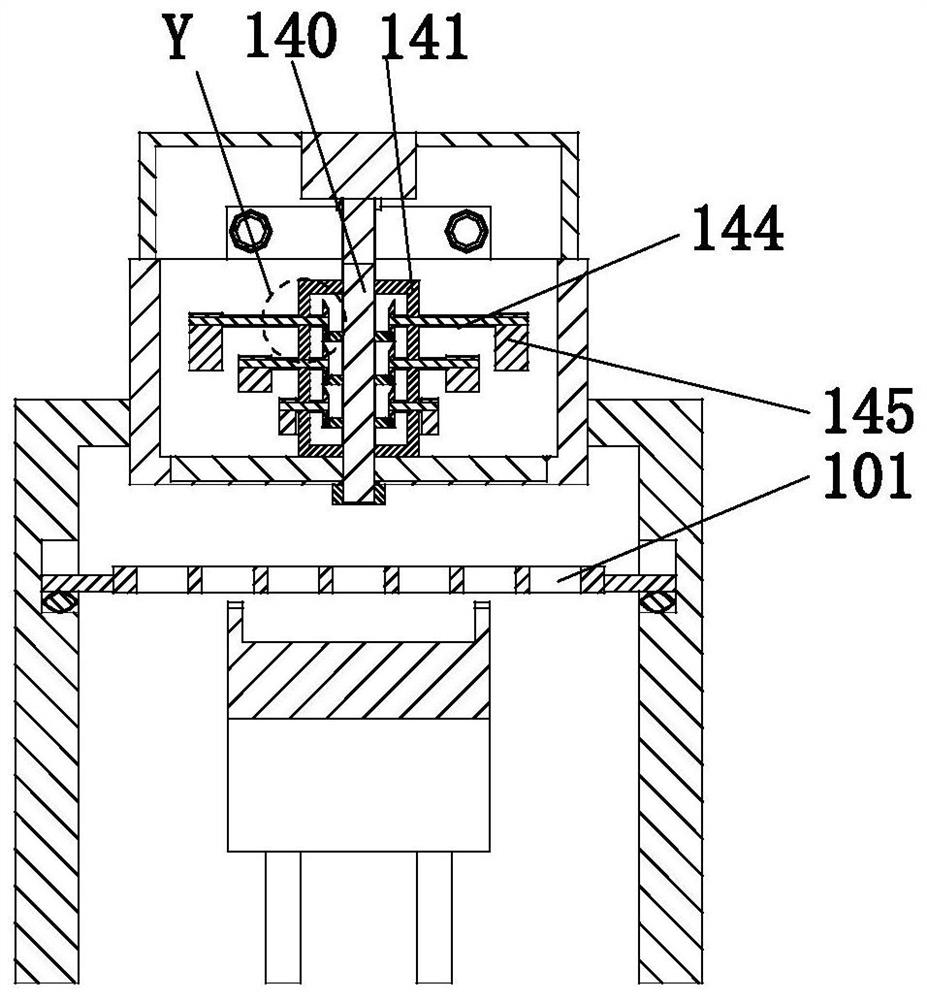

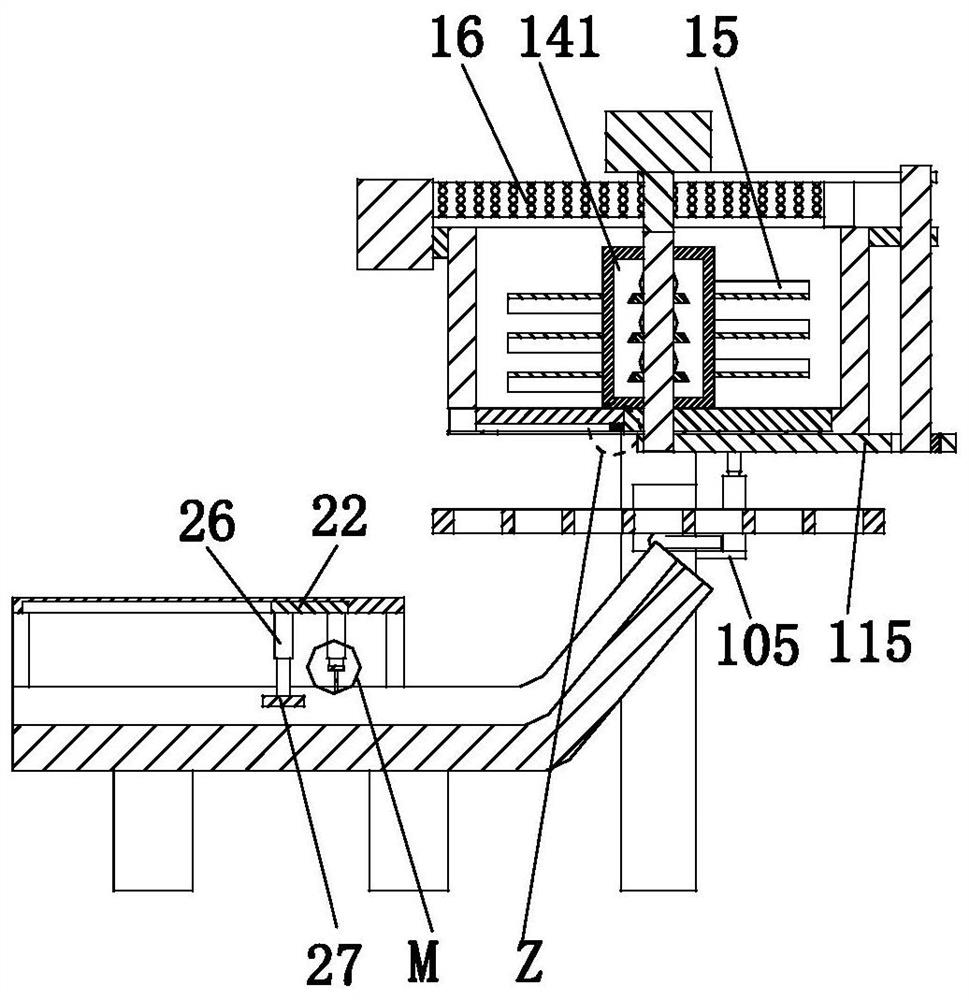

New energy biomass fuel processing method

InactiveCN112300847AFunctionalImprove suction effectBiofuelsSolid fuelsNew energyProcess engineering

The invention relates to a new energy biomass fuel processing method. The method employs a new energy biomass fuel processing device. The new energy biomass fuel processing device comprises a stirringmechanism and a cutting mechanism, wherein the lower end of the stirring mechanism is installed on the existing working ground, the cutting mechanism is arranged at the left lower part of the stirring mechanism, and the lower end of the cutting mechanism is arranged on the existing working ground. According to the invention, new energy biomass fuel processing is conducted by adopting the design concept of combining multi-directional mixing and stirring structures, and the arranged stirring mechanism has the a function of mixing and stirring and a function of impurity sucking and removing at the same time, so the probability that impurities are in a raised state can be increased, and impurity sucking and removing effect is improved; and the arranged cutting mechanism can conduct compactiontreatment on mixed raw materials before cutting, and therefore, the single-time rapid cutting speed and quality of a cutter are improved.

Owner:南京茂辉环保技术开发有限公司

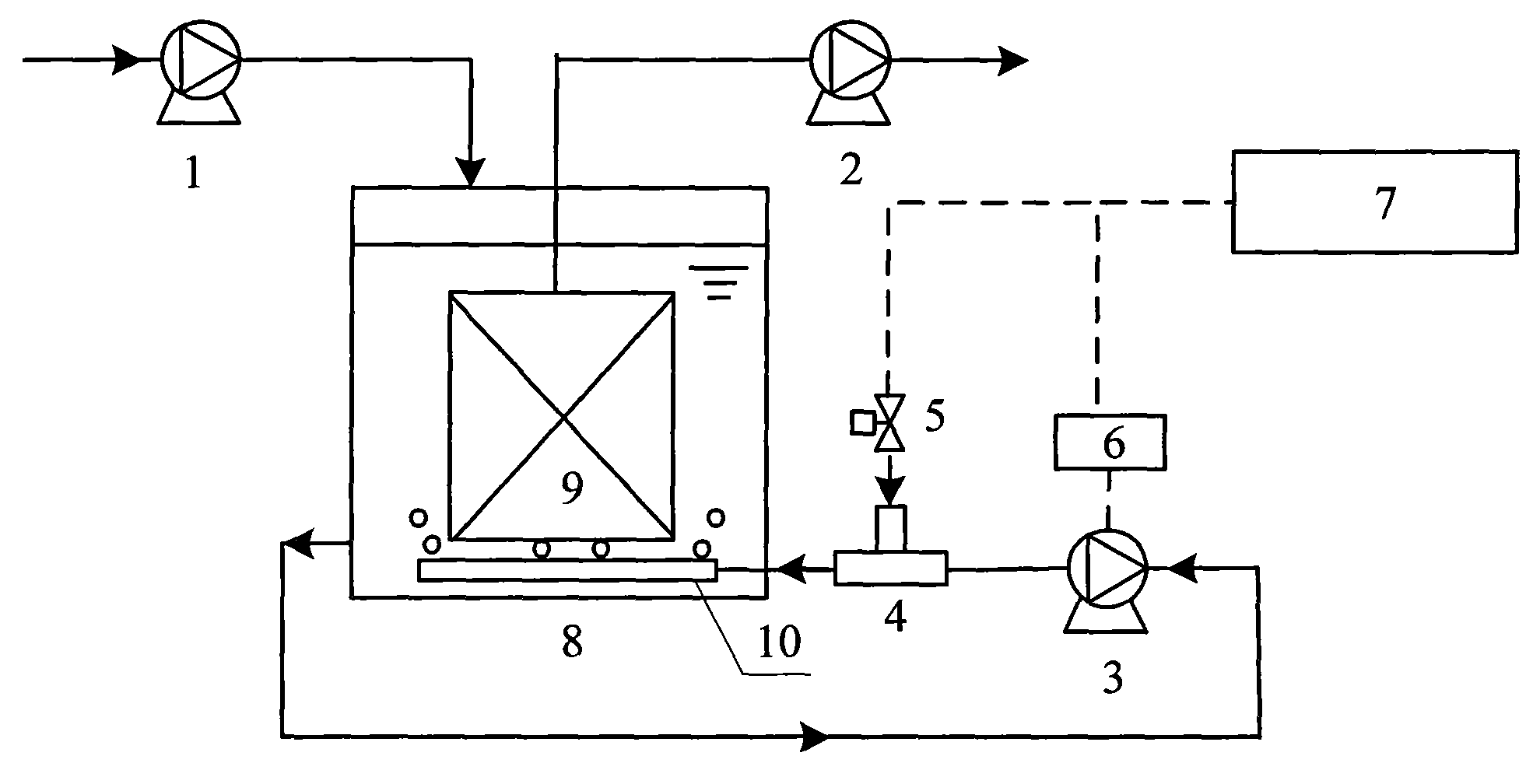

UASB external circulation temperature and PH regulating system

InactiveCN109574219AIncrease agitationImproves contact mixingWater treatment parameter controlTreatment with anaerobic digestion processesWater pipeSewage treatment

The invention relates to the field of the sewage treatment and in particular to a UASB external circulation temperature and PH regulating system. The UASB external circulation temperature and PH regulating system comprises a UASB pool. The bottom of the UASB pool is provided with a dendritic water distributing pipe. The left end of the dendritic water distributing pipe is connected with a water inlet, and the right end of the dendritic water distributing pipe is connected with a circulation water return pipe. The circulation water return pipe is provided with a temperature sensor and a PH sensor, and the circulation water return pipe is further connected with a circulation water pump. The circulation water return pipe is connected with an upper water return perforated pipe. A steam heaterfor heating the pipe and a liquid caustic soda pipe for transmitting liquid caustic soda are installed between the circulation water return pipe and the upper water return perforated pipe. The steam heater is connected with a steam pipe. The liquid caustic soda pipe is connected with an alkali addition metering pump. A liquid caustic soda storage box for storing the liquid caustic soda is installed beside the alkali addition metering pump. The benefit is that the UASB external circulation temperature and PH regulating system is capable of guaranteeing a suitable reaction temperature and a PH value in the UASB pool, promoting sludge to be stirred, improving the contact mixing effect of sewage and sludge, and improving treatment efficiency.

Owner:苏州万科环境工程有限公司

A feed production and processing drying treatment device

ActiveCN111947419BSpeed up dryingImprove drying qualityFeeding-stuffDrying gas arrangementsProcess engineeringFodder

The invention relates to a drying treatment device for feed production and processing, which includes a drying mechanism and an air drying mechanism. The air drying mechanism is installed directly below the drying mechanism, and the lower end of the air drying mechanism is installed on the existing working ground. The invention adopts the design concept of double drying structure and phase structure to carry out the drying treatment of feed production and processing. The set drying machine and air drying mechanism can adopt two drying modes for the feed, and the drying effect of the feed increases step by step. The method of blowing hot air and drying the feed adopted by the drying mechanism can make the feed receive a more comprehensive drying treatment in a loose state, so that the drying speed and drying molding quality of the feed can be greatly improved.

Owner:ANHUI LINGHANG ANIMAL HEALTH PROD

Alloy baking stove

ActiveCN102435063BEliminate the phenomenon of gathering at the edges and cornersEasy to addVertical furnacesCooking & bakingCombustor

The invention relates to an alloy baking stove which is a device for baking alloy. The alloy baking stove comprises a stove cover, a stove body, a refractory material layer, a heating device, a material unloading device, a material level meter and a thermometer, and is characterized in that the inner refractory layer is provided with an inclined hole; one end of the inclined hole is communicated with a baking chamber, and the other end of the inclined hole is communicated with an annular flue; the angular inclination of the inclined hole is between 20 degrees and 80 degree; 1-10 burners are mounted on a device body; a burning cavity is arranged in each burner; the burning cavities are communicated with the annular flue; and the axis line of each burner is tangential to the central line of the annular flue. The alloy baking stove provided by the invention has a simple structure, is convenient to use, safe and reliable, and has the advantages of good heat preservation effect, uniform alloy heating temperature and high energy utilization rate; and equipment is convenient to install and maintain, automatic control can be realized, material charging and unloading are convenient, the operation cost is low, and heating fume and the alloy can exchange heat sufficiently.

Owner:ZHEJIANG HANGZHEN ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com