A reaction kettle with a cooling device

A technology for cooling devices and reactors, applied in chemical/physical/physical-chemical fixed reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve waste of materials, prolong stirring time, and material-liquid mixing Poor effect and other problems, to achieve the effect of reducing the generation of air bubbles, improving the degree of agitation, and maintaining sufficient contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

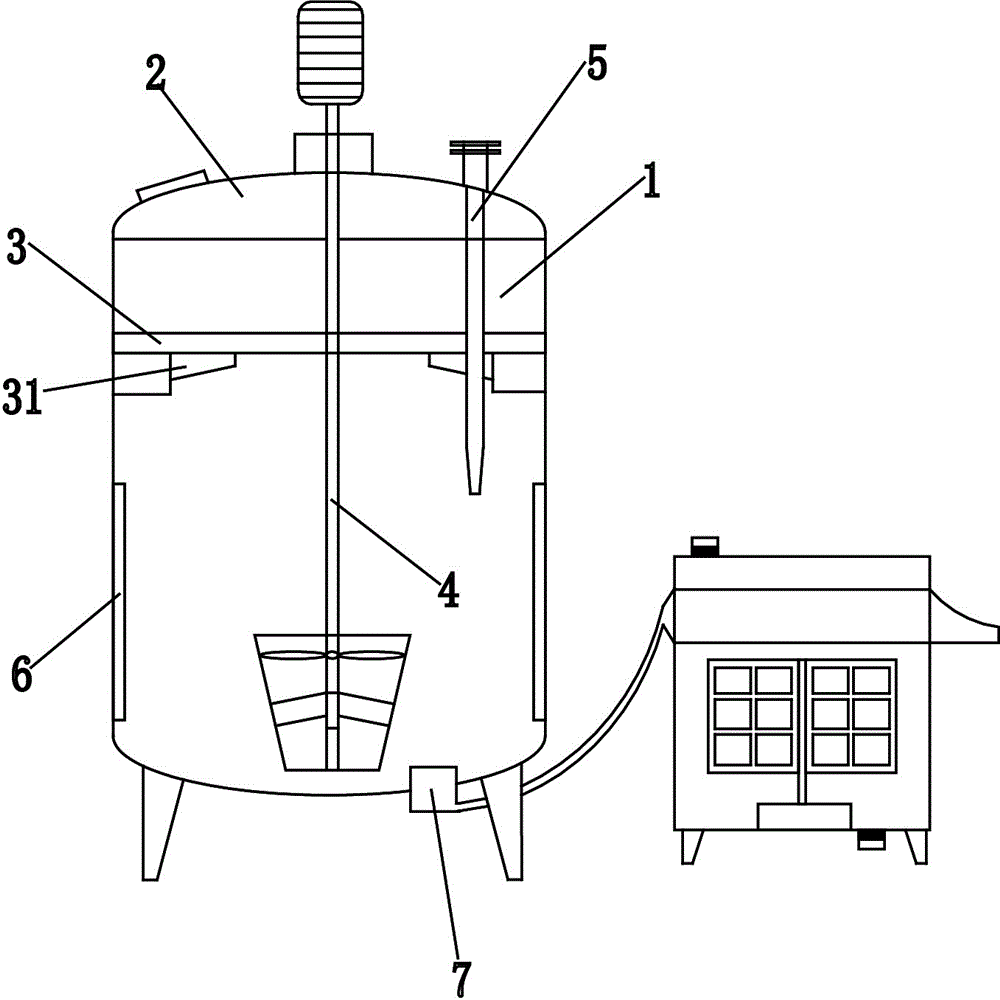

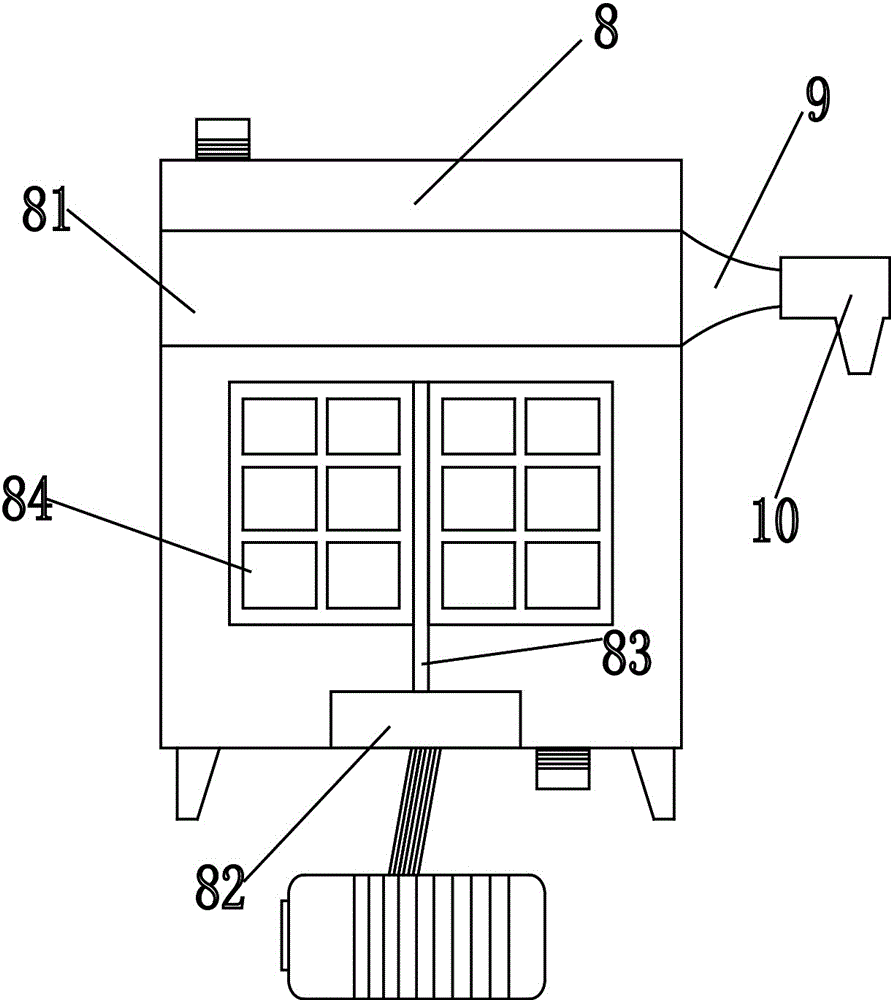

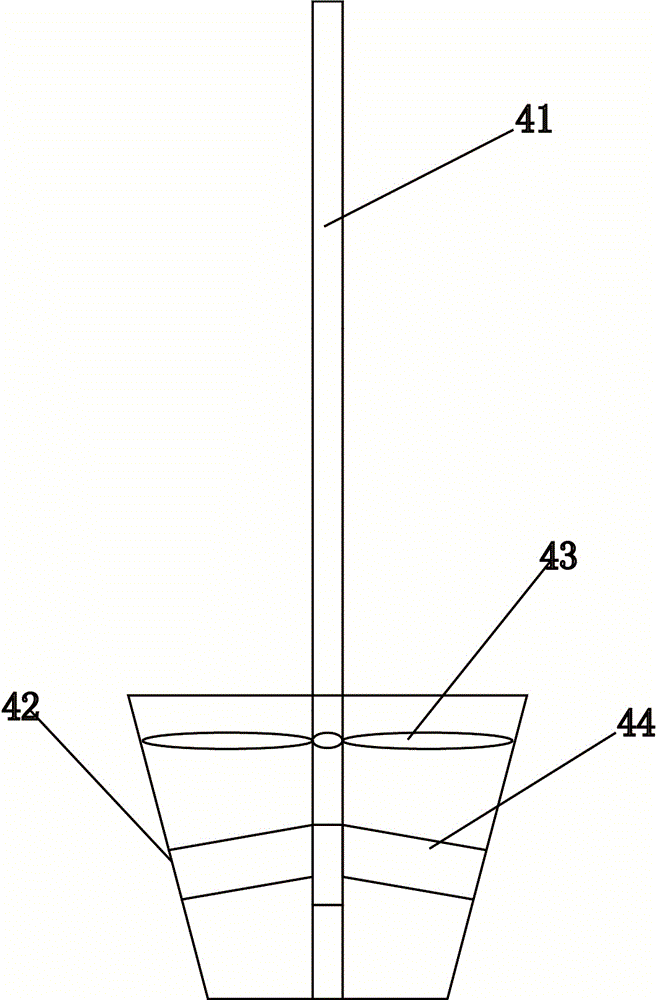

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 — image 3 , a reaction kettle with a cooling device, comprising a kettle body 1, a kettle cover 2 and a stirring device, the upper end of the kettle body 1 is provided with a feed inlet, the lower end of the kettle body 1 is provided with a discharge port A7, the The stirring device includes an agitator A4, a transmission device, a shaft seal and a support seat. The agitator A4 is located inside the kettle body 1, and the shaft seal and the support seat are located on the kettle cover 2. Through the transmission The device is connected with the agitator A4, and the lid 2 is evenly provided with plug holes, the plug holes are funnel-shaped, and the thermometer sleeve 5 extends into the kettle body 1 and the upper end is fixed on the lid 2 Above, the thermometer casing 5 is equipped with a thermometer, and the agitator A4 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com