New energy biomass fuel processing method

A technology of biomass fuel and processing method, which is applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of single agitation direction of agitation structure, easy edge concentration of raw materials, and low mixing and agitation effect, so as to improve mixing and agitation. The degree of complexity, increase the range and amplitude of agitation, and improve the effect of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways predetermined and covered by the claims.

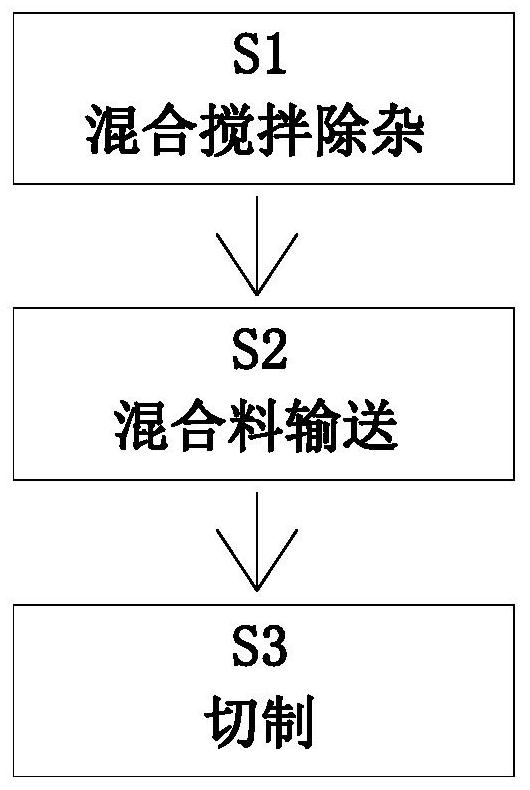

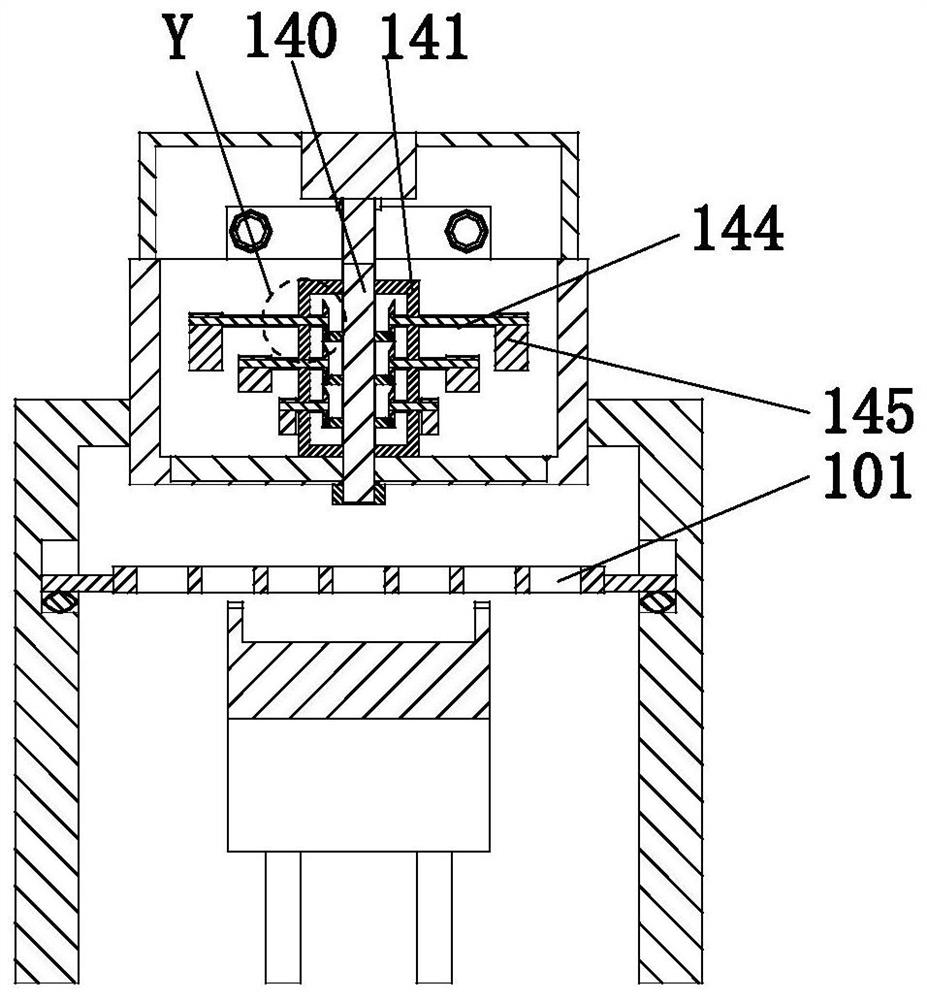

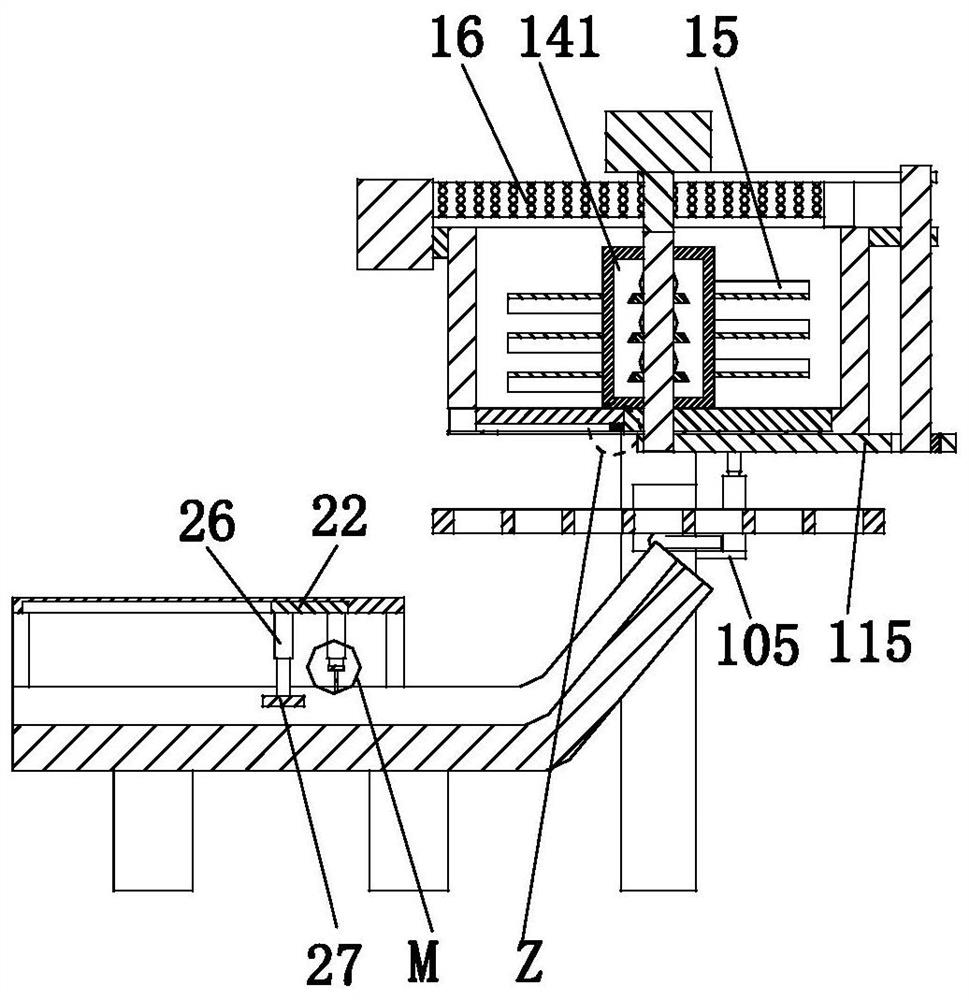

[0039]Such asFigure 1 to Figure 12As shown, a new energy biomass fuel processing method, which uses a new energy biomass fuel processing device, the new energy biomass fuel processing device includes a stirring mechanism 1 and a cutting mechanism 2, using new energy biomass fuel The specific processing methods for processing new energy biomass fuels in processing equipment are as follows:

[0040]S1. Mixing and impurity removal: Pour the raw materials into the mixing barrel 11 manually, and at the same time, the motor 13 drives the connecting piece 14 to rotate, and the connecting piece 14 drives the stirring blade 15 to rotate synchronously to mix and stir the raw materials. The dust machine 18 works synchronously and synchronously sucks and remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com