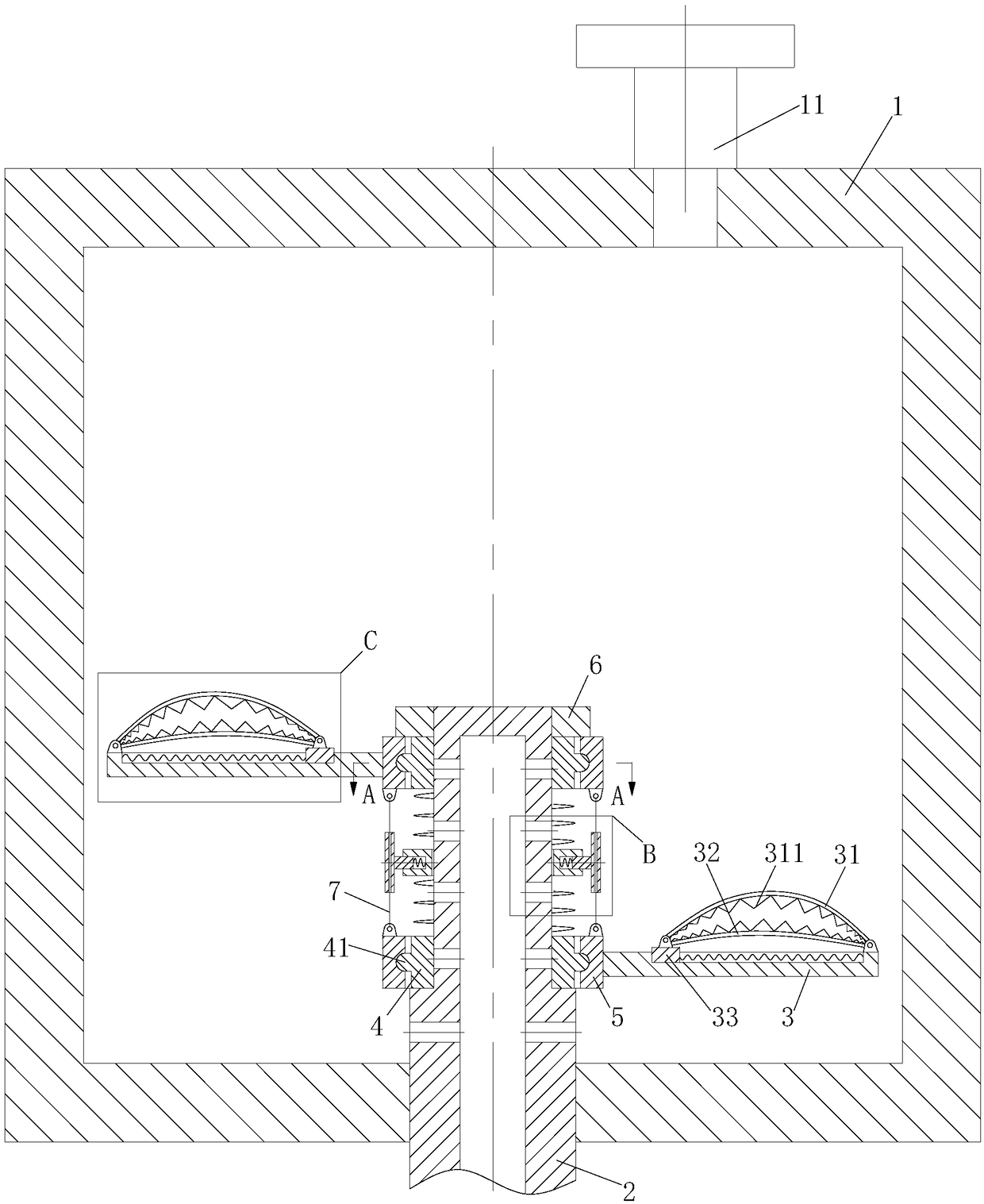

Industrial waste gas treatment device

A treatment device, industrial waste gas technology, applied in the direction of gas treatment, membrane technology, dispersed particle separation, etc., can solve problems such as insufficient contact, air pollution, excessive acidic substances in waste gas, etc., to increase efficiency, improve service life, reduce The effect of fatigue on the probability of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

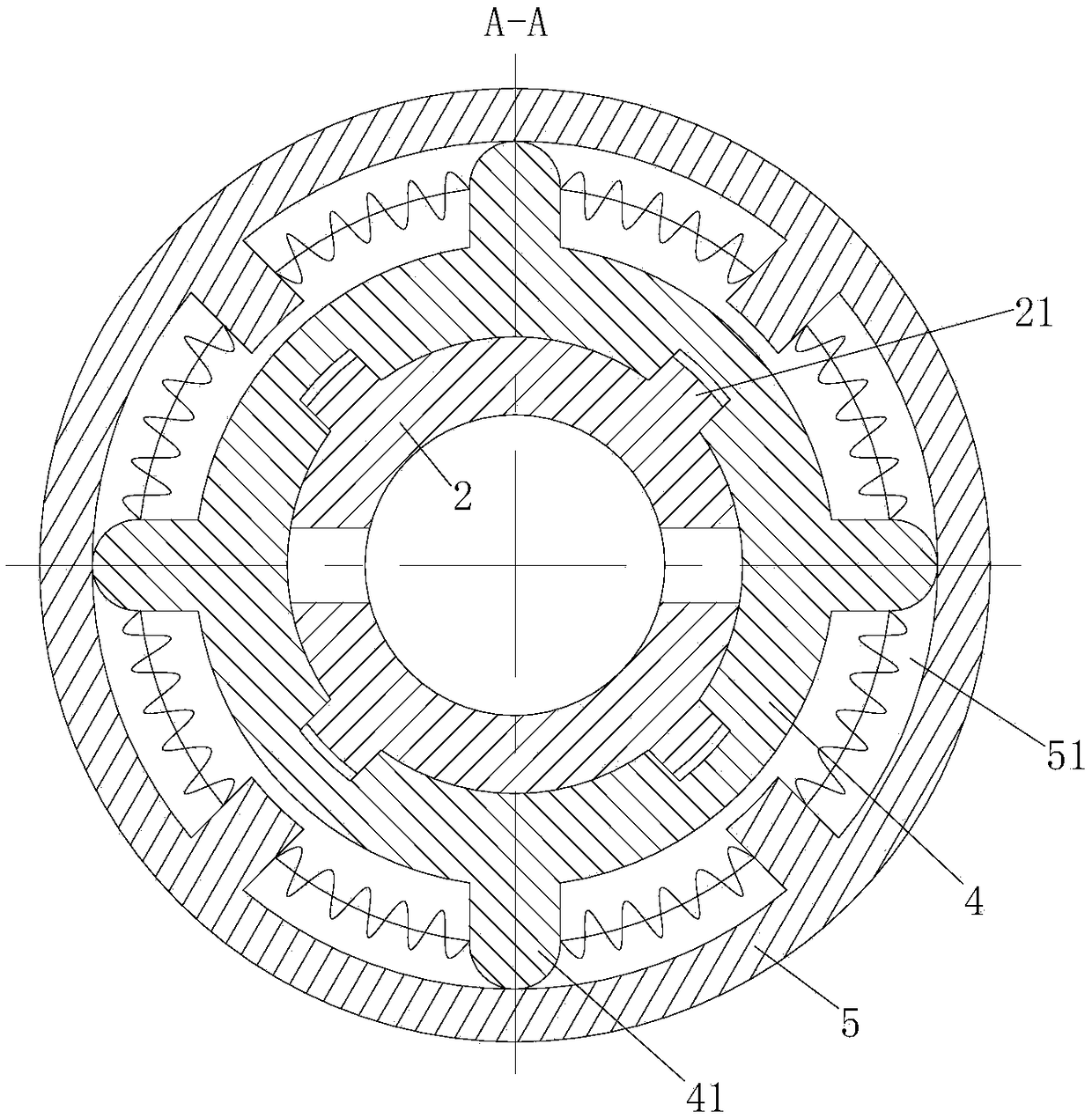

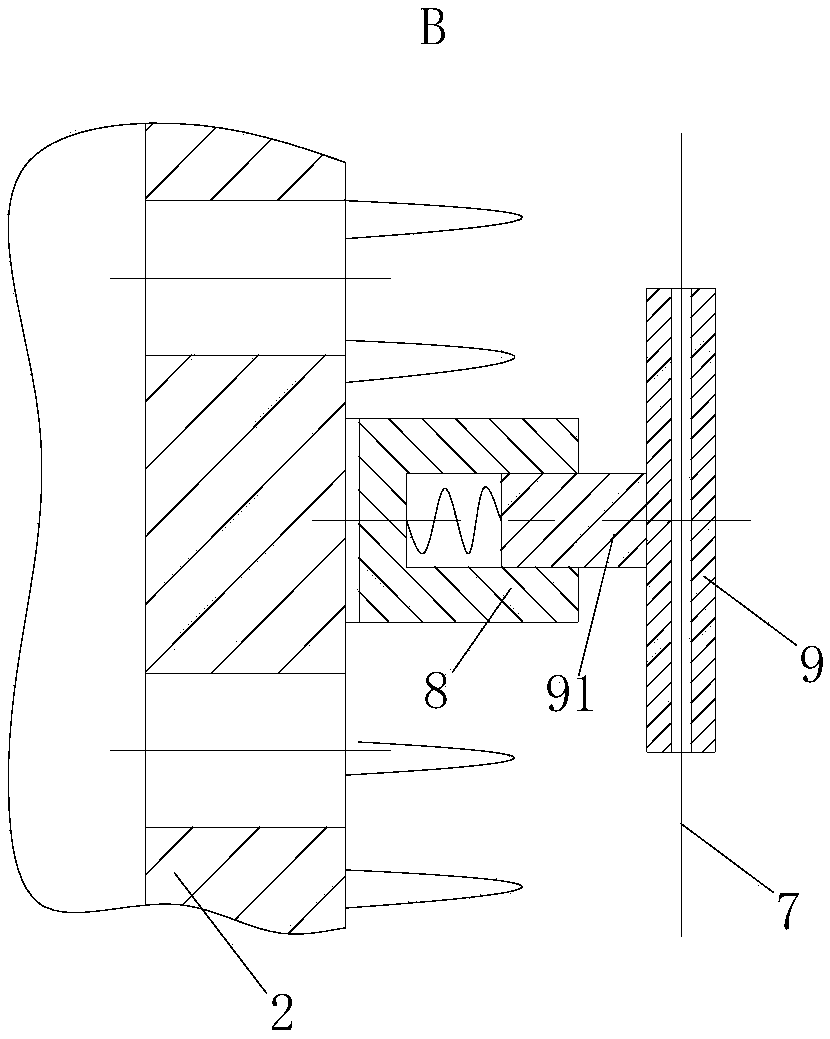

[0030] As an embodiment of the present invention, the lower end of the No. 1 elastic rod 31 is provided with a toothed swing plate 311, and the upper end of the No. 2 elastic rod 32 is provided with a toothed swing plate 311; The middle part of the rod 31 and the second elastic rod 32 gradually becomes smaller toward both ends, and the tooth shape of the toothed swing plate 311 on the first elastic rod 31 and the tooth shape of the toothed swing plate 311 on the second elastic rod 32 are arranged alternately; During work, the slide block 33 on the stirring rod 3 is moved by the centrifugal force, and the slide block 33 pushes the No. 1 elastic bar 31 and the No. 2 elastic bar 32 to bend. The teeth of the toothed oscillating plate 311 on the number elastic rod 32 are occluded, and the toothed oscillating plate 311 after the occlusion forms a surface, thereby pushing the area of the solution to increase, increasing the degree of agitation of the solution, and further improving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com