Hole guiding and pile planting equipment and construction method

A technology for planting piles and equipment, applied in drilling equipment and methods, drilling equipment, sheet pile walls, etc., can solve the problems of large pile driving resistance, affecting the use of pipe piles, and high pile explosion probability, ensuring quality and improving uniformity. , the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

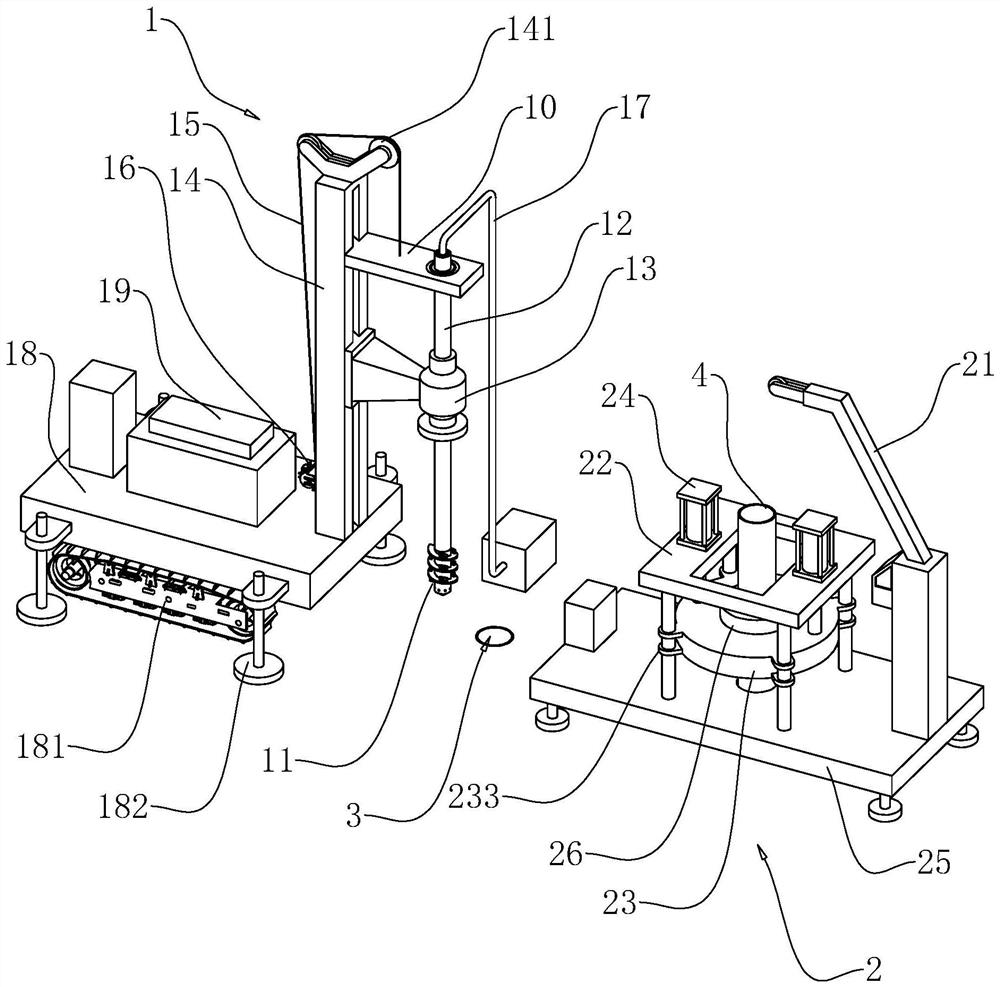

[0051] The embodiment of the present application discloses a pilot hole pile planting equipment for preparing cement composite pipe piles. refer to figure 1 , The hole-leading pile-planting equipment is composed of a hole-leading mechanism 1 and a pile-planting mechanism 2.

[0052] refer to figure 1 , The hole guide mechanism 1 includes a drill bit 11, a drill pipe 12, a drilling power head 13, a mast 14, a traction rope 15, a hoist 16, a material delivery pipe 17, a follower frame 10, a positioning workstation 19 and a mobile chassis 18. Wherein, the mast 14 is fixed vertically on the upper surface of the mobile chassis 18; the winch 16 is fixed on the side of the mast 14, and the top of the mast 14 is also provided with a pulley block 141. One end of the traction rope 15 is connected to the winch 16, and the other end is fixedly connected to the follower frame 10 connected to the other side of the mast 14 by going around the pulley block 141; . The drill rod 12 is a ste...

Embodiment 2

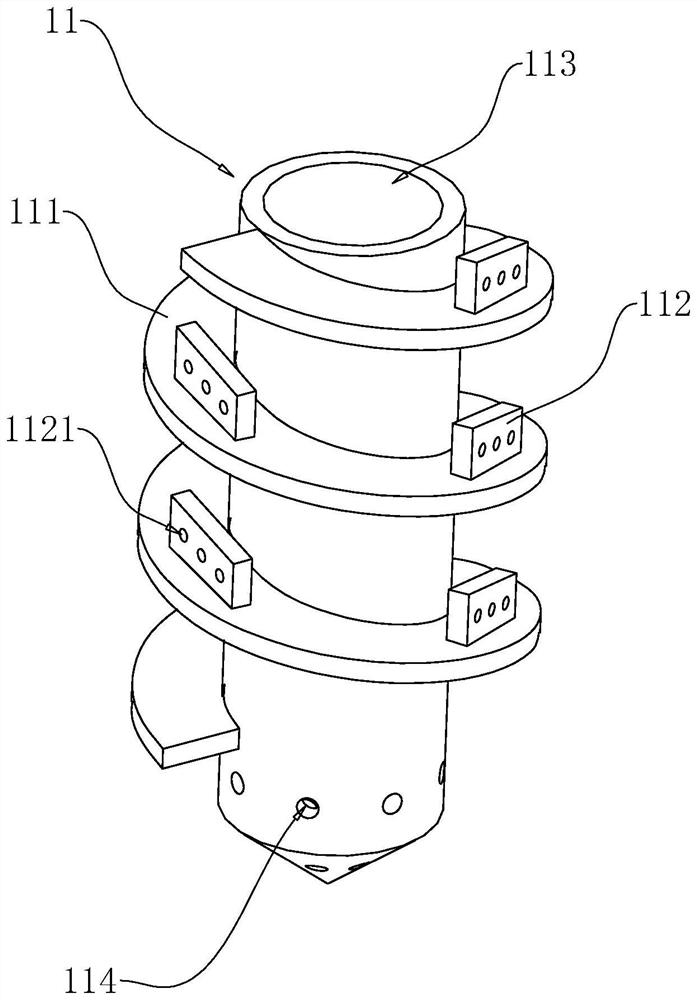

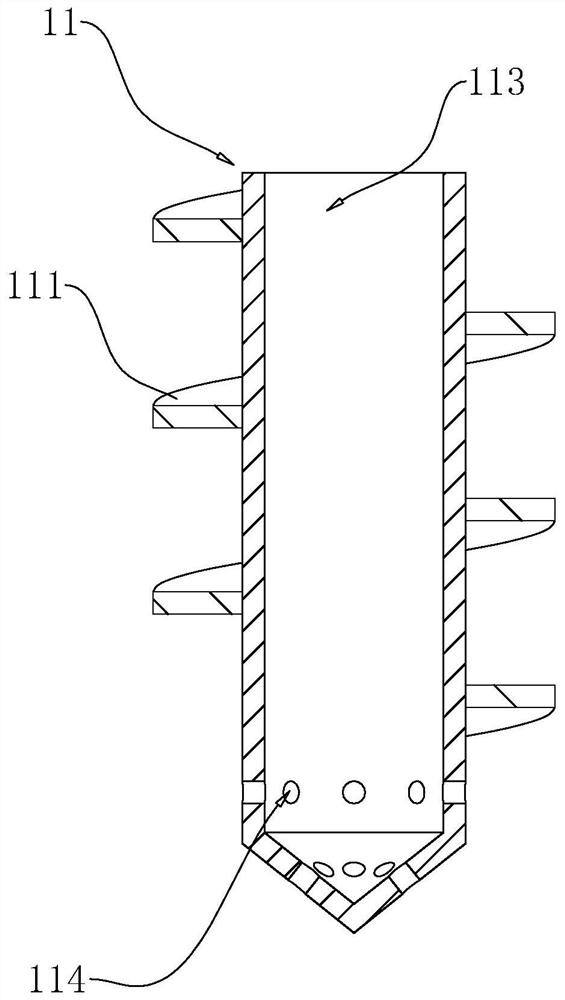

[0068] The embodiment of the application discloses a pilot hole pile planting device and a construction method using the device. refer to Figure 5 , this embodiment is basically the same as Embodiment 1, except that the main blade 111 is a paddle-type blade, and its windward blade surface has an included angle of 135° with the rotation plane (ie, the horizontal plane). There are four main blades 111, which are evenly connected to the outer peripheral surface of the drill bit 11 through connecting columns.

[0069] refer to Figure 5 , the branch blade 112 is a rectangular piece, fixed vertically on the windward blade surface of the main blade 111 , and the length extension direction of the branch blade 112 is parallel to the length extension direction of the main blade 111 .

[0070]Through the above arrangement, under the mutual cooperation of the main blade 111 and the branch blade 112, the degree of agitation of the cement slurry can be improved, which can not only effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com