Pretreatment process method and device for removing aniline in wastewater through potassium ferrate

A technology of potassium ferrate and process method, which is applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment and other directions, can solve problems such as shortening, solve secondary pollution, improve biochemical The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

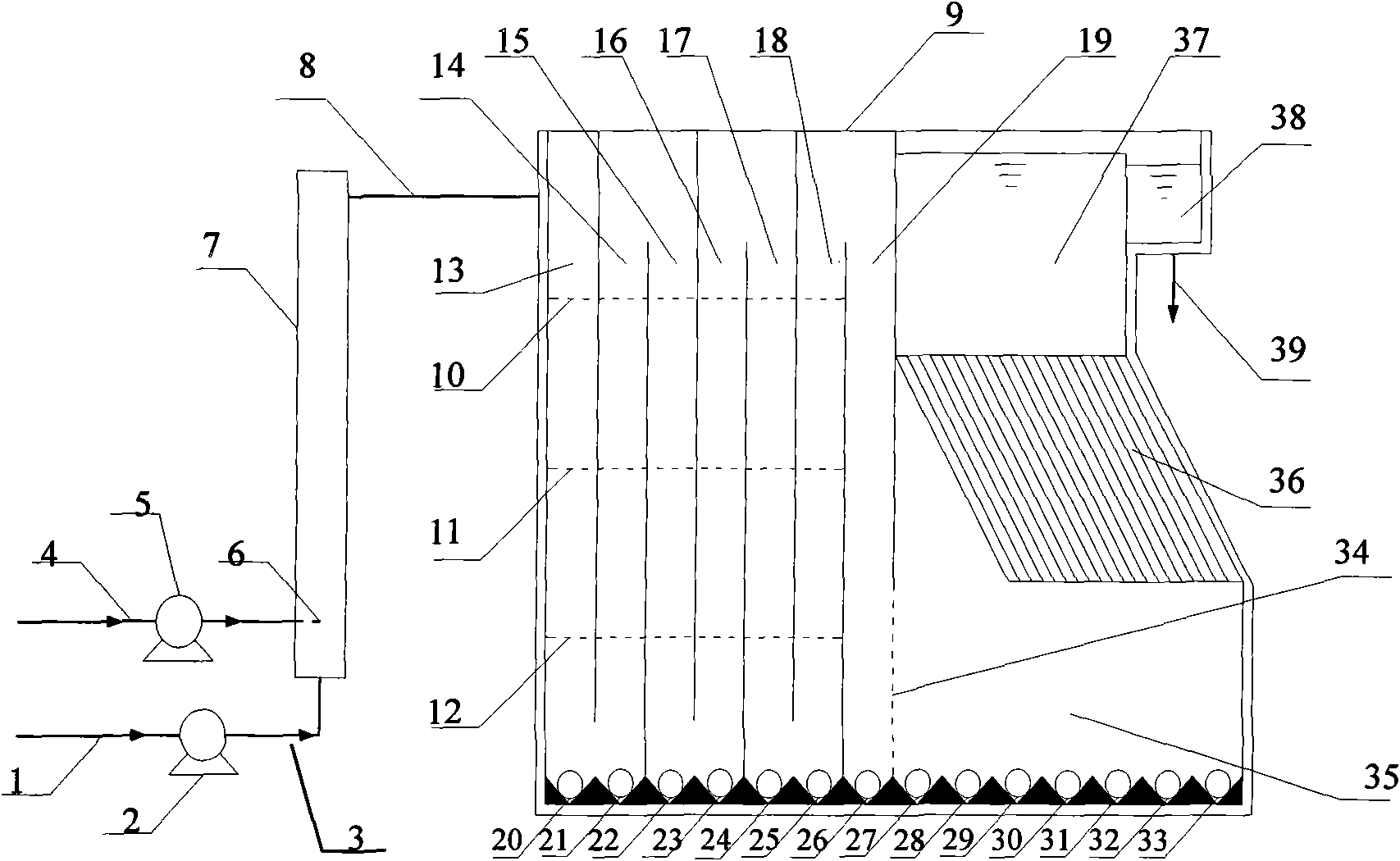

[0034] The aniline-containing wastewater to be treated is sucked by the lift pump 2 through the water inlet pipe 1 and injected into the tubular mixer 7, in the tubular mixer 7 and the high-speed rail injected into the tubular mixer by the metering pump 5 through the feed pipe 4 Potassium is mixed thoroughly. Flow through the connecting pipe 8, enter the coagulation reaction zone 13, pass through the grid-shaped shelf 10, shelf 11, and shelf 12 from top to bottom, and then enter the coagulation reaction zone 14, and pass through the grid-shaped shelf from bottom to top. Shelf plate 12, shelf plate 11, shelf plate 10, and then enter coagulation reaction zone 15, respectively pass through grid-shaped shelf plate 10, shelf plate 11, shelf plate 12 from top to bottom, and then enter coagulation reaction zone 16, by Go through the grid-shaped shelf 12, shelf 11, and shelf 10 from bottom to top, then enter the coagulation reaction zone 17, pass through the grid-shaped shelf 10, shel...

Embodiment 2

[0036] In order to degrade aniline effectively, the waste water with aniline concentration of 62mg / L was artificially prepared, and a set of production equipment was established by using the new technology proposed by the present invention, and the treated water volume was 0.3m 3 / h.

[0037] The rising flow rate in the tube mixer is 0.8-1.0m / s, its height is 1000mm, its inner diameter is 10mm, its outer diameter is 15mm, and an orifice plate is set every 25mm.

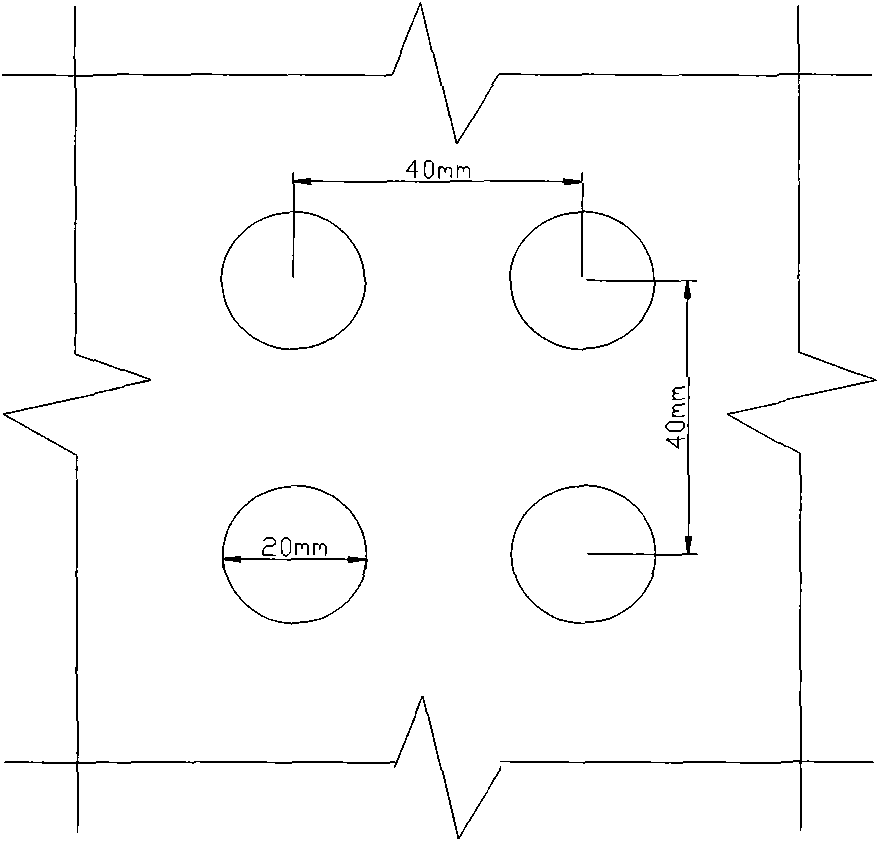

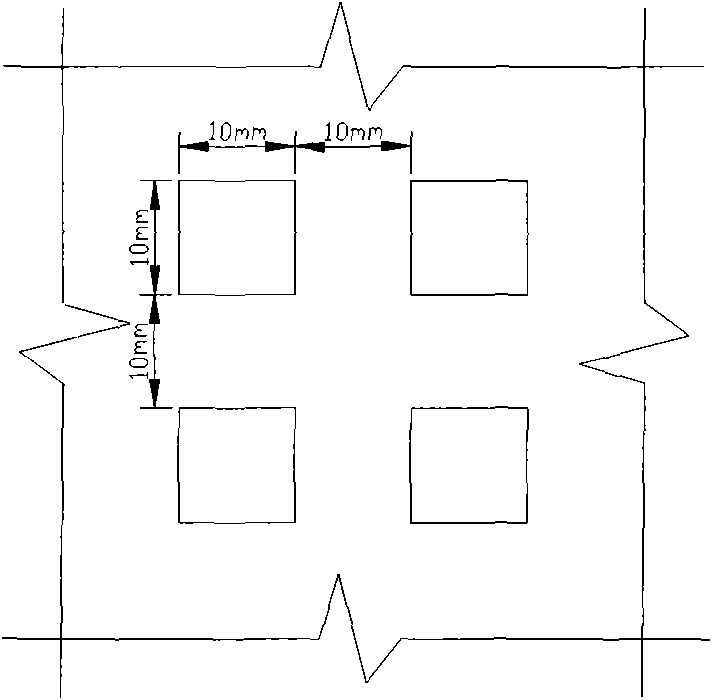

[0038]The length and width of the lower bottom of the integrated coagulation and sedimentation device are 1400mm*400mm, the length and width of the upper bottom are 1200mm*400mm, the height is 1200mm, and the length, width and height of the drainage tank are 200*400*200. Among them, the size of the coagulation zone is 600mm*400mm*1200, the height of the bottom of the sedimentation zone is 400mm, the height of the inclined plate sedimentation zone is 400mm, and the height of the clear water zone of the sedimentation ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com