Preparation method of pouring type prefabricated polyurethane elastomer sport field material

A technology for polyurethane elastomers and sports grounds, applied in construction, roads, road repairs, etc., can solve the problems of material thickness differences, uneven thicknesses of raw materials, unevenness of sports ground materials, and achieve uniform distribution and prevent accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

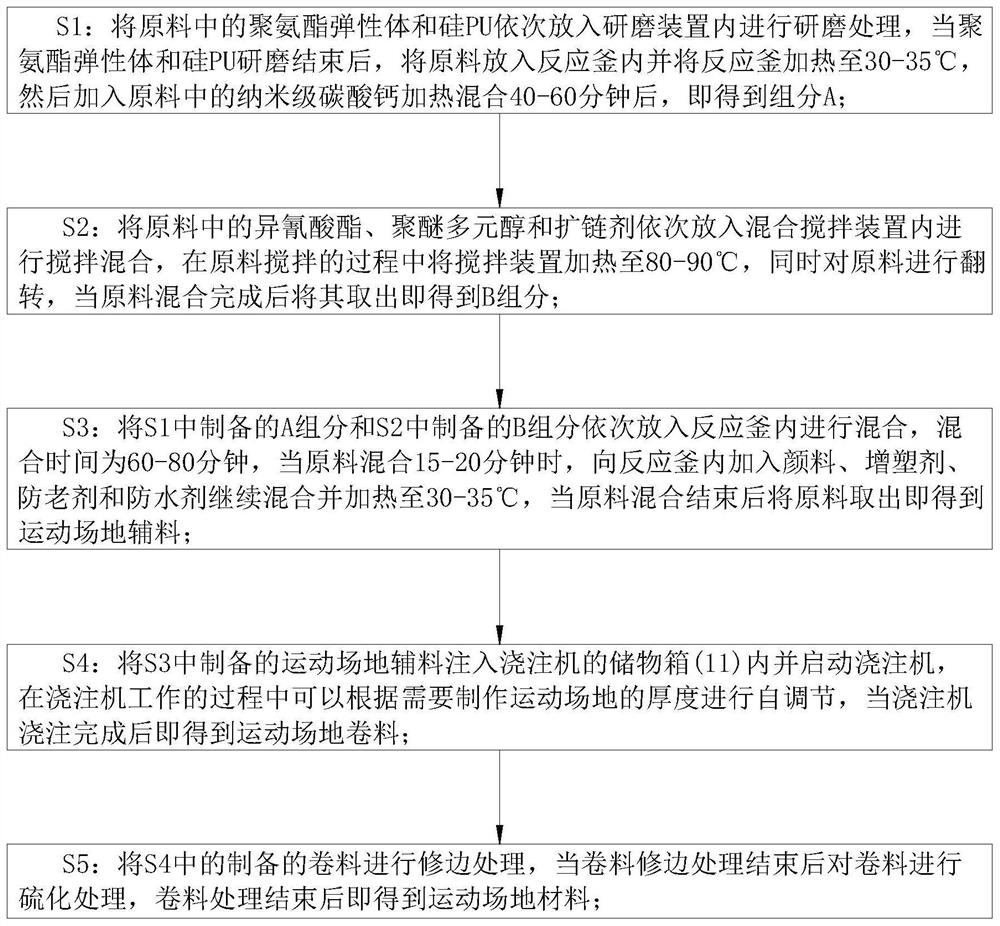

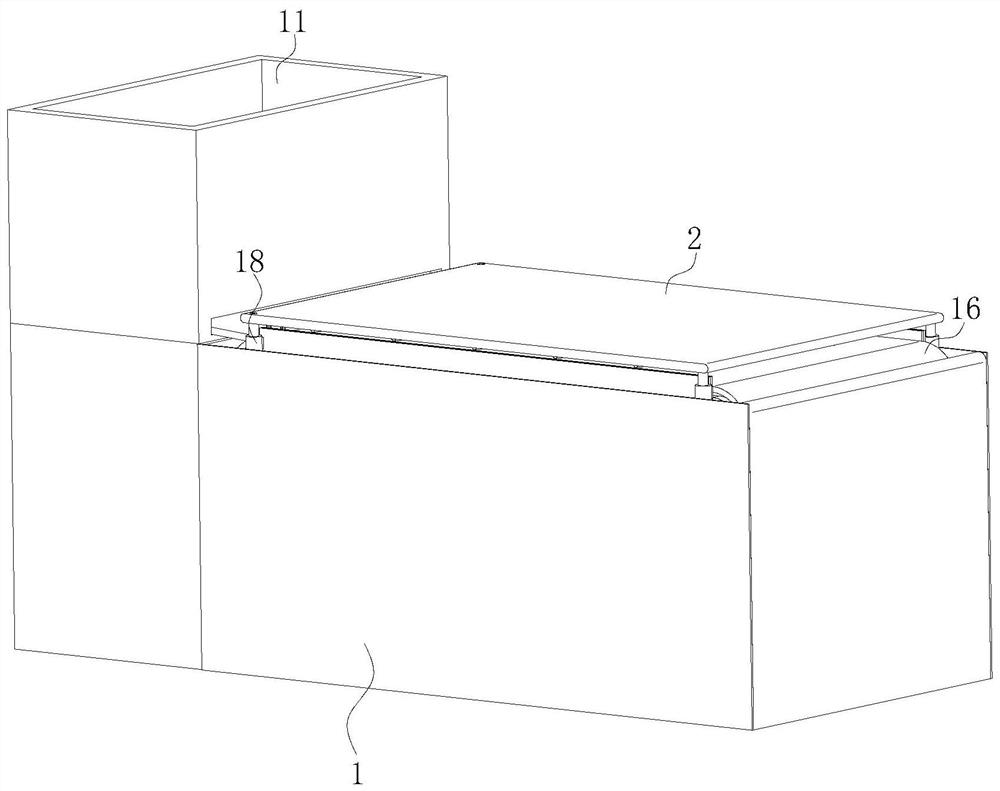

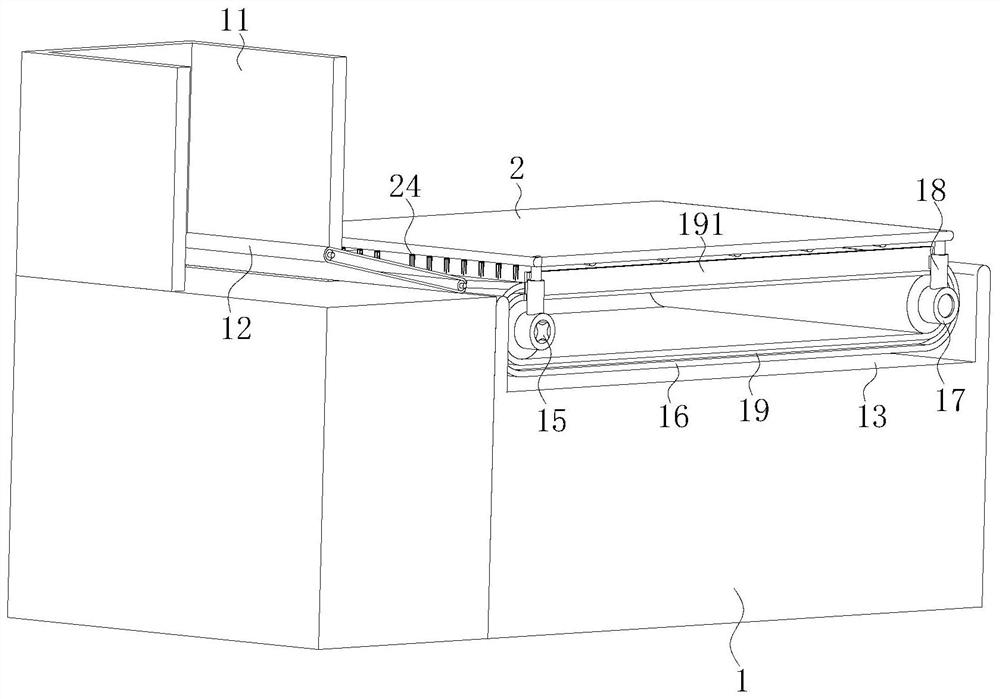

Method used

Image

Examples

Embodiment approach

[0059] As an embodiment of the present invention, the anti-aging agent contains 15-20% acrylic acid;

[0060] The acrylic acid organic synthesis raw material and synthetic resin monomer contained in the antiaging agent are a kind of green environmental protection material, which can improve the environmental protection performance of the sports field material and have a strong polymerization speed. It is used in the present invention It can increase the polymerization speed of acrylic acid and other raw materials, thereby improving the performance of sports field materials. At the same time, acrylic acid can also improve the wear resistance of sports field materials, thereby improving the service life of sports field materials. At the same time, acrylic acid has strong anti-ultraviolet rays The ability to slow down the aging of sports field materials and improve the service life of sports field materials.

[0061] As an embodiment of the present invention, during the process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com