Production system and production method for sodium sulfate by adopting single effect and mechanical thermal compression technology

A production system and production method technology, applied in the direction of alkali metal sulfite/sulfate dehydration, etc., can solve the problem of low evaporation efficiency of the evaporation tank, achieve the effects of simplifying equipment, improving evaporation efficiency, and simplifying the structure of the preparation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

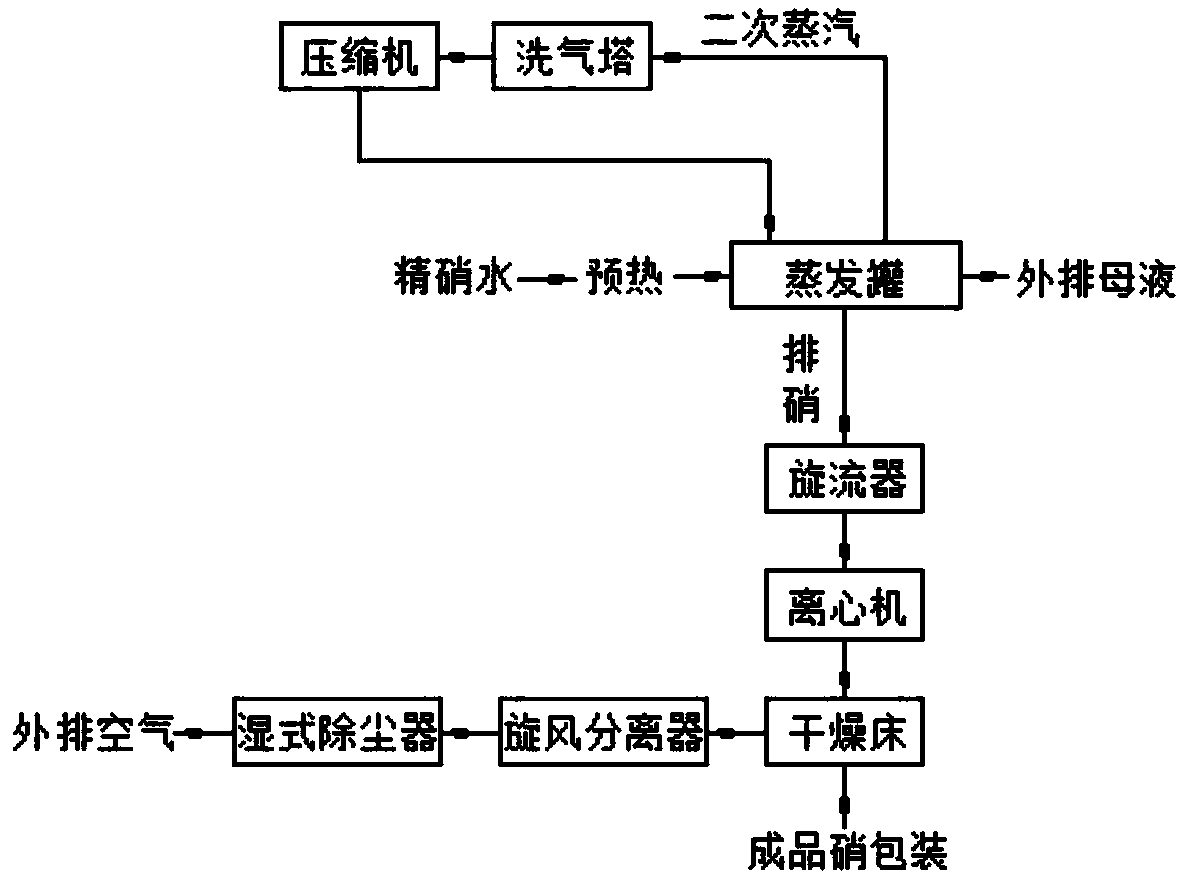

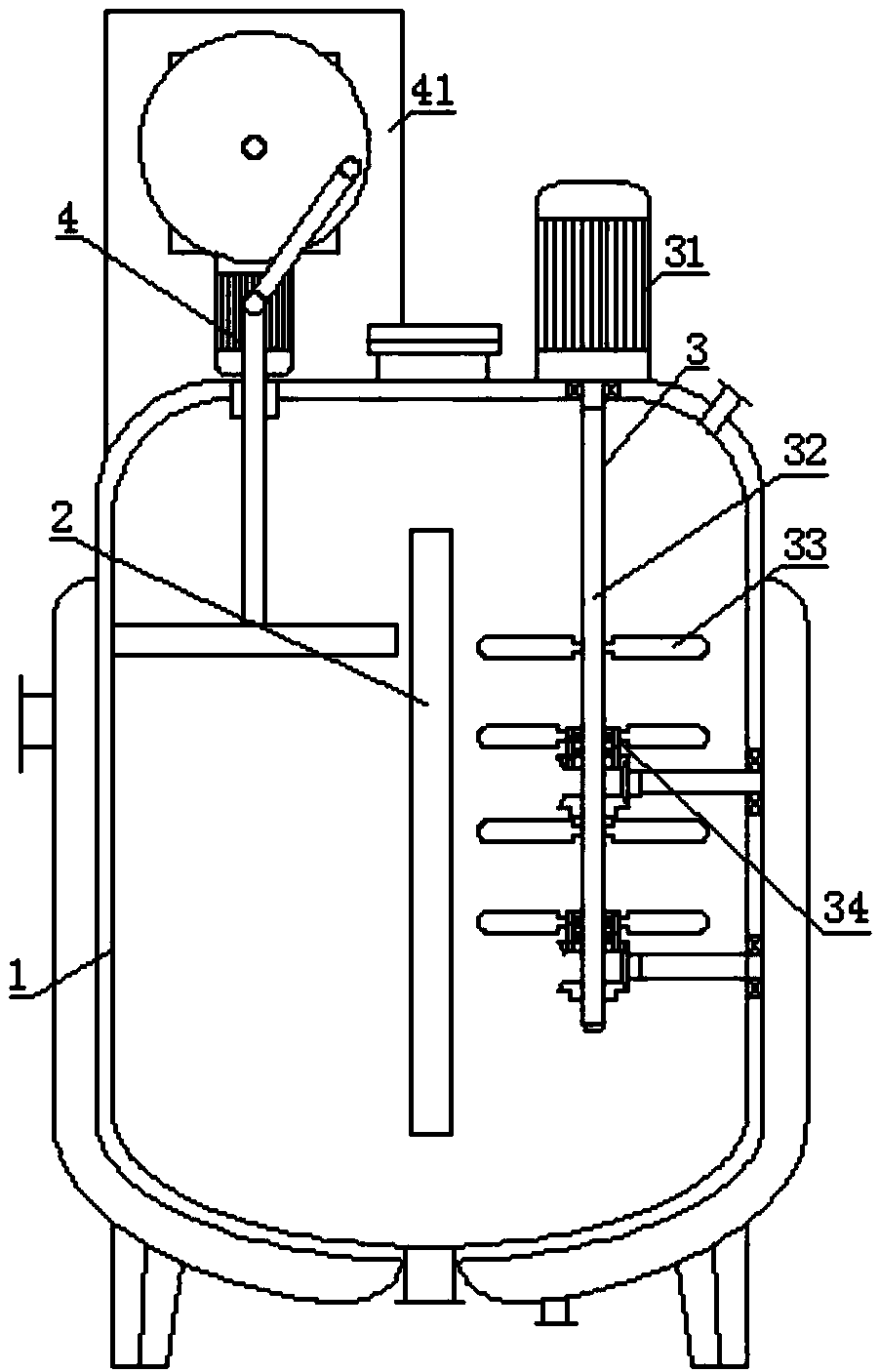

[0033] like figure 1 and figure 2 , the present invention includes an evaporation system, the evaporation system is connected with a drying system for concentrating the nitrate slurry discharged from the evaporation system, and the drying system is connected with a purification system for purifying the air containing nitrate discharged from the drying system; the evaporation system includes an evaporation tank, an evaporation tank The steam outlet of the steam tank is connected to a scrubber and a compressor in turn through a pipeline, the outlet of the compressor is connected to the air inlet of the evaporation tank through a pipeline, and the nitrate outlet of the evaporation tank is connected to the drying system; the evaporation tank includes a tank body 1, a tank body 1 is fixed with a partition 2, and there are gaps between the partition 2 and the upper and lower ends of the tank body 1. The partition 2 separates the inside of the tank 1 into a stirring chamber and a co...

Embodiment 2

[0037] like image 3 As shown, on the basis of Embodiment 1, the stirring mechanism 3 includes a motor 31, the motor 31 is installed on the tank body 1, the output shaft of the motor 31 is connected with a rotating rod 32, the rotating rod 32 is located in the stirring chamber, and the rotating rod 32 is connected with the tank body 1 by a bearing, and several forward stirring paddles 33 and some reverse stirring mechanisms 34 are respectively installed on the rotating rods 32 .

[0038] When the motor 31 is started, the forward stirring paddle 33 rotates forward together with the rotating rod 32, while the reverse stirring paddle 345 on the reverse stirring mechanism 34 rotates reversely. Therefore, the stirring directions of the nitric acid slurry in different height layers are different in the stirring chamber, avoiding the formation of vortex or internal and external stratification of the nitric slurry in the mixing chamber, improving the heating uniformity of the nitric s...

Embodiment 3

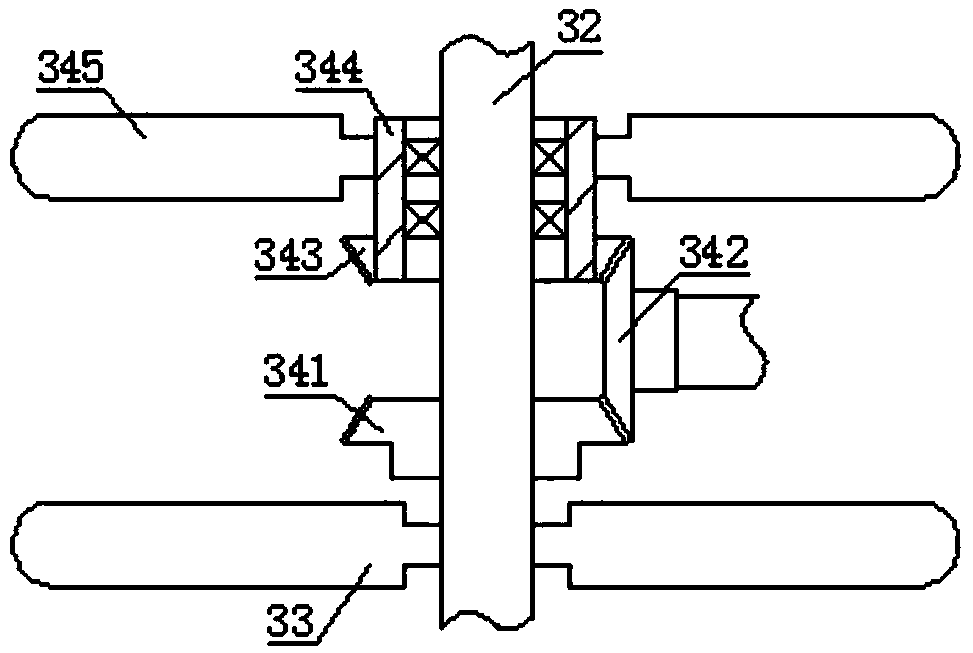

[0040] On the basis of Embodiment 1 and Embodiment 2, the reverse stirring mechanism 34 includes a driving bevel gear 341, and the driving bevel gear 341 is fixed on the rotating rod 32; the driving bevel gear 341 is meshed with a connecting bevel gear 342, and the connecting bevel gear The rotating shaft of 342 is connected to the inner wall of the tank body 1 through a bearing, and the connecting bevel gear 342 is also meshed with a driven bevel gear 343. A collar 344 is fixed inside the driven bevel gear 343, and the collar 344 is connected to the rotating rod 32 through a bearing. On the collar 344, a reverse stirring paddle 345 is fixed.

[0041] The driving bevel gear 341 forwardly rotates together with the rotating rod 32 , and the connecting bevel gear 342 transmits power to the driven bevel gear 343 . Connecting the bevel gear 342 plays a reversing role, and the driven bevel gear 343, the collar 344, and the reverse stirring paddle 345 all rotate in the opposite direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com