High-entropy alloy CoCrFeMnNi and atomization powder making method manufacturing technique

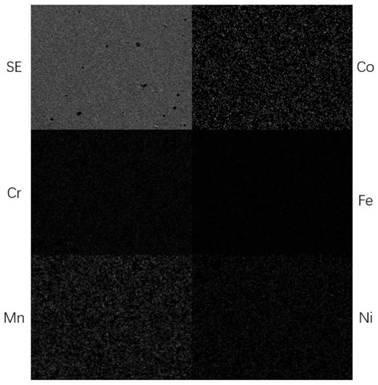

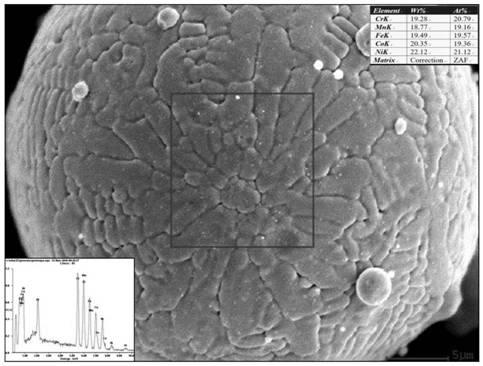

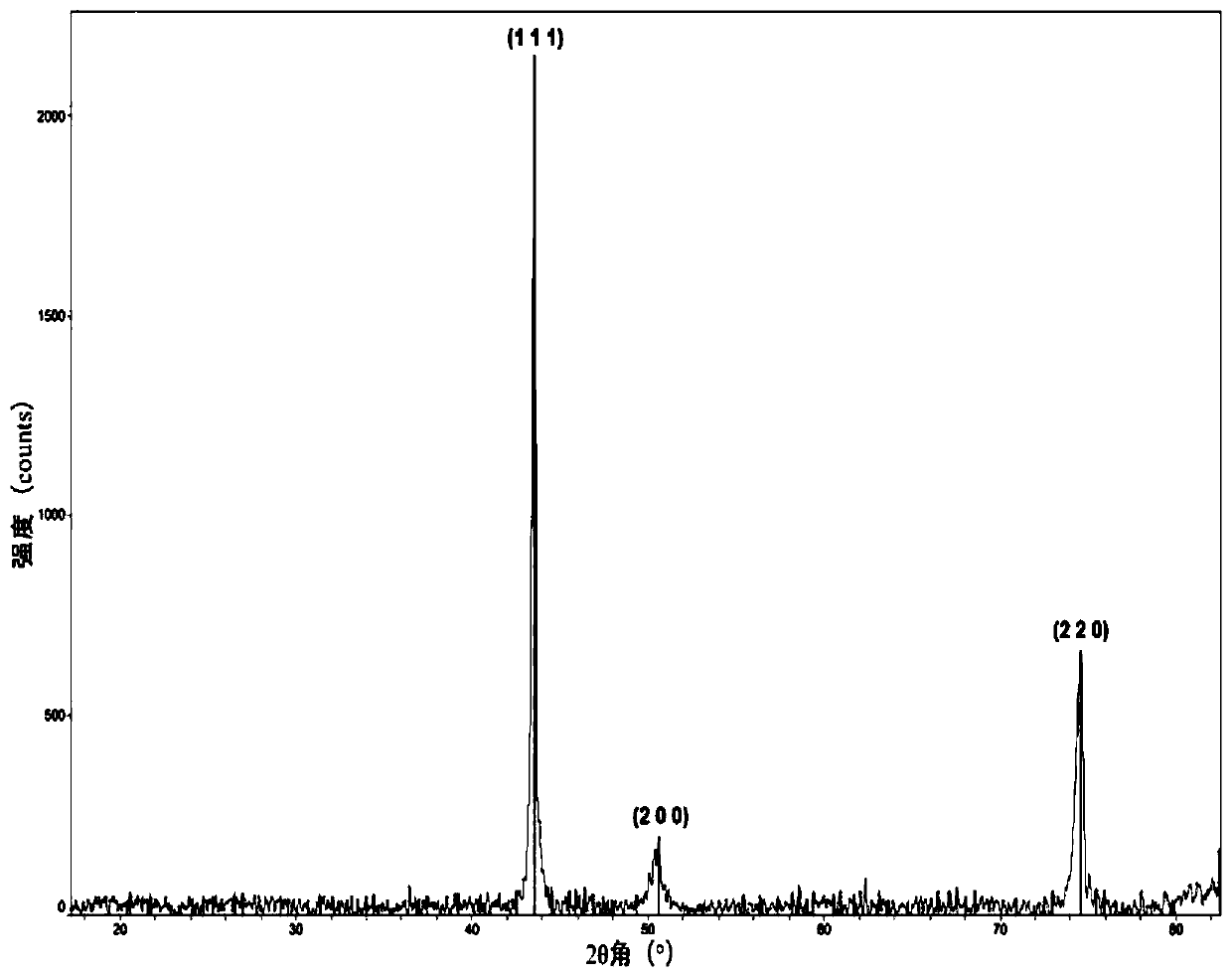

A high-entropy alloy and atomization powder-making technology, applied in the field of metal materials, can solve the problems of uneven mixing, large particles, and microsegregation of high-entropy alloy CoCrFeMnNi, and achieve no microsegregation, uniform composition, and particle size deviation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The atomization pulverization preparation process of high-entropy alloy CoCrFeMnNi, the steps are as follows:

[0048] (1) Carry out cutting and cleaning pretreatment on Fe, Co, Ni, Cr and Mn elemental small pieces, and cut them into small pieces of the required weight by using a grinding wheel cutting machine. As a standard, use circular table saw, manual saw, wire cutting, etc. to cut the raw materials of each component into small pieces as large as possible, and use an electronic balance to weigh them, and then lightly polish the small pieces of each element to determine their quality. Fine-tuning is carried out to ensure that the amounts of each element are equal in substance, and the mass of each elemental small block obtained after cutting is: Fe elemental 111.6905g, Co elemental 117.8666g, Ni elemental 117.3866g, Cr elemental 103.9225g, Mn elemental 109.8813g; Cleaning is to immerse the cut element in acetone solution and add 28Hz ultrasonic vibration for 180 sec...

Embodiment 2

[0055] The atomization pulverization preparation process of high-entropy alloy CoCrFeMnNi, the steps are as follows:

[0056] (1) Carry out cutting and cleaning pretreatment to Fe, Co, Ni, Cr and Mn element simple substance small block, cutting is to adopt the grinding wheel cutting machine to process the simple substance small block of required weight, and cleaning is to immerse the cut simple substance into acetone solution And add ultrasonic vibration for 180 seconds to remove simple surface oil;

[0057] (2) Fe, Co, Ni, Cr and Mn elemental small pieces of equal substance amount are smelted with intermediate frequency induction furnace to obtain CoCrFeMnNi alloy bar stock, and the respective purity of Fe, Co, Ni, Cr and Mn elemental small pieces are all the same. It is 99.999%, and the parameters for melting with medium frequency induction furnace are: slowly increase the melting power of induction furnace at a speed of 7kW / 5min, so that the melting power reaches 44kW, and ...

Embodiment 3

[0062] The atomization pulverization preparation process of high-entropy alloy CoCrFeMnNi, the steps are as follows:

[0063] (1) Carry out cutting and cleaning pretreatment to Fe, Co, Ni, Cr and Mn element simple substance small block, cutting is to adopt the grinding wheel cutting machine to process the simple substance small block of required weight, and cleaning is to immerse the cut simple substance into acetone solution And add ultrasonic vibration for 180 seconds to remove simple surface oil;

[0064] (2) Fe, Co, Ni, Cr and Mn elemental small pieces of equal substance amount are smelted with intermediate frequency induction furnace to obtain CoCrFeMnNi alloy bar stock, and the respective purity of Fe, Co, Ni, Cr and Mn elemental small pieces are all the same. It is 99.992%, and the parameters for melting with medium frequency induction furnace are: slowly increase the melting power of induction furnace at a speed of 7kW / 5min, so that the melting power reaches 44kW, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com