Patents

Literature

61results about How to "Effective agitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

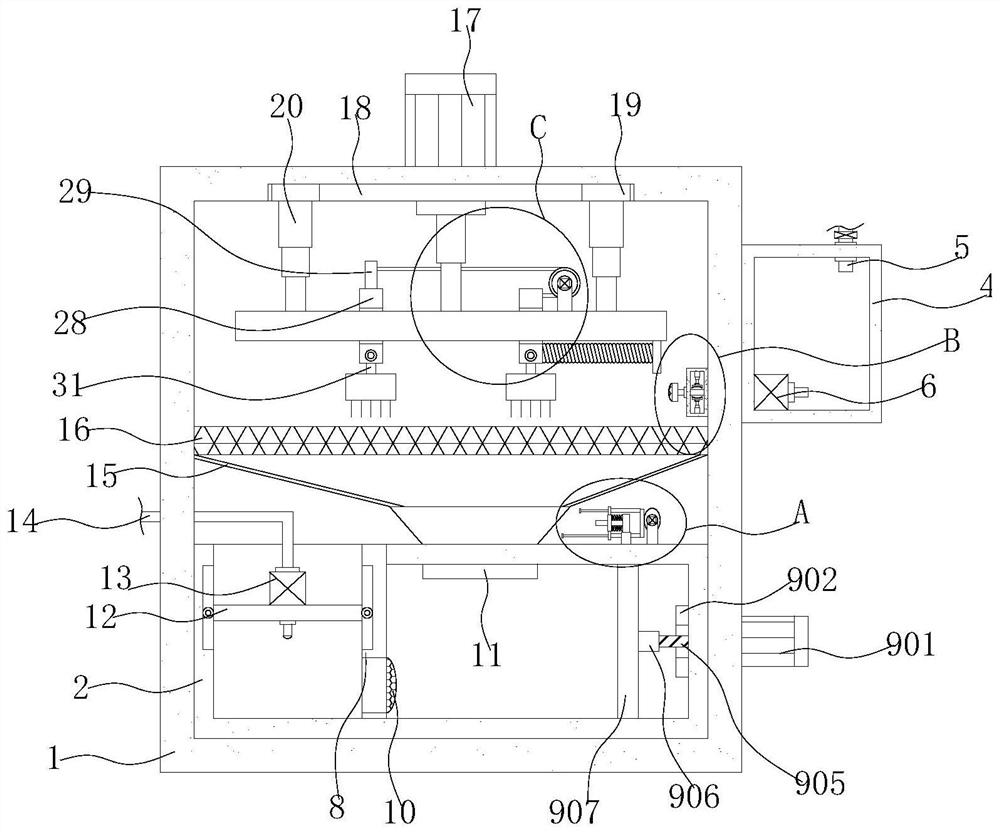

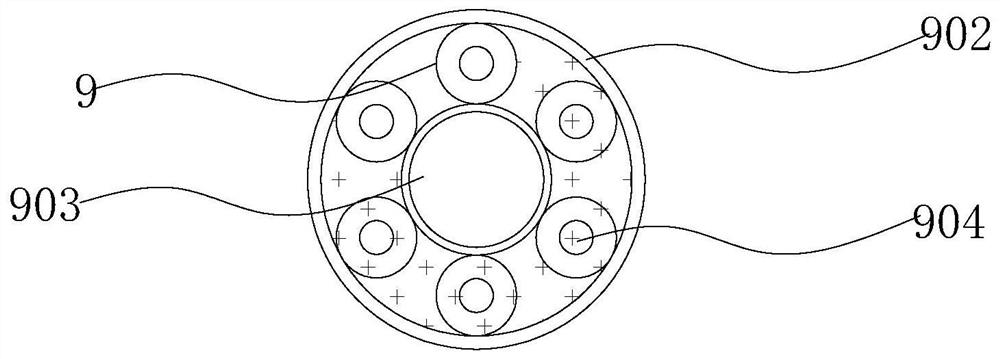

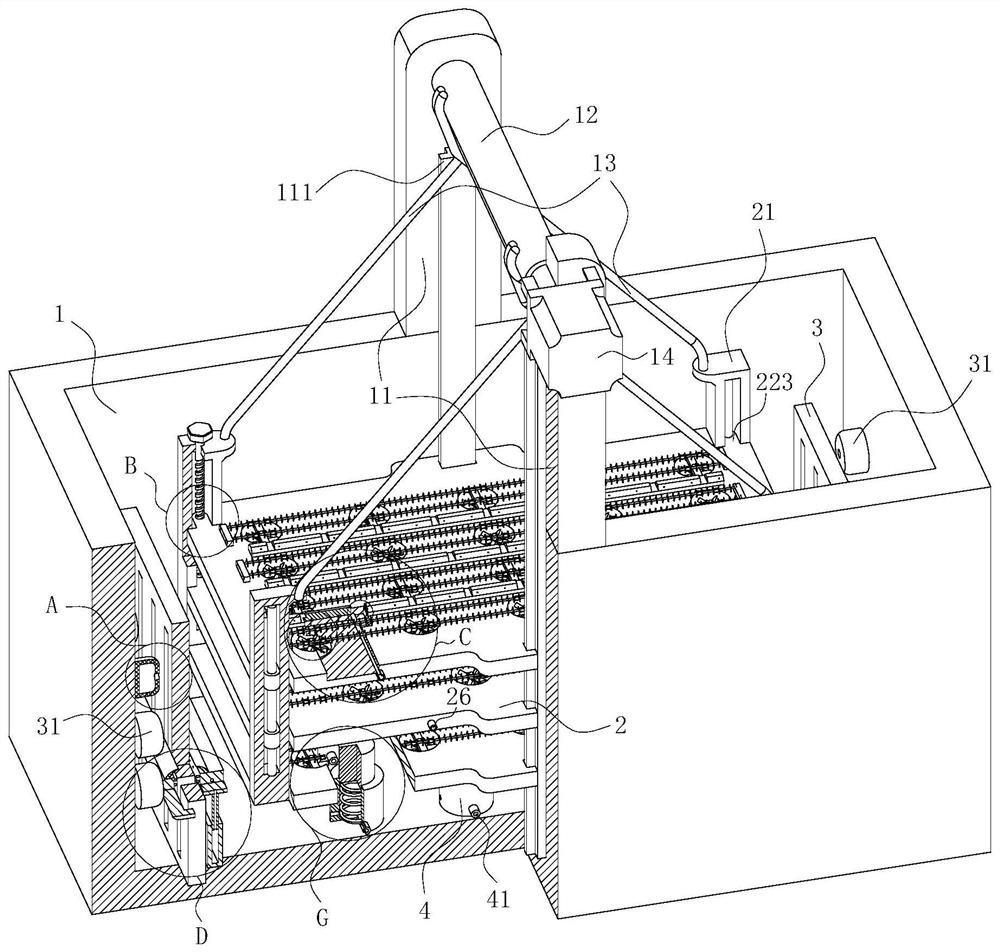

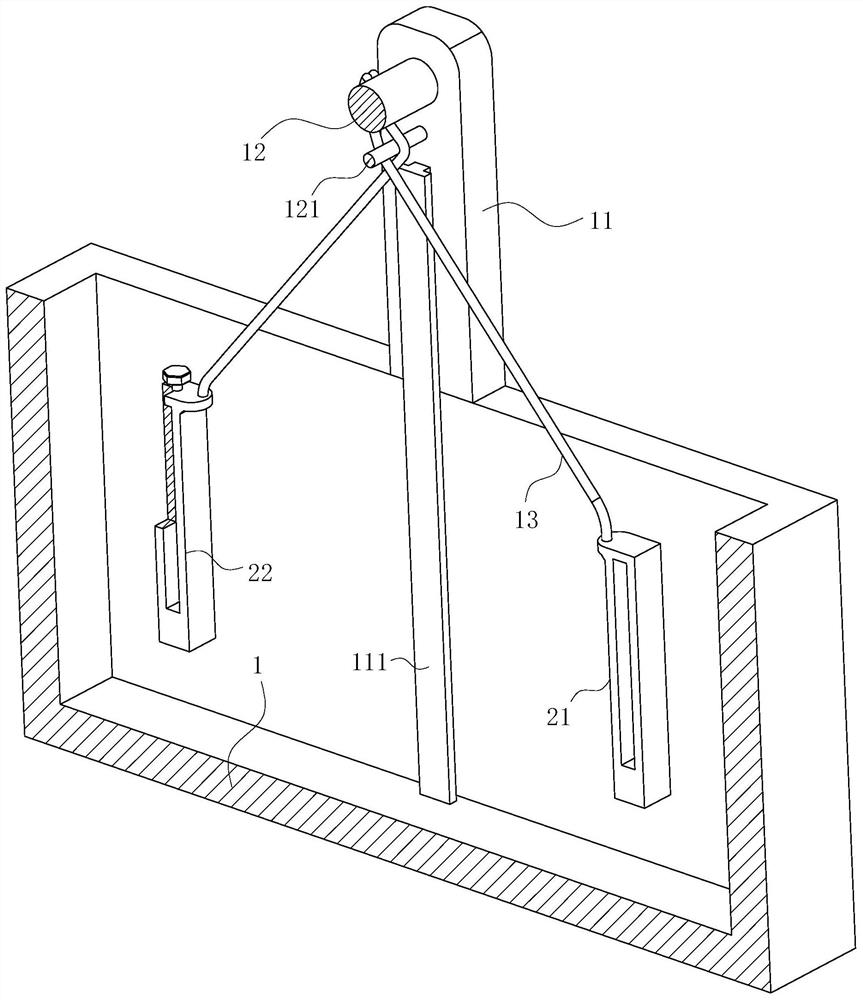

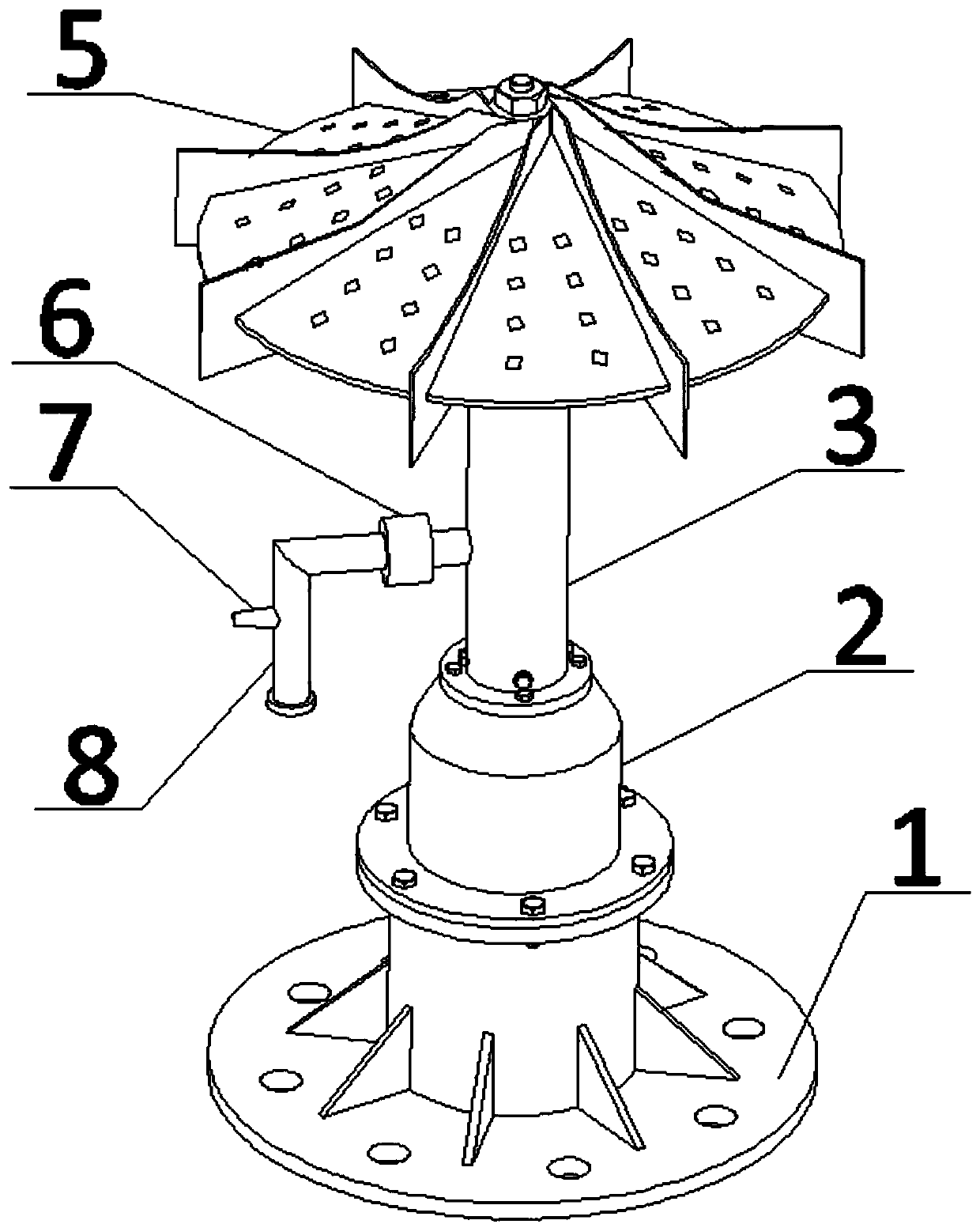

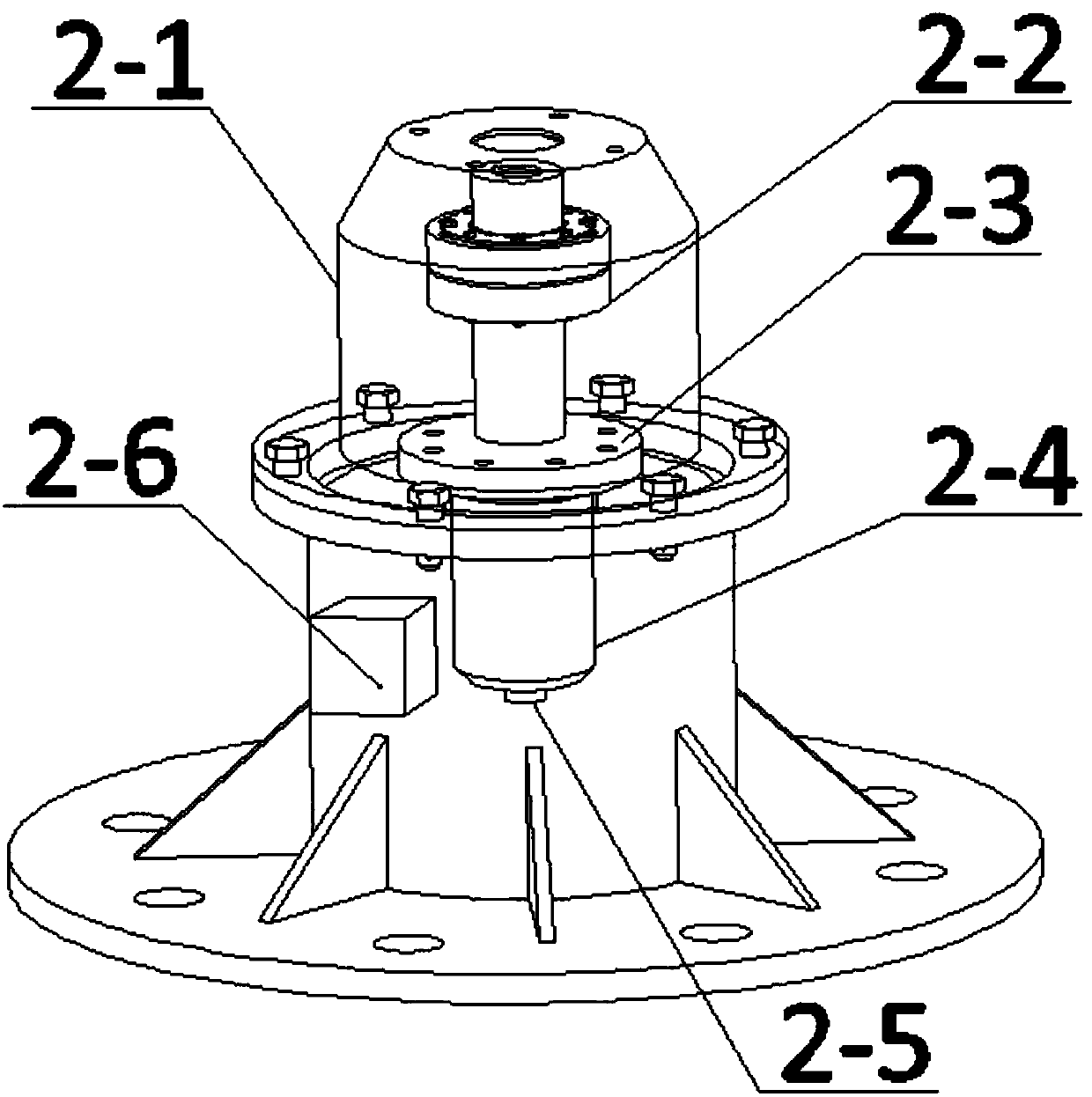

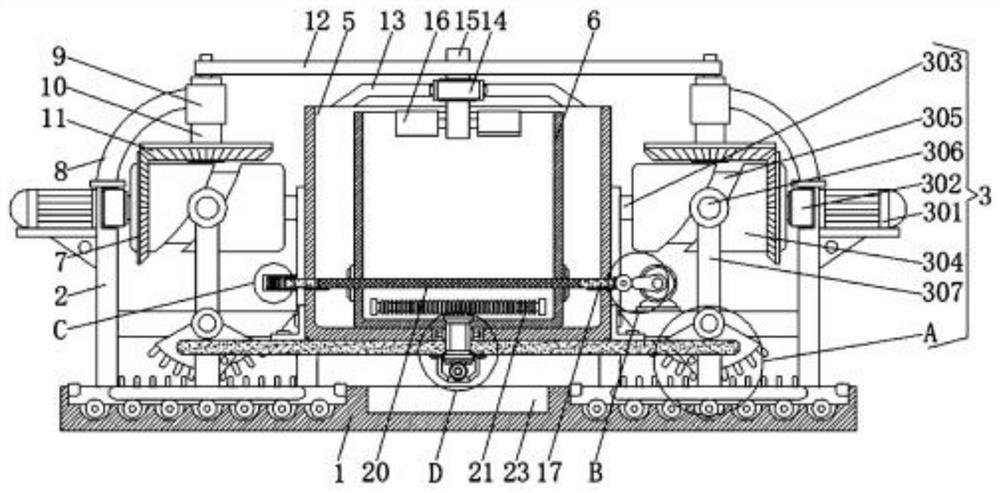

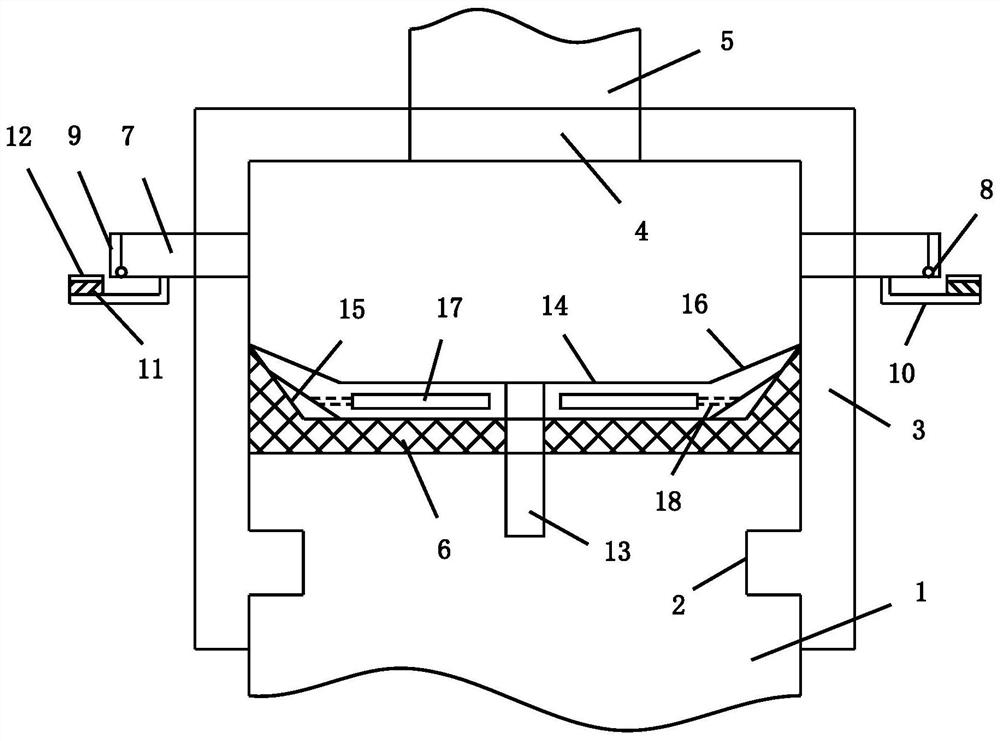

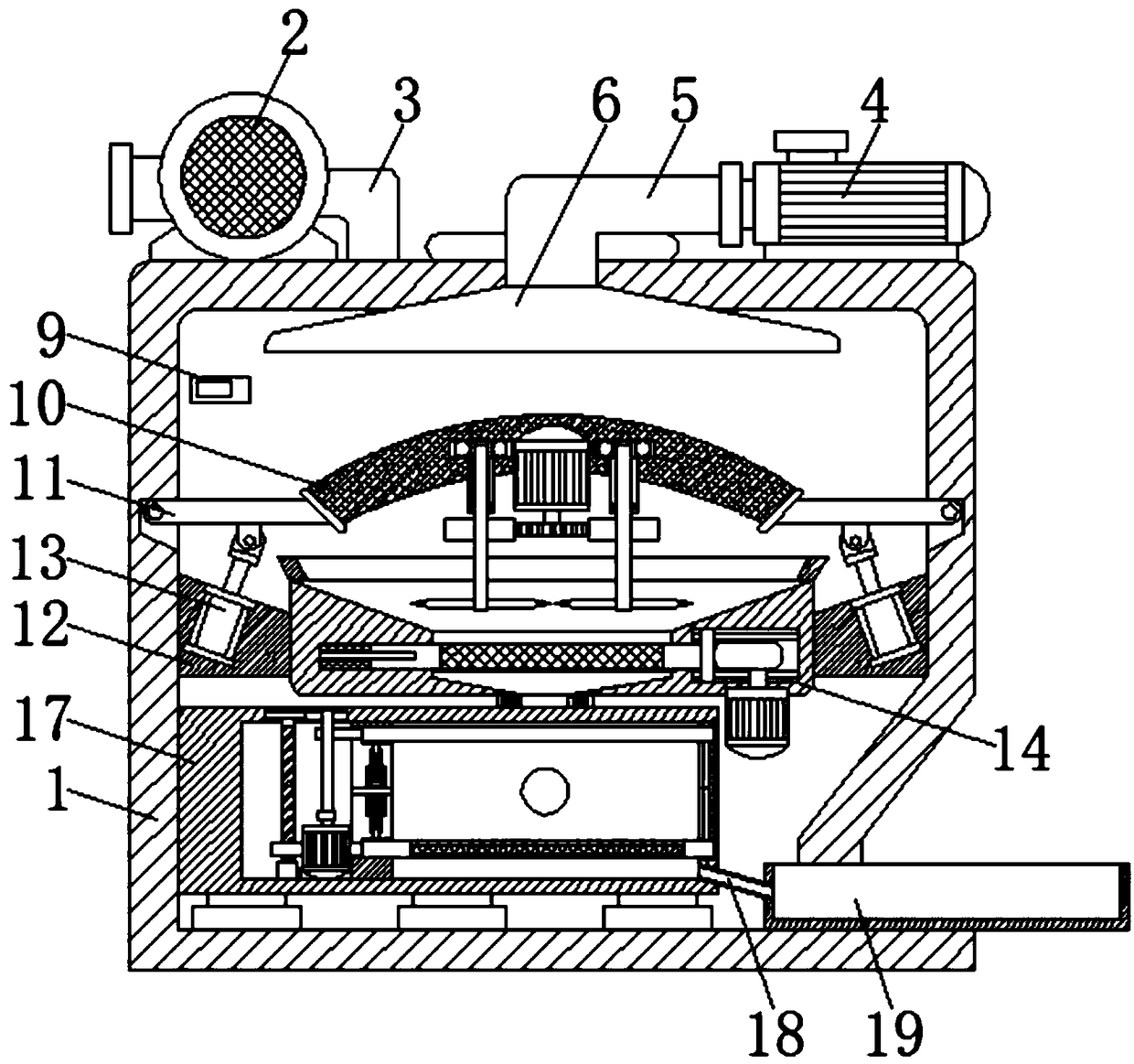

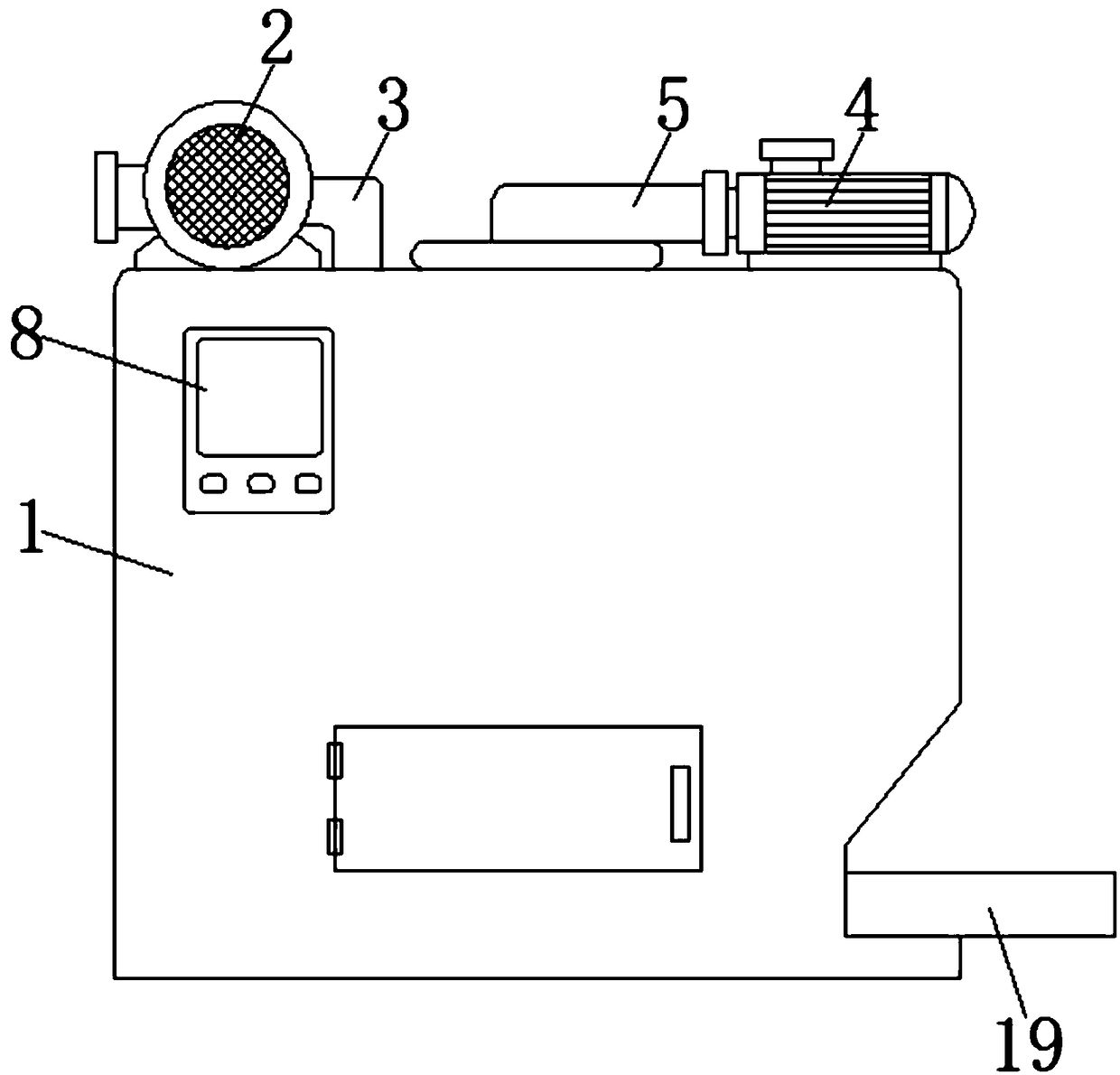

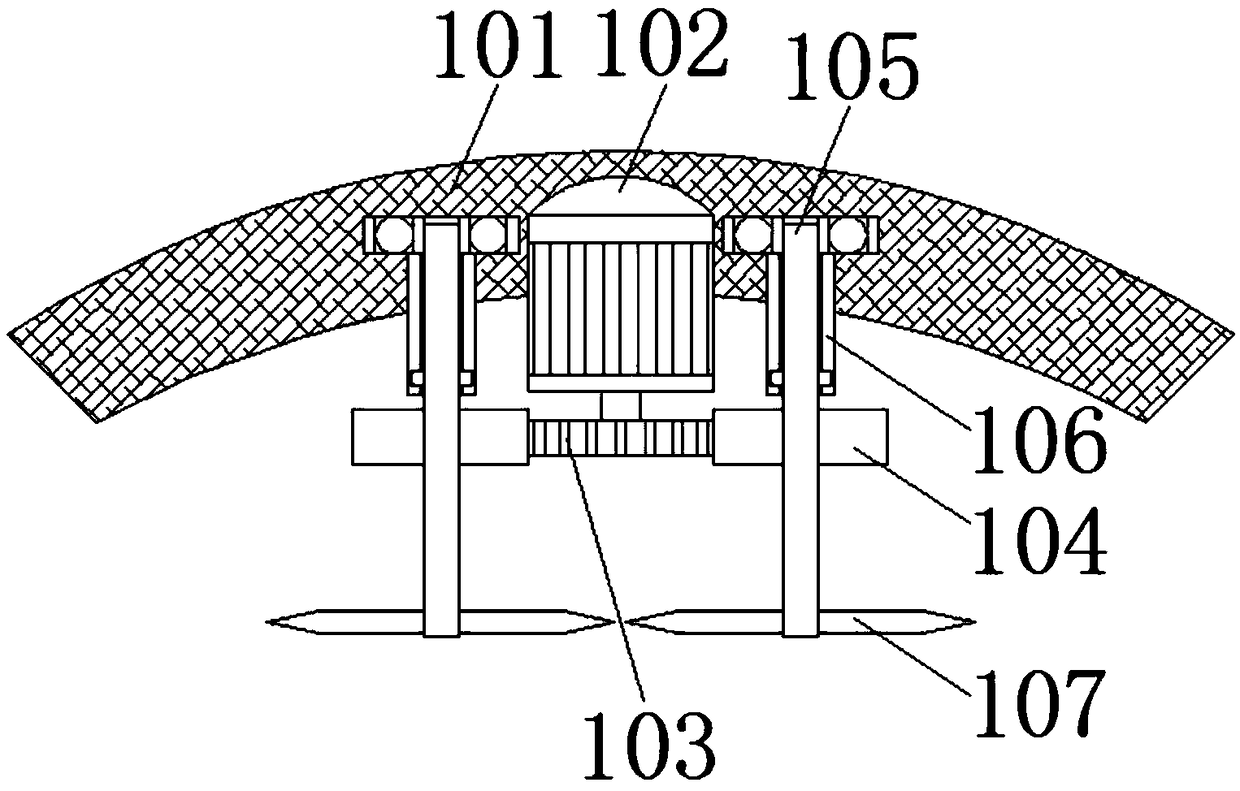

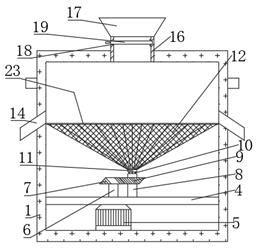

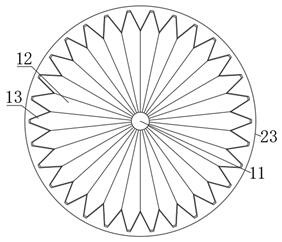

Short necked clam cleaning device based on linkage of vibrating force and stirring centrifugal force

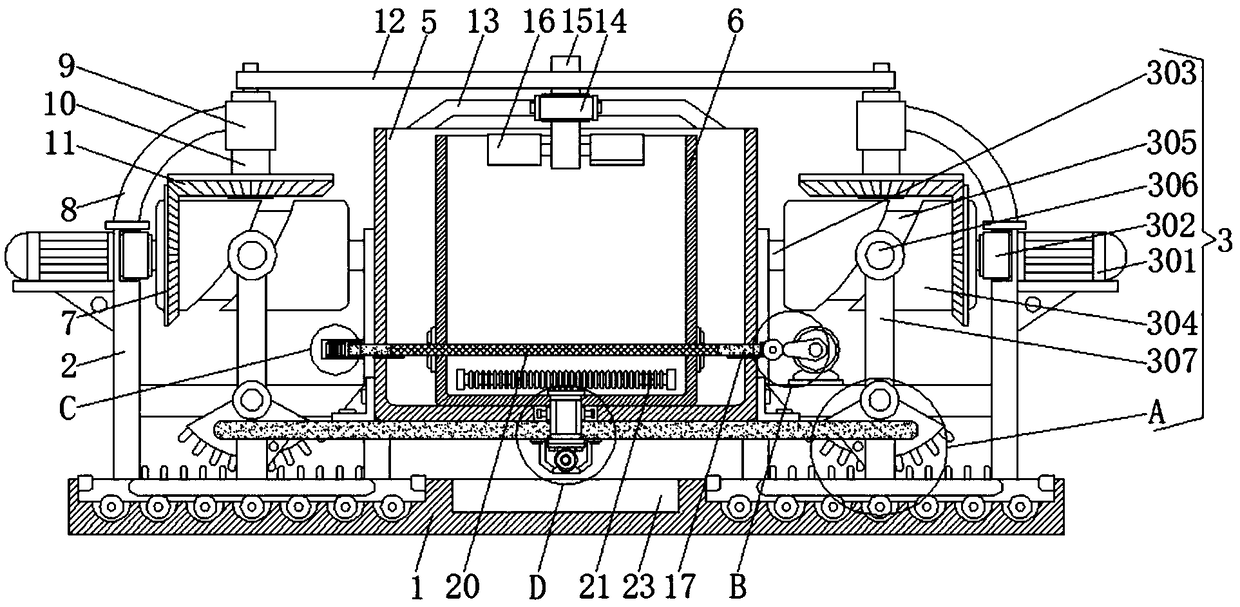

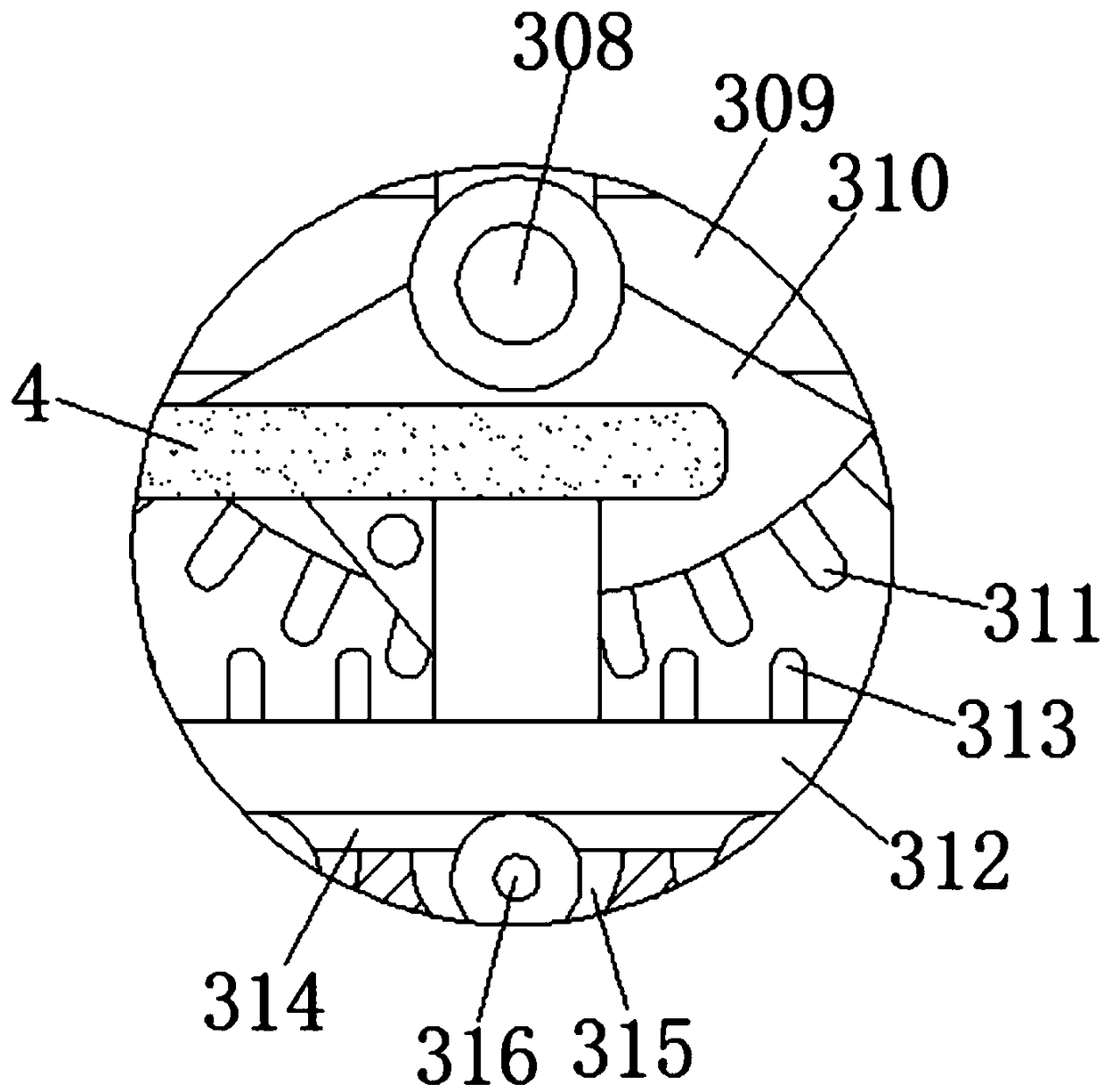

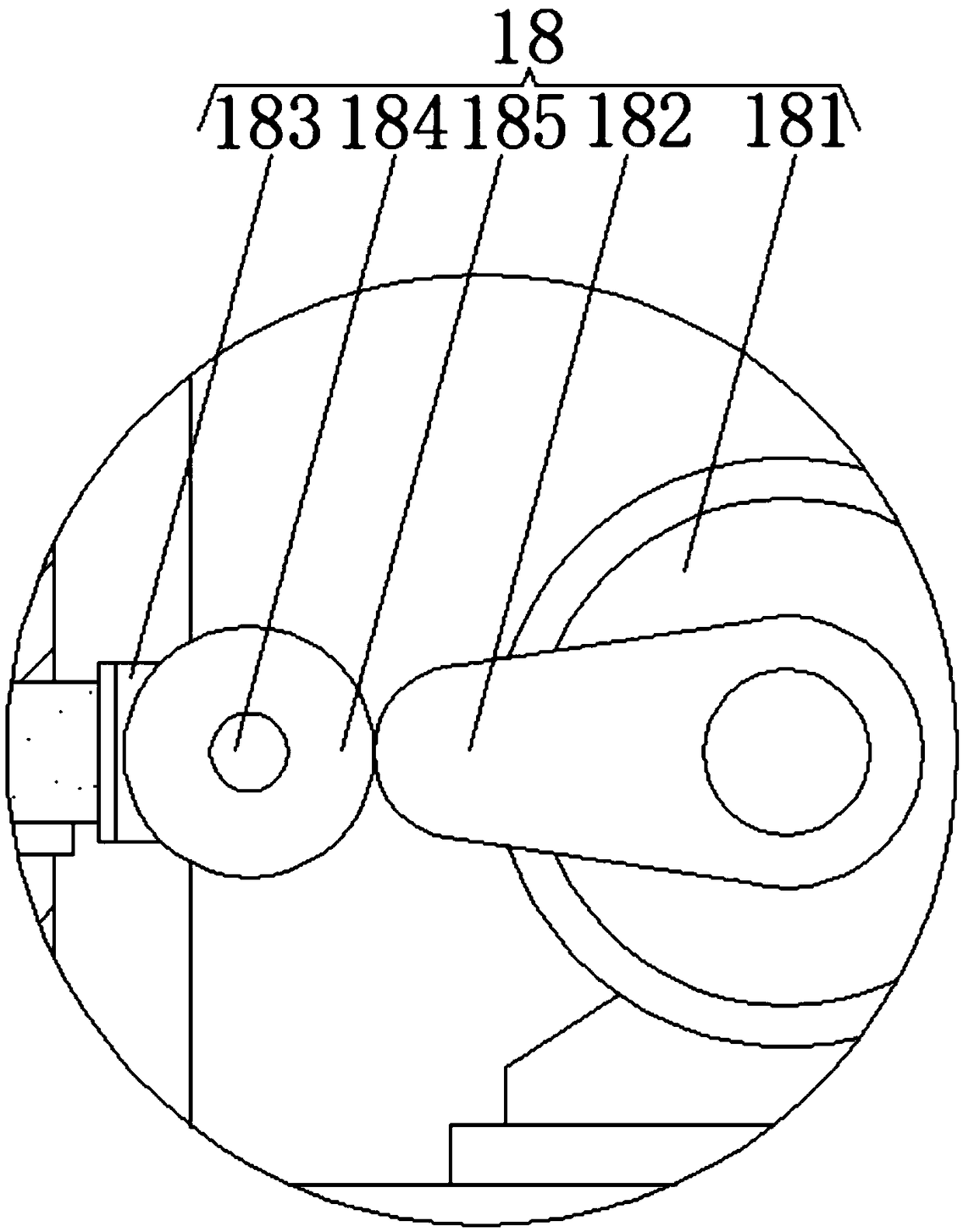

The invention discloses a short necked clam cleaning device based on linkage of vibrating force and stirring centrifugal force, and relates to the technical field of short necked clams. The short necked clam cleaning device based on linkage of vibrating force and stirring centrifugal force comprises a bottom plate, wherein two supporting frames are fixedly connected to the left side and the rightside of the top of the bottom plate; a vibrating driving mechanisms is fixedly mounted on each of the two supporting frames; the left side and the right side of the bottom of a supporting plate are respectively and fixedly connected to the two vibrating driving mechanisms; a tank body is fixedly connected to the middle part of the top of the supporting plate; and a water tank is mounted in the tank body in a sleeving manner. According to the short necked clam cleaning device based on linkage of vibrating force and stirring centrifugal force disclosed by the invention, the vibrating driving mechanisms are fixedly mounted on the supporting frames, so that through the supporting plate, and the tank body and the water tank can be driven to be in repeated horizontal transverse movement, so thatin the sand splitting course of the short necked clams, a manual shaking method is effectively replaced; and when the workload of workers is alleviated, the washing effect of the short necked clams can be effectively improved.

Owner:日照尊诚食品有限公司

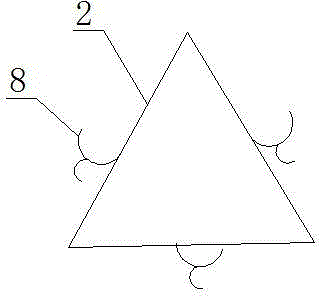

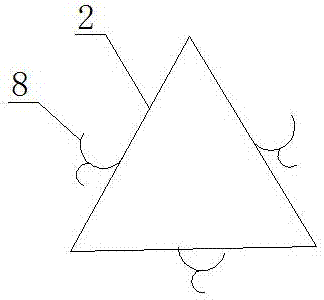

Vortex street mixer

The invention discloses a vortex street mixer which comprises an inlet flange, a vortex street generator I, a vortex street generator II, a mixer main body pipe and an outlet flange, wherein the mixer main body pipe is of a hollow cylindrical structure, the inlet flange and the outlet flange are respectively welded at the upper end and the lower end of the mixer main body pipe, the vortex street generator I and the vortex street generator II are both set to be of a hollow isosceles triangular column structure, and the vertex angle directly faces the fluid inlet direction; the vortex street generator I and the vortex street generator II are arranged by forming a right angle by passing through the center of circle of a pipeline interface, the vortex street generator I is welded between the upper end face and the lower end face of the mixer main body pipe, and the vortex street generator II is welded on a corresponding side wall vertical to the axis of the mixer main body pipe. The pipeline mixer which is simple in structure, high in use reliability and remarkable in mixing enhancing effect is favorable for generating eddy current, improving the fluid mixing degree and improving the mixing effect, is used for liquid-liquid and gas-gas quick mixing reaction, and is wide in applicability.

Owner:QINGDAO HEADWAY TECH

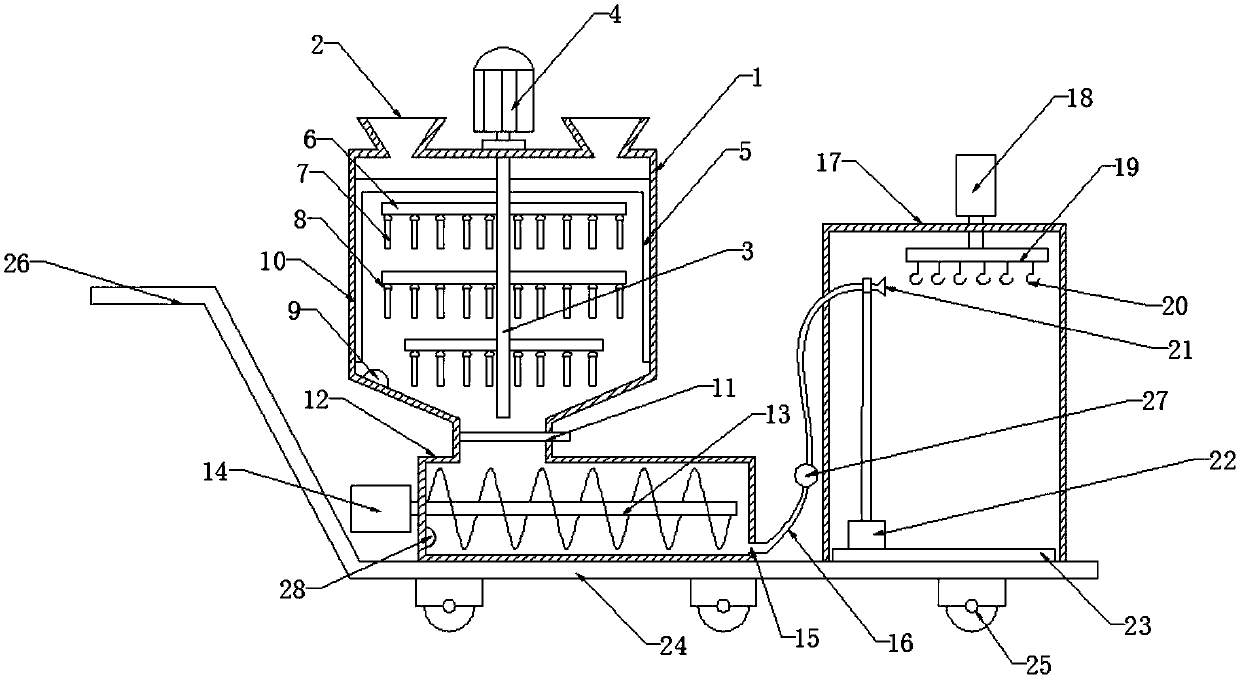

Efficient spraying machine

InactiveCN109718979AEffective agitationPrevent precipitationSpray boothsAgricultural engineeringEngineering

The invention provides an efficient spraying machine. The efficient spraying machine comprises a first stirring barrel, a second stirring barrel, a discharging pipe, a nozzle, an air cylinder and a base; the second stirring barrel is positioned below the first stirring barrel; the side walls of the first stirring barrel and the second stirring barrel are correspondingly provided with a heat preservation layer; a main shaft which is vertically arranged is arranged in the first stirring barrel, a scraper plate is connected to the main shaft, the scraping plate is attached to the inner wall of the first stirring barrel; a plurality of stirring rods are further arranged on the main shaft, and 3-5 stirring bars are hinged to the stirring rods through a connecting ring; a spiral shaft which is horizontally arranged is arranged in the second stirring barrel; a discharging opening is formed in the bottom of the second stirring barrel; and a spraying box is further arranged on the base, an aircylinder which is telescopic in the vertical direction is arranged in the spraying box, and a spray head is arranged on a telescopic rod of the air cylinder. The efficient spraying machine has a heating and heat preservation function, the problem of paint precipitation can be effectively solved, and time and labor are saved.

Owner:新昌县永益包装有限公司

Granular sauce storage device

The invention provides a granular sauce storage device belonging to the technical field of daily life, solving the problems that an outlet of a whole granular sauce storage device can not discharge smoothly after the prior granular sauce storage device is used for a while. The granular sauce storage device comprises a shell with a hollow cavity inside, an outlet 1 communicated with the hollow cavity of the shell is arranged at the bottom of the shell, a rotatable discharging piece is arranged at the bottom of the outside of the shell, and the discharging piece is provided with an outlet 2; a scraping piece which is fixedly connected with the discharging piece is also arranged in the shell, the scraping piece can block the outlet 1, and the outlet 1 is communicated with the outlet 2 when the scraping piece blocks the outlet; and the shell is also provided with a driving mechanism which can drive the discharge piece to rotate. The granular sauce storage device has the advantages of simple structure, convenient use, constant discharging and high stability.

Owner:肖招银

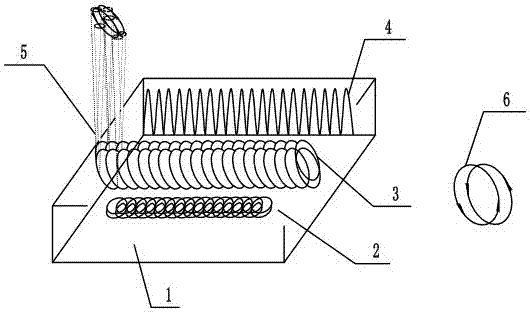

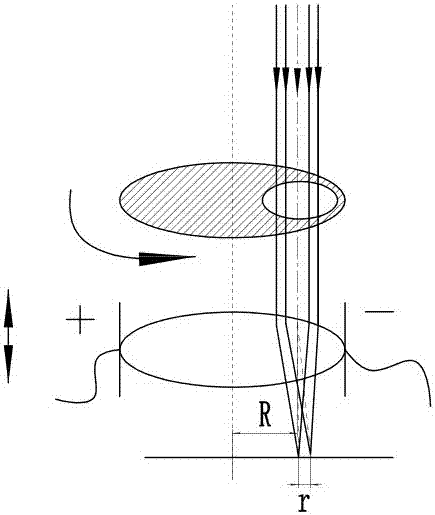

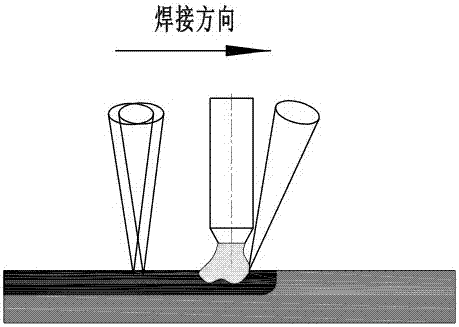

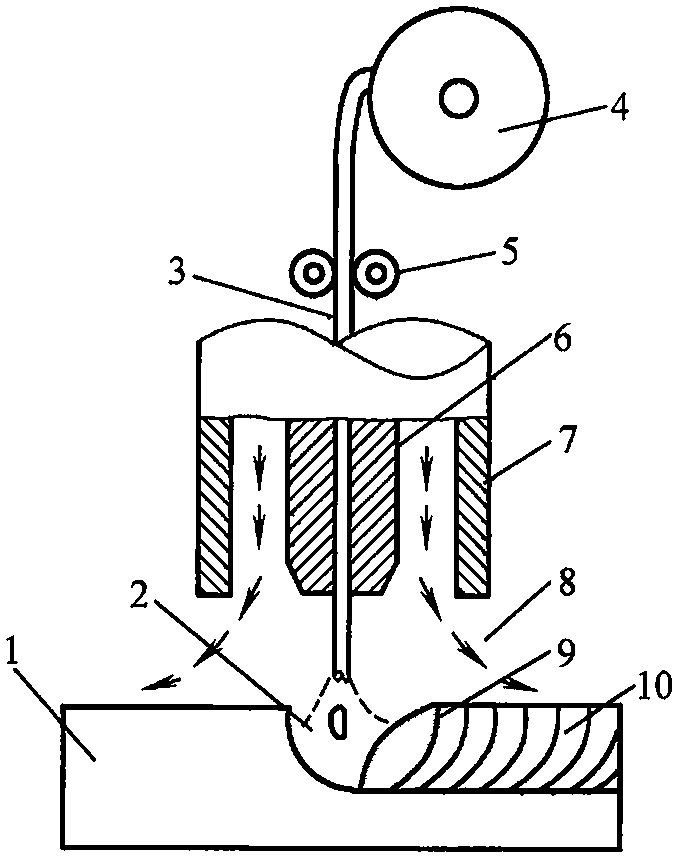

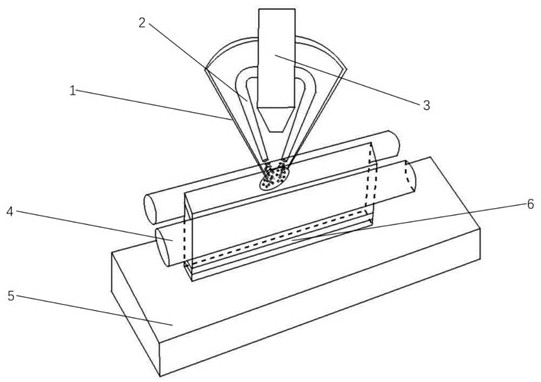

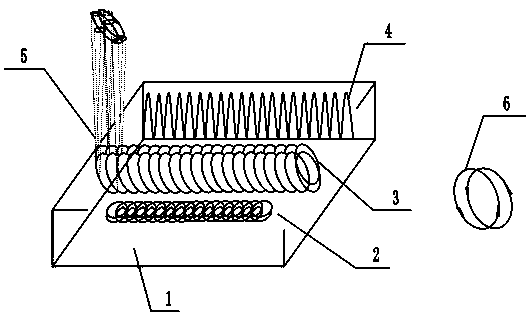

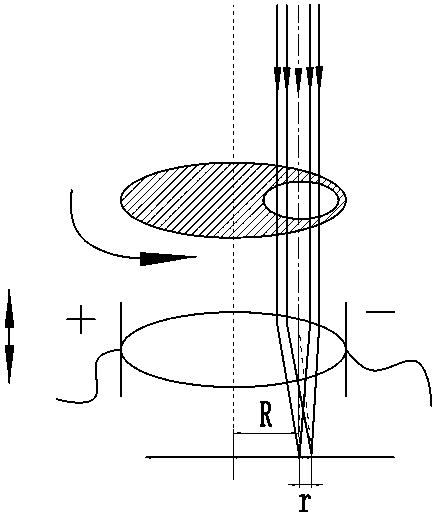

Multifocal laser reinforced arc hybrid welding method

ActiveCN107363407AEffective agitationImprove the finishLaser beam welding apparatusEngineeringLaser beams

The invention discloses a multifocal laser reinforced arc hybrid welding method. According to the method, four heat sources, namely the single-focus laser, welding gun arc and the bifocal heat sources are provided and sequentially arranged in the welding direction in series, different heat output can be achieved by changing laser power and current and voltage of a welding gun system, and welding modes required on site are achieved. Bifocal laser adopted by the method is formed by dividing a single laser beam into a bifocal laser beam through an optical beam splitting system, double laser beam focuses vertically distributed in the weld joint direction can do mutual crisscross motion, a molten pool is fully and effectively stirred, when the bifocal laser with high power is used as a welding heat source, the weld penetration is advantageously increased, the molten pool is stirred, pores and splashing are effectively reduced, and meanwhile, the weld joint weld penetration and weld width can be regulated and controlled by finely adjusting the focal distance of the two focuses. When the bifocal laser with lower power is used as a heat treatment heat source, the smooth finish of welded surfaces is advantageously improved, the weld joint uniformity is improved, pores and splashing are effectively reduced, and the weld joint quality is improved.

Owner:WENZHOU UNIVERSITY

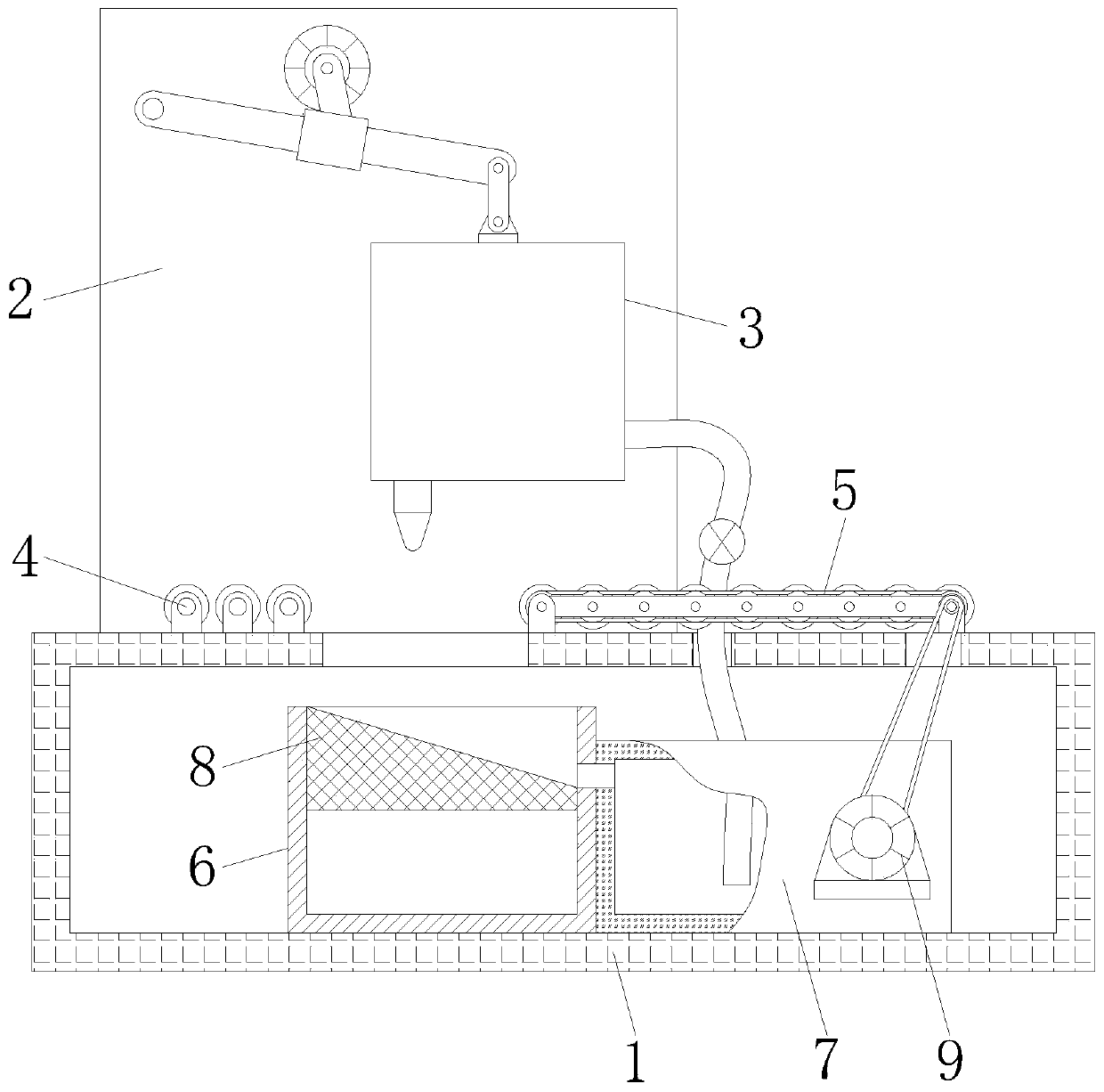

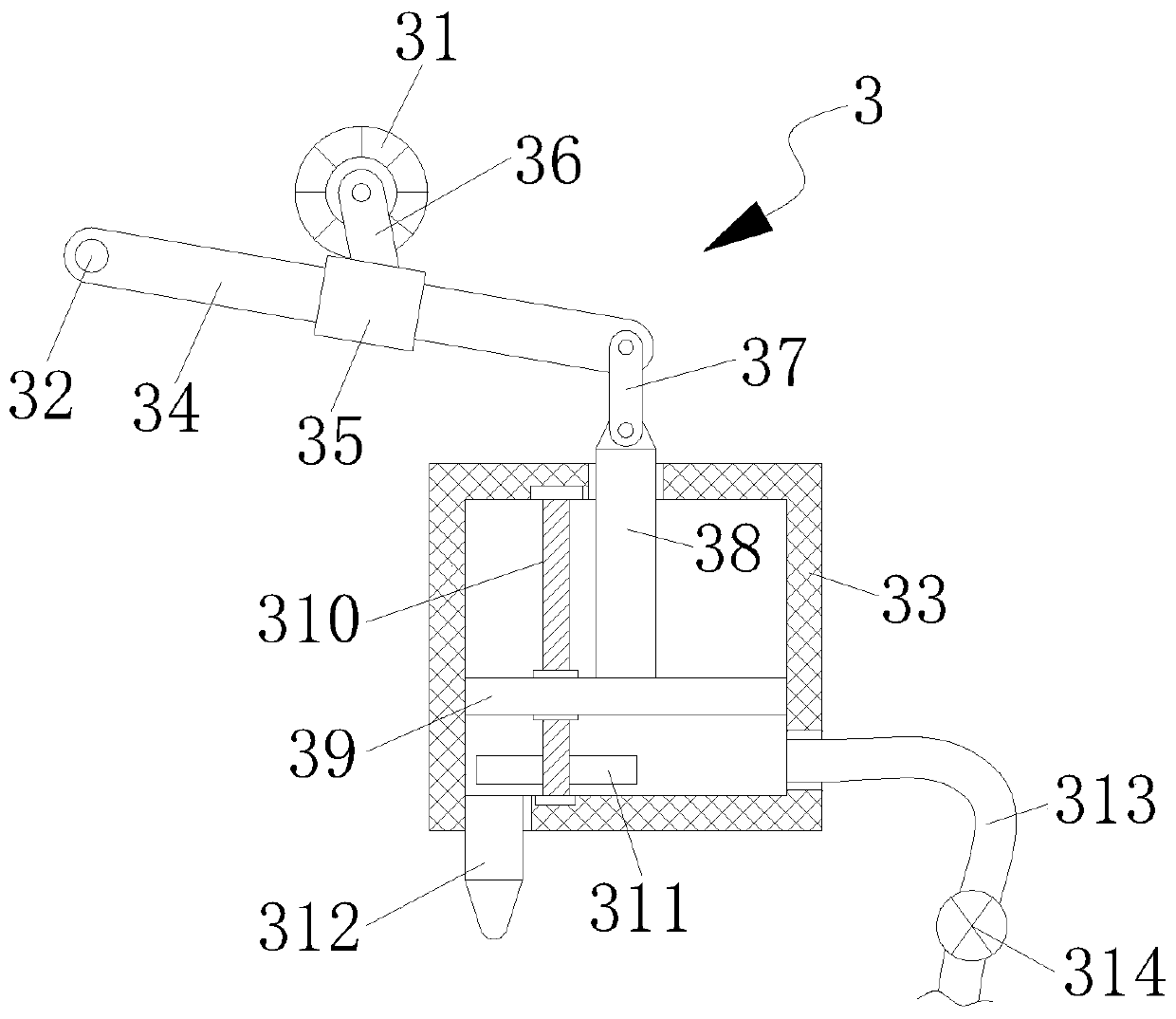

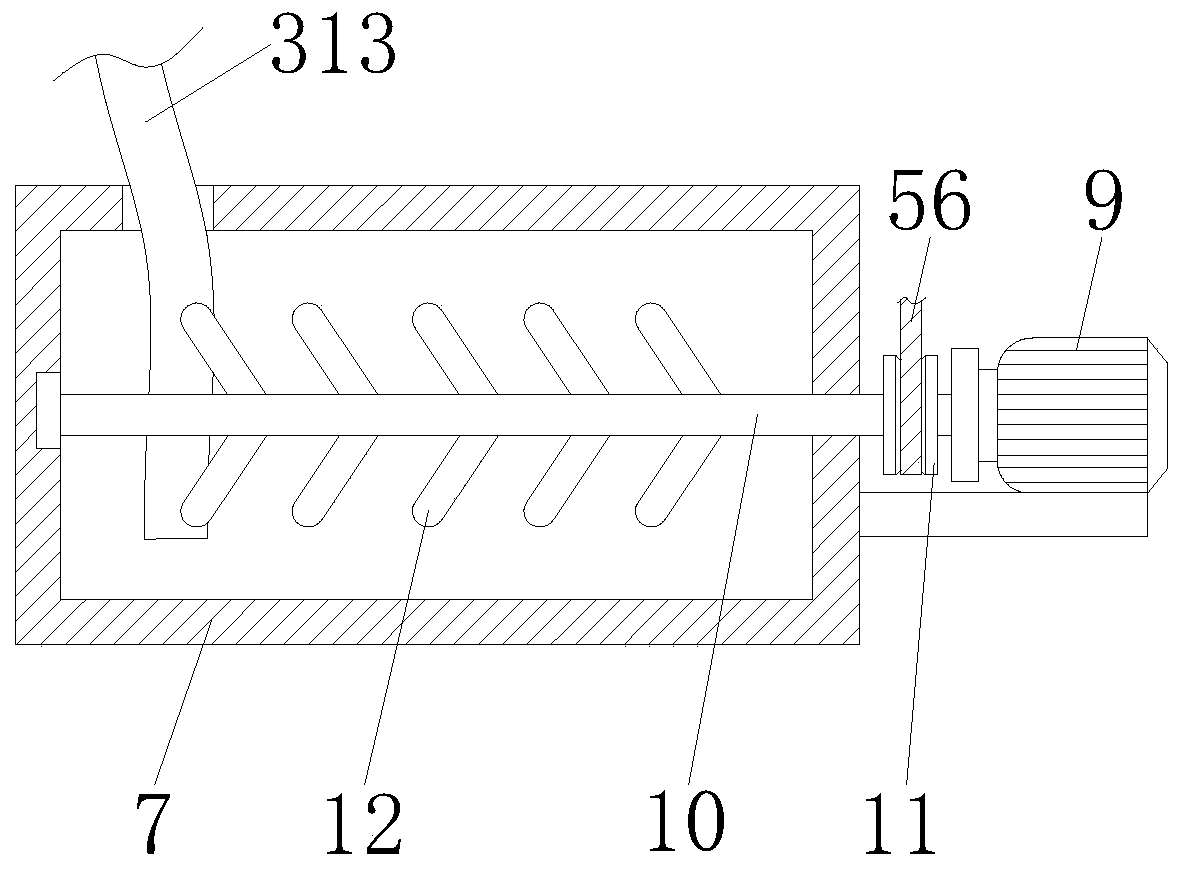

Whole outer surface spraying device for scaffold semi-finished product

InactiveCN110314796AImprove efficiencySave paint resourcesLiquid spraying apparatusWork in processEngineering

The invention relates to the technical field of scaffold spraying, and discloses a whole outer surface spraying device for a scaffold semi-finished product. The device comprises a bottom box, a through opening is formed in the top of the bottom box, a fixed table is fixedly mounted on the top of the bottom box, a spraying mechanism is arranged on the front face of the fixed table, three guide wheels and a conveying mechanism are fixedly mounted on the top of the bottom box, a collecting box and a storage box are fixedly mounted on the inner bottom wall of the bottom box, a guide plate is fixedly mounted between the inner side walls of the collecting box, a through pipe communicates between side faces, close to each other, of the collecting box and the storage box, a first motor is fixedlyconnected to the front face of the storage box through a fixed plate, and a rotating rod is fixedly connected to an output shaft of the first motor. The problems that an existing scaffold spraying device seriously wastes the spraying coating, the resources are wasted, the input cost is high, the coating in spray leakage is scattered in the air, a certain pollution is caused, and manual spraying efficiency is low are solved.

Owner:安徽长青建筑制品有限公司

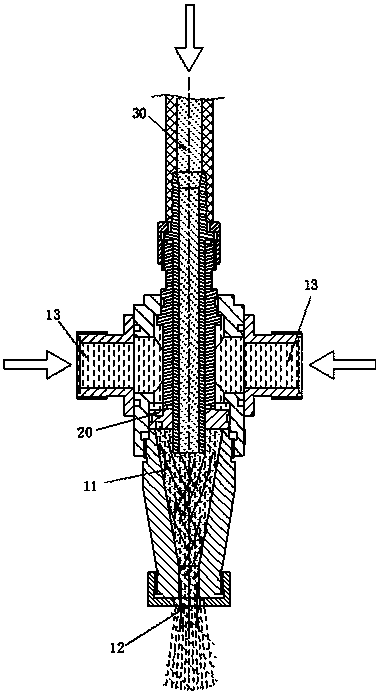

Spiral-flow type spraying structure and spray gun thereof

The invention provides a spiral-flow type spraying structure and a spray gun thereof. The spiral-flow type spraying structure comprises a body; the body is internally provided with high-pressure waterflow channels and a mixing cavity; the high-pressure water channel is provided with a high-pressure water nozzle at the bottom of the mixing cavity; the body is provided with a jet flow outlet communicated with the inside and outside of the mixing cavity at the opposite side of the bottom of the mixing cavity; a plurality of the high-pressure water flow channels are arranged on the same circumference; and the plurality of high-pressure water flow channels are obliquely arranged to force a plurality of high-pressure water flows to be sprayed into the mixing chamber in a spiral shape and form flexible eddy currents in the mixing chamber. The jet flow sprayed by the spiral-flow type spraying structure provided by the invention acts on an object to be hit at a certain tangential angle, and continuously rubs on the surface of a workpiece for a certain distance before leaving the surface of the workpiece, thus increasing the effective working time of the jet flow and having high efficiency;and the jet flow is favorable for forming mist-like jet flow after being sprayed out, and the working effect is more uniform when used for polishing, cleaning or polishing the workpiece.

Owner:纪新刚

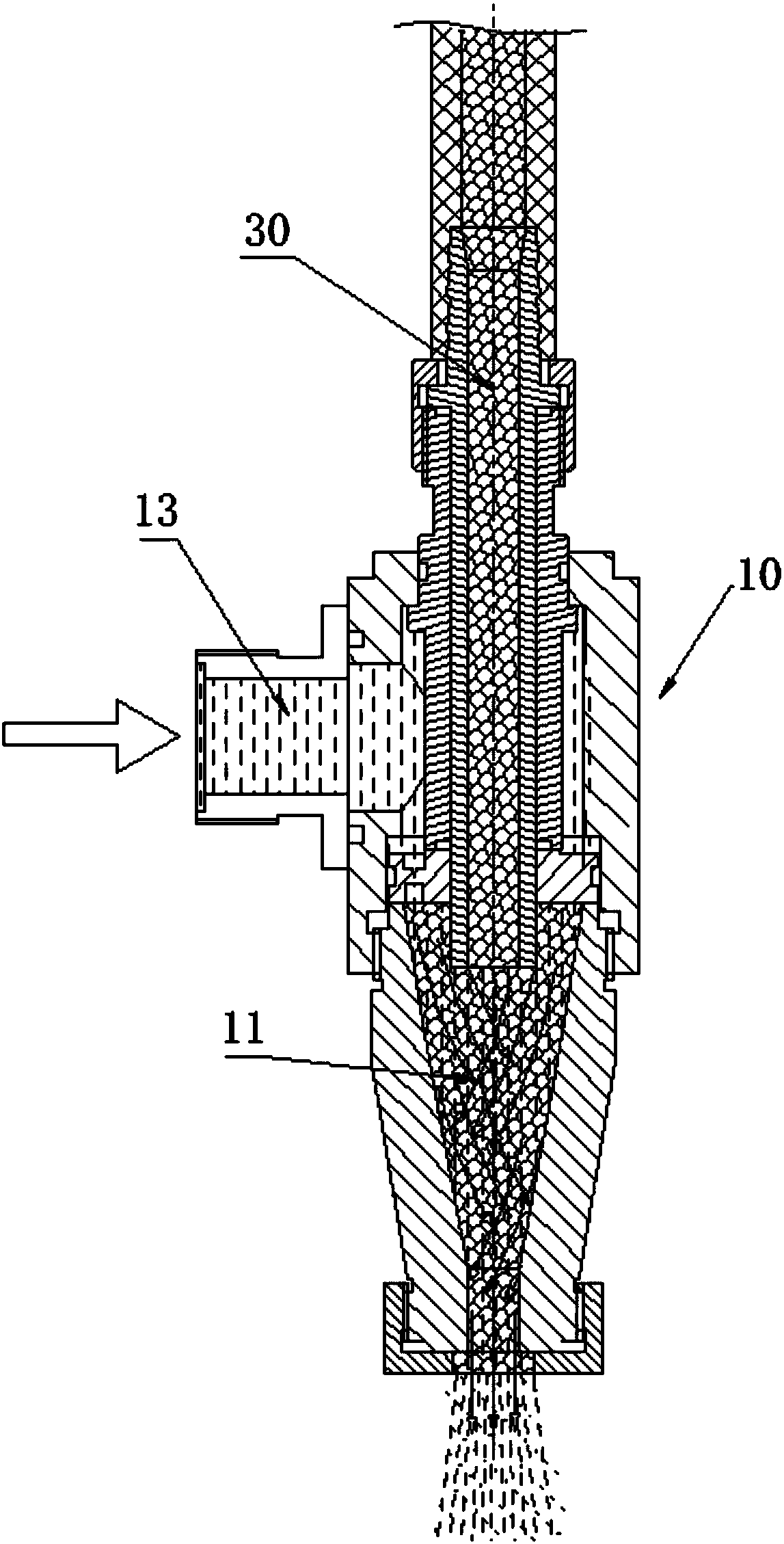

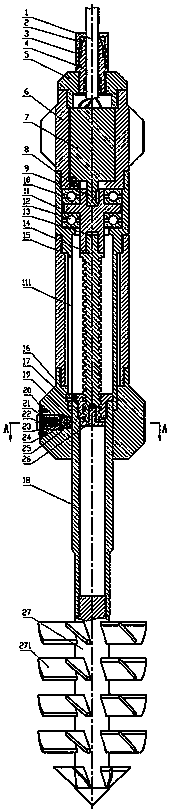

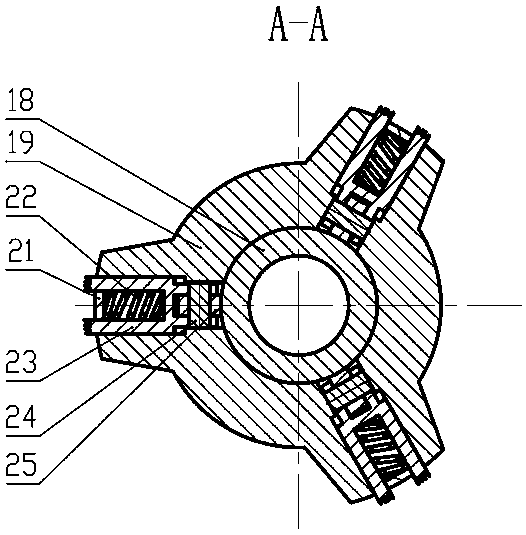

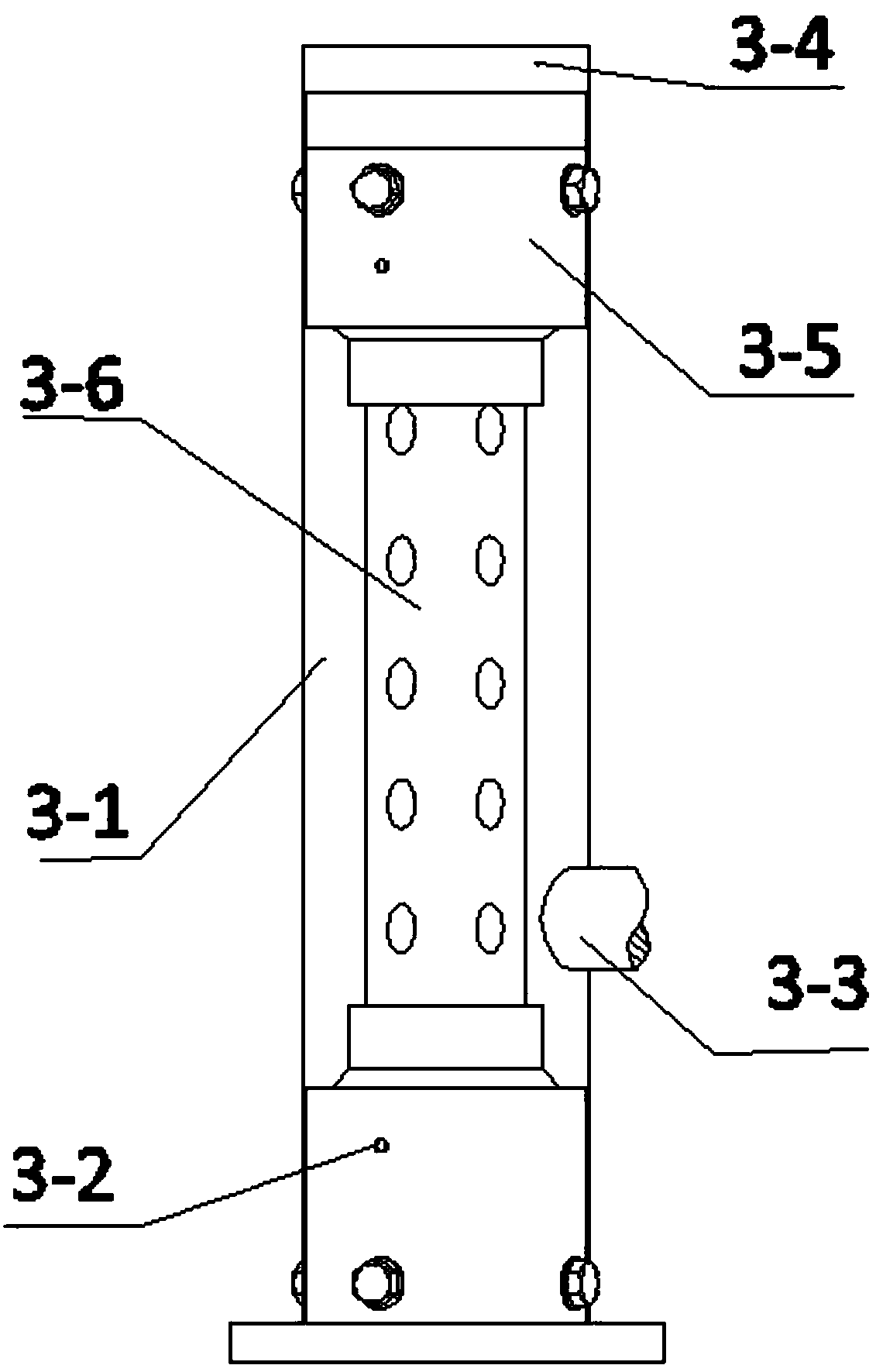

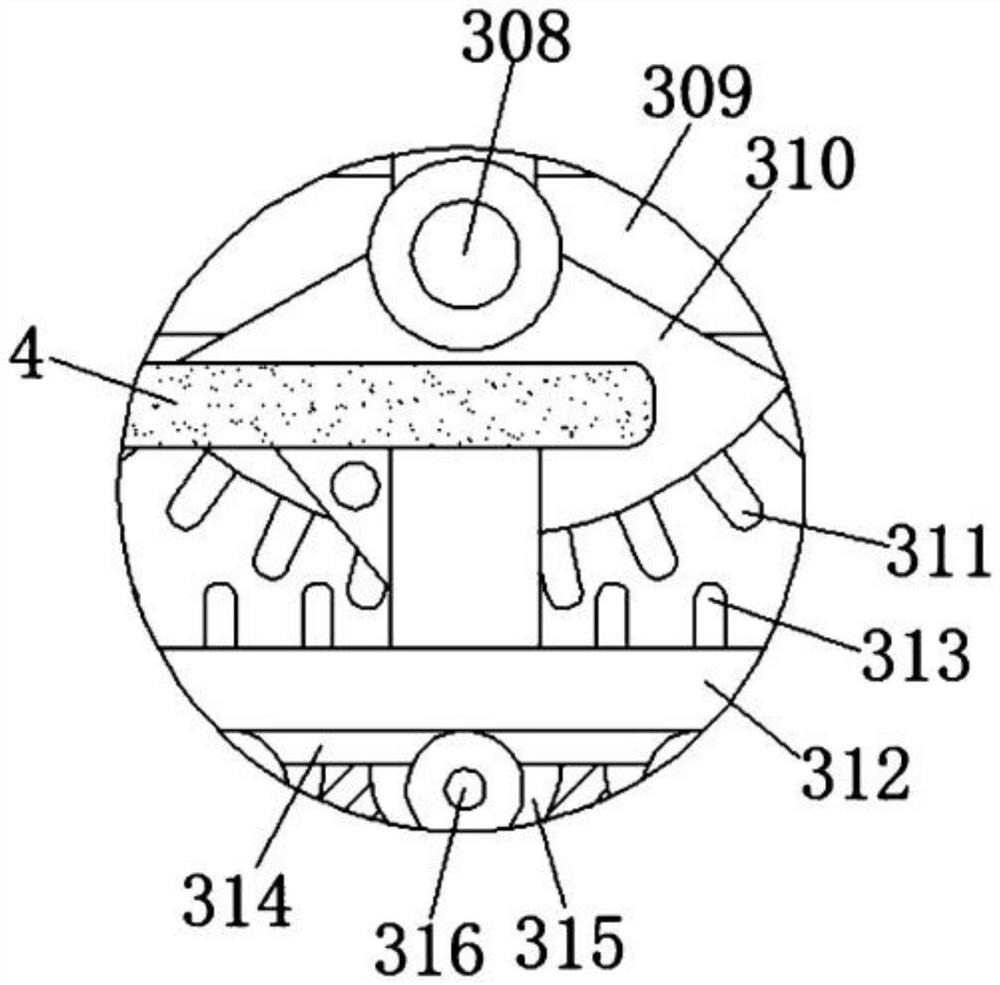

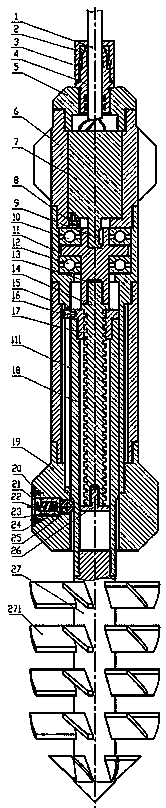

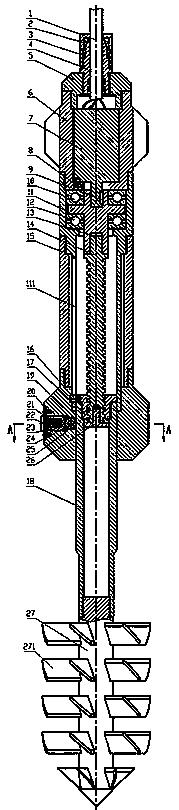

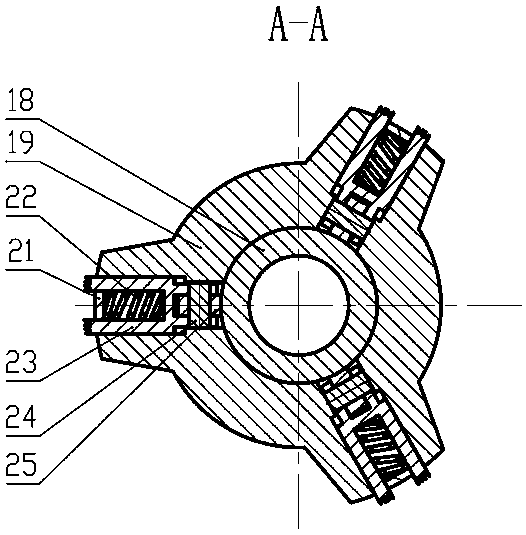

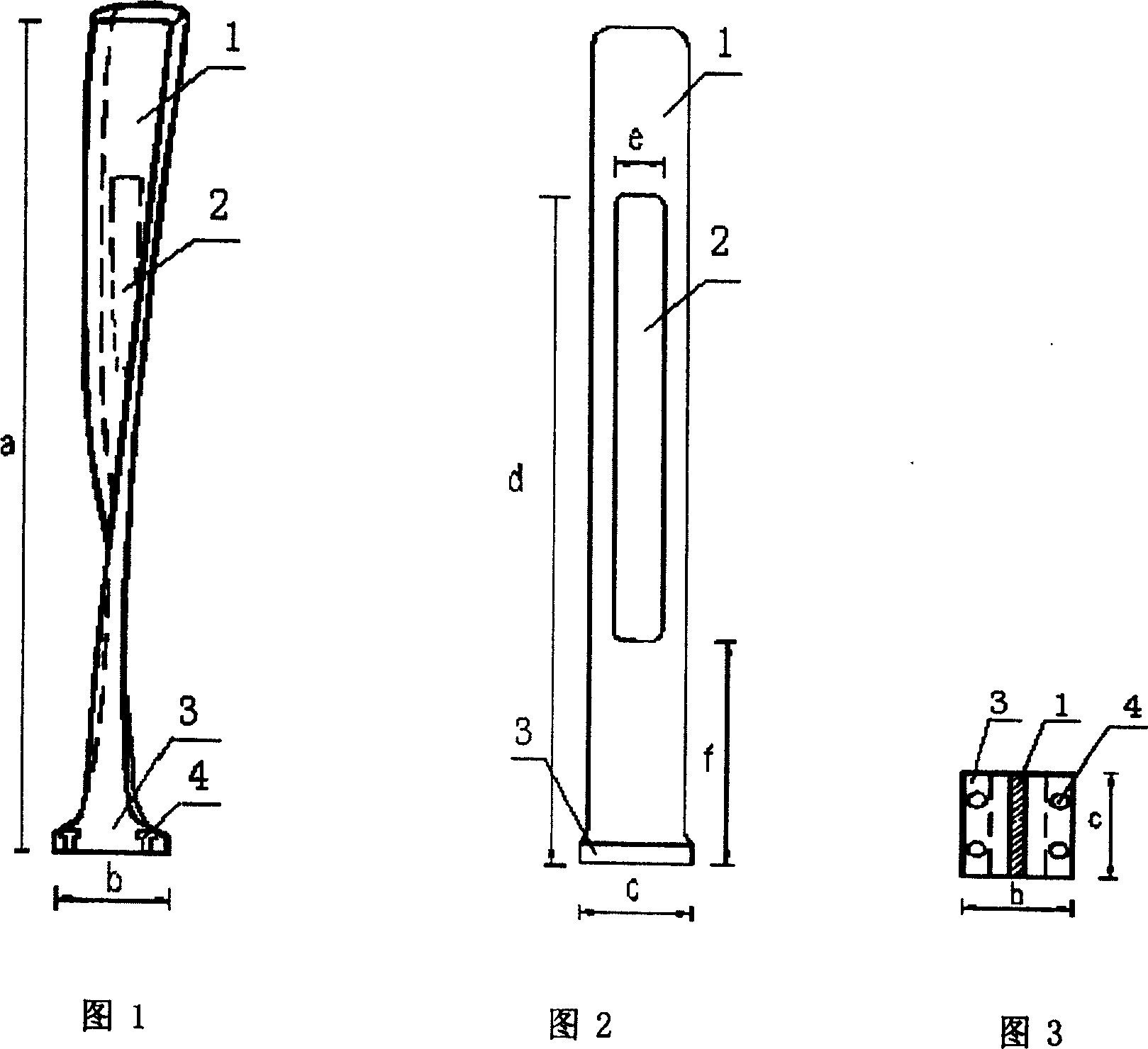

Reciprocating type borehole dredging tool

The invention relates to a reciprocating type borehole dredging tool used in the process of drilling well-completion practice. The reciprocating type borehole dredging tool solves the problem of blocked drilling fluid in a sleeve and being difficult to lower a logging instrument. According to the technical scheme, the upper end of a cable is connected to a ground console, and a wire core of the lower end of the cable communicates with a wire connecting opening of a stepping motor; an output end of the stepping motor and a bearing seat are driven by a key; a drive screw sleeve is installed at the lower portion of the outer circle of a drive screw, and the lower portion of the outer circle of the drive screw sleeve is connected with a screw thread of the upper portion of the inner cavity ofa sliding sleeve; the lower end of the drive screw and an anti-falling-cap thread are tightened; the lower portion of the outer circle of the sliding sleeve is provided with a conical convex platform,and the lower end of the inner cavity of the sliding sleeve is connected with the upper end of the outer circle of stirring heads; and anchor claws are placed in radial step holes on centralizing wings of the outer circle of the anchor, cover plates are fixed with bolts b on the centralizing wings of the outer circle of the anchor, and the cover plates pass through grooves of the outer end facesof the anchor claws. The stepping motor is adopted to drive the reciprocating type borehole dredging tool, the control is simple, the reciprocating movement of the stirring heads is used, drilling fluid can be stirred effectively, the viscosity of the drilling fluid is reduced, and the borehole dredging operation is carried out effectively.

Owner:东营市大学科技园发展有限责任公司

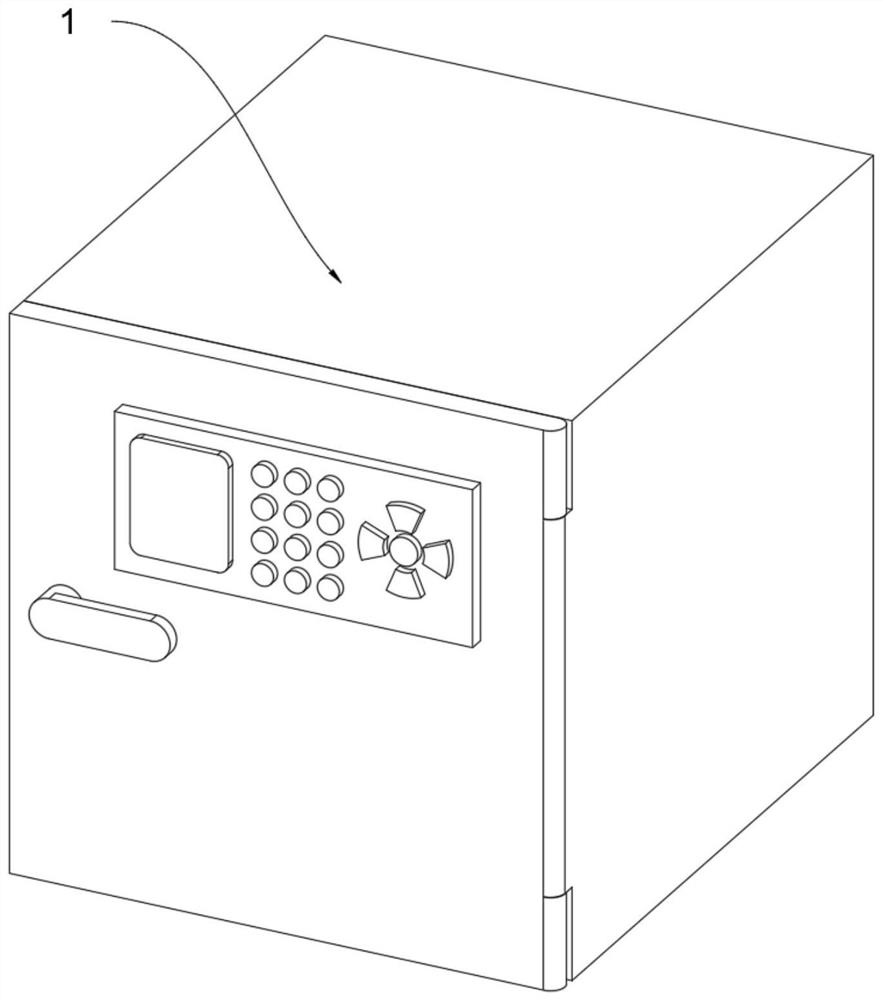

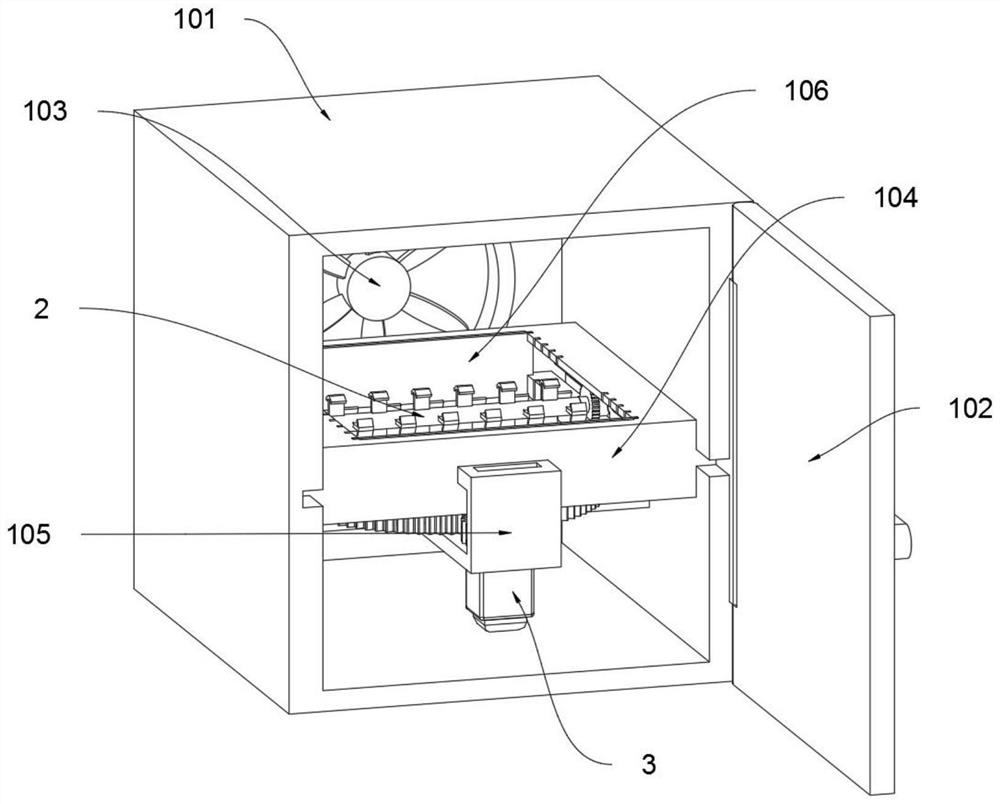

Cleaning device for numerical control milling machine for processing conveying machinery parts

ActiveCN111889777AEffective vibration effectAvoid security impactMilling equipment detailsMaintainance and safety accessoriesNumerical controlProcess engineering

The invention discloses a cleaning device for a numerical control milling machine for processing conveying machinery parts, and relates to the technical field of conveying machinery. The cleaning device for the numerical control milling machine for processing the conveying machinery parts comprises a numerical control milling machine shell, a collecting box is welded and mounted at the bottom of the inner side of the numerical control milling machine shell, a vibrating mechanism is arranged at the top of the collecting box, a cleaning liquid box is welded and mounted on the outer wall of one side of the numerical control milling machine shell, an infusion tube is welded and mounted on the outer surface of the top of the cleaning liquid box, and one end of the infusion tube extends into thecleaning liquid box. According to the cleaning device for the numerical control milling machine for processing the conveying mechanical parts, a certain vibration effect can be effectively carried out when waste materials are collected, the situation that debris remains in the device and cannot be well recycled can be well avoided, the collection rate of the device for collecting the debris can be effectively improved, and the situation that a worker manually recovers the debris, the debris has certain safety influence on the worker can be effectively avoided.

Owner:洛阳米科尼精密机械有限公司

Steel plate electroplating process of Zn-Co-W alloy

The invention belongs to the technical field of surface treatment, and particularly relates to a steel plate electroplating process of a Zn-Co-W alloy. The process comprises the steps of S1, steel plate pretreatment: the surface of a Zn-Co-W alloy steel plate to be electroplated is polished, cleaned and deoiled, and then the steel plate is subjected to anodic electrolytic polishing treatment; S2,steel plate electroplating treatment: the Zn-Co-W alloy steel plate treated in the step S1 is put into an electroplating device as a cathode, and electroplating is conducted by using a direct-currentpower supply; and S3, steel plate post-treatment: after treatment in the step S2 is completed, the electroplated Zn-Co-W alloy steel plate is put into a post-treatment furnace to be subjected to heattreatment, after treatment is completed, the temperature is naturally reduced to the room temperature, and a finished product of the electroplated Zn-Co-W alloy steel plate is obtained. The steel plate electroplating process of the Zn-Co-W alloy is low in cost and easy to operate, and an obtained coating is good in performance and more attractive.

Owner:淮南纳创电力工程有限公司

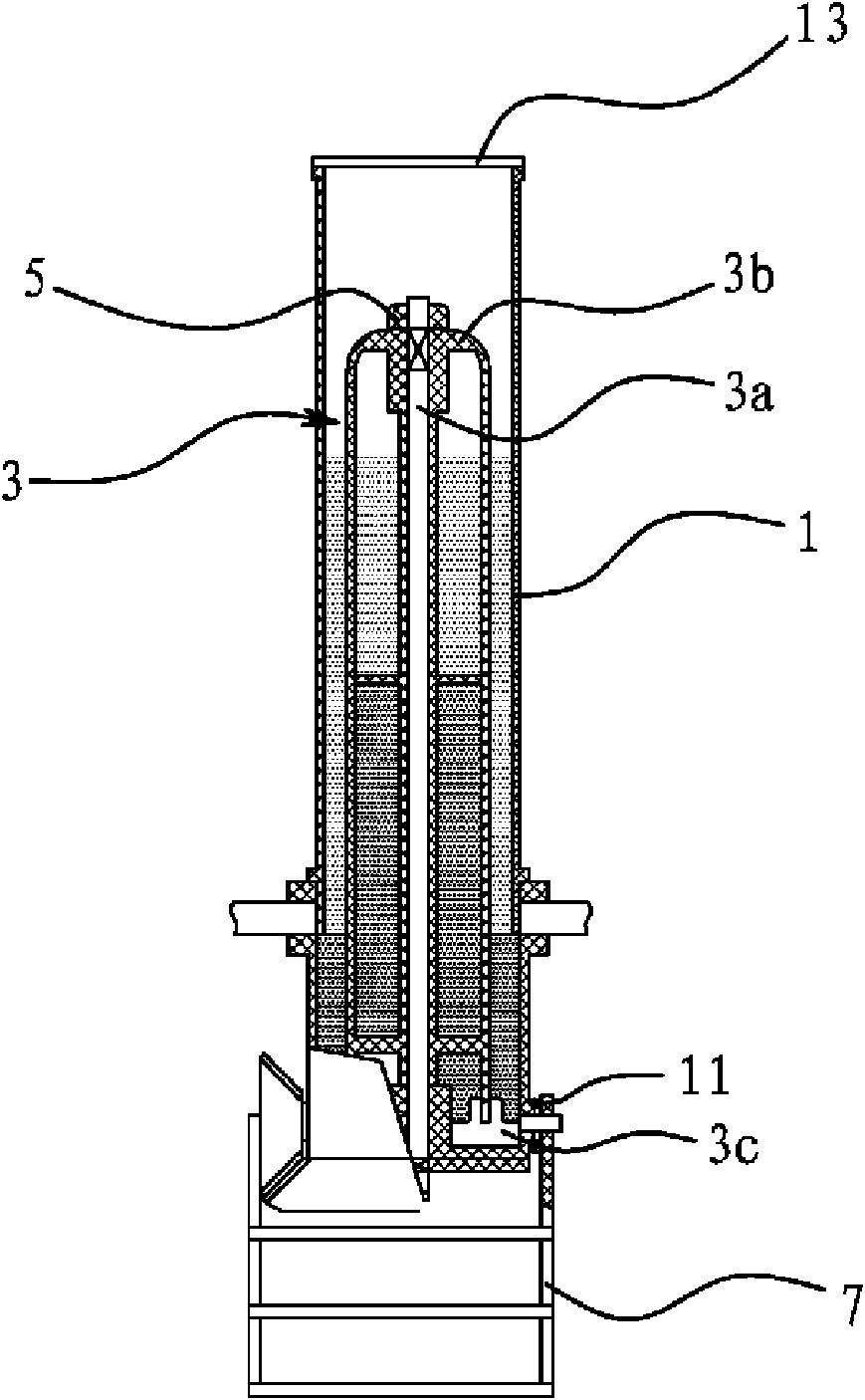

Biomass fuel boiler device and working method thereof

InactiveCN108019740AHigh thermal efficiencyStir quicklyCombustion using catalytic materialChamber safety arrangementSpray nozzleHeating efficiency

Provided is a biomass fuel boiler device and a working method of the biomass fuel boiler device. The device is characterized in that a motor in a power chamber drives a transmission shaft to rotate, and the transmission shaft in a transmission chamber is of a cavity structure with through holes in the surface; an inner cavity of the transmission chamber communicates with the outside through a gasinlet pipe, a fresh air path driven by a mixing motor to rotate is arranged in a mixing chamber, and a mixing shaft is rotationally arranged in an inner cavity of the fresh air path; through holes areformed in the surface of the fresh air path, meanwhile the surface of the fresh air path is fixedly connected with gas disturbance blades, and the upper end and the lower end of the mixing shaft arecorrespondingly and fixedly connected with a gas inlet pipe of a rotary spray head and the upper end of the transmission shaft; and through holes are formed in the lower surface of a converging chamber at the upper end of the mixing chamber, a catalyst spray nozzle is connected to the lower portion of the mixing chamber, and the exterior of the gas inlet pipe of the rotary spray head is connectedto the upper opening end of the converging chamber through a bearing. The method comprises the steps that the rotary spray head is controlled to rotate, or meanwhile the gas disturbance blades are controlled to rotate, and a catalyst is introduced. The device and method are good in disturbance effect, and the heating efficiency of a boiler can be improved.

Owner:XUZHOU INSTITUTE OF TECHNOLOGY

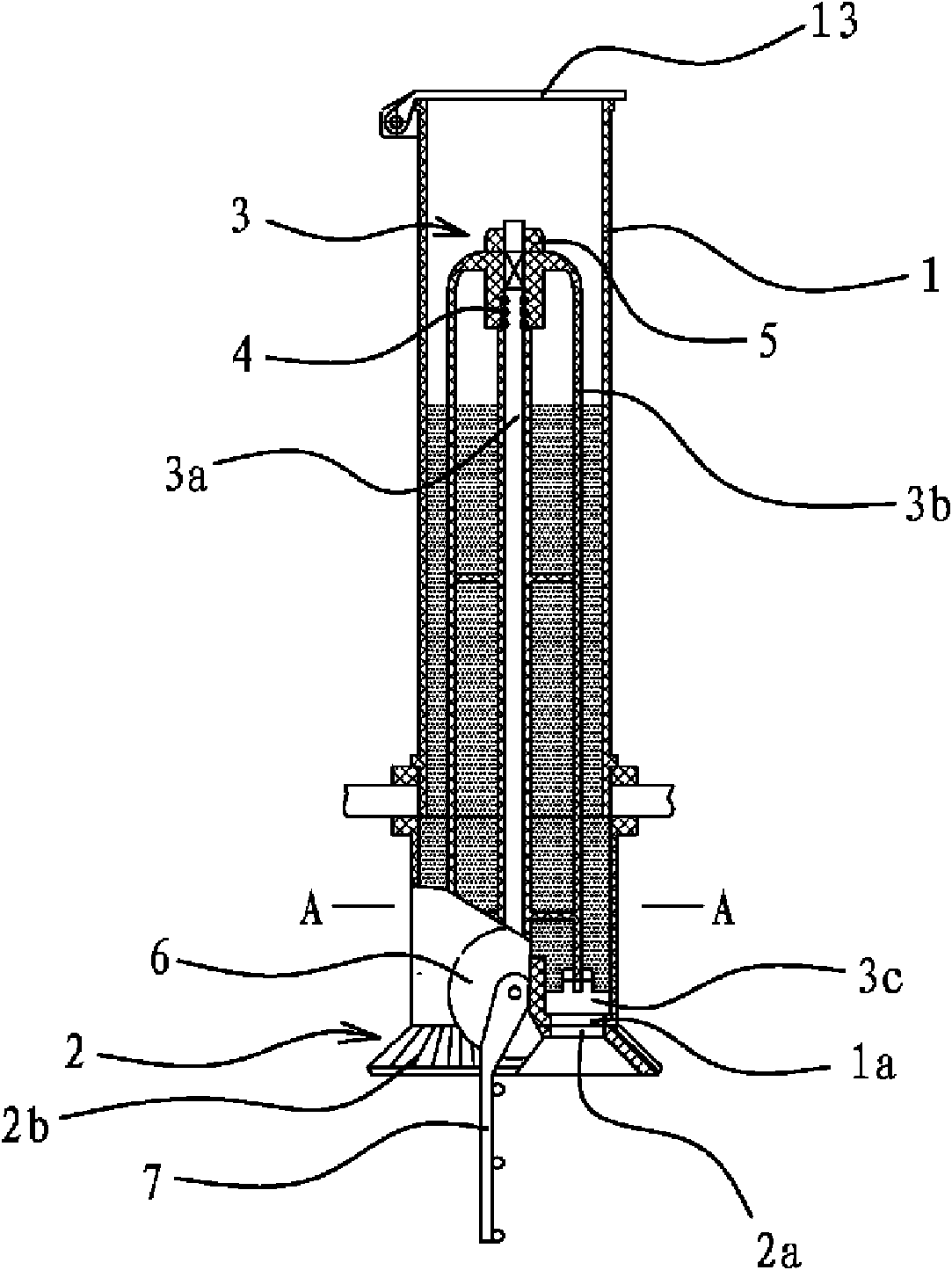

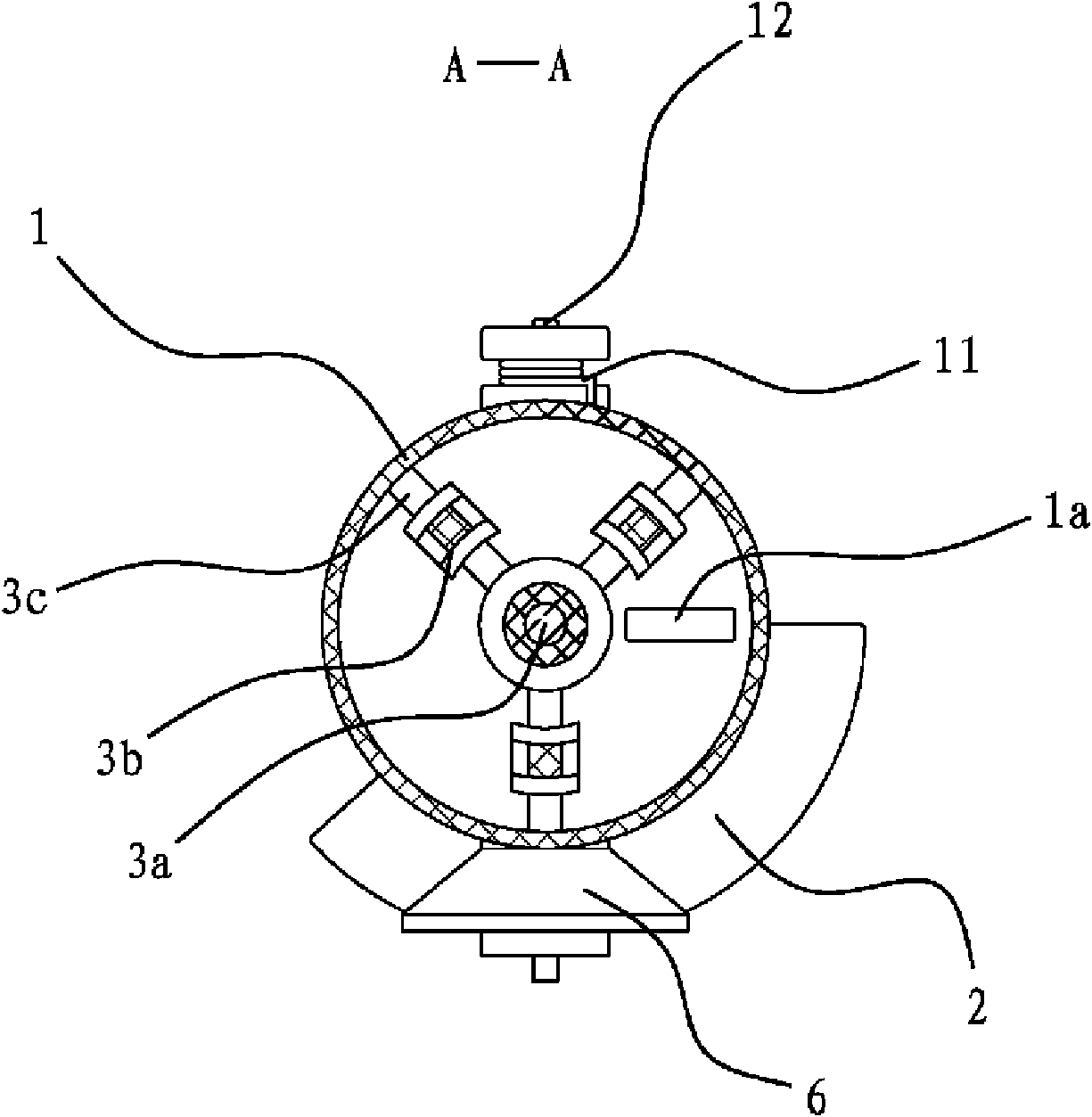

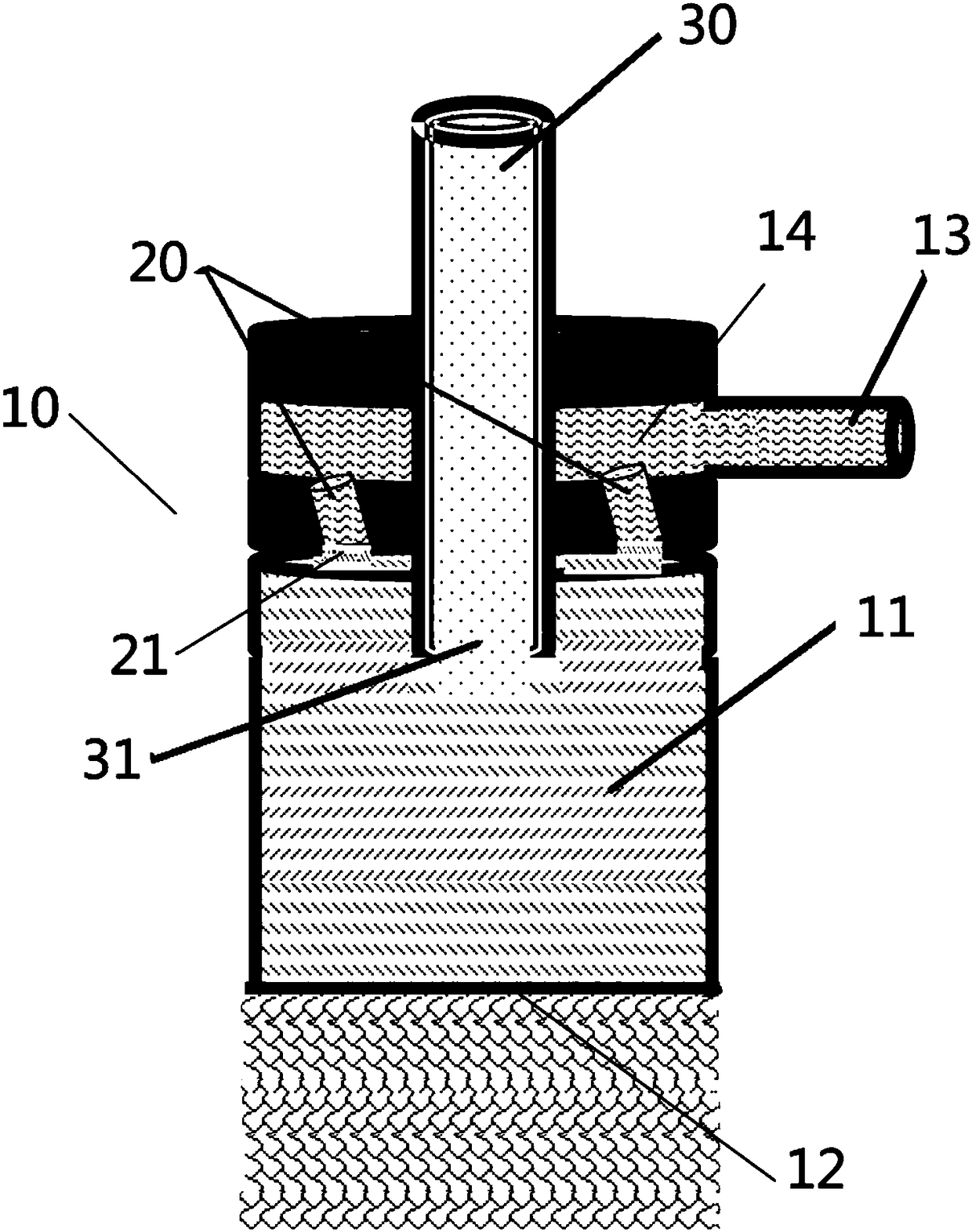

Automatic residual feed and manure extracting device of aquaculture pond

InactiveCN105794714AImprove collection efficiencyEffective agitationPisciculture and aquariaWater qualitySludge

The invention discloses an automatic residual feed and manure extracting device of an aquaculture pond. The automatic residual feed and manure extracting device comprises a sludge discharge part, a back washing and flushing part, a mud pump bin and a sludge absorbing part at the bottom layer, wherein the sludge discharge part is positioned at the top end of the device, and is used for connecting a water draining hole of the mud pump with an outer sludge discharge tube; the back washing and flushing part comprises cleaning tubes which are positioned at the two sides of the sludge discharge part, and cleaning ring tubes at inner and outer layers for flushing and stirring sludge on the bottom of the pond; the mud pump bin is positioned below the sludge discharge part, and is used for mounting and fixing the mud pump; the bottom-layer sludge absorbing part is positioned on the bottom of the device, comprises a plurality of sludge absorbing tubes which are arranged in a radial manner; and a single side of each sludge absorbing tube is provided with a plurality of sludge absorbing holes. According to the automatic residual feed and manure extracting device, open-and-shut control on a sewage discharge path and open-and-shut control on a cleaning water path are carried out through a controller; when the water of the outer sludge discharge tube is clear and a sludge discharge solenoid is closed, a flushing solenoid valve is opened, and is automatically closed after flushing is carried out for a certain time; inclined flushing holes of the clearing ring tubes at inner and outer layers can effectively stir the sludge on the bottom layer, so that the bottom layer waste collecting efficiency is improved.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

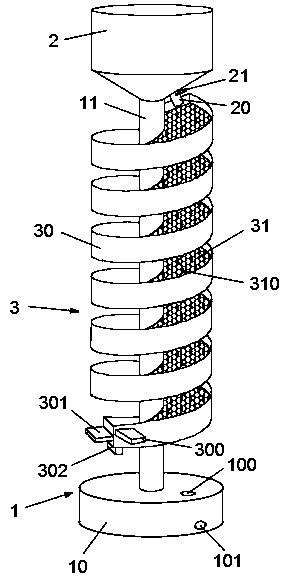

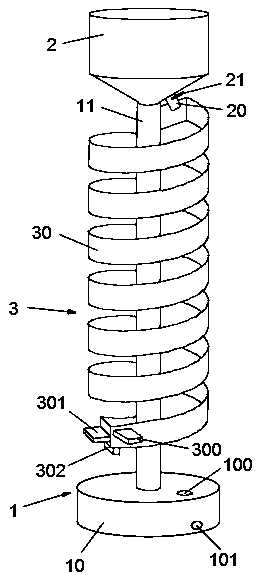

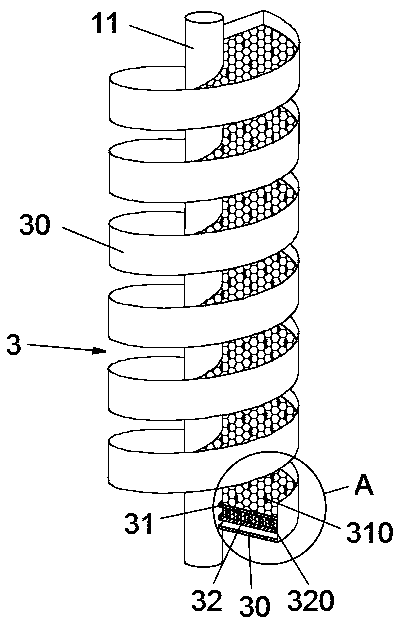

Soybean sieving machine

PendingCN109433572AIncrease sieving lengthSmall footprintSievingScreeningEngineeringEnergy consumption

The invention relates to a soybean sieving machine which comprises a rack, a blanking cabin and a sieving main body, wherein the rack comprises a base and a vertical rod fixed at the upper end of thebase; the blanking cabin is fixed at the upper end of the vertical rod; the sieving main body comprises a spiral sieving groove fixed outside the vertical rod longitudinally; a first-level screen meshand a second-level screen mesh are arranged in the spiral sieving groove at an interval and divide the spiral sieving groove into three layers from top to bottom; the pore of the first-level screen mesh is greater than that of the second-level screen mesh; a feeding pipe is arranged at the lower end of the blanking cabin; a large impurity discharging pipe is fixed at the upper-layer position of the spiral sieving groove at the bottom in a penetrating manner; a soybean discharging pipe is fixed at the middle-layer position of the spiral sieving groove at the bottom in a penetrating manner; anda small impurity discharging pipe is fixed at the lower-layer position of the spiral sieving groove at the bottom in a penetrating manner. The soybean sieving machine adopts the spiral sieving manner, is low in noise, energy consumption and sieving cost, small in occupied area and high in sieving effect.

Owner:罗源县圆梦农林专业合作社

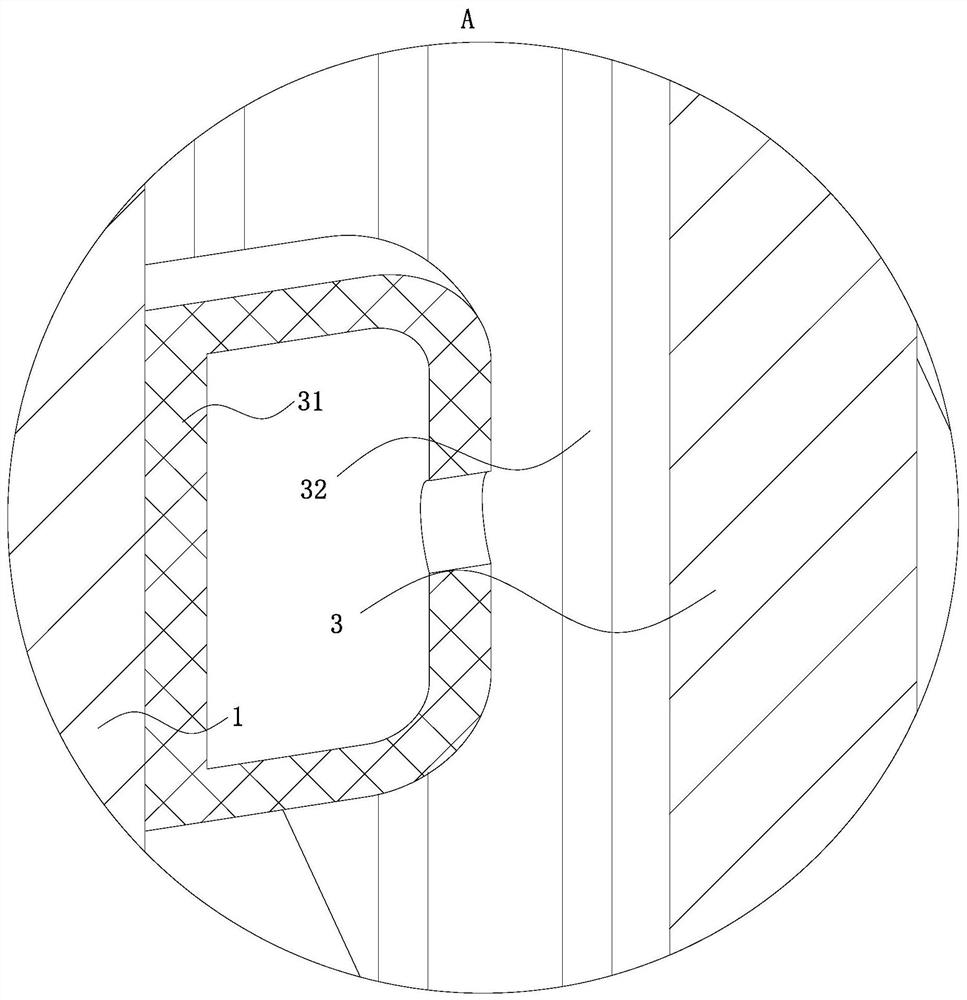

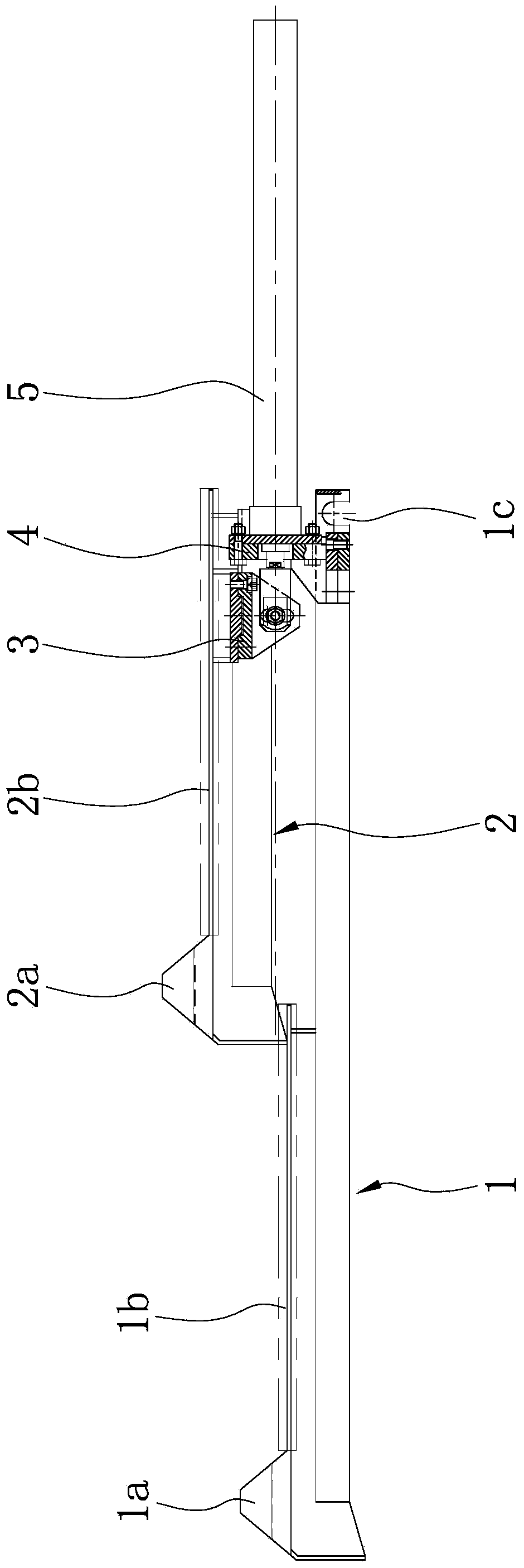

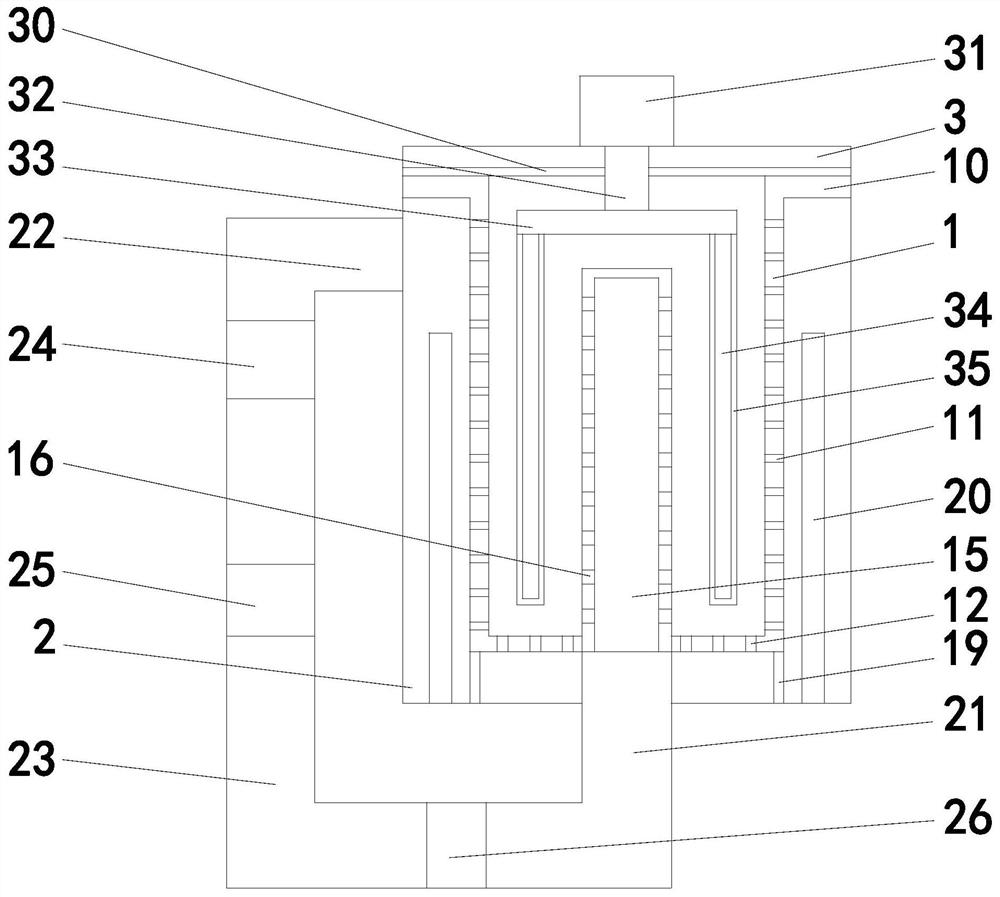

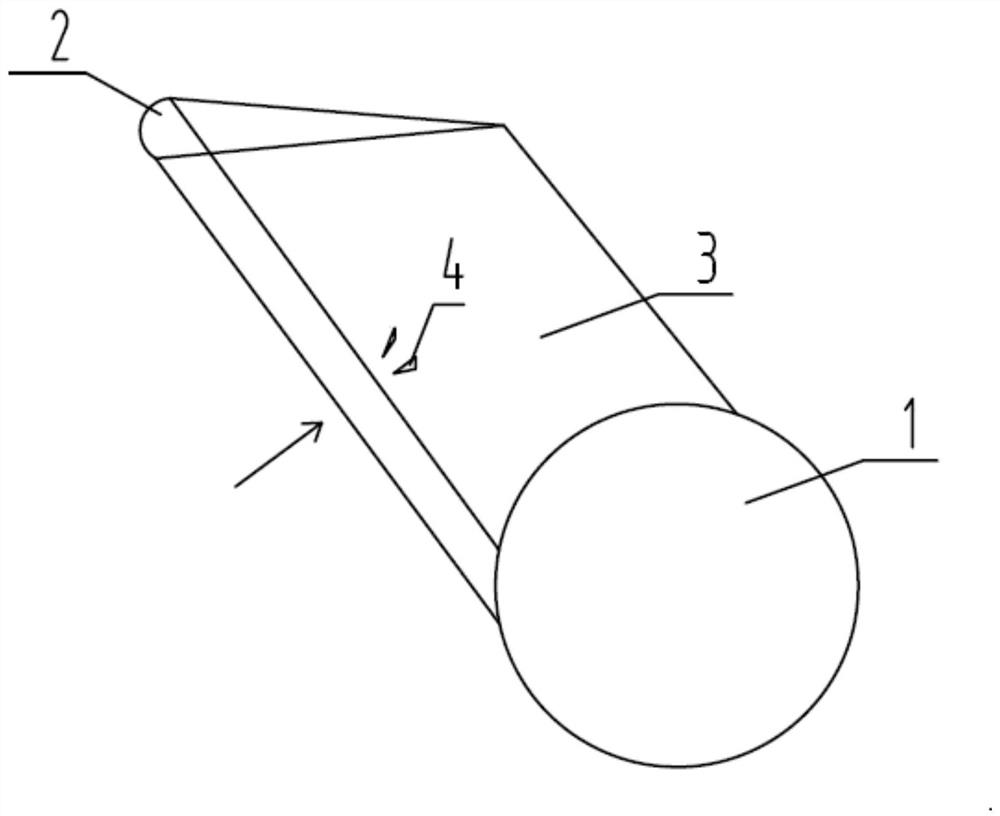

Grate set for garbage incinerator

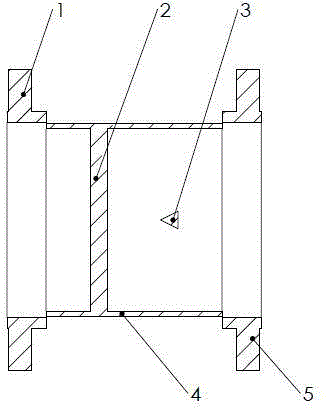

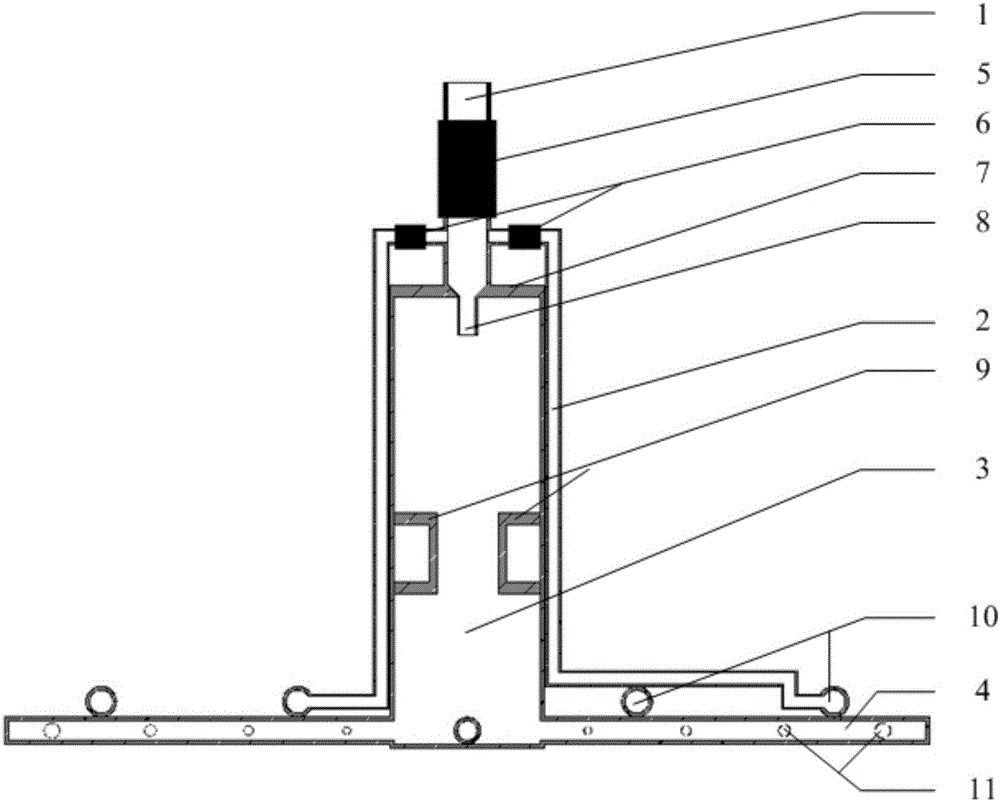

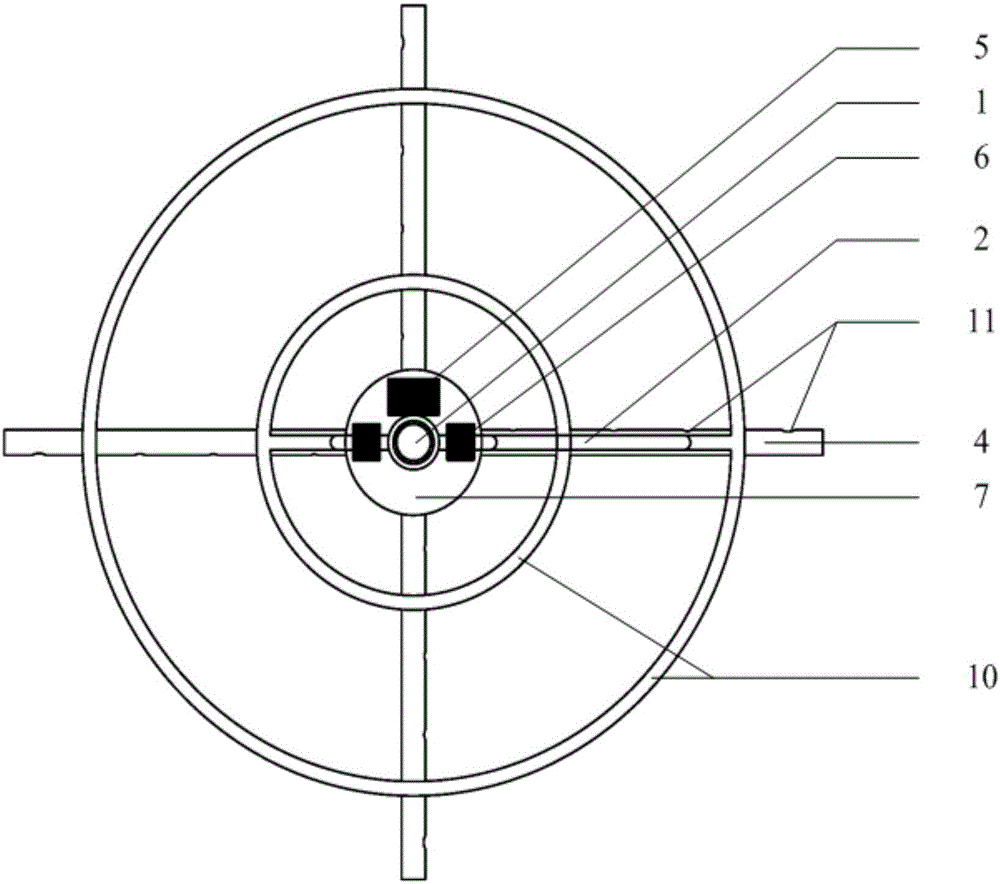

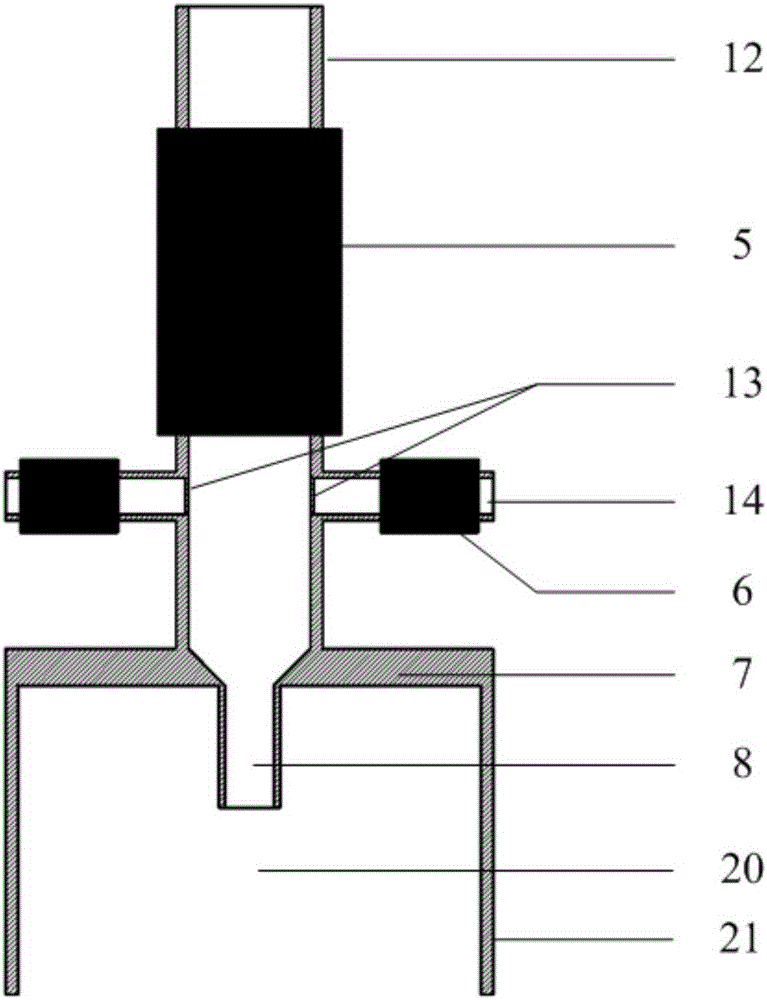

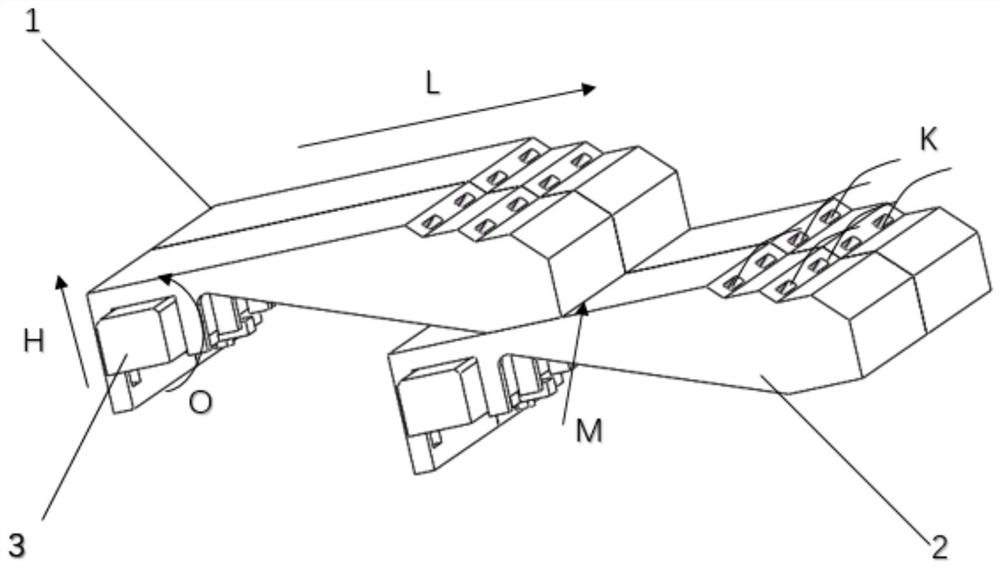

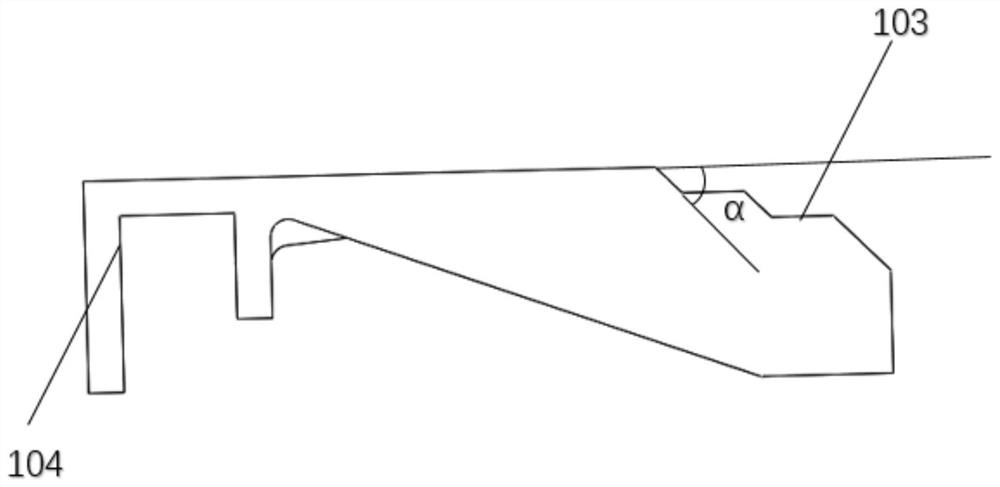

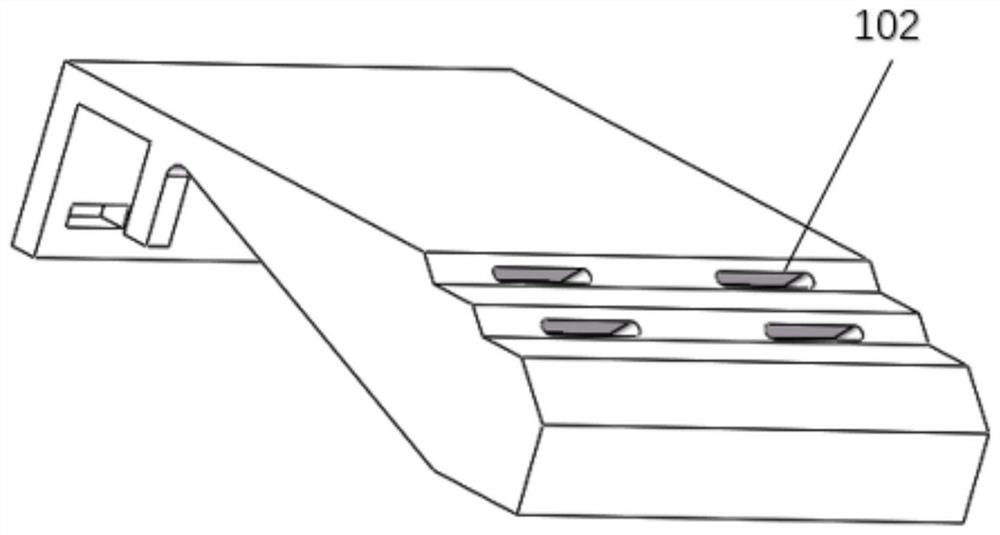

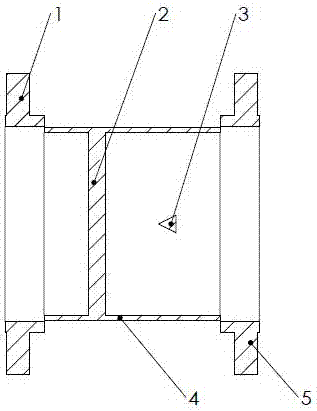

The invention discloses a grate set for a garbage incinerator. The upper end of the front of a fixed grate segment (1) is provided with a first back movement plane (1b), the front end of the first back movement plane (1b) protrudes upwards to form a first head boss (1a), the upper end of a movable grate segment (2) is provided with a second back movement plane (2b), the top of the front end of the second back movement plane (2b) protrudes upwards to form a second head boss (2a), a driving support (3) is fixed at the bottom of the rear end of the movable grate segment (2), a positioning seat (4) in the rear of the driving support (3) is fixed at the rear end of the fixed grate segment (1), a driving device (5) is mounted on the positioning seat (4), and the front end of the driving device (5) is connected with the driving support (3). The grate set has the advantages that since the fixed grate segment and the movable grate segment are modularized, on one hand, assembly process is simplified, and assembly difficulty is lowered; on the other hand, labor intensity of workers is reduced, and assembly efficiency is improved greatly.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

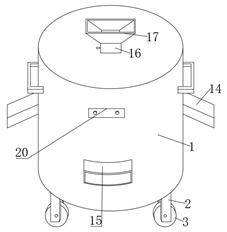

Clam cleaning device and method based on oscillation force and stirring centrifugal force linkage

Owner:杨小洲

Ice crushing device and refrigerator

ActiveCN109695982APrevent ice cubes from stickingReliable useDomestic cooling apparatusLighting and heating apparatusIce storageEngineering

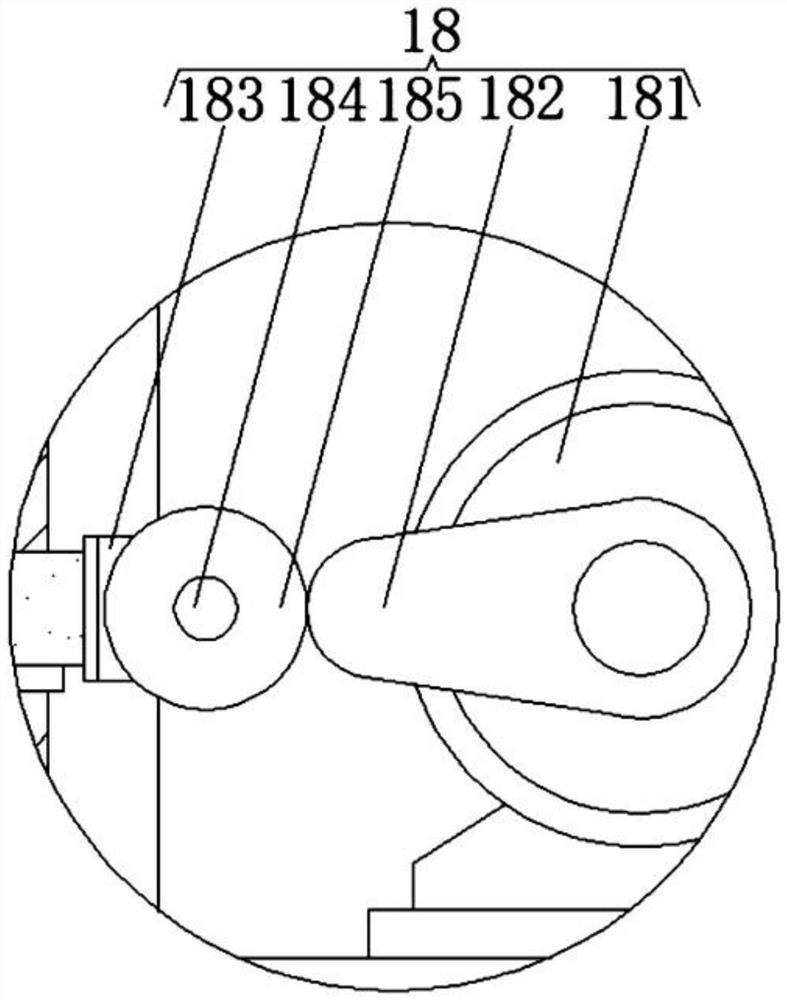

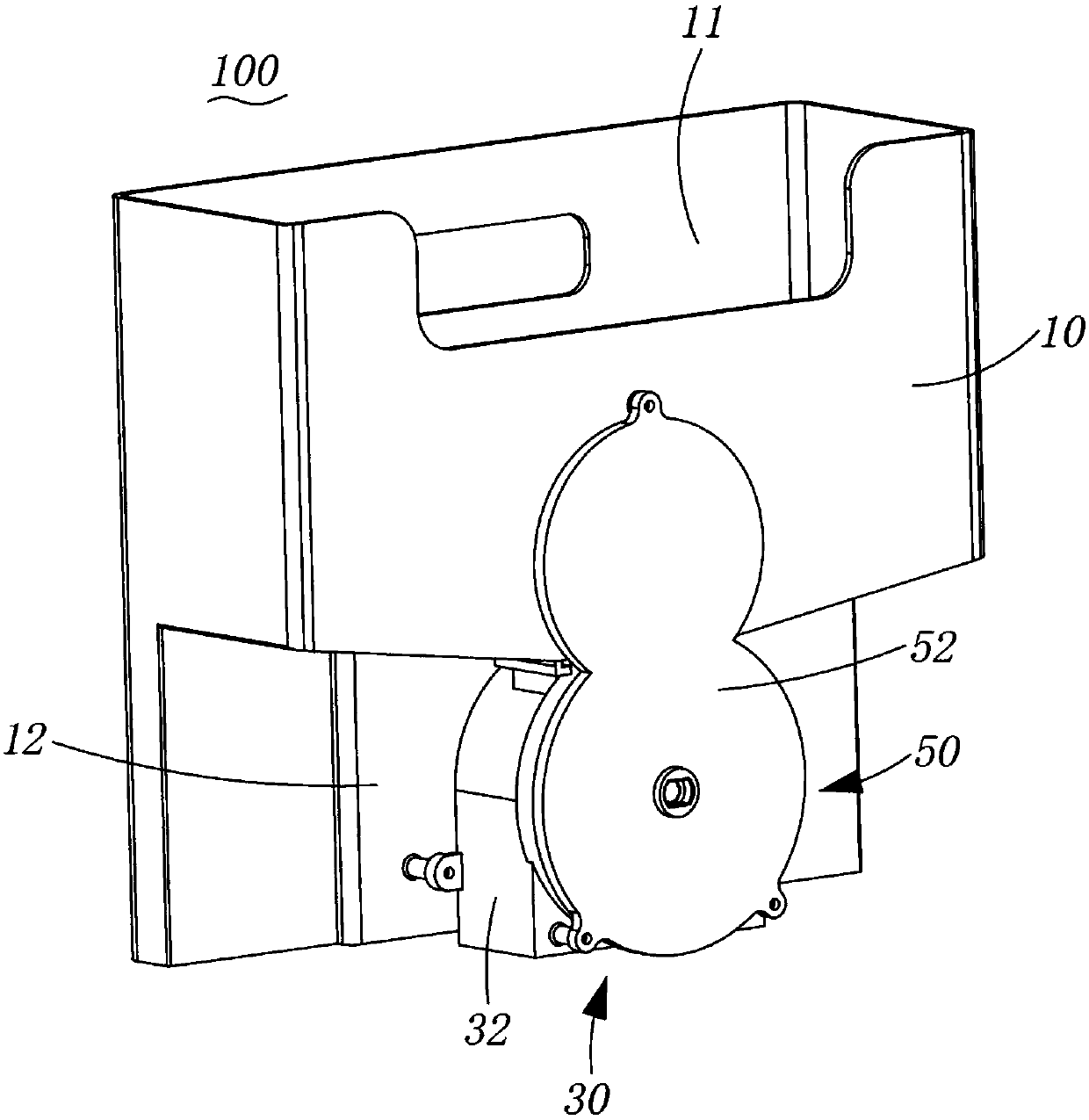

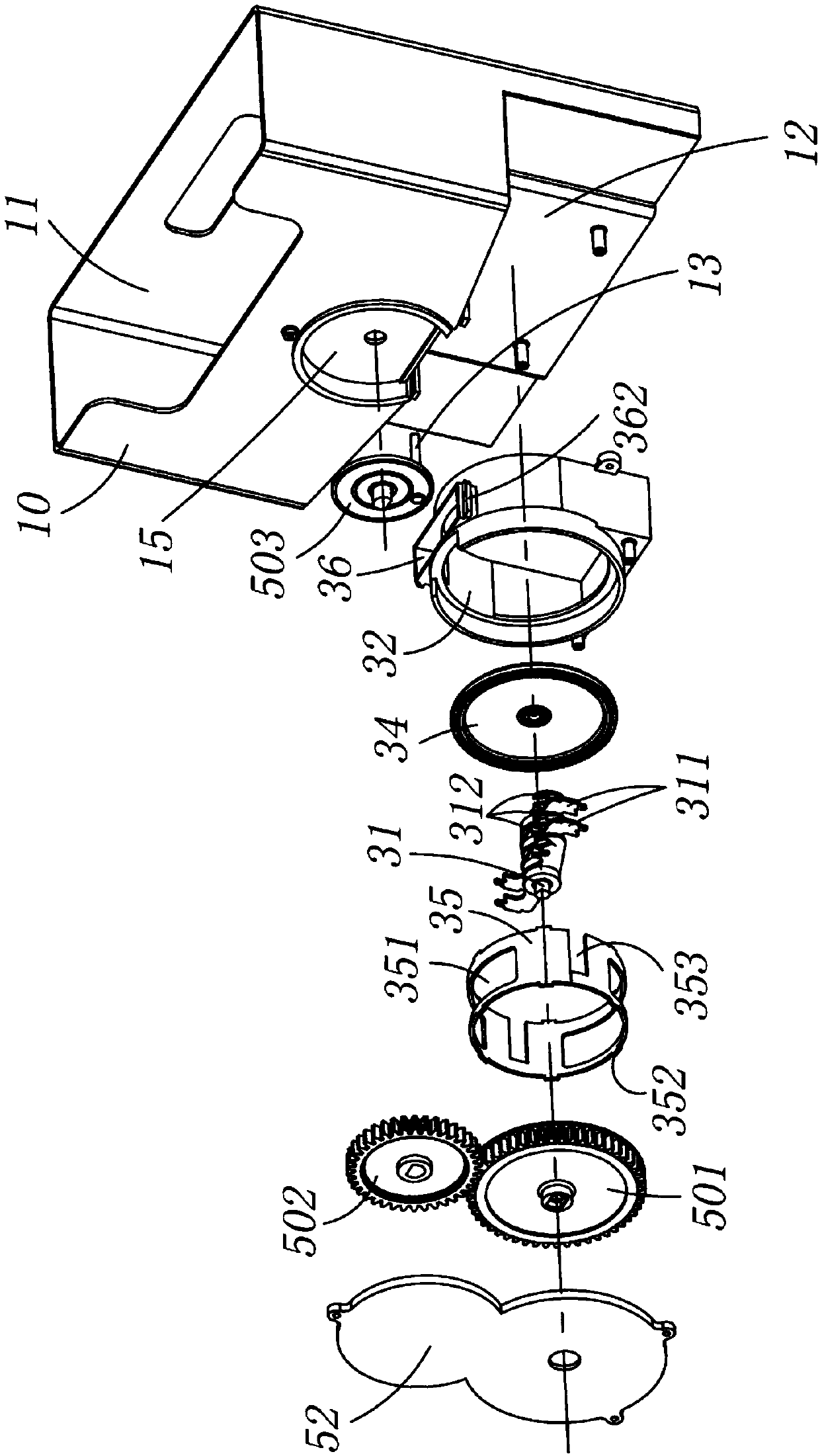

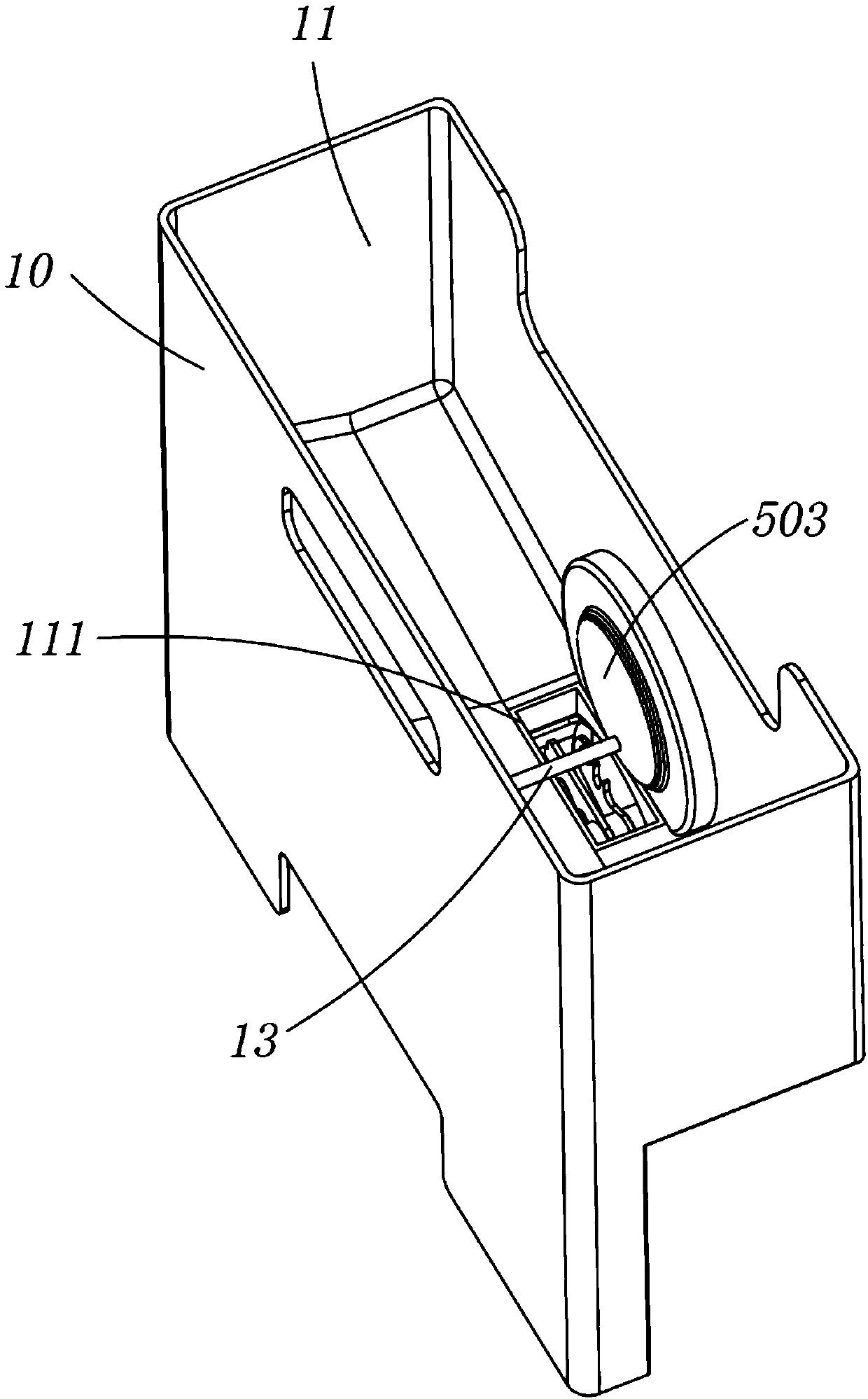

The invention discloses an ice crushing device and a refrigerator. The ice crushing device comprises an ice storage box, an ice crushing module, and a driving mechanism, wherein the ice crushing module is arranged at the bottom of the ice storage box, and comprises an ice skate blade shaft, a plurality of movable ice skate blades and a plurality of fixed ice skate blades, wherein the movable ice skate blades and the fixed ice skate blades are mounted on the ice skate blade shaft, the ice crushing module communicated with the ice storage box through an ice outlet at the bottom of the ice storage box; the driving mechanism is arranged on one side of the ice crushing module and is used for driving the movable ice skate blades to rotate relative to the fixed ice skate blade at least; a drivingstructure comprises a motor, and a first transmission unit and a second transmission unit, wherein the first transmission unit and the second transmission unit are driven by the motor, an ice stirring rod is arranged in the ice storage box, the first transmission unit drives the movable ice skate blades to rotate relative to the fixed ice skate blades, and the second transmission unit drives theice stirring rod to rotate, the rotation axis of the first transmission unit is parallel to the rotation axis of the second transmission unit. The ice crushing device and the refrigerator are more reliable in use.

Owner:HAIER SMART HOME CO LTD

Fire grate block structure of garbage incinerator and fixed connection mode of fire grate block structure

PendingCN112594707AEfficient flipEffective agitationIncinerator apparatusEnvironmental engineeringMechanical engineering

The invention belongs to the field of garbage incineration treatment, and relates to a fire grate block structure of a garbage incinerator and a fixed connection mode of the fire grate block structure. The front portion of a fire grate block is of a step fall structure, a plurality of vent holes are formed in steps, the rear end of the fire grate block is of a quasi-rectangular clamping groove structure, and two limiting holes are symmetrically formed in the rear portion of the fire grate block. The fire grate block is clamped to a fire grate beam through a quasi-rectangular clamping groove, and then the fire grate block is connected with the fire grate beam through a fixed connecting device. Garbage materials are fully stirred through movement of the fire grate block and the structure ofthe fire grate block, so that the garbage materials are better mixed with primary air; and by means of the fixed connection mode, the fire grate block is not prone to being screwed up or floating up,and meanwhile dismounting and overhauling are convenient.

Owner:SHANGHAI SUS ENVIRONMENT

Water-saving irrigation spray head

ActiveCN112657690AImprove liquidityEffective agitationClimate change adaptationSpray nozzlesWater savingSpray nozzle

The invention discloses water-saving irrigation spray head. The water-saving irrigation spray head comprises a micro-irrigation spray nozzle, wherein an annular sliding groove is formed in the top of the micro-irrigation spray nozzle, and a filter cylinder is movably connected to the annular sliding groove in a clamped mode; the top of the filter cylinder is connected with a water inlet pipe through a rotary joint, a filter screen is fixed to the bottom of the filter cylinder, and a plurality of water outlet pipes are annularly distributed on the side wall of the filter cylinder; and the water outlet pipes are tangent to the outer wall of the filter cylinder, and the lower edges of water outlets of the water outlet pipes are connected with magnetic baffles through torsional springs. According to the water-saving irrigation spray head, the defects in the prior art can be overcome, and the possibility of blockage of the water-saving spray head is reduced.

Owner:HEBEI ZETIAN WATER SAVING TECH CO LTD

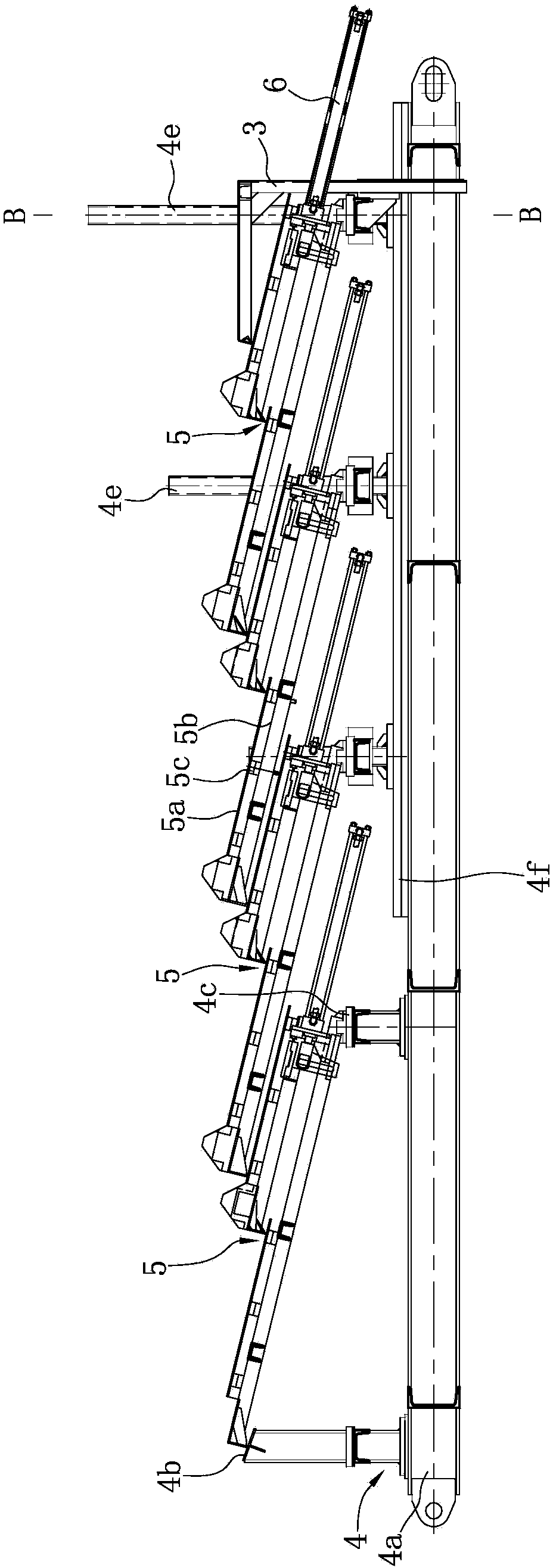

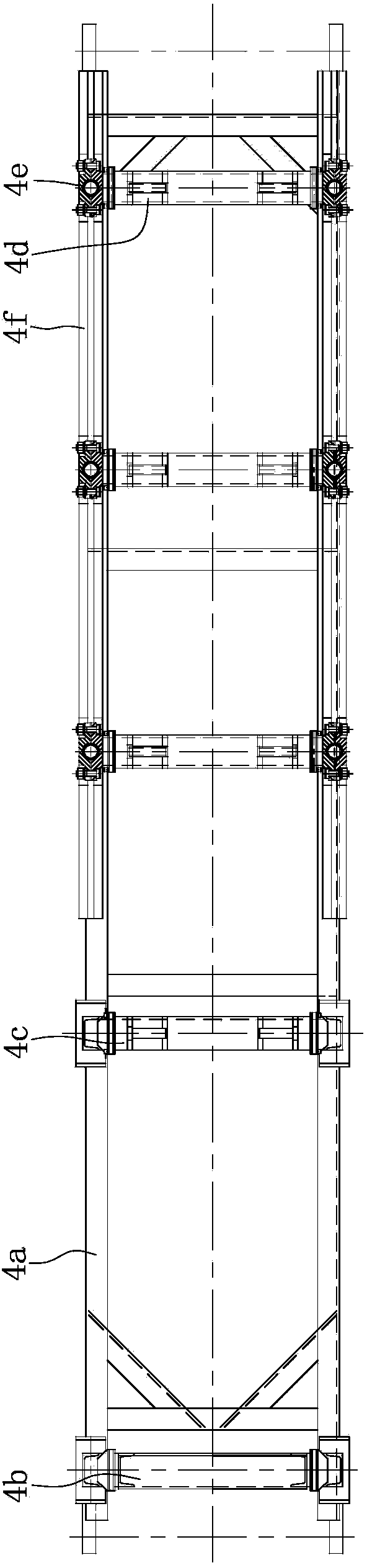

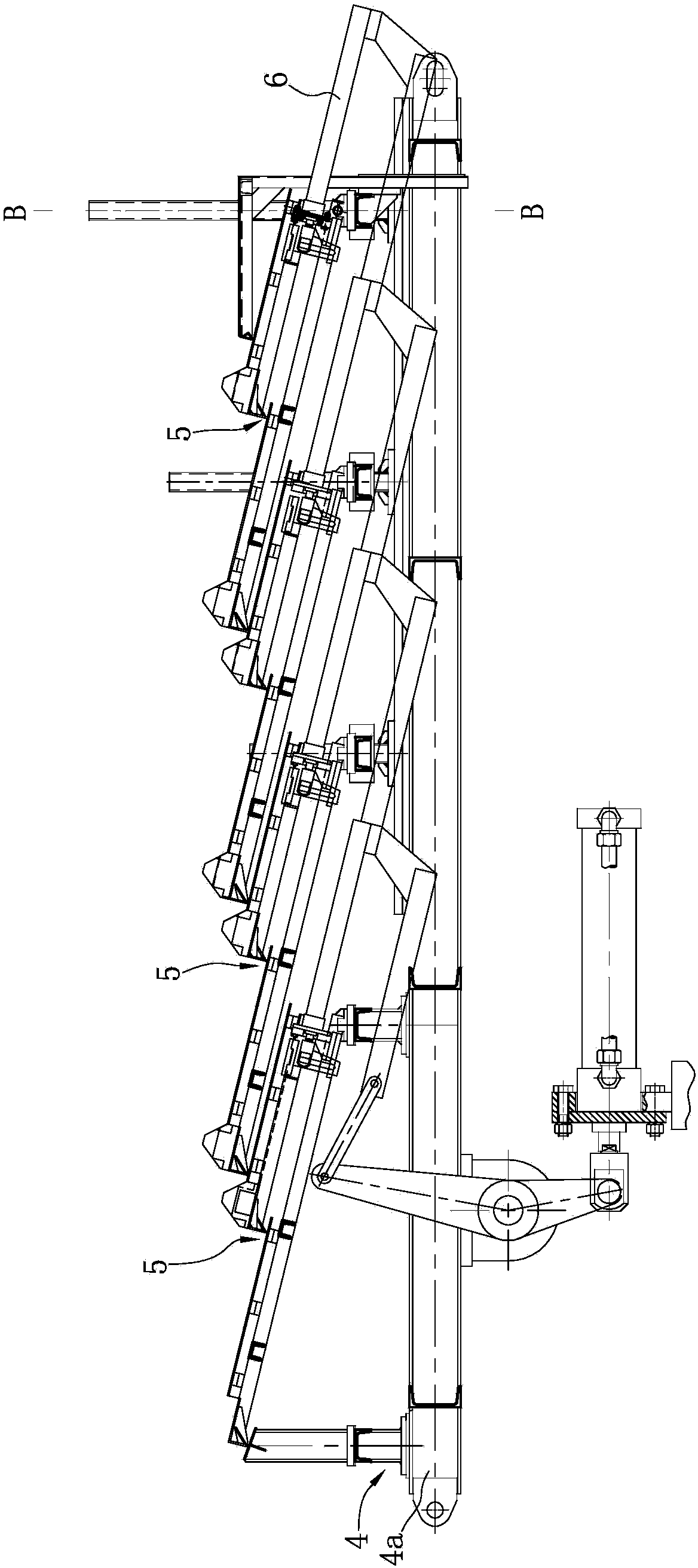

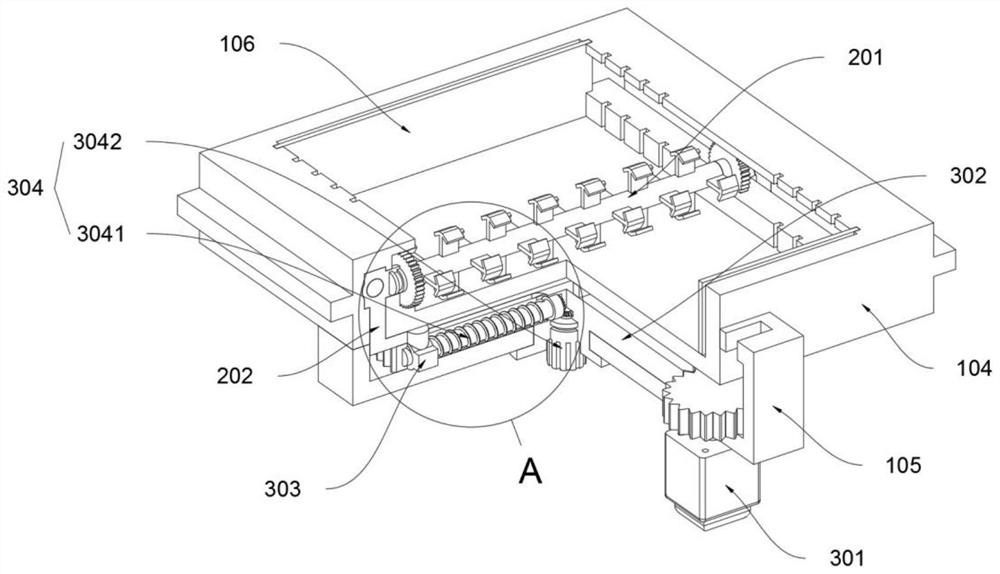

Composite fire grate structural parameter matching and adjusting device

ActiveCN103742924AEasy to assembleFirmly connectedInclined grateIncinerator apparatusComputer moduleMotion parameter

The invention discloses a composite fire grate structural parameter matching and adjusting device. A standard fire grate module set comprises multiple stages of standard fire grate modules (5). Each stage of standard fire grate module (5) comprises a fixed fire grate and a movable fire grate. The front end of the fixed fire grate of the first stage of standard fire grate module (5) is fixed on a first crossbeam (4b), and the rear end thereof is fixed on a second crossbeam (4c). The front end of the fixed fire grate of each next state of standard fire grate module (5) is in lap joint with the back of the movable fire grate of each previous stage of standard fire grate module (5). Except for the first stage of standard fire grate module (5), the rear end of each fixed fire grate of each stage of standard fire grate module (5) is fixed on the corresponding third crossbeam (4d), the front end of the movable fire grate of each stage of standard fire grate module (5) is in lap joint with the back of the fixed fire grate of the same stage, and a drive device (6) is mounted at the rear end of the movable fire grate of each stage of standard fire grate module (5). The composite fire grate structural parameter matching and adjusting device has the advantages that structural and motion parameters adjustment of forward and reverse push fire grates of a comprehensive system can be completed on a platform support frame.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

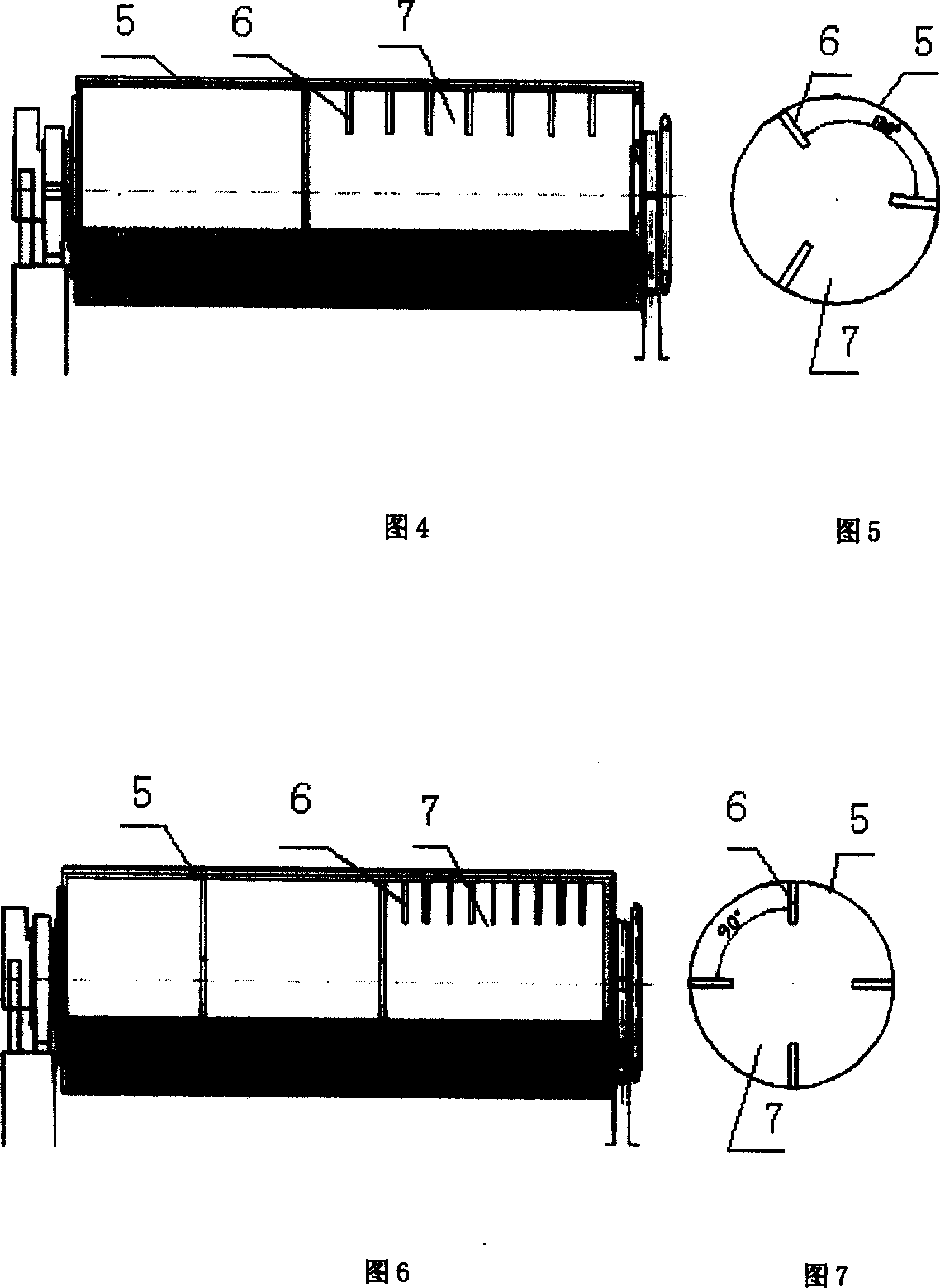

Bolt drying device with uniform heating function

InactiveCN111895748AEvenly heatedEffective agitationDrying gas arrangementsDrying machines with non-progressive movementsThermodynamicsEngineering

The invention discloses a bolt drying device with a uniform heating function. The bolt drying device comprises a drying box, a material containing barrel, an air outlet barrel, an air inlet pipe and an air outlet pipe. The top of the material containing barrel is covered with a sealing cover. A flange is arranged on the edge of the top of the material containing barrel. The drying box is fixed tothe bottom of the flange and surrounds the material containing barrel. The air outlet barrel is arranged in the material containing barrel. The top of the air outlet barrel is sealed. The bottom of the air outlet barrel is open and penetrates the bottom wall of the material containing barrel. A plurality of first through holes are formed in the side wall of the air outlet barrel. The bottom of theair outlet barrel is connected with the air inlet pipe. The air inlet pipe penetrates the drying box from the outer portion of the drying box. The drying box is connected with the air outlet pipe. Aplurality of second through holes are formed in the side wall of the material containing barrel. According to the bolt drying device, the air outlet barrel and the material containing barrel are combined, the first through holes, the second through holes and third through holes are matched, bolts are heated uniformly, the drying effect and drying efficiency are effectively improved, and use is convenient.

Owner:HAIYAN HATEHUI MACHINERY HARDWARE

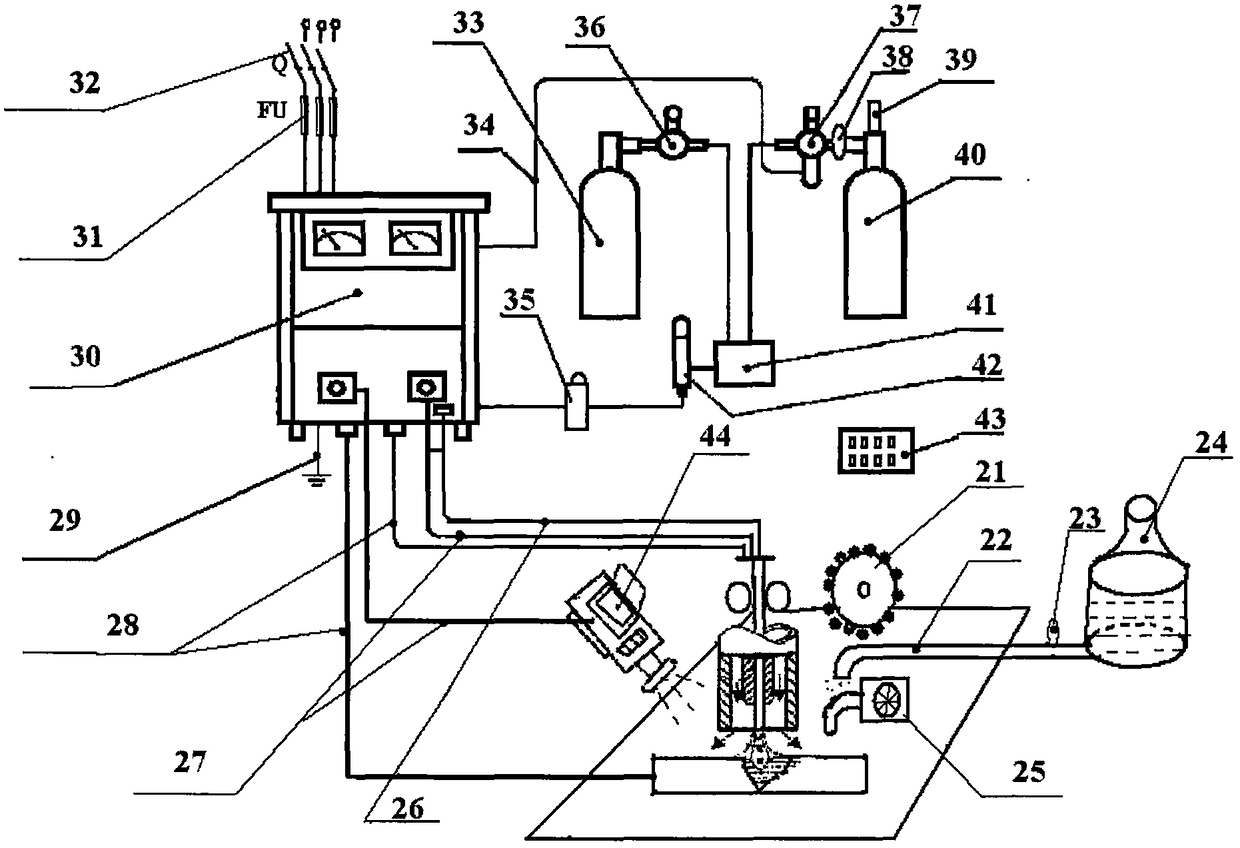

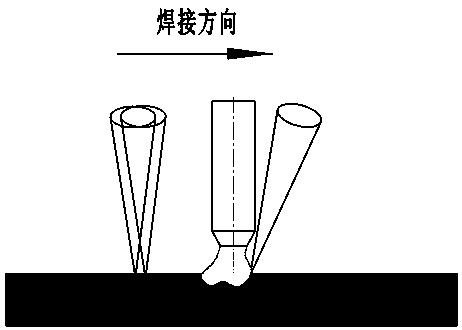

Automatic aluminum alloy plate welding equipment with acetone cleaning device

ActiveCN106583889BImprove welding qualityImprove liquidityWelding accessoriesMelting tankEngineering

The invention relates to mechanical washing and welding devices, in particular to an automated aluminum alloy plate welding device with an acetone washing unit. The device consists of a welding piece, an electric arc, a spraying gun, an electric hot air blower, an inert gas pipeline, a CCD camera and the like. The negative pole of a power supply cabinet and control system is connected with the welding piece through welding electric wires, and the power supply cabinet and control system has two superposed pulses; and the CCD camera is a color CCD camera, the pixel is 250 thousand-280 thousand, and the color resolution is 420 lpi. According to the automated aluminum alloy plate welding device, the CCD camera is used for monitoring the conditions of molten pools, welding wires and weld joints when aluminum alloy thick plates are welded, so that the parameters such as pulse current and the forward speed of a welding gun are adjusted in time, and the weld joint quality of an aluminum alloy is greatly improved. Before welding is conducted, acetone is sprayed for washing, mechanical strength of the weld joints is high, and the automated aluminum alloy plate welding device is suitable for the fine machinery manufacturing industry and an aluminum alloy welding occasion with very high welding requirements.

Owner:宿迁保沃纳米科技有限公司

A reciprocating borehole dredging tool

The invention relates to a reciprocating type borehole dredging tool used in the process of drilling well-completion practice. The reciprocating type borehole dredging tool solves the problem of blocked drilling fluid in a sleeve and being difficult to lower a logging instrument. According to the technical scheme, the upper end of a cable is connected to a ground console, and a wire core of the lower end of the cable communicates with a wire connecting opening of a stepping motor; an output end of the stepping motor and a bearing seat are driven by a key; a drive screw sleeve is installed at the lower portion of the outer circle of a drive screw, and the lower portion of the outer circle of the drive screw sleeve is connected with a screw thread of the upper portion of the inner cavity ofa sliding sleeve; the lower end of the drive screw and an anti-falling-cap thread are tightened; the lower portion of the outer circle of the sliding sleeve is provided with a conical convex platform,and the lower end of the inner cavity of the sliding sleeve is connected with the upper end of the outer circle of stirring heads; and anchor claws are placed in radial step holes on centralizing wings of the outer circle of the anchor, cover plates are fixed with bolts b on the centralizing wings of the outer circle of the anchor, and the cover plates pass through grooves of the outer end facesof the anchor claws. The stepping motor is adopted to drive the reciprocating type borehole dredging tool, the control is simple, the reciprocating movement of the stirring heads is used, drilling fluid can be stirred effectively, the viscosity of the drilling fluid is reduced, and the borehole dredging operation is carried out effectively.

Owner:东营市大学科技园发展有限责任公司

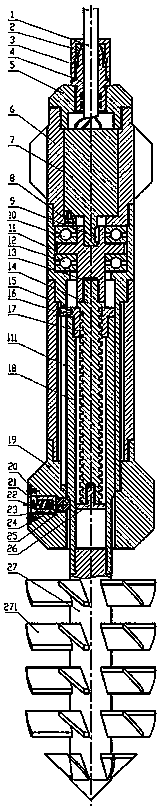

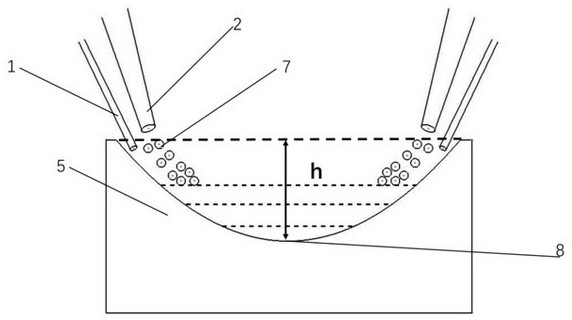

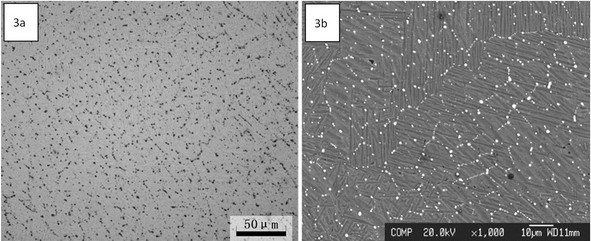

A Laser Additive Manufacturing Method for High Stability Particle Dispersion Strengthened Titanium Alloy

ActiveCN113458415BExcellent high temperature stretchImprove creepAdditive manufacturing apparatusIncreasing energy efficiencyHigh energyTitanium

The invention discloses a laser additive manufacturing method for high-stability particle dispersion strengthened titanium alloy, comprising the following steps: 1) preparing nanocrystalline powder mixed with titanium alloy, Y, Ca, Al, and Th; 2) mixing The nanocrystalline powder is directly sent into the molten pool formed by the laser beam through the powder feeding tube; 3) The mixed gas of argon and oxygen is blown through the side blowing tube to stir the laser molten pool; 4) The laser beam, the powder feeding tube and the side The blowpipe oscillates synchronously for laser additive forming. In order to solve the high stability and uniformity of titanium alloy as a high-temperature alloy with dispersion-strengthened particles added, the present invention proposes to prepare nanocrystalline powder by high-energy ball milling process, and through reasonable control of powder feeding rate and gas feeding rate, combined with appropriate laser melting Deposition process parameters, so as to realize the excellent and high stability particle dispersion strengthened titanium alloy prepared by laser additive technology.

Owner:北京煜鼎增材制造研究院股份有限公司

A vortex mixer

The invention discloses a vortex mixer, which comprises an inlet flange, a vortex generator I, a vortex generator II, a mixer main pipe and an outlet flange, the mixer main pipe is a hollow cylinder structure, and the inlet flange The outlet flange and the outlet flange are respectively welded to the upper and lower ends of the main pipe of the mixer. The vortex generator I and the vortex generator II are both set in a hollow isosceles triangular column structure, and the top angle is facing the direction of the fluid inlet; the vortex generator I and vortex generator II are installed at right angles to each other through the center of the pipe interface. The vortex generator I is welded between the upper and lower end faces of the mixer main tube, and the vortex generator II is welded on the side perpendicular to the axis of the mixer main tube. on the side wall. The pipeline mixer of the present invention has simple structure, high reliability, and remarkable mixing enhancement effect, which is beneficial to the generation of eddy current, improves the agitation degree of fluid, improves the mixing effect, and is used for liquid-liquid, gas-gas rapid mixing reaction, and is suitable for wide range.

Owner:QINGDAO HEADWAY TECH

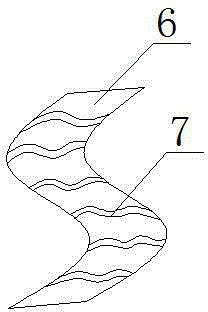

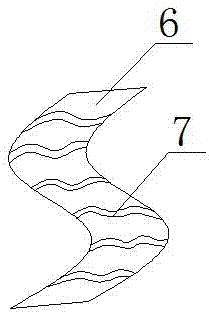

Apparatus for preventing tube mill material from being agglomerated

The present invention relates to an equipment of preventing material in mill from adhibiting. The equipment's character is that it is consisted of paddle (1) and pedestal (4).The shape of (1) is twisty. There are orifices (2) amid of (1) and (3) at the bottom of it. It is set fixed orifices (4) on the top of (3).This invention can accelerate the attrition between steel ball in mill and material which prevents material from adhibiting. Because of the increase of attrition pots the action grinder puts on material is more effective.

Owner:WUHAN UNIV OF TECH

A method of multi-focus laser enhanced arc hybrid welding

ActiveCN107363407BEffective agitationImprove the finishLaser beam welding apparatusEngineeringMelt depth

A multi-focus laser-enhanced arc hybrid welding method provides four heat sources: single-focus laser, welding torch arc, and double-focus heat sources, which are arranged in series in the welding direction in sequence, and can change the laser power and the current and current of the welding torch system. voltage to achieve different heat output, and realize the welding mode required by the field. The dual-focus laser used in the present invention is divided into dual-focus laser beams by an optical beam splitting system. The staggered movement can fully and effectively stir the molten pool. When its high power acts as a welding heat source, it is beneficial to increase the penetration depth, stir the molten pool, and effectively reduce pores and spatter. At the same time, by fine-tuning the focal length of the double focus, the weld can be adjusted Depth of penetration and width of penetration. When its low power is used as a heat source for heat treatment, it is beneficial to improve the smoothness of the welding surface, the uniformity of the weld, reduce the pores and spatter, and improve the quality of the weld.

Owner:WENZHOU UNIVERSITY

Earth excavation dust disposal device for road construction

ActiveCN108722073AWater saving effectSolve environmental problemsUsing liquid separation agentStationary filtering element filtersWater filterWater storage tank

The invention discloses an earth excavation dust disposal device for road construction, relating to the technical field of road construction. The earth excavation dust disposal device for road construction comprises a body, a fan, a dust guide pipe, a water pump, a water guide pipe and a dividing plate, wherein the fan is arranged on the left side of the top of the body, and an air outlet of the fan is communicated to one end of the dust guide pipe; one end, far from the fan, of the dust guide pipe penetrates through the body and is communicated to an inner cavity of the body; the water pump is arranged on the right side of the top of the body, and a water outlet of the water pump is communicated to one end of the water guide pipe. When the water level reaches a preset value, a sealed baffle plate is opened by operating an air cylinder, so that a water body is discharged into a water filter mechanism through a guiding mechanism, and therefore, the water filter mechanism operates to filter water and discharge the water to a water storage tank through a water delivery pipe, so that the problem that the surrounding grounds and plants of a construction environment are affected by a mixture of dust and water after dust removal in the prior art is solved while a water resource effect is saved.

Owner:无锡国家高新技术产业开发区市政公用事业有限公司

Particle screening device for raw material processing

InactiveCN112474252AAvoid stackingImprove screening efficiencySievingScreeningElectric machineStructural engineering

The invention belongs to the technical field of raw material processing, and particularly relates to a particle screening device for raw material processing. Aiming at the problem of low screening efficiency of an existing particle screening device, the following technical scheme is provided: the particle screening device comprises a box body, a partition plate is arranged on the inner wall of thebox body, a motor is arranged at the bottom of the partition plate, the output shaft of the motor is connected with a first straight shaft, the first straight shaft is fixedly sleeved with an incomplete bevel gear, the top of the partition plate is connected with a second straight shaft, the second straight shaft is fixedly sleeved with a complete bevel gear, a plurality of supporting columns arearranged at the top of the second straight shaft, a fixing block is arranged at the tops of the plurality of supporting columns, a screen plate is arranged at the top of the fixing block, and a plurality of material conveying parts are arranged on the circumferential outer wall of the screen plate. According to the particle screening device, raw materials are partitioned in the material conveyingparts, the raw materials with different particle sizes are layered in the material conveying parts, therefore, the screening efficiency is improved, meanwhile, under the action of centrifugal force,the raw materials move upwards along an inclined plane, large-particle raw materials directly fall from a first discharging mechanism, and thus the overall screening efficiency is effectively improved.

Owner:刘蒙

Blowing-type drying machine based on chemical fertilizer production

ActiveCN114576955AEffective agitationEffectively looseManure dryingGranular material dryingAgricultural scienceAgricultural engineering

The invention provides a blowing-type drying machine based on chemical fertilizer production, which comprises a loosening assembly, a loosening roller is rotatably connected to the interior of a linkage frame, and the loosening assembly can effectively stir and loosen chemical fertilizer particles in a drying tray, so that the chemical fertilizer particles in the drying tray can be quickly and uniformly dried; meanwhile, the use space in the drying tray can be adjusted by changing the use position of the partition baffle in the drying tray, and the effective loosening length of the loosening assembly can be adjusted, so that the device can adapt to rapid and uniform drying treatment of different amounts of chemical fertilizer particles; the problems that the use space of a drying tray of an existing drying machine cannot be changed, the drying tray cannot be suitable for rapid drying and supporting of different amounts of chemical fertilizer particles, the chemical fertilizer particles are dried unevenly, and the drying degrees of the chemical fertilizer particles at the top and the bottom are different are solved.

Owner:YUNNAN TIANTENG CHEM IND

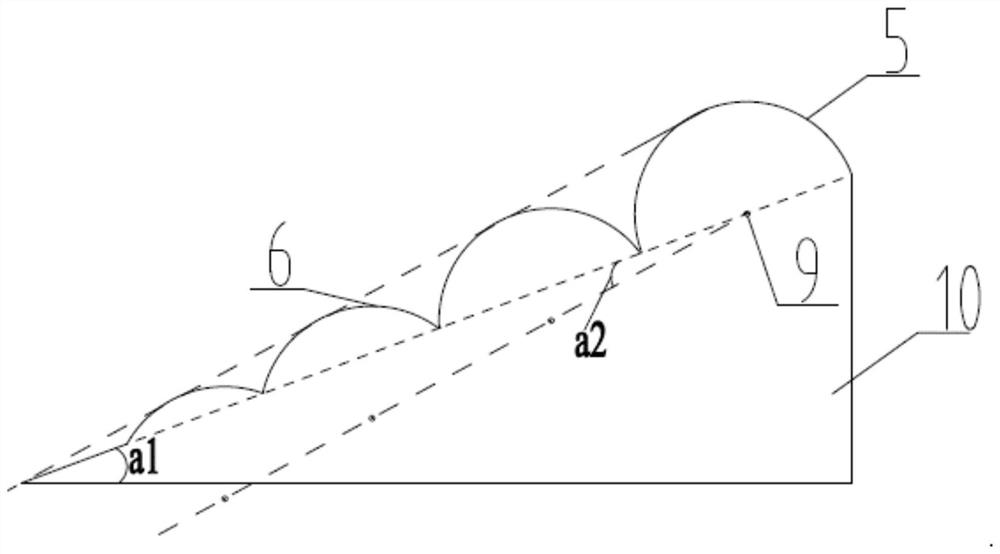

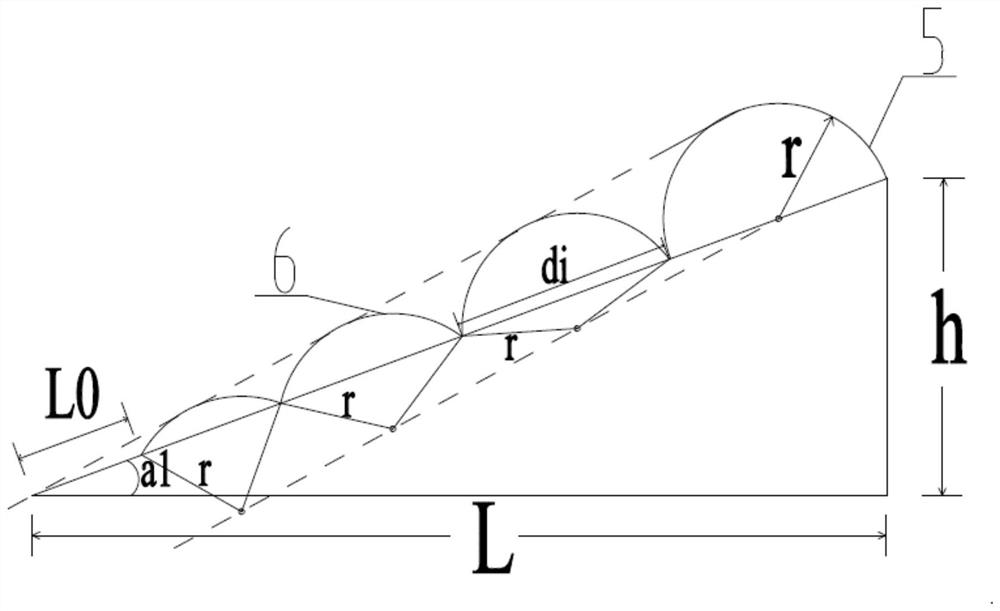

A fan blade with wave-shaped vortex generator and design method thereof

ActiveCN112943565BAvoid observationWell formedMachines/enginesWind energy generationRight triangleSuction force

The invention discloses a fan blade with a wave-shaped vortex generator and a design method thereof, belonging to the technical field of wind power generation. It includes a number of wave-shaped vortex generators arranged on the blade suction surface of the blade leading edge side; the wave-shaped vortex generators include a right-angled triangle substrate, the horizontal straight side of the substrate is connected with the blade suction surface, and a number of wave-shaped vortex generators are arranged on the hypotenuse of the substrate Bow-shaped fins, the arc length of several bow-shaped fins decreases along the vertical side to the horizontal straight side, and all the bow-shaped fins are tangent to the same tangent; the lowermost end of the hypotenuse is the area without bow-shaped fins; wave-shaped vortex generator Arranged symmetrically in pairs, the bow-shaped fins face the direction of incoming flow, the two wave-shaped vortex generators deflect at the same angle and the front ends move closer to the axis of the symmetry plane. This structure can more fully stir the airflow in the separator, increase the momentum and energy of the airflow near the wall, and generally more effectively delay the stall of the blade and increase the lift of the blade.

Owner:HUANENG CLEAN ENERGY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com