Multifocal laser reinforced arc hybrid welding method

A composite welding and multi-focus technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high laser assembly precision requirements, large penetration depth fluctuations, high weld porosity, etc., to ensure high-speed stability Welding, improving the finish, improving the effect of weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

[0020] 1. Before welding, grind or clean the surface of the workpiece to be welded, and fix the polished or cleaned workpiece to the welding tool;

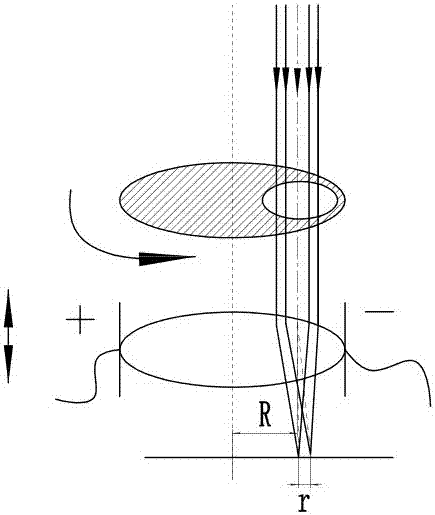

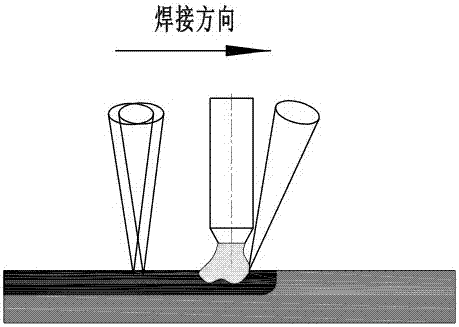

[0021] 2. During the welding process, the laser beam and the arc welding torch are always arranged in series on the same axis, and they work together on the area to be welded. The geometric parameters are set as follows: the angle between the laser beam and the vertical direction is 5°~15°, and the The focal length is -4~+4mm;

[0022] 3. Set the welding mode and process parameters:

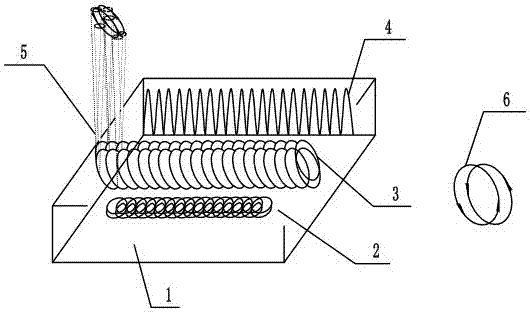

[0023] The laser beam and the arc welding torch are arranged in series according to an axis. The laser beam includes a single-focus laser and a double-focus laser. The laser is set obliquely to the position of the arc welding torch, the end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com